Horizontal Form Fill Seal Machine Manufacturer in China

Jochamp innovations manufacture a wide range of horizontal form fill seal machines that can help your company excel by saving time and money. Our services can assist you in finding the ideal horizontal form fill seal machine system for your special application.

- Professional technologies

- Exceptional seal integrity

- Excellent packaging for high-volume production

- Supply of all kinds of packaging machinery

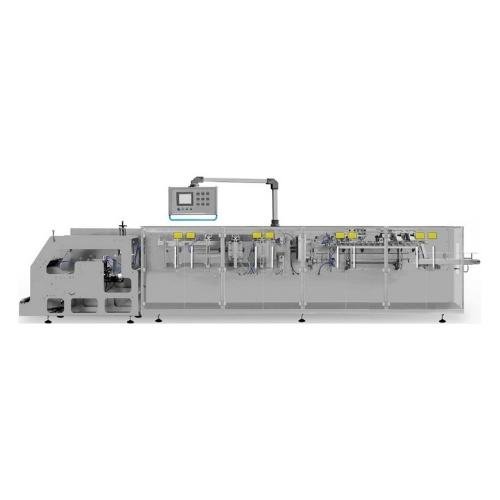

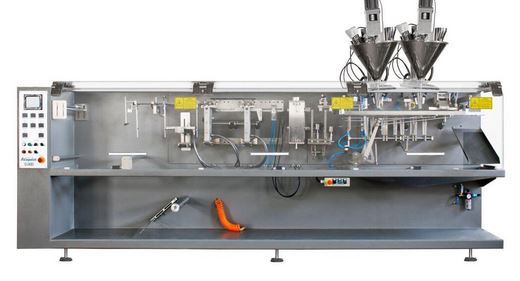

JOCHAMP Horizontal Form Fill Seal Machine

Jochamp horizontal form fill seal machines are ideal packaging solutions for high-volume food packaging, sealing, and export operations. It’s designed for speed and efficiency, successfully packing and vacuum sealing products in a shorter length of time.

Another advantage of horizontal form fill seal machines is their ability to package a wide range of goods. Meats, cheeses, fruits, vegetables, soups, broths, cereals, and powders, as well as liquid and solid foodstuffs, they may all be packed by using a horizontal form fill seal machine.

If you want to speed up your packaging process, save money, and ensure that your items are properly packaged. Consider Jochamp horizontal form fill seal machines for your production and packaging necessities. Send your inquiry now!

Types of Horizontal Form Fill Seal Machine

Jochamp Horizontal Form Fill Seal Machine Feature

Horizontal form fill seal machine making a variety of alternative pack presentations with maximum efficiency. Different pack options in sachet and stand-up pouch are available.

By lowering labor expenses, the Jochamp horizontal form fills seal machine will make your packing process cheaper. In a shorter amount of time, more items may be wrapped.

The horizontal form fills seal machine from Jochamp technologies can fill up to 60 units per minute or more. For your application machine needs, choose Jochamp an expert and trusted provider.

Food products packed into the vacuum-sealed pouches and bags used with the horizontal form fill seal machine will be protected from open-air and other elements that could cause spoilage.

Horizontal Form Fill Seal Machine Application

Jochamp horizontal form fill seal machine is designed for the packaging of large items. Such as trays of quick-frozen food, biscuits, hamburgers, instant noodles, daily-use items, pharmaceutical sundries, and many more. All of our forms fill seal packing equipment is built to last and provides efficiency and precision in each application.

It is an automatic high-speed packaging machine that produces items with a pleasing look, strong sealing, good health, and long storage life. To learn more, please contact us immediately.

Jochamp Horizontal Form Fill Seal Machine Characteristics

Excellent horizontal form fill seal machine features that you have gotten from Jochamp services such as:

- Intelligent control, low-noise operation, and a good ambiance.

- The machine achieves a high level of automation throughout the packaging process: feeding, shaping, filling, and sealing.

- Humanoid design, industry-standard touch screen, intuitive display parameters, man-machine overlapping interchange manner operation, menu operation, simple to use.

- Horizontal sealing and film are in sync, resulting in more stable and beautiful sealing.

