Pharmaceutical Packaging Machines Provider

JOCHAMP is an experienced and professional manufacturer, supplier, and provider of various pharmaceutical machinery around the world. We specialized in different pharmaceutical machines including granulation, coating machine, blister packaging machine, cartoning machine, counting machine, labeling machine, tablet press machine, soft & hard capsule filling machine, oral liquid filling production line, and suppository machine. Our machine professional packaging ensures the safety and provides some factors including:

- Consumer Convenience

- Product containment & stability

- Compliance with packaging standards

- Uniformity of the packages

Pharmaceutical Packaging Machines

As a pharmaceutical machine provider, JOCHAMP strives to produce reliable, flexible, and high-efficient pharmaceutical packaging machines. All of our packaging machines are equipped with the latest and high technologies that will surely fulfill every pharmaceutical industry’s needs for their packaging.

Aside from pharmaceutical packaging machines, we have also extensive industry and product support such as cosmetics, food, hardware, tobacco, stationery, household items, etc. Our strict coordination and production rhythm provide optimization of the production process and maximize its output.

Why Pharmaceutical Packaging Machines

The JOCHAMP anti-dust technology is applicable for capsules, tablets, pearls, gels, and other most kind of tabloids.

With innovative technology and a multi-language operating panel. Can able to make alarms, display errors, and self-diagnose.

JOCHAMP Pharmaceutical packaging machines are easy to operate, clean, maintain, and adjust. Also with a low maintenance cost.

JOCHAMP pharmaceutical packaging machine is a mechatronic device that offers convenient and reliable operation.

Packaging Requirements

Choosing the right packaging requires determining the physical and chemical characteristics of the product. The marketing requirements and the protective needs of the product also need to consider. When choosing material for packaging, it depends on the following:

- Customers conveniences (weight and size)

- The level of protection needed

- Compatibility with a dosage form

- Sterilization method

- Filling method

Pharmaceutical Quality Standards

Packaging standards for pharmaceuticals is a very important matter and concern for some customers and drug manufacturers. We know that the main purpose of pharmaceutical packaging is to protect every medicine from contamination, moisture, and other external factors. World Health Organization (WHO) set some quality standards in the field of pharmaceutical products such as:

- Anti-tampering Standards

- Packaged Labeled on Pharmaceutical Products

- Pharmacopeia Standards

- Regulations for Medicines with Aspirin

- Pharmaceutical Products Packaging Site

- International Regulations Regarding Pharmaceutical Packaging for Children

Pharmaceuticals Packaging Machinery Functions

With the modernization of the pharmaceutical industry globally, the demand for pharmaceutical packaging has also risen. Many advanced types of pharmaceutical packaging machinery are being used for the solution of pharmaceutical packaging products.

For these matters, JOCHAMP continues to produce some advanced designs of pharmaceutical packaging machines that serve automation and mechanization of the pharmaceutical packaging process. We believe that the general and main functions of pharmaceutical machines for packaging are to provide proper labeling and ensure the containment & safety of various drug products.

Your Leading Pharmaceutical Packaging Machines Provider

JOCHAMP is a professional producer of pharmaceutical packaging machines that also provides extensive packaging machinery support such as filling, carton packaging, outer packaging, end-of-line packaging, etc. Our company advocates a flexible production line for packaging, provides minimizes downtime through our packaging machine, and differentiates each process failure. We are also able to provide a wide range of extended applications such as:

- Labeling

- Date Coding

- Defective Product Injection

- Weight Detection

- Metal Detection

- Image Detection

JOCHAMP Pharmaceutical Packaging Machines

JOCHAMP just not aim to provide quality pharmaceutical packaging machine but also to provide the best service to our valued customers worldwide. Here is the scope of our company’s services:

- Installation Services – we ensure to send an operational packaging machine, that’s why before shipment, we conduct inspection and testing of our machine. The instruction manual is provided and videos on how to use and install the machine.

- Warranty Services – our company provides a “one-year warranty” service for our machine with guidance and technical consultation. We also provide a long-term accessories and equipment parts supply.

- Customization – we accept any customization requirements. Just tell us the design and specific requirements, and we will make that customized machine.

