Food Packaging Machine Provider in China

JOCHAMP factory makes a certain big production ability with durable & quality food packaging solution by conducting quality inspection and strict control for the manufacturing process. We have an experienced and professional R&D team with the innovative technology in our equipment. We also dispense great technical support for every client’s needs. Here are some JOCHAMP capabilities and advantage offers:

- 15 years of professional experience in providing packaging solution

- With experienced foreign-trade-team and technicians

- High-quality products, 100% stable, precise, and rugged

- Provides on-time delivery

- We can customize your exclusively designed solution

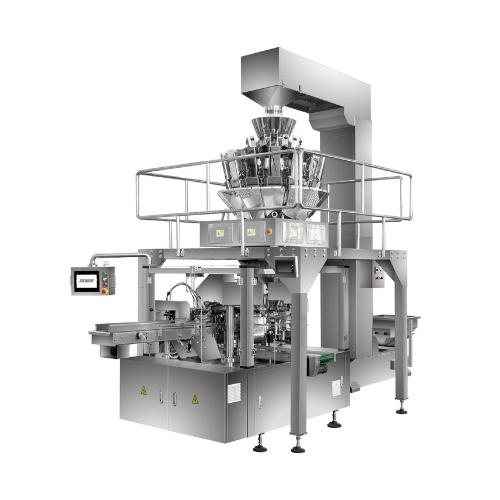

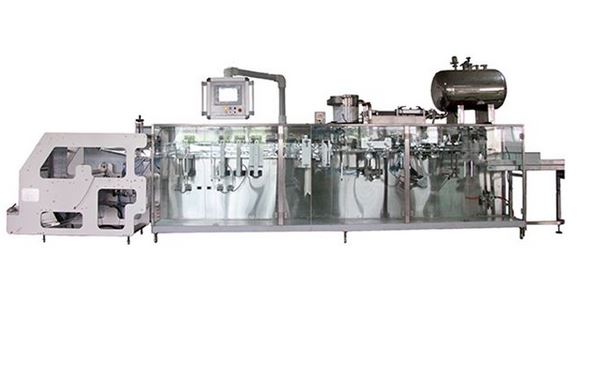

JOCHAMP Food Packaging Machine

Various types of packaging machines depend on the type of food to be packed and depending on the product’s storage life, there are also changes in packaging styles. JOCHAMP food packaging machinery is professionally manufactured in China. Our packaging machine products are certified ISO14001, ISO9001, and CE.

Our focus is to supply food packaging machines with high-end industrial-grade for our customers worldwide. Considering market needs, we have succeeded in a whole series of both semi-auto & automatic packaging machines that combine all packages of product functions. Because of this, our company reaches the high packing efficiency, better product presentation, and labor cost-saving for our food packaging equipment.

Food Packing Machine Applications

Packing Machine for Food (12)

Why JOCHAMP Food Packaging Machine

JOCHAMP food packaging machine uses only a small space and provides minimization or elimination of additional equipment.

The material and high-end construction of JOCHAMP food packaging machine will provide and allow long hours of operation.

With JOCHAMP photoelectric switch features, our food packaging machine can able to trace color points and cut them accurately.

Our food packaging machine can be operated by any person through advanced PLC controls. That’s why our machine is easy to operate.

Advantages of Food Packaging Machine

In every food system, the packaging is a very essential part. Some food products are eventually packaged more than once before delivers to every customer. That’s why using food packaging machine are truly a great advantage to every food production company. Food packaging also can cater a various flexible package forms such as:

- Bags

- Boxes

- Cups

- Trays

- Cans

- Pouches

- Tubes

Strong R&D Strength

By considering deeply the demands of our customers and improving our current solutions of packaging, we and our professional engineers work hard to develop and gain more progress in terms of advanced technology and continue to provide more intelligent solutions.

With our ongoing innovations and research, maybe soon – our food packaging machine become more automated in terms of feeding systems and may apply some high-technology features like adopting the robotic arms technology system.