- The length adjustment range is exceptionally wide, making it ideal for packing a wide range of products.

Jochamp Provides the Broadest Range of Machine

Jochamp offers the most comprehensive line of horizontal form fill seal machines available. Our machines are customized to meet the needs of our customers and cover all their requirements. The design is built on a modular frame that is made up of three separate modules: pouch formation, filling, and dosing-sealing.

These machines come in a variety of styles based on the products to be filled. As a result, we can always provide our customers with the machines that best suit their needs.

Reputable Horizontal Form Fill Seal Machine Provider

Jochamp offers a professional international trade team that can help you with anything from payment to document certification to freight and customs. We have spent over 15 years focusing on R&D and manufacturing horizontal form fill seal machine series.

Professional and dependable services are some of the solutions that Jochamp provides to all consumers globally. Regular after-sales care, giving guidance on maintenance. European quality, Asian price. Our machines are all thoughtfully designed to meet or exceed industry demands and requirements.

Allow Jochamp to provide your horizontal form fill seal machine to match your needs. To secure the safety of equipment during shipment, we use sturdy transport packaging, plus quality assurance for one year and lifetime after-sales service. Contact us right now!

JOCHAMP Horizontal Form Fill Seal Machine

Check out these features to look for when choosing a horizontal form fill seal machine.

Take a look at the following fundamentals:

- Product specification

- Sizes of products

- Pouch fabric

- Dimensions/size of the pouch

- Pouch design

- Speed required

- The product to be packed’s hourly output

- Temperature of filling

- Forming

The machine starts by creating the bag from the roll of film.

- Product dosing and filling

The filling is the next phase in the process, which is done by connecting the bagging machine or another filling machine.

- Sealing and finishing

After the product has been placed in the bag, the top is secured, the bag is finished, and then it’s cut away.

Why Choose Jochamp Horizontal Form Fill Seal Machine

Jochamp is professional in manufacturing horizontal form fill seal machines that can surely improve production efficiency. It provides high-speed and intelligent operation ensures reduced labor costs, and increases your profit.

Jochamp has advanced manufacturing lines and technology for the appropriate specific production of your machines. We custom packaging machines to meet customers’ individual needs. This equipment can fill and seal a pack in one operation efficiently and quickly.

Jochamp can provide a solution that meets your needs at an affordable price. It is low cost but never compromises its consistent performance, precise operation, efficiency and durability, and energy efficiency. Choose Jochamp to provide the best machine for your needs.

Form fill seal machines are packaging machines applicable to beverages, medical, cosmetics, food, stationery, tobacco, chemical, pharmaceutical, and many more. Jochamp is a knowledgeable producer who can provide you with machines for these products.

Related Product

Horizontal Form Fill Seal Machine: The Ultimate Guide

In this guide, you will find all information about horizontal form fill seal machines. Whether you want to learn about features, filling options, sealing mechanism, working principle or other vital features – you will find all information right here. So, keep reading to learn more.

These are machines that the ability to form a package, fill it with product and finally seal it all in a single machine unit.

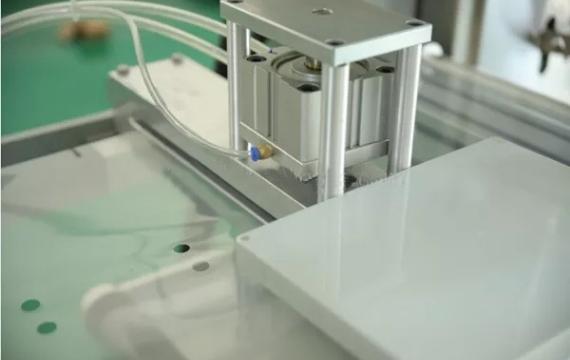

horizontal form fill seal machine

The operation takes place when the film or other material slides on a horizontal plane after which the ends of the packed product are cut from each end.

A Horizontal Form Fill Seal Machine contains the following main parts:

An Infeed Conveyor: it is made of stainless steel which is both hygienic and safe when packaging products.

The Forming Area: responsible for pulling and forming the multi-linked film

Film Feeding and Positioning: responsible for pulling the film or laminate out then tensioning it using some weighted pivot arm and various rollers in readiness for forming.