Let’s discuss the following various application of pharmaceutical packaging machines in the list below:

- Capsule Packaging – one of the common types of capsule packaging machine is the blister packaging machine. A machine that ensures the integrity and safety of capsules.

- Tablets Packaging – a blister packaging machine or strip packing machine are the best machines for packing tablets. It makes tablets safe from environmental interference and alterations.

- Liquid Medicine Packaging – these are common machines in the market that are very useful machines for liquid medicine and help to avoid contamination and spilling.

- Ampoule Packing – blister machine is best for ampoule packing. This machine is very essential for drugs and lab samples.

- Needle Packing – as the needle is dangerous when handled carelessly, it needs to be packed. The needle packing machine provides both small-scale and large-scale levels of packing.

- Vials Packing – just like the other packaging like ampoule packing, a blister machine can also use to pack vials.

Why JOCHAMP Pharmaceutical Packaging Machines

JOCHAMP pharmaceutical machines help to improve consistency and the ease of work production. It also helps to lower the labor cost of production. We offer the three different types of pharmaceutical packaging machines:

- Fully automatic pharmacy packaging machine – has an automatic feeding system and runs in every stage.

- Semi-automatic pharmacy packaging machine – operator handles some packaging processes like insertion of the product manually.

- Manual pharmacy packaging machine – a machine is operated manually throughout all packaging processes.

The digital capacity and capability of a machine are the prior things to consider when planning to buy one. In the market today, there are a lot of innovations and inventions for pharmaceutical industry solutions. The efficiency and ease of use are the main focus and roles of pharmaceutical packaging machines. With JOCHAMP packaging technology and innovations, we can able to provide the following advantage to our clients:

- The most cost-effective solution

- The most conservative packaging production

- The stable and less downtime operation

- Modular packaging solution

Don’t take the risk of wasting your money on some unknown brand in the market today just because they offer a cheap price. The reality is that it hurts seeing your production has a low quality and is less efficient. The design of the machine also matters in choosing the right packaging solution for the specific products.

JOCHAMP can provide every specific design that suits every packaging need. We can also offer different types of pharmaceutical machinery for different types of pharmaceutical products like syrups, capsules, tablets, or other pharmaceutical products.

Related Product

Pharmaceutical Packaging Machines: The Complete Buying Guide

When it comes to choosing pharmaceutical machines, there are many designs and options depending on your packaging needs. This guide explores some of the critical machines in the packaging industry.

pharmaceutical packaging machine

Pharmacy Blister Packing Machine

It is a pharmaceutical packaging machine that seals the tablets and ensures they are not affected by either moisture or light.

Uses Of Blister Packing Machine

In the pharmaceutical industry, the machine is used as a unit dose packaging thus offering a strong barrier to the drugs.

Also, by forming barriers against the drugs, the quality is also safeguarded.

pharmacy blister packing machine

Advantages Of Blister Packing Machine

- To the patients and caregivers, packaging by blister machine is convenient as it enhances an easy removal of capsules and tablets.

The blister is pressed and the capsules or tablets are forced out of the strip.

- The packaging is lightweight and volume consumed is less as compared to other packaging like glass.

How Blister Packing Machines Work

The machine works on the form, fill and seal mechanism.

There are roles of flat sheets where pharmaceutical products are packed, then closed employing the same name of the appliance.

Tablet Packaging Machine

The machine positions and perfectly does the large number packaging of tablets in tubes that have been elongated.

Uses Of Tablet Packaging Machines

The machine ensures safety of the drugs

Containment of the drugs is also ensured

Advantages Of Tablet Packaging Machines

Fragile products such as the effervescent tablets can be packaged with short lead times.

Latest designs of these machines have improved features which enhances its operation proficiency.

Also, the machine’s security features are well designed which in turn enhances its operations.

How Tablets Packaging Machines Work

The machine is powered on and empty bottles are put into the machine manually by the operator.

Thereafter, tubes are forwarded into the filling position where tablets are forced into the tubes.

Tablet packaging machine

The then filled tubes are directed into channels where verification of quality is done.

Verified tubes are then routinely capped while the unverified tubes are rejected by sensors.