Quality Assurance

JOCHAMP can assure a quality food packaging solutions with the following guaranteed standards and ratings such as:

- High demand and high standards

- The inspection passing rate of parts is 98%

- 97% passing rate of product delivery

- 100% passing rate on manufacturing finished products

- 99% processing rate of customer feedback

Company Capabilities and Services Offers

As a leading manufacturer of packaging solutions, JOCHAMP has many capabilities and services to offer. Here are some of the lists:

- High-tech enterprises for packaging equipment

- Repair service and field maintenance

- Provides video technical supports

- Commissioning & Training, and field installation

- Perfect after-sales service

Leading Food Packaging Machine Manufacturer in China

JOCHAMP food packaging machine can be customized to meet the individual needs of our clients. We provide a complete line of food packaging machines for dry food, dry fruit, ice cream, biscuit, bread, coffee, vegetable, and many more. Our automated food packing machine is fabricated from drug-grade, food-grade, and corrosion-resistant materials, including 304 stainless steel. Being a leading manufacturer in China, we aim to provide our clients with hygienic and safe packaging machines.

JOCHAMP is a quality-oriented company in China with over 3000 square meters of manufacturing area. We achieve excellence and adhere to strict quality standards in our series of machinery. Every detail of our machines is meticulously tested by our experienced quality controllers through our modern testing facilities. Additionally, the electrical appliances and accessories of our food packaging machine are imported from the famous brand – Schneider, Omron, Panasonic, Siemens, etc.

JOCHAMP Food Packaging Machine

JOCHAMP is offering a fast and reliable packing solution with our food packaging equipment that can manage to package consumables like milk powder, coffee granules, oatmeal, chocolate, and more. With excellent capabilities and an experienced team, we can produce a large quantity of food packaging units annually that pass different certifications and are trusted globally.

As a professional provider and manufacturer, JOCHAMP invested in management systems and high-end facilities. We can design and create packing machines that exceed the quality performance and clients’ expectations. Here is the main key to the success of our company in providing solutions for packaging machinery:

- Management System – the management system with the integration of innovative Chinese technology let us produce a large quantity of packaging machine yearly.

- Factory – we have a 3000 sq meter area for manufacturing our packaging machinery and are CE certified in producing high-class packing machines.

- Talents – almost 100% of our staff has 20 years of experience in the packing industry.

Why Choose JOCHAMP Food Packaging Machine

Different food industries need food packaging equipment, we highly recommend to used our food packaging machine to achieve efficiency, packaging quality, and cost savings. Our food packaging machines are:

- Can fit in every production environment

- Provides lower production cost

- Offers customized packing system

The packaging versatility and flexibility are the features that a contract packager’s focusing on. JOCHAMP food packaging machines will help the different food industries to meet their different packaging needs and pursue market space. JOCHAMP can provide every contract packing industries the following.

- High-Efficiency Packaging Machine

- Multifunctional Packaging Machine

- Flexible Packing Machine

JOCHAMP follows a strict screening process for its raw material. We need to maintain the consistency of the quality of our processed parts, electrical components, sheet metals, and other materials. We also conduct strict sourcing when using 304-grade stainless steel to ensure a food-grade type of packaging machines.

We ensure a steady supply of food packaging machine solutions to ensure a long-lasting and strong partnership with our customers worldwide. JOCHAMP also strives for the best service as long as possible and we truly valued every customer.

Related Product

Food Packaging Machine

The food industry has adopted the packaging concept from other sectors.

It includes manufacturing, cleaning, filling, sealing, combining, labeling, wrapping, and palletizing.

Sometimes, you can package food without machines, using heat sealers and human labor.

However, for large-scale production, you can rely on the efficiency of the food packaging machine to get the job done in the shortest time possible.

Here’s what you need to know about food packaging machines.

There are various types of packaging machines, but the most common are the following:

- Pallet Wrappers

- Sealers

- Shrink Tunnels

- Carded Packaging Machines

- Case Erector

- Seal Machines

There are 4 main different types of packaging methods, this includes:

- Flexible Packaging

- Plastic Packaging

- Pharma Packaging

- Anti-Corrosive packaging

Aside from packaging purposes and maximizing the production output, food packaging machines also can give the following important functions:

- Protection and preservation of food products

- Food waste reduction and containment

- Provides marketing information by its label

- Provides traceability function

- Tamper Indications

- Other Functions

food packaging machine

Before we look at a food packaging machine, we need to define food packaging.

This refers to the enclosure of food in a container or bag to prevent contamination by biological, chemical, or physical components.

In most cases, it’s used as an effective means of preserving food.

Food packaging has become an integral part of the food industry.

Today, almost every food product is sold in a packaged container or pouch.

This practice was invented and introduced to prevent waste, extend shelf life and preserve food taste.

Although it positively impacts food hygiene, some food safety issues have arisen.