Sealing and Cutting: contains sealing bars or sealing jaws that use heat to seal the package and cut for packing.

Human Machine Interface (HMI): a touchscreen used to monitor the process, faults and set parameters.

The Horizontal Form Fill Seal Machine works in a sequence of operations that are as follows:

Loading Product

The product to be filled into the packages is placed inside the filling area using an infeed conveyor.

Normally, the purpose of the conveyor is to ensure the materials are packed in sequence after moving them.

Also, the conveyor also ensures a constant distance is maintained between each product.

This aligns them to the process of sealing and cutting after introducing the product is inside the pack.

Unwinding Packaging Material

Some of the packaging materials may include plastic laminates, paper or aluminium foils and are available in rolls.

For the material to be used, it has to be it has to be unwound or rolled out.

It is first pulled out then tensioned using some weighted pivot arm and various rollers in readiness for forming.

The process of unwinding usually takes place behind the machine.

Forming Of The Package

The material is tensioned and fed to the filling tube while flat.

Besides, the packaging material must however be given the packaging shape for the filling process to be performed efficiently.

The forming collar or the forming shoulder is the machines part that is responsible for forming the packaging shape.

The material is meticulously twisted round the forming tube while being pulled along it.

In some designs, the film is moved using pull down belts immediately after the forming process.

In other designs, the sealing jaws equally perform this task of pulling down the packaging film.

Sealing

The initial sealing, done on the side, is done after the packaging material has been wrapped well on the forming tube.

An overlap has to be there between the packaging reel width and the forming collar when the material is round the tube.

The two overlapping parts of the material are then pressed against each other using sealing bars or sealing jaws.

Using heat, the parts are welded together and a side seal is created.

Product Filling

This process uses the dosing system placed near the forming tube to dose the product amount into the package.

The material passes through the filling tube into the open package being manufactured.

Top Sealing

The sealing jaws that sealed the bottom are activated right after the product dosing has been completed.

They perform the final top seal of the process the same way they did the bottom seal.

Some machine designs have sealing jaws that have and up and down vertical motion.

This allows them to pull the material along the machine while unrolling it form its reel placed on the unwinder.

Cutting And Discharge

After the packaging has been sealed, it is cut and goes straight to a collection system that discharges it.

This is usually a conveyor belt that takes the product to the next step of packaging that is packing.

The most popular types of form, fill and seal machines in the packaging industry are the Horizontal Form Filling Machine and the Vertical Form Filling Machine.

The most significant difference between them is the manner in which they dispense their products into packages.

Besides their basic structure, they have very few differences that distinguish the two with each better than the other.

horizontal form fill seal machine

These minor differences enable a client to source for the most compatible machine for their production lines.

Horizontal Form Filling Machines can best be used to package product that are easily contained and are solid.

Such products tend to be standalone goods like candy bars and moderately small children’s toys.

Vertical Form Filling Machines are the most suitable for packaging of products that are granulated, loose or difficult to manually handle.

vertical form fill seal machine

They include products like sugar, a variety of liquids and potato crisps.

There are several benefits related to the operations of the Horizontal Form Filling Machine. They Include:

Flexibility: A variety of products ranging from dry products, solids or liquids can be easily filled and sealed without any problem. It can also be adjusted to accommodate various sizes of packages thus increasing and diversifying the output.

Economical Packaging: products can be easily sealed using cheap packaging material that is also not heavy.

Increased Production Time: the process of forming, filling the product and sealing the package occurs simultaneously in a single machine. This makes the production time very fast and automation makes it very efficient.

Product Protection: the nature of its operation ensures that at no point does the come into contact with people which hygienic for medicines and food. The efficiency of the package sealing also averts damage to the product with moisture and dust protection.

The Horizontal Form Fill Seal Machine is widely used in many industries to pack various products. Such industries include:

- Cosmetic Industry: products such wet wipes used for cleaning babies are produced using VFFS machine.

- Agricultural Industry: many chemicals and various types of seeds are packaged using the Horizontal Form Fill Seal Machine.

- Pharmaceutical Industry: the machine is used for packaging drips, gauze bandages, blisters and syringes.

