Biscuit Packing Machine Manufacturer

JOCHAMP has rich experience in manufacturing packing machines for biscuits. Our biscuit packing machine can be customized according to different specifications, such as high-speed, single row on-edge, multi-row, and horizontal flow wrap.

- Easy-To-Operate

- Stable Performance

- Asian Price, European Quality

- 15 Days Delivery Time

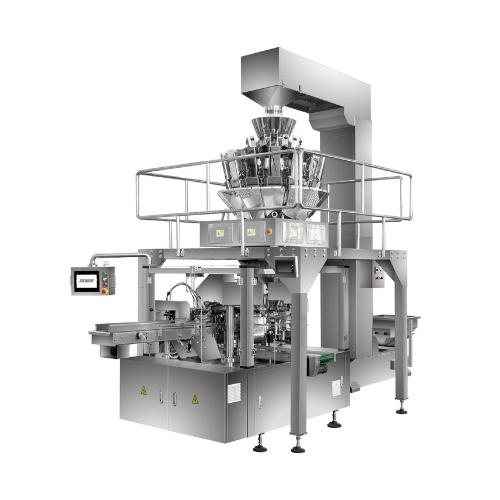

JOCHAMP Biscuit Packing Machine

JOCHAMP biscuit packing machine is equipped with different intelligent selections. They are suitable for all kinds of small-scale and large-scale industries that provide consistent performance levels. Our packing machine for biscuits is automated, efficient, and very durable in terms of its quality.

JOCHAMP is a leading biscuit packing machine manufacturer in China for over 10 years. These machines exceed the biscuit industry requirement for a quick size changeover. Being one of the leading manufacturers in China, we ensure a functionally superior and visually compelling machine for you. All the components of the packing machine for biscuit meets international standards.

Contact us for more information.

Packaging Form of Biscuit (4)

Biscuit Packing Machine Advantage

Our biscuit packing machines can accommodate 10-100 packets every minute. Thus, it can guarantee a streamlined production method.

Our machines are manufactured with a multi-channel feature. This feature ensures consistent production work even if one channel fails.

The machine is integrated with advanced PLC control. This feature allows any person to operate the packing machine easily.

The biscuit packing machine has a photoelectric switch that can track color points. It can also guarantee accurate cutting.

Features of Biscuit Packing Machine

JOCHAMP manufactures packing machines for biscuits with the following features:

- Quick, fool-proof, and easy changeover

- No packet no-wrap feature

- Stack control options

- Quicker biscuit size changeover

- No requirements for size change parts

- No biscuit no pack feature

- 2 in 1 discharge selection: dual chain/belt system

- PLC/7servo system with HMI touchscreen

- Easy to change over from one system to another

Applicable Bag Shape Options

Our biscuit packing machine can pack different bag shapes, such as:

- Pillow bag

- Gusset bag

- Flat bottom stand-up bag

- Qual seal stand-up bag

- Brick shape bag

- Hanging hole bag

- Quick tear notch bag

If you need to customize the biscuit packing machine, please don’t hesitate to contact our team.

Fully Customized Machine and Advantage

JOCHAMP packing machine for biscuits can be customized according to your specific materials. Normally, we use aluminum and metal materials to improve their durability. Our custom biscuit packing machine can be available in custom features, colors, designs, and shapes. They are also available in powerful engines and specific voltage capacities which improves the performance. Our packing machine for biscuits is capable to increase productivity substantially.

JOCHAMP biscuit packing machines reduce major costs related to energy bills and minimize labor costs. They are hassle-free to operate and have a quicker packing speed operated by automated, smart technologies. Our machines have been trusted by leading wholesalers and suppliers at varying prices.

Your Trusted Biscuit Packing Machine in China

JOCHAMP develop and design our broad range of biscuit packing machine that are durable in nature, higher level in quality, and functional with the highest precision. JOCHAMP biscuit packing machines are available in numerous models to fit various packaging solutions. We manufacture custom packing machines for biscuits based on international standards, such as ISO9001, SGS, CE, and cGMP certifications.

JOCHAMP successfully exported a broad range of biscuit packing machines to more than 120 countries. In China, we are a well-known packaging solution provider that supports one-year quality assurance, Asian price, and European quality. Being a leading biscuit packing machine supplier, we aim to provide satisfying services and high-quality machines to our clients worldwide.

JOCHAMP Biscuit Packing Machine

JOCHAMP has been providing cost-effective biscuit packing machine service for over ten years. We can help you no matter what your needs are. We are dedicated to offering satisfactory service, good quality, timely delivery, and competitive price to our clients.

- CE certificates

- ISO9001:2015 Certificates

- Different Design Patents

- Free sample, engineer solution, and one-on-one customer service

- Develop plans based on the needs and materials. We can recommend packaging models and equipment that fit your needs.

- Additional expansion functions such as labeling, cursor positioning, coding, punching, etc.

- Professional R&D team. Non-standard models can be customized based on your needs.

- After-sales engineers and experienced team to provide head-on service.

Why Choose JOCHAMP Packing Machine for Biscuit

The staff from JOCHAMP in every department has an average experience of 10 years in the field of packing solutions. Thus, you can ensure biscuit packing machines with the highest level of quality, durability, and reliable performance.

JOCHAMP has more than 3000 square meters of fabricating area. We are also certified with international certifications to manufacture top-grade biscuit packing machines.

We adopt innovative management systems and technology that allows us to create hundreds of machines per year. We have upgrade maintenance and system remote diagnosis.

Related Product

Biscuit Packing Machine

If you are looking for any information about biscuit packing machine, you will find it right here. This guide explores all fundamental aspects of biscuit packaging machine – from parts, features, benefits, working principle to classification criteria, just to mention a few.

While selecting a Biscuit Packing Machine, one should ensure that all the processing requirements of the biscuit packaging are met.

The market production needs must also be met by ensuring the packaging is attractive and consumers will love it.

Figure 1 biscuit packing machine

The following should be put into consideration when choosing the most appropriate Biscuit Packing Machine:

Applicability And Adaptability

The machine should easily be able to adapt to changes in the market and come with a strong applicability.

Such changes may include social conditions, economic or local natural changes.

The machine must also be able to undertake other deep processing’s that are multi-level like packing other dry foods besides biscuit products.

Real time adjustments in production should also be able to be carried out on it and with stable parameters.

Advanced Technology And Equipment

Technological progress can easily be promoted using high technical content and with advanced equipment.

This can lead to improved quality of biscuit packaging, an improved degree of continuity with very reasonable structures.

It also enables one to counter market competition with advanced equipment and increase the safety and hygiene standards of process.

Low Operational Costs

The factors to consider include the maintenance and operation cost, material consumption per unit product and the machines energy consumption.

The processing capacity and processing level should also be high without compromising the quality of the packaging.

The initial purchasing capital on investment should be low to ensure product costs are low too. Human to machine interaction should be minimal to reduce the cost of labor and regular servicing to extend service life of the machine.

Size And Product Shape

The Biscuit Packing Machine comes in very many shapes, sizes and varieties depending on the manufacturer.

The machine should be able to cater for the packaging needs of your biscuit products shape and size.

The volume of the biscuit product is also very important as the machine needs to package the product in the quantity required. The size of the machine should also be able to comfortably be accommodated in the premise with sufficient space for mobility and ventilation.

Production Speed

Some Biscuit Packing Machines are faster than others when it and the product and production speed required by the machine should be considered.

A slow packaging line will require a slower machine same way a high packaging line will require a machine that matches the packing demands.

Durability Of Equipment

It is important to ensure that the Biscuit Packing Machine required is durable because replacing components will be adding costs and wearing down the machine. A machine that is sturdy structurally with long lasting parts so be considered.

Integrating the two is very possible since the Biscuit Packing Machine contains packages already folded and in shape for packing.

Figure 2 biscuit packing machine

The packages can be fed into the Biscuit Making Machine that will open them, fill them with biscuit products and eventually sealing them.

Figure 3 biscuit making machine

Polypropylene

Polypropylene is widely used as a biscuit packaging machine because of its superior qualities that are exhibited in its various forms.

The use of cellulose films has greatly declined in favor of Polypropylene due to its technical performance and cost effective price.

This type of plastic film normally orient well during their casting and ca can shrink differently based on its two dimensions.

Modern technology has enabled the a developed and efficient control for easy handling by packaging machines in terms of tear strength and sealing shrinkages.

The most common type of Polypropylene used for packaging biscuits is usually the orientated polypropylene (OPP).

It can be used in gauges much thinner than cellulose films with very good strength and with a natural barrier to moisture.

Metallized Films

The Metallized Cellulose Films can be used to achieve very many advantages in regards to Laminates of Aluminum Foils.

High Purity Aluminum is vacuum deposited on the surface of the material with its appearance resembling an Aluminum Foil but with the strength and flexibility of the base film.

Gloss lacquers which is heat resistant can be used to tint the metallized color surface.

The major technical advantage of Metallized Films is the lower oxygen permeability compared to the base film together with light exuding characteristics.

Laminates

Laminates can have enhanced properties by when being created by joining two or more material sheet with varied combination varieties.

An example is the combination that includes metallized films, polyethylene and thick card together with aluminum foil together.

Laminating makes it possible for a printed surface to be sandwiched to protect the printed ink or to expose high very high gloss display.

The disadvantages of single films and its cost should always be considered against the sandwiching and printing process of laminates since it is expensive.

Plastic-Coated Papers

This is a laminated type of composite packing material that has a paperboard that has either been treated on the surface or contains a plastic layer.

It is versatile and can be used to package either biscuits or products in the drink packaging business.

They qualify to be heat sealed with enhanced properties like good tear strength and resistance to both abrasion and water.

Curtain coating can be used to coat them with a melted plastic layer or laminated to a plastic film using adhesives or heat.

Aluminum Foil

This type of packaging material is normally Aluminum in its purest form but rolled to a very low thickness of around 0.006mm.

Provided no pin holes have punctured it, it can provide a total barrier to factors like gas, moisture, unwanted light and any form of grease.

Its outstanding dead fold properties makes it impossible to spring back just after it has been folded and with increased flexibility due to its thin nature.

However, it has to be coated with a thermoplastic such as wax or polyethylene in order for it to be heat sealed effectively.

Carton Materials

Film wrapped biscuits are normally placed inside a carton packaging but is usually for multipack formation, display or for additional mechanical protection.

In as much as it adds to the cost, the packaging looks appealing and can be made of non-greaseproof material since the biscuit wrappers inside are moisture proof.

Waste paper pulp is the cheapest option for the box material but its hygiene hazard which limits its use in cargo containers.

Very strong adhesives can be used to seal the box carton materials without worrying about the odor.

Flexible Films

Flexible Films are usually moisture proof and sealable and come in two major types namely plastic based (Polypropylene) and regenerated cellulose.

The cellulose films are usually coated using a transparent blockade and are transparent in nature.

The polypropylene are normally barriers on their own already without the coating although they can still be coated.

Due to the favorable price in and enhanced technical superiority, the polypropylene is preferred for biscuit wrapping compared to other materials.

High Speed Biscuit Wrapping Machine

This is a wrapping machine that operates at extremely high speeds by wrapping biscuits in piles.

It can be flexibly used to wrap both sandwich biscuits and dry biscuits efficiently with the handling line beginning from the processing system.

It is composed of a dribble board that acts as the beginning of the handling line by leading the biscuits in between guard rails.

Figure 4 high speed biscuit wrapping machine

The guard rails are made in such a way that they can be adjusted to counter the speed of the biscuit product and its flow.

The biscuits are then aligned using a vibratory conveyor as is necessary and then transferred into vertical channels.

An adjustable number of product per pile is then created by a loading system and the piles charged into chains of wrap.

Some of the benefits of this machine include:

- It can be integrated into any existing biscuit production line provided the infeed and conveying system have been appropriately aligned.

- It is fully automated and therefore the margin of error is greatly reduced.

- Requires minimal human machine interactions thus reduces the cost of labor.

- It has very high operational speeds

- It can accommodate a wide range of sizes and shapes of biscuit products

Single Row On-Edge Biscuit Packing Machine

This type of Biscuit Packing Machine is mostly used to package cream sandwich biscuits that are round, square or rectangular in a condition of “standing on edge”.

The biscuits are fed manually into a conveyor belt that is “L” type.

Pusher mechanisms that are specially designed are then used to smoothly transfer the biscuits into the main feed conveyor.

After exiting the main feed conveyor, nylon lugs are simultaneously used to carry the biscuits through a folding box that is adjustable.

Figure 5 single row on edge biscuit packing machine

The biscuits go into the folding box together with the wrapping material used for the center seal and sealed by two hot sealing rollers.

Finally, the rotating hot crimpers are used to perform the sealing on the ends and eventual cutting for packaging.

Its main advantages include:

- It is cost efficient because a smaller seam width is used on the wrapping and sealing process.

- Reduces environmental pollution by reducing the use of boxes

- It avoids wastage of packing material by using a motor stoppage function to evade film scalding when the engine stops

- Packing errors are greatly reduced using photoelectric detection, controlled frequency and two-way dogging

- It can be integrated into any existing biscuit production line provided the infeed and conveying system have been appropriately aligned.

Multi Row Biscuit Packing Machine

The Multi Row Biscuit Packing Machine is made up of a machine frame, a pallet, poking plates and chain wheels with chains.

The poking plates and the poking plate frames are placed on the chains attached to the chain wheel.

This is a Biscuit Packing Machine that first arranges the biscuits into stack of 3 or 4 and then aligns them in rows.

The feeding arrangement of the machine is volumetric hence single plain biscuit stacks can easily be fed into the machine.

After the single stacks are clustered into 3 or 4 stacks, they are carried as rows by the guide rods into the forming box.

Figure 6 multi row biscuit packing machine

The forming box is where the ultimate sealing and cutting processes are carried out on the packed biscuits.

This machine contains an inverter (AC Drive unit) that ensures the motion of the machine is functioning smoothly.

It is also equipped with an air type gusseting set up and through manual feeding can pack cream sandwich biscuits.

Some of the benefits of the Multi Row Biscuit Packing Machine include:

- Servo drives ensure a smooth operation

- The HMI ensures easy monitoring of the machine states and visualization of every function

- The quality of the wrappings is impeccable

- It can use a variety of fold wraps

- It has very high operational speeds

- It can accommodate a wide range of sizes and shapes of biscuit products

- Continuous conveyor belts ensure that products are handled gently and with easy separation

- The machine is robust with a modular build and design

- Installed PLC ensures packaging errors are eliminated and the process is flawless

Pile Pack Biscuit Packaging Machine

This is a type of packaging machine that can be incorporated in any pre-existing packing machine. However, the transmission ratio of the packing machine has to be established prior to facilitate a seamless operation.

The quantity of biscuits and their thickness can then be set as parameters on HMI display by the operator.

The Pile Pack Biscuit Packaging Machine will then automatically the speed of the packing machine and synchronize appropriately.

Figure 7 pile pack biscuit packaging machine

Some of the benefits of Pile Pack Biscuit Packing Machine include:

- The damage on biscuits is reduced as compared to the step down pusher in a biscuit packing machine.

- It conveys biscuit very fast thus it improves the packing and operation speeds.

Horizontal Flow Wrap Machine For Biscuits

This is a Biscuit Packing Machine that is used in packing biscuits that have a large size with regular shapes.

The biscuits are normally packed in either gusseted film wrap bags or into pillow bags.

The major benefits of this machine are:

- It has PID (Proportional Integral Derivative) to temperature that is separate. This enables it to use a wide variety of packing materials.

- It has a clear HMI (Human Machine Interface) display that can self-diagnose any machine failure and display it.

- The PLC enables convenient adjusting of operating functions and easy future upgrades.

- The machine can easily be stopped at selected positions hence avoiding the product sticking to the knife.

This greatly reduces the wastage of packing films.

- The sealing and cutting is very precise based on a digital position of the cut input and color mark tracking using highly sensitive opticals.

Figure 8 horizontal flow wrap biscuit machine

Vertical Form Fill And Seal Machine For Biscuits

The vertical form fill and seal biscuit packing machine contains a Human Machine Interface (HMI) with a control converter that uses dual frequency.

It also contains a mark tracking technology that is executed using very sensitive photoelectric.

Its major advantages include the following:

- It has a very stable and simple transmission system that packages the biscuit in form of pillow bags.

The packing efficiency is greatly improved besides the initial intended purpose of discharging and packing biscuits and eventually sealing them.

- It can easily be adjusted based on the available upgraded technology and different market demands.

The programmable Logic control software that runs it enables the machine to be updated while retaining the operation advantages from before.

- The vertical form fill and seal biscuit packing machine is fully automated and uses a microchip together with a stepper motor.

This makes the machine very reliable and safe for operations with an easy and convenient way of setting the operation parameters.

- It has minimal contact with the packaged biscuits with devoid of any manual human intervention.

The machine is made of stainless steel which can withstand vagaries of weather and any other extreme conditions making it durable.

- The vertical form fill and seal biscuit packing machine can be stopped and positioned automatically.

This greatly improves the machines precision and accuracy with the sealing cutter not sticking to the to the packaging film.

Figure 9 vertical form fill and seal biscuit machine

Double Chute Biscuit Packing Machine

This type of machine is specifically designed for packaging of biscuits with minimum human labor and very high output.

The biscuits are normally arranged in a “standing on the edge” type of formation.

It contains two feeding attachments (Chutes) which are used to accurately load biscuits in stacks into the main feeding conveyor.

When the package undergoes final cutting and scaling process, they are guided by the nylon lug found on the top chains.

Figure 10 double chute biscuit packing machine

This procedure ensures that each package is properly gusseted and has attained the appropriate weight and form.

Some of its advantages include:

- Requires minimal human machine interactions thus reduces the cost of labor.

- It has very high output rate

- It can accommodate a wide range of sizes and shapes of biscuit products

Multi Pack Biscuit Packing Machine

This is a packing machine that mainly packages family pack biscuits which can be grouped into either three or four stacks.

Feeding of the plain biscuits in single stacks is done using a volumetric feeding system that is equipped within the machine.

The single biscuits stacks are then clustered in stacks of three or four with the biscuit rows being conveyed to the forming box using guide rods.

This is where the boxes are finally sealed and cutting operation takes place.

The Multi Pack Biscuit Packing Machine contains an Inverter (AC Drive Unit) that ensures it functions smoothly.

It has an air type gusseting assembly and can use manual feeding to pack cream sandwich biscuits.

Biscuit Tray Packing Machine

This is a type of packing machine that packs biscuits by gently placing them in various trays that are performed.

It is an efficient way of packing and can handle various forms of biscuits like shingled or flat and uprightly pack them on the same machine.

Figure 11 biscuit tray packing machine

The trays to be used for packing can either be multi row or single row with each compartment having one or more items.

Some benefits of this machine include:

- The output is greatly increased compared to other machines.

- It can be easily integrated with other packing machines

- Required minimal human input

Horizontal Flow Wrap Biscuit Packing Machine

This machine is also called a Horizontal Form Fill and Seal Machine and is used in wrapping biscuit products.

It contains two end sealing jaws which are rotary with two other center sealers that are either hot or cold.

It is controlled by PLC with a running speed display and its tension control is improved using a dancing roller.

The bag length can also be adjusted automatically using a device and with a set of reel holder for auto centering.

Some of its advantages are:

- It can be used on a variety of products by adjusting the parameters.

- The packing efficiency is greatly improved besides the initial intended purpose of discharging and packing biscuits and eventually sealing them.

- Its precision and accuracy is improved with the sealing cutter not sticking to the packaging film.

This is because it can automatically be stopped and positioned.

A Biscuit Packing Machine has the following distinct features:

- Their quality is very high with its operations being very convenient and their performance very stable

- Their proportional integral derivative (PID) controller is independent of temperature. This makes it appropriate for use with all types of packaging materials.

- It has photoelectric detection which together with its continuous change and frequency control assist in eradicating errors in packing biscuits.

- Color track marking is done using highly sensitive photoelectric sensors with digital cutting position and input sealing.

This ensures that the sealing and cutting positions are very precise and accurate.

- The whole packing process is run by a Programmable Logic Controller (PLC) that reduces the chances of error and eases troubleshooting.

- Their magazines are elaborately designed