Cosmetic Packaging Machine Manufacturer

Jochamp is your reliable cosmetic packaging machine supplier in China. We manufacture modern and high output packaging machines for your business.

- Ergonomic and durable design

- Complies with CE, IOS9001, SGS certification

- Fastest delivery time of 45 days

- Cost-effective machines

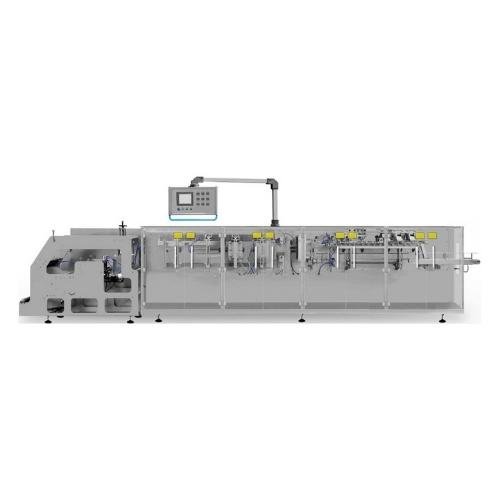

JOCHAMP Cosmetic Packaging Machine

Jochamp cosmetic packaging machine is specialized in packing cosmetic products such as creams, lotions, hair gel, body lotions, shampoo, toothpaste, scrubs, and other cosmetic products. These machines are available in various models and specifications. It delivers flexible, high-speed, fast operation, high performance, and improved productivity.

Jochamp designs one-stop packaging machine solutions for various kinds of cosmetic products in any kind of container. From filling, capping, and labeling to cartooning, our machines offer excellent function consistently. It is easy to clean and maintain.

No matter what your packaging machine specifications, we’ll find or create the right solution for you. Message us today!

Various Cosmetic Packaging Machine for Your Choices

Different Cosmetics Packing Machine Applications (4)

Cosmetic Packaging Machine Features

We supply direct factory machines to meet your budgets. It is cost-effective but never compromises the quality.

You can ensure the durability and performance of our machines due to its servo motors and intelligent systems, and integrations.

Our cosmetic packaging machines are offered with 1 year of warranty and lifetime after-sales service. It delivers long-lasting service.

Designed an excellent cosmetic packaging line based on your specifications and configurations. Choose the design and parts.

Cosmetic Packaging Machine for Business

Our range of Cosmetic Packaging machines will ensure enhanced production and efficiency. It can reduce labor costs, waste, and product rejection, and reduce injury and accidents to personnel. These machines provide uniform and high-quality packaging to your products.

Jochamp delivers superior types and specifically built packaging machines to exceed the constantly changing requirements of the cosmetics industry. It accommodates more cosmetics container shapes and sizes.

Packaging Equipment for the Cosmetic Industry

Packaging machines that can be utilized to prepare cosmetic products are wide and varied. We can create a cosmetic packaging line with complete machines to finish your production efficiency. This includes:

- Container Cleaning Equipment

- Filling Equipment

- Capping Machines

- Labeling Equipment

- Induction sealers and neck banders

- Cartoners or shrink wrap machines

Custom Cosmetic Packaging Machine

Jochamp is an expert in providing custom cosmetic packaging machines for your business. Our engineers can create reliable, versatile, and maximum performance equipment. We will assist you in designing, executing, and implementing the ideal packaging machine or integrating it with your current equipment.

Different tooling is available at Jochamp to handle a wide range of cosmetic product packaging. If your factory produces many products, you can customize a range of tooling to ensure that your equipment and products are performing at their best. Choose the various sizes and specifications to improve your cosmetic packaging process.

Your Trusted Cosmetic Packaging Machine in China

JOCHAMP manufacture and design high functional cosmetic packaging machine. It performs very well, durable with the highest precision. You can find several models of this machine that can fit your needs. These are certified to CE, SGS, cGMP, and ISO9001. It guarantees to offer years of consistently superior service. Our company adopt latest technology and techniques to supply suitable machines at reasonable rate.

Whether you’re a start-up cosmetic manufacturer or an established packager company, Jochamp has the perfect packaging machine for your projects. We custom-built machines that meet your production demands and budget. For more inquiries, please contact us immediately.