The various types of Horizontal Form Filling Machines include:

- Flow-wrappers sachet FFS

- Blister pack FFS

- Four side seal machines and thermoform FFS

- Milk Packing FFS

- Powder FFS

- Granule FFS

The Horizontal Form Filling Machine has the following unique features:

- Design is very robust with a rigid construction

- Structure is mostly stainless steel

- It has a very reliable Programmable Logic Control System

- Human Machine Interface (HMI) for setting parameters, displaying errors and product information

- They have a safety no-product no-package feature and no-cut for products out of position

There is a unique filling technology required for every product that includes:

Hot Fill

This is where a non-sterile packaging is filled with a commercially sterile heated product such as high-acid products.

The packaging is sterilized by keeping the product at a set temperature and time before the filling process.

Ultra Clean Fill

This types of fill are used for cold-chain solutions with high sterility packed using laminar flow or UV lamps.

Products with short shelf-life such as fruit juices and yoghurts can have high levels of sterility.

Clean Fill

This method kills bacteria by using cold and the product remains cold until it is filled into the packaging.

It mostly applied in packing foods containing milk as an ingredient and avoids the use of preservatives.

Aseptic Fill

Involves a pre-sterilized package being filled with a commercially-sterilized product where each is sterilized separately.

The packaging a pre-sterilized closure that is sealed hermetically in a microorganism-free atmosphere.

The sealing options available in the Horizontal Form Filling Machine include:

- Ultrasonic Sealing: vibrations of high frequency are used for package sealing brought about by vibrations of molecules in the film.

- Heat Sealing: electric resistance in sealing jaws is used to seal the package. It is reliable and costs less.

- Induction Sealing: electro-magnetic field generates heat used to seal the package using sealing jaws.

There are several factor that have to be put into serious consideration when a Horizontal Form Fill Seal Machine has to be chosen. They include:

Machine Controls

The control system is responsible for entire machine functions like starting, stopping and parameter adjustments.

A good Programmable Logic Controller (PLC) with an easy to use Human Machine Interface (HMI) can ease the machine operations.

Frame

The Horizontal Form Fill Seal Machine frame is responsible for stabilizing and supporting all the equipment.

It has to be robust and strong, meaning a heavy frame construction results in a smooth machine operation.

Stainless Steel are the ideal machine frame with a good strength-to-weight ratio and resistance to corrosion.

Welding the frame instead of bolting it helps in reducing contaminant build up.

Servo-driven Mechanism

The most accurate controls over components of the machine can be achieved using servo motors.

A continuous feedback is provided by the servo-driven component’s closed loop system with regard to position.

This will also include the components acceleration and deceleration and its velocity.

All this facilitates precise repeatability with adjustments and real-time data acquired.

Noise Levels

The louder a Horizontal Form Fill Seal Machine is, the more the wear and tear it experiences due to vibrations.

Noise is usually a sign of vibrating moving parts or friction between the moving parts.

This leads to an increase in the maintenance cost for part replacement and machine malfunction.

The best assessment for the noise levels of a Horizontal Form Fil Seal Machine is to have it run by the manufacturer at their premise.

Sealing Jaws

These are the components responsible for bonding together the sealant layers that make a reliable package seam.

They must be reliable enough to produce the perfect seal continuously form the first to last package.

The most preferred heat sealing jaws are the once forged using one piece of material only. This ensures that the heat pressure applied on the package is consistent thus preventing product loss.

Ease Of Changeover

Most Horizontal Form Fill Seal Machines have the ability to process packaging bags of different shapes and sizes.

This changeover is made possible by programming adjustments and physical configurations.

A Horizontal Form Fill Seal Machine with the lowest downtime from changeover is highly recommended.

It should also not require any special tools for the changeover to be effected, it should be automatic.

Film Tracking

Packaging films while flat have a tendency of shifting off-centre while being processed through the Horizontal Form Fill Seal Machine.

Tracking the film manually requires constant human intervention and machine stoppages thus is not cost-effective.

Modern Horizontal Form Fill Seal Machines solve this by having automatic film tracking.

This implies that the film is kept centred with a consistent tension by the machine adapting in real time.

More Resources:

For all your horizontal form fill seal machines, contact us now.