Most food packaging is made of Styrofoam, polyethylene, and plastics that are considered toxic when heated.

In some cases, non-food substances, such as dyes, transfer from these materials to the food, which is dangerous if consumed.

However, government regulations govern the materials used in food packaging.

These laws set specific standards for the certification of food-grade materials and subject them to various tests to ensure they’re safe.

Food packaging aims to protect food from contamination and damage caused by external factors. However, they also preserve food quality and extend its shelf life.

As well as identifying and classifying food, the packaging indicates the ingredients used and the date of production and expiration.

Food manufacturers often use packaging to increase visibility and make their products desirable to consumers.

- Containment and food waste reduction

- Protection and preservation

- Marketing and information

- Traceability

- Tamper indication

There are many different types of food packaging machines, including:

- Vacuum Food Packaging Machine

Vacuum packaging has become widely used in today’s food industry.

This machine is designed to preserve the freshness of food while maintaining the quality of taste and flavor.

A vacuum food packaging machine is defined by the way it works.

It places food in a film bag and de-aerates it by lowering the pressure in the vacuum chamber before sealing the bag.

The mechanism is designed to prevent discoloration while enhancing the presentation effect.

Vacuum packaging is often preferred because it preserves food 3-5 times longer than most packaging methods.

vaccum food packing machine

Since there’s no oxygen, this method can prevent the growth of fungi, aerobic bacteria, and mold.

This packaging method is often used for storing dry foods such as cheese, smoked fish, nuts, cereals, and cured meats.

You should remember that for vacuum packaging, you must use packaging materials with low oxygen permeability.

Biscuit Packaging Machine

A biscuit packaging machine is an automated packaging machine specifically designed for packaging food products such as biscuits, wafers, and crackers.

These machines are versatile and can handle different shapes and sizes – round, rectangular, and square.

The biscuit packaging machine is preferred for its ability to reduce labor costs, improve hygiene and maintain food quality.

biscuit packaging machine

Due to their automated nature, these machines are used in packaging processes requiring a high level of accuracy repeatedly.

This machine works on the same principle as a vertical packaging machine. It uses a large roll of plastic film to form a bag into which the food is filled and sealed.

Coffee Packaging Machine.

As the name suggests, coffee packaging machines package coffee into coffee bags and pouches. These machines are designed to ensure that each bag or pouch meets certain weight specifications before being sealed.

There are different coffee packaging machines, each with its own operating mechanisms.

However, you should opt for a machine that offers different sizes and the ability to create multiple bag configurations.

coffee packaging machine

Coffee packaging machines offer several advantages, such as flushing out excess nitrogen to preserve coffee flavor and performing additional finishing functions.

They include; folding over, final sealing and thermal transfer.

These machines form coffee bags, fill them with a specified amount of coffee, and seal them.

Your packaging machine should have three important functions: a degassing valve, a nitrogen purge, and a tight seal.

These functions ensure that the flavor of the coffee is preserved and its shelf life is extended.

Bundling Food Packaging Equipment

Bundling food packaging equipment is often used by food suppliers as they can shop large quantities of food.

The food is divided into different specifications before being bundled and stored as a whole.

There are many applications for this equipment, including the packaging of stick sweets and individually wrapped hot dogs.

bundling food packaging machine

A food bundling machine is ideal for a supplier looking for an economical yet efficient packaging machine.

Bagging Machine

Bagging machines are widely used in the Chinese food industry and are mainly used for packaging sauces and soups.

This machine is used to pack food into bags, pouches and sacks. A bagging machine works similarly to a pouch packaging machine and is designed for different sizes.

bagging machine

This machine is versatile and can be used for different types of food, including cereals, sugar and custard powder.

Capping Machine.

A capping machine is most often used to shop beverages and syrups.

However, it is important to know that this machine does not function as a stand-alone food packaging machine.

It works in conjunction with other food packaging equipment, especially those that require bottling.

capping machine

The machine seals food packages with an airtight lid. It is often used by soft drink and alcohol manufacturers.

Closing Machines

Closing machines are not necessarily a food packaging machine, but they play an important role in your food packaging line.

Food suppliers use this machine to secure food packaging by tying a metal wire around the food bag or sack.

closing machine

A sealing machine can also be used as a tamper-evident measure.

They can customize the wire wrapping to prevent tampering during distribution and improve traceability.