JOCHAMP Cosmetic Packaging Machine

Jochamp can manufacture various types of packaging machines for specific cosmetic products. Some are the following:

- Cosmetic Fragrances

- Body care products

- Decorative cosmetics

- Hair care cosmetic

- Health & beauty

- Easy to operate

- High degree of automation

- Compact packaging line design

- High performance, high accuracy

- Maintain efficiency of the packaging process

- Minimize labor intensity

- Intelligent fault diagnosis

Jochamp Services for Your Business

Jochamp is composed of expert team to provide efficient, accurate and quick installation support. The process includes product-specific adjustment, site acceptance test, personal on sites contact person, etc.

As a professional supplier, Jochamp will provide consultation and a customized quote for the recommended original spare components to guarantee reliable production, functionality and high performance. We have high availability of spare parts.

Jochamp provide excellent trainings that guarantee employees’ training need meets. These trainings provide theoretical and practical skills to operators. It includes operator training, electrical training, software training, process expert training, maintenance & repair, inspection and repairs.

Related Product

Cosmetic Packaging Machine

Cosmetics can be defined as a product that is applied to the body to increase beauty and/or hide a defect.

These products are wide-ranging and may include lipstick, eye shadow, and other makeup, nail polish, facial creams, skin lotions, and shampoo.

They come in different forms, such as powder, jelly, paste, powder, liquid, compressed gas, etc.

cosmetic packaging machine

When selecting an ideal cosmetic packing equipment, some factors you must always have in mind include the following;

Performance

Different cosmetic packing machines come with various specifications that define their respective performance.

For instance, speed, capacity, and automation level are some notable specifications that influence the general performance of this equipment.

Thus, ensure you keenly look into the particular specifications to guide you in determining the most suitable one for your needs.

Efficiency

Ordinarily, the efficiency of this machine lies on several aspects, including its user-friendliness, automation, and reliability among others.

Efficiency is an important consideration when choosing this machine since it determines your production throughput.

Durability

When choosing this equipment, you should never overlook the aspect of durability.

It is quite broad but primarily determined by the hardiness of the parts, components, and systems.

A durable cosmetic packing equipment gives you value for money as it guarantees return on investment.

Easy Maintenance

The operation of this machine usually entails running for several hours and, at times, days or weeks, depending on the cosmetic packing demands.

As such, it would be fundamental to ensure its maintenance processes are straightforward and non-technical.

Available Floor Space

This piece of machine is available in different sizes or dimensions.

Hence, it is imperative to establish the available space on your floor to determine the ideal size of cosmetic packaging machine that can fit appropriately.

Ensure you pick a machine that leaves some room in your floor space for other operations, such as storage needs.

Cost

This equipment is available at different price rates depending on the features, model, specifications, and manufacturer among others.

Hence, ensure your pick a cosmetic packaging machine that suits your budget and offers value for money.

Cosmetic packaging machines are available in different variants based on several elements surrounding the particular product.

The working mechanisms of these machines also vary depending on mode of operation, container being filled, and nature of product.

Here are the notable ones you are likely to use in packaging different cosmetic products;

Cosmetic Container Cleaning Machines

It is a piece of equipment designed to remove dust and any other foreign particles and substances from container prior to packaging.

You can find it in different variants and often use different container cleaning mechanisms.

Some variants use water, clean pressurized air, or other media in rinsing contaminants from the different containers before cosmetic product packaging.

cosmetic container cleaning machine

Besides, you can find them in manual, semi-automatic, and fully automatic units, which is imperative in broadening your choice options depending on your output.

They include the following;

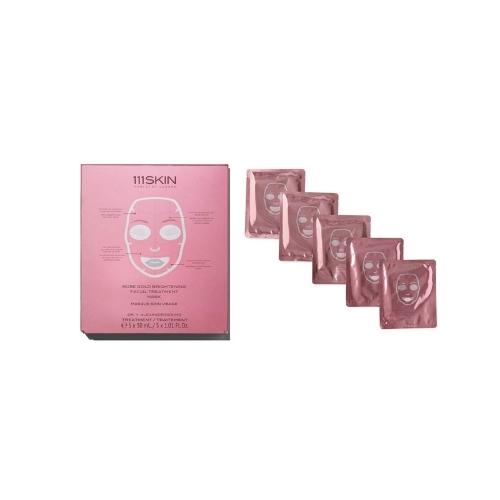

Sachets

These refer to a relatively small bag that is filled with a specific type of cosmetic product and hermetically sealed.

They are available in different sizes, shapes, and designs but are usually sturdy and enhance product’s shelf-life since it is airtight.

Tins

These are cans or containers usually designed in a cylindrical shape or design used for packaging and storage of different products, including cosmetics.