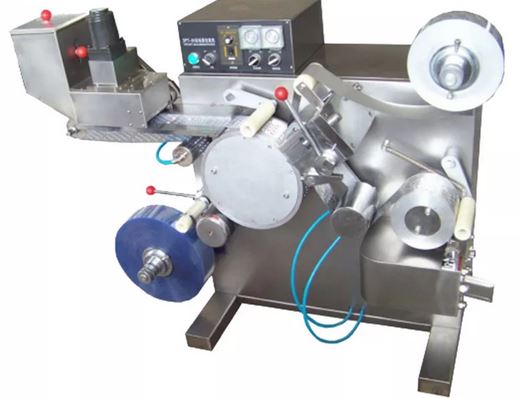

Strip Packing Machine

This is a machine that does the packaging of caplets, tablets, soft gelatin capsules, capsules and coated tablets.

strip packing machine

Uses Of The Machine

The machine is used in the packaging of both coated and uncoated capsules.

Also, the machine is used in the packaging of capsules, hard gelatin and soft gelatin.

Moreover, for confectionary products like medicinal chewing gums and lozenges, the machine is tasked to package them.

Advantages Of Strip Packaging Machine

The costs of packaging while using this machine are low.

Integrity of the product is maintained since the shielding material prevents the products from environments conditions.

Temper proof strips prevents the products from any alterations before use.

How Strip Packaging Machine Works

The products are passed from the hopper into the roller sealing cavities.

Laminated foils are met by the product at the sealing cavities.

In a continuous strip, the product is packed and sealed by the foil.

The strip is then cut into desired sizes of the strip package.

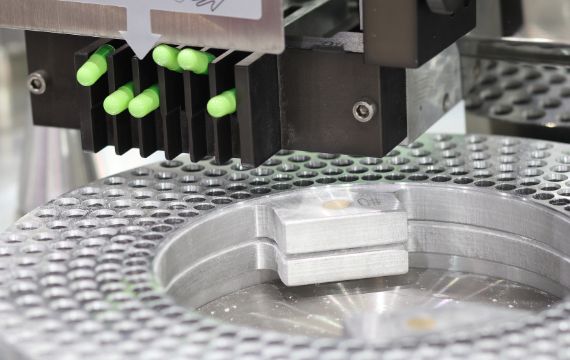

Capsule Filling Machine

This is a machine that is suitable in the filling of pellets, granules and powders into the capsules.

Uses Of Capsule Filling Machine Works

The machine fills pharmaceutical substances which can be granules, pellets or powder into their individual capsules.

capsule filling machine

Advantages Of Capsule Filling Machine

The machine consumes low levels of power.

Additionally, the machine is highly accurate, precise and flexible.

Its high speeds and scalability makes it more efficient in its operations.

It prevents industries in production losses of powder, granules and pellets because of its accuracy.

The machine is simple to use and easy to operate.

How Capsule Filling Machine

For the manual capsule filler;

The capsules are put into the manual capsule filler

Additionally, the capsule is the filled with the intended material that can be pellets, granules or powder.

Besides, the capsules are the covered where the middle plate is placed on the filled cap plate.

Pharmaceutical Tube Fillers

It is a pharmaceutical machine that is designed to fill tubes with contents at the same time sealing them.

pharmaceutical tube filler

Uses Of Pharmaceutical Tube Filler

In the pharmaceutical industry, the tube filler are used in the packaging of gels, ointments and creams in desired quantities.

Advantages Of Pharmaceutical Tube

The production efficiency is improved due to increased speeds as a result of this machine.

There is an aspect of consistency and reliability since there is uniform filling of the tubes depending on their sizes.

Wastage of the products is minimized since the machine measures the contents accurately.

How Pharmaceutical Tube Filler Works

Tubes are inserted into the tube holder.

At this point, the rotary table rotates with the tube holders thus positioning themselves.

Then, functions are set at the control unit where the machine will conduct functions systematically.

The machine starts by filling, then sealing, printing the batch numbers and cutting the tail.

Powder Filling Machines

Pharmaceutical powders filling machines is essential in filling a greater range of non-free flowing and free flowing powdered products.

powder filling machine

Uses Of Powder Filling Machines

Majorly, the machine is used in the filling of powdered products.

Also, the machine is tasked in the filling of granulated products.

Advantages Of Powder Filling Machines

They enhance a cost effective production since costly powder spills and unnecessary labor are reduced.

The powder filling process is precise and uniform because of machine’s high levels of accuracy to ensure correct amount is filled.

By adjusting machine components, the machine allows an easy changeover of container sizes hence it is flexible.

How Powder Filling Machines Work

The machine works on the principle of using long screw type in the dispensing of distinct powder quantities into different pouches.

Depending on the powder type, whether non free flow or free flow, different auger configurations are required in the machine programming.

Cartoning Machine In Pharmaceutical Industry

In this industry, the cartoning machine is tasked by packaging pharmaceutical inventories into their cartons.

cartoning machine

Uses Of Cartoning Machine In Pharmaceutical Industry

The machine packages pharmaceutical products into their respective cartons.

Advantages Of Cartoning Machine

There is improved labor productivity as the machine works at a faster rate compared to the manual packaging.

With this machine labour costs are reduced while high speeds, precision and stability have been maintained.

The machine is error free unlike in manual packaging where after some hours, there will be lots of errors in the packaging.

How Cartoning Machine Works

A guide rail puts the carton in position at a right angle position and the push plate opens the carton.

Thereafter, the loading is done where the product is put into the carton before it is moved to the folding spot.

At the folding spot, motors having push plates do the task.

Thereafter, is closing the carton’s tongue.

Liquid Filling Packaging Machine In Pharmaceutical Industry

It is a machine in the pharmaceutical industry that is used in the packaging of liquids into containers.

liquid filling packaging machine

Uses Of Liquid Filling Machines

The liquid filling machine is used during the filling of liquids in IV bags, bottles, ampoules and vials.

Advantages Of Liquid Filling Machines

There is an increased scale of production because the liquid fillers are able to fill many containers in a short while.

There is guaranteed consistency when using this machine unlike using the hand filling method which will result into errors.

Under proper maintenance, the liquid filling machine promises durability hence production for a longer while thus offering reliability.

How Liquid Filling Machines Work

The containers are placed at the right position in the machine.

In the product hopper, the accurate amount of liquid you want to fill is poured.

The machine is started and containers will move in the correct direction.

Finally, the machine will seal the containers.

Label Applicator

This is a machine that attaches labels that are preprinted with pressure sensitive adhesive on their backsides to products.

Uses Of Label Applicator

The machine is used in the attachment of labels onto packages, containers, bottles and other products.

Advantages Of Label Applicator

Higher seeds are witnessed when using this machine compared to manual labeling which is slow thus consuming a lot of time.

To have labels placed in consistent manner, this machine is ideal since it will apply the labels in a precise manner.

The machine is portable because it can be moved from one point to another while accommodating a newer configuration.

How Label Applicator Works

The machine works by loading a label roll into the applicator.

The applicator will now be ready for applying of the labels onto the different products.

Majorly, the labels are normally preprinted hence it becomes easier.

Tablet Counter

This is a machine that counts tablets and capsules medications.

tablet counter

Uses Of Tablet Counter

The machine is used in the counting of prescription medication s accurately which are either in tablet or capsule form.

By doing this, the safety of the patient medication is guaranteed hence reducing cost and increasing efficiency of pharmacy or hospital.

Advantages Of Tablet Counter

The use of this machine eliminates the risk of contamination of the tablets and capsules during the counting processes.

The machine saves on the costs of production since it reduces manual labor and counts numerous pills in a short time.

To solve the time management menace in the counting and dispensing of pills, the only solution is the tablet counter.

How Tablet Counter Works

The tablet counter utilizes a technology of advanced real time image processing which aids in the accurate counting of tablets.

Pouch And Sachet Packaging In Pharmaceutical Industry

It is a machine ideal for the packaging of some pharmaceutical products that demand for sachets and pouches.

Uses Of Pouch And Sachet Packaging

The machine is used in the packaging of pharmaceutical products of the following natures;

- Granular form

- Solid form

- Liquid form

Advantages Of Pouch And Sachet Packaging

The machine can be used in filling different pouch and sachet sizes because it is easier to adjust hence more convenient.

Additionally, the machine is easier to use and operate as the functions are put into the control system which runs by itself.

The machine has an independent temperature control adjustment mechanism which is adjusted on the touch screen.

How Pouch And Sachet Packaging Works

The package is put into the machine on a conveyor belt where size, volume and shape are determined.

The product is injected into the pouches at the filler station.

- Sealing of the package is the done

- Printing labels

- Package folding

Quality Inspection Machines

It is a machine that undertakes the procedure of checking and testing the product qualities to ensure required standards.

Uses Of Quality Inspection Machines

They get quality assurance of products, components and packages hence making sure the standard specifications are met.

Also, they are used in the monitoring of speeds of production while chucking out errors involved.

Advantages Of Quality Inspection Machines

The machines enhance qualities of products since the quality control processes are highly accurate compared to manual labor.

The company witnesses reduced costs of production as it is only required to hire a quality control machine technician.

How Quality Inspection Machine Work

The quality inspection machine is calibrated basing on different standards specifications of the pharmaceutical products.

Apart from the calibration, the machine measures, examines tests and gauges the attributes of products.

In case the product meets the set specifications on the machine, the product is considered of quality standard.

Mechanical Properties

The packaging in this industry should be one that is able to protect drugs.

Therefore, the packaging material being used should have a particular toughness and strength to withstand environmental factors.

Safety Performance

Since the drugs being packaged are for human consumption, the packaging materials should not have any toxic traits.

Any toxic trait in the drugs will lead to pollution hence affect ting human health.

Economic Performance

The packaging material used in the packaging procedures should come from a low cost source.

The low costs of low materials will enable the packaging cost and the final product being affordable.

Barrier Performance

Environmental factors like heat, moisture, smell, light and water vapor should be prevented from affecting the drug.

Therefore, a certain barrier should be in place to prevent the drug’s deterioration hence proper functioning.

The production efficiency is improved through the use of these machines because specialization in pharmaceutical packaging is achieved.

Packaging products using pharmaceutical machines is precise as compared to manual packaging where spillage occurs hence product wastage.

The costs of production are reduced as manual labour is minimized since the machine handles all packaging aspects.

High levels of hygiene are maintained and minimum environmental exposure when the machines are used thus leading to minimal contamination.

The machines ensure that there are faster productions of drugs thus they are ever available in markets on time.

Since the machines work together with the label applicator machines, the marketing and branding of products have improved.

Machine utilizes minimal space during its operations unlike manual labor which demands many workers who consume more space on the investment.

Protection

The pharmaceutical packaging equipment is able to protect the products and packaging materials in different ways.

For instance, equipment for container cleaning like the rinsing machines can be used prior to the filling process.

The rinsing machines removes any available dust and debris using water or air to ensure the product will not be contaminated.

Presentation

Machines like the labeling machine in the pharmaceutical industry aid in the product presentation.

The use of company logos and other relevant information on the labels help the products to show off thus enhanced marketing.

Additionally, coding equipment can be used on the products to show their dates of expiry, batch numbers together with other information.

Through doing this, your product stands out being the best among other products from competitors.

Preservation

Packaging machineries have different ways of providing additional security to products.

For instance a secure seal will prevent moisture that might lead to product destruction hence enhanced product preservation.

Type Of The Machinery

When purchasing the machinery, you need to conduct a proper research on the available options in the market.

Therefore, you need to go for a model that has been tried and tested to perform better.

Also, you need to acquire a machine model that will meet your packaging needs since the product determines the machinery.

The Machine Should Comply With Regulatory Standards

Before getting the machine, you need to know different regulatory standards the machine should comply with.

Knowing the regulatory standards of machines will enable you obtain a machine that complies with the laws.

The Machine’s Technology

The digital competencies of the machine should be considered when purchasing a machine.

Despite the new innovations and interventions in this industry, you need to acquire a machine that is efficient and easier in operating.

They are used in the following areas;

Tablet packaging where the blister and strip packing machine are widely used.

Needle packing hence the needle and syringe packing machines are critical.

The carton sealing machines are used to seal boxes and cartons of different sizes and shapes.

Capsule packaging where the blister packaging machine is widely used.

The liquid packaging machine is used in packaging and sealing of liquids.

For all your pharmaceutical packaging machines, contact us now.