Accumulation Machine

An accumulation machine is used as part of a food packaging machine.

It’s usually used in conjunction with a capping machine, its main function being to align and organize the bottles to be filled with food.

accumulation machine

Due to its peculiarity, this machine is used by beverage manufacturers. In this way, they can track and record the number of liquid food products filled to account.

Stick Packaging Machine

A stick packing machine is used in the food and pharmaceutical industries.

It’s used to measure and pack specific quantities of food and is perfect for takeaway products. They’re versatile and suitable for drink mixes, honey, sugar and many other food products.

Similar to a vertical form fill and seal machine, this machine cuts a roll of film into sticks, fills them with food, and seals them.

stick packaging machine

There are many reasons why stick pack machines are popular, including their versatility and speed. They can produce up to 1,600 stick packs per minute, depending on how they are tuned.

Premade Pouch Packaging Machine

Premade pouch packaging machines are one of the latest achievements in the food packaging machine industry.

The mechanism uses a pre-made pouch that’s automatically removed at the end of the production line.

It’s then filled and sealed, using some processes such as nitrogen filling and dust removal.

premade pouch packing machine

The biggest advantage of this machine is that you can customize each bag to the product specifications.

Besides, you can choose from a variety of designs, such as squeeze bags, resealable bags, zipper bags and spout pouches.

Vertical Form Fill Seal Food Packing Machine

A vertical form fill seal food packaging machine is a multifunctional machine used in the food processing industry.

It’s popular because it can pack and seal products at the same time, increasing efficiency and productivity.

vertical form fill seal machine

The machine forms plastic bags from a film roll, fills the bag with food and seals it.

The use of this machine reduces human contact with food and lowers the risk of contamination.

Horizontal Form Fill Seal Food Packing Machine

A horizontal form fill and seal machine for food products works similarly to a VFFS.

It makes pouches or bags from a roll of film, fills it with the food item, and seals it, all in one go.

The only difference between the two is that the HFFS performs this action horizontally.

horizontal form fill seal food packing machine

The main advantage of this machine is that it’s flexible in terms of sizes and shapes, giving you full control over the production process.

Pick Fill Seal Machine

A pick-fill seal machine is an automated food packaging machine used to handle food items in various forms, powder, solid, and liquid.

It is programmed to pick, fill and seal pouches with food items.

This machine offers flexibility in terms of pouch size and shape.

pick fill seal machine

Pouches used in this machine are premade and can be changed according to product specifications. Customers can also choose from a wide range of pouches, including spouts, zippers and stand-up pouches.

Case Packing Machine

A case packing machine is used to assemble several food items and prepare them for distribution. You can use it for small business as well as for big business.

There are various case packing machines that differ depending on the type of items to be packed.

Most business owners find case packing machines beneficial, especially when transporting their products to a distant location.

case packing machine

They provide additional protection against vibrations and shocks that could damage the food during transportation.

Cartoning Machines

A food cartoning machine, also called a food cartoner, is used to make various cartons, including erect, sealed, side-seamed, and folded.

It’s often used as part of larger food packaging machinery where cartons are filled with products or bags of products before covering and sealing.

The machine is programmed to fill a single carton horizontally or vertically with product before sealing it with adhesive.

You can use this machine to add an extra layer of protection to your products, especially when they are in transit.

Sealing Machines

One of the most important steps in food packaging is the sealing process.

You must properly seal your product to prevent environmental damage caused by exposure to air or physical impact.

With this in mind, you need to invest in a sealing machine.

These machines are used to seal containers carrying food items, including pouches, bottles, bags, and containers.

You can also customize your sealing machine to perform a secondary function of tamper prevention.

Sealing machines are primarily used in the food and beverage industry as end-of-line machinery. With the seal, you can enhance product traceability and provide additional information to consumers.

Food Pouch Packing Machine

A food pouch packing machine is an automated packaging machine designed to fill and seal food pouches with specified amounts of food items.

It’s mainly used for liquid and semisolid food items such as juice, soup, and sauce.

However, it can also be used to store dry foods such as cereals and nuts.

food pouch packing machine

This machine has a simple working principle: a premade bag is loaded into a hopper at the top of the machine and fed into a sealing mechanism.

The bag is filled with the food product before sealing and readied for shipping.

Frozen Food Packaging Machine

With frozen foods becoming a popular choice in the food industry, you need to think about adding a frozen food packaging machine to your setup.

This machine is used for packaging premade and frozen foods, including soup, chicken, pizza, pasta, and steak.

These machines are popular for their speed and versatility, ability to fill premade bags and pouches with food products before cutting and sealing.

With a frozen food packaging machine, you can enjoy increased productivity, less waste, and fresher food for longer.

Nitrogen Food Packaging Machine

A nitrogen food packaging machine is used in the food industry to replace the oxygen inside the food packaging.

This machine is also referred to as a nitrogen flush packaging machine. Its primary function is to remove oxygen that reacts with the food, replacing it with nitrogen.

Unlike oxygen, nitrogen helps preserve the texture and flavor of food items while prolonging their shelf life.

You can as well use it to prevent package collapse, ensuring delicate food items don’t get damaged in the packaging due to physical impact, vibrations, or shock.

Nitrogen food packaging machines are mostly used for packaging food items such as nankeen, chips, and nuts.

Food Tray Packaging Machine

Food tray packaging machines are semi-automatic since you must manually fill the tray with specific amounts of food before sealing.

It’s mostly used in restaurants and fast food chains for on-the-go customers.

They also package food items such as meat, fruits, and vegetables at the local grocery store.

food tray packaging machine

Food tray packaging machines come in various types and sizes, depending on your needs and budget.

You can choose bench-top manual packing machines or semi-automatic models.

Food Sachet Packaging Machine.

As the name suggests, a food sachet packaging machine is used for packaging food items into sachets.

These sachets often come in small sizes and shapes. You can use it to store and protect food items such as sauce, cereals, coffee, juice, jam, oils, and water products.

Sachet packaging machines are known for their reliability, fast filling properties, and customizable features.

It also offers the flexibility of food items, shapes, seals, and sizes.

Sachet packaging machines can make sachets, measure products, fill and seal, print dates, cut, and tally the final quantity.

Food packaging machines are relatively pricey regardless of commercial or domestic type.

However, these machines are a must-have for food producers looking to upscale their production while minimizing production costs.

There isn’t a definitive price for a food packaging machine. A food packaging machine’s price is influenced by its functionality and brand.

You will likely spend $10,000 to $65,000 on a packaging machine.

Food packaging machines should also be priced based on various factors such as mechanical parts, capabilities, and labor requirements.

Food packaging tends to vary depending on the product type and production level. Some of the food packaging options depend on the materials used.

However, the most common options include:

Aseptic Packaging

This method combines paper, aluminum mixture, and a layer of polyethylene.

Aseptic packaging is used for sensitive products that require sterility, including milk and liquid eggs that require preservation for an extended period.

Bags

This is the most popular packaging option.

Bags are made using plastic materials to protect the content from external influence, including air and moisture. You can use this option for food products such as fruits, vegetables, and snacks.

However, they are perfect for food products consumed within a short time frame.

Cartons

This option is mostly used for bulk commodities.

It’s made using corrugated cardboard and is coated with paraffin or plastic to increase durability and lower permeability to vapor and moisture.

Cartons come in various options depending on their use. You can choose gable-top, folding, aseptic, and egg cartons. Each carton is designed with product specificity. They are mostly used to hold eggs during transport, juice, and milk.

Boxes

Food product distributors commonly use these for their versatility. They are made from different materials, including metal, corrugated, fiberboard, or wood.

You can rely on boxes for their sturdiness and ability to withstand damage, especially vibrations and shock caused by moving around.

Wrappers

This packaging is used for small individual food items such as candy. Wrappers are made using thin plastic and are generally used to protect food from the environment and enhance product appeal.

Flexible Packaging

Flexible packaging is a versatile packaging option used on a number of products.

Without a definitive shape, it takes the shape of the product. It functions similarly to bags by protecting the content from environmental influence and prolonging the shelf life of food.

Pallets

Pallets are good for transporting large food items. It involves shrinking the food into small quantities before packing them in large containers for security.

Cans

These packaging methods make use of thin metal containers coated with zinc to prevent corrosion.

They are arguably the best choice when prolonging the shelf life of food items and protecting them from direct sunlight and other influences.

Cans are used to store a wide range of products, including soup, fruit, soft drinks, meat, gravy, and vegetables.

You can as well use it for dry foods such as biscuits and cereals.

Trays

These are designed with raised edges to balance the food product in the container. They are made using flat, thick paperboard materials and are used for items such as seeds, meat, drinks, and even eggs.

Finding a food packaging machine is easy; choosing the best packaging material can be challenging. Several options, each with specific properties, respond to specific food items.

However, it’s advisable to choose the medical grade and government-approved options.

Here are some of the best packaging materials you can use:

Medical Grade Plastic

This is arguably the most popular food packaging material, preferred for its versatile applications. Plastic containers and bags can prevent contamination and provide mechanical strength.

Plastic is also used because it can easily be molded into any shape to meet the item’s specifications.

Several plastics are used in the food industry, including polyethylene, PVC, and polystyrene. Each of these plastics varies in strength, malleability, and cost.

Metals (aluminum, tin, steel)

Food packaging materials made using metals such as tin, steel, and aluminum are used to store canned foods and beverages.

They feature a zinc coating to prevent corrosion and can last up to years, prolonging the shelf life of the food item.

Glass

Unlike most food packaging materials, glass is inert and doesn’t react with any food item.

They are also impervious to gas and moisture and prevent any environmental trigger from reaching your food.

However, the only downside is that they are fragile, heavy, and relatively pricey to manufacture.

This material has high malleability and can be molded into various shapes and sizes to meet product specifications.

Paper, Wood, and Cardboard

Wood, paper, and cardboard are widely used in packaging due to their affordability and excellent printing properties.

Paper packaging is mostly sensitive to moisture and cannot withstand excessive weight. However, this is mitigated by combining paper with plastic or paraffin.

On the other hand, cardboard is slightly stronger and more reliable. This material is used to make packaging containers and boxes.

Their sturdy nature and resilience make them a good option for transporting food items from one location to another.

You can as well rely on the strength of wood to make crates used to transport bulk food items such as vegetables.

However, people have recently been moving towards recyclable products to reduce environmental impact and ensure sustainability.

As mentioned before, food packaging has become a mainstay in the food processing industry. However, the efficiency and reliability of this process lie with the packaging machine you use.

Your packaging machinery should have specific features to ensure seamless production.

These features revolve around reliability, traceability, quality, and automation.

Below are some of the features you should consider when choosing your packaging machinery:

Flexibility Of Equipment

One of the main features you need to consider is the flexibility of the machinery.

Your equipment should accommodate containers and bags of various shapes and sizes.

Food packaging machines should also be versatile enough to handle different types of food items.

System Reliability

You don’t want a system that breakdown now and then in the middle of production.

The machinery should offer a degree of reliability, performing optimally when needed. Reliability should also mean your machines can serve both short and long runs.

Level Of Automation

Your food packaging machinery should be accurate, standard, and straightforward, especially one designed for large-scale production.

These factors are influenced by the level of automation, which is important when switching the type and size of product fed into the machine.

Be sure to pick a machine that automatically adapts to the new changes without wasting time and effort.

It should be able to reduce human influence while producing specified product details.

Quick Changeovers And Ease Of Cleaning

Food machinery deals with different types of food materials and can easily attract foreign elements such as mold and microorganisms.

With this in mind, you should find a mechanism with quick changeovers, easy cleaning, and reliable maintenance procedures.

Traceability

One of the primary functions of packaging is traceability. You should be able to trace your product from the packaging to distribution.

Your machinery should be able to record and collect relevant information regarding the product.

The machinery should also track employee performance, quality control, system output, and energy consumption.

With this information, you can make informed decisions regarding the production process.

Food packaging machines for small businesses work similarly to those used in commercial food packaging.

The only difference is the scale of the setup. Small businesses tend to have a limited budget for purchasing equipment.

Small businesses use packaging machines with smaller capacity lines and minimal maintenance requirements to reduce costs.

However, commercial food packaging machines are more complex and require more weekly maintenance procedures.

Small businesses also rely on simple machines that offer comprehensive services. This means all the processes required in packaging are performed by one machine.

On the other hand, commercial food machines are distinctive, with each process taking place at different stages of the production line.

China is considered the industrial center of the world, and some leading brands have located their production lines in China.

Before buying a food packaging machine, it’s advisable to check some of the available options. This is easier if you buy directly from the source.

Here, you’ll find several options that match your budget and production level.

If you buy directly from China, you’ll also have access to a manufacturer’s warranty that can last up to several months.

Plus, you can also easily negotiate with the supplier on features and price range. You can include customizable features that are tailored to your production process.

You may also like our food packaging line or food packaging systems.

For all your food packaging machines, contact us now.