You can find them in metallic or plastic materials and are usually opened by cutting the open or removing the covers.

Tubes

These are collapsible squeeze packaging materials designed for packing a wide range of cosmetic products, including creams, ointments, thick liquids, gels, etc.

The design structure of tubes offers a layer of protection, which prevents the content from breakage.

They are available in aluminum and plastic materials designed to hold a more varied content.

Bottles

These are packaging containers with a relatively bigger body in diameter than the opening, often made from different types of thermoplastic materials.

Usually, bottles used in cosmetic packaging are lightweight, highly shatter-resistant, and in several aspects in different sizes.

Cleaning Cosmetic Containers

Typically, cosmetic container cleaning is broad since several techniques are used in the process.

The common methods used in cleaning cosmetic containers include the following;

Rinsing

It involves cleaning cosmetic containers by removing any contaminants before they get into the machine to receive the product.

The process uses a rinsing machine to remove dust, debris, and other impurities that may be present in the container.

It entails blasting the surface of the container with water, clean air, or any other cleaning solution.

Rinsing machines can handle different types of cosmetic containers, including bottles and tins of different materials.

Vacuuming

This is a cleaning method that involves blasting inside of a cosmetic container with air while sealed to create a vacuum and remove any loose debris.

You can use this technique to clean different cosmetic packaging containers made of different materials such as thin metal and plastic.

There is a special vacuuming machine often used in cleaning cosmetic containers using high-pressurized nozzles.

Washing

It is the process of cleaning the outer and inner surfaces of a specific cosmetic container.

This method varies slightly from container rinsing, which primarily involves cleaning the inner part of the container.

Usually, it is common for relatively large cosmetic containers with the aid of washing equipment.

Different cosmetic filling machines use various mechanisms to fill a wide range of cosmetic products into several containers.

Here are some notable machines and how they fill the cosmetic products into respective containers respectively;

Overflow Cosmetic Filler

One unique aspect of overflow cosmetic filling machine is its ability to fill bottles uniformly, as much the results often vary slightly in volume.

In essence, it creates visually appealing products when on the shelves, especially those packed in clear containers such as glasses.

Thus, it gives the product a more professional look while maintaining an even fill.

cosmetic filling machine and equipment

This cosmetic filler is thus mostly suitable for filling cosmetic products with thin to medium viscosity at a relatively fast rate.

Any leftover product in this equipment is pushed back to the storage tank to reduce wastage.

Ordinarily, the working principle of overflow cosmetic filler entails pumping the product into container using a two-part nozzle.

The container fills up to the intended or predetermined fill height, and the surplus product or foam are pushed out of the container back to the storage tank through the return nozzles.

Gravity Cosmetic Filling Machine

This type of cosmetic filler fills the respective cosmetic product using gravity force.

Ideally, gravitational force enables the equipment to fill the containers with same volume of product using time-based filling principle.

It features a hopper placed above a set of nozzles filled with the product to be bottled.

Essentially, this machine pumps the product bulk supply into a holding tank positioned above a set of pressurized valves.

The nozzle valves open up once the containers are placed below the nozzles, and gravitational force draws the cosmetic product down.

gravity cosmetic filling machine

Timing of the nozzle valve allows it to shut again once an accurate quantity of product flows into the container, new containers set underneath the valves, and the process repeats.

Gravity cosmetic fillers are best suited for liquid cosmetic products with relatively thin viscosities that rarely change with ambient temperatures.

It is also suitable for applications where product recirculation in a fluid path is not necessarily desirable.

Auger Cosmetic Filling Machine

This is a type of cosmetic filler variant designed to fill the right amount of product into the respective container.

Ideally, it has a vessel known as a hopper where the product is stored, which enables the filler to dispense a predetermined amount of product into the container in each cycle.

Auger is essentially a drill resembling a screw for drilling precise holes in materials.

Thus, the auger cosmetic filler fills cosmetic products into respective packages using an auger screw.

You can use this machine to fill containers with granular, powdery, liquid, and semi-liquid cosmetic products.

auger cosmetic filling machine

This machine can handle different products with the right setting, such as free-flowing, ointment, liquid, and non-free-flowing among others.

The working principle of this machine is relatively straightforward and involves machining the lower auger parallel flights within the machine to a constant pitch.

It enables each pitch to attain desired the precise volume.

Auger drive rotates the auger at a consistent speed to enable it to produce a constant dosing flow.

Agitation blade rotating in the opposite direction to the auger de-aerates and homogenizes the product as it breaks any bridge while at it.

The same agitation blade extends the auger drive’s throat to regulate number of rotations.

Net Weight Filler For Cosmetic Packing Machine

As the name indicates, this cosmetic packing equipment fills the product on the principle of a pre-set weight.

It uses a load cell fixed underneath the loading plate that guarantees highest filling accuracy.

Hence, this machine is most suitable for filling relatively expensive, aggressive, abrasive, and delicate cosmetic products.

The working mechanism of this equipment is more or less similar to having advanced weighing scale underneath the bottle to determine amount of product filled.

net weight filler

It starts by load cell being regulated by an electronic card that gives feedback to every filling cycle.

The feedback comes in handy in auto-correcting the machine using a properly designed algorithm for next cycle.

It is vital since product properties often vary in pressure and temperature and likely to affect in-flight product, thus the ultimate weight.

The filler measures the empty bottle’s weight, and it records the tare weight to measure whether it is within the expected defined tolerance.

If tare weight exceeds the tolerance, a signal is relayed to a specific particular filling station not to fill the container for that cycle hence rejecting it.

Once the machine accepts the tare weight, nozzle is activated to dispense the product into the container filled with a laminar flow.

Laminar flow guarantees uniformity with little turbulence, and this eliminates foaming due to product characteristics.

Once filled, the containers are measured for final weight after nozzle closes.

The container proceeds to capping station filling carousel, complete the cycle, and permits the next container.

A major significance of net weight filler for cosmetic products is that it provides statistical data of every filling station for each cycle.

The closing or sealing mechanism will depend on the type of container/packaging solution.

For instance, the way you seal a pouch differs from that of a bottle, tin, sachet, or tube.

Here are the common sealing mechanisms that different cosmetic packaging machines use;

Hot Air Sealing For Cosmetic Tubes

It refers to a sealing method that uses heat and pressure on different pieces of cosmetic packaging tubes, often through a rotary press.

Essentially, it is a direct contact method and uses a constantly heated sealing or die bar to apply heat to a particular container contact area.

This sealing technique provides a permanent seam resistant to water and air pressure. As such, it guarantees product’s safety and longer shelf-life.

Most cosmetic product tubes sealed using hot air sealing are often made of thermoplastic materials.

Ultrasonic Sealing Cosmetic Tubes

This sealing technique involves use of acoustic vibrations to produce heat at a molecular level inside the tube film.

Such vibrations actuate molecules of the tube material to start moving before the thermoplastic softens, melts, and form-fit or cohesive joints bond tube.

The tube is held under pressure for a short time and joined molecularly.

It is the molecular friction that allows cosmetic tube to seal without need for direct heat on material.

Impulse Sealing Cosmetic Tubes

This is a common type of heat sealing technique used for joining cosmetic tubes made of thermoplastic material.

It uses impulse heat sealers with round or flat replaceable heating elements made of Nichrome alloy.

The process considers several parameters to ensure it attains the best results, with a complete cycle lasting between 2-6 seconds.

This cosmetic tube sealing method offers straight, tough, waterproof, and perfect seals.

Besides, an impulse heat sealer only uses power when sealing and does not produce odor and smoke.

Cosmetic Bottle Cap Sealing

It is the sealing method used to seal cosmetic containers with caps.

The sealing process in this technique involves using an induction cap sealer.

This machine creates a hermetic seal by passing a capped cosmetic container under it in a non-contact process.

The equipment has a sealing head producing electromagnetic fields, which heat the foil liner inside the cap.

This hot foil then melts the inner seal polymer coating.

Heat and cap pressure enables the inner seal to bond to the container lip leading to a hermetic seal.

Plunger Type Cappers In Cosmetic Packaging

It is a type of cosmetic sealing that includes simple threading, which allows screwing of the closure on the container or bottle to form a seal.

This sealing method is ideal because it makes it easy to access the product when needed and preserves it.

Essentially, the positioning of the drives ensures they prevent foreign materials from spreading into the container while it is opened.

The caps also fit perfectly to the containers since the machine applying them uses constant force.

Snap Capper Cosmetic Packaging

It is a type of cosmetic packaging that features press-on, push-on, or Snap-on caps on different containers and bottles.

This packaging eliminates tedious work of opening and closing the containers or bottles since you only need to press or push the cap.

It is ideal for enhancing safety of the cosmetic product inside the container since it is dustproof.

Labeling In Cosmetic Packaging Machine

After filling and capping different cosmetic products, the next step is applying labels on the containers.

Ordinarily, it is the product label that offers an opportunity to inform your target customers and set your business apart from the imminent competition.

Labeling is imperative in cosmetic packaging because it enhances creativity by allowing application of labels on different parts of the container.

Hence, labeling machines are quintessential in the overall production process of cosmetic packaging.

This machine is available in different variants depending on the technology integrated, size, and shape of the cosmetic container.

The cosmetic container material also determines the ideal type of labeling equipment you will use effectively.

The working principle of typical labeling equipment for cosmetic packaging starts with receiving the container from the sealing and capping unit.

Conveyor sends the container into the labeling unit, and the labels move from the roll forming bar towards the container.

While at it, the in-feed systems maintain a precision of the desired spacing in labeling process.

The peel plates cut the film from the roll-forming bar as the stickers constantly move in straight lines.

Hence, the machine keeps applying the labels appropriately on the cosmetic product container.

After applying the stickers on the container, the product exits the equipment and moves to the next phase of the production process.

Quality Inspection In Cosmetic Packaging Machine

Like any other packaged item, quality control and inspection of cosmetic products are fundamental concerns that can never be overlooked.

There is a special machine designed to inspect the overall quality of the cosmetic packaging before they go to the market.

Several aspects revolve around quality inspection in cosmetic packagings, such as packaging procedures.

Some cosmetic products must be packaged according to industrial procedures for safety among other elements.

Correct packing style is another aspect that is usually looked into during quality inspection when packaging cosmetic product.

Some are packed in bundles and crates, whereas others are packaged in cases.

While at it, dimensional measurements of the packaging style should be consistent for a particular product.

Quality control hence ensures the cosmetic package has correct cautionary symbols, weight indication, shipping marks, package assortment, and right inner and outer numbers.

The contents must also be protected from waterproofing and ensure suitable padding material is used.

Usually, all these main quality inspection aspects are undertaken by different machines.

This machine is, nonetheless, important since it ensures the cosmetic product heading to the market meets all the packaging requirements.

These are machines you will use alongside the main cosmetic packaging machine.

Ideally, they facilitate the packaging process and ensure it is seamless from the start to the end.

They include the following;

Induction Sealing Machine For Cosmetic Packaging

It is used to create hermetic seals by passing a capped cosmetic container under it in a non-contact process.

Essentially, this machine has a hot plate that applies pressure, which pushes plastic film liner onto the container to melt and create a closure.

Neck Banders In Cosmetic Packaging Process

It is a device designed to apply heat-shrinkable foil around the neck of a cosmetic container or bottle.

This equipment takes a role of tube film then folds the counter film tube to its seams to enable it to open the tube film.

Cartoning Machines For Cosmetic Packaging

It refers to a type of equipment designed to create cartons by erecting, closing, folding, side-seaming, and sealing processes.

Essentially, this machine is integral in cosmetic packaging since it ensures the containers are put inside and organized properly in a batch.

Shrink Wrapping Machines In Cosmetic Packaging

It is a machine designed to apply heat to shrink a thermoplastic foil around the product.

This machine covers the container before sending it through an oven or heat tunnel for shrinking.

auxillary cosmetic packaging machine

Some notable benefits that make investing in this equipment worthwhile include the following;

- Increases safety among the machine operators during packaging process.

- Improves packaging throughput

- Enhances product quality and appearance

- Improves the overall shelf-life of the cosmetic product

- Reduces operational costs since it eliminates labor charges.

Typical cosmetic packaging equipment is used for packing a wide range of cosmetic products, such as following;

Fragrances

Most fragrances require creative designs and high product safety.

Hence, this equipment comes in handy to offer a high level of flexibility regarding fragrance container handling and guaranteeing product safety.

Body Care

Most body care products are available in different containers and are usually filled to the right quantity.

This machine is, thus, vital in ensuring packaging of various body care products in a wide range of containers and filling them appropriately.

Decorative Cosmetics

These types of cosmetics are usually available in frequent colors and often encounter product changes.

The essence of this machine in packaging decorative cosmetics is that it facilitates a faster process and guides effective format changes.

Hair Care Products

Often, hair care products are usually packaged in large quantities, and this always needs efficient systems to guarantee consistency and accuracy.

Hence, this equipment is handy in ensuring such products are packaged accurately.

Health And Beauty Products

Sustainable packaging materials are a common concern when packing different types of hair and beauty products.

As such, this machine allows you to attain such packaging solutions at cost-effective rates.

For all your cosmetic packaging machines, contact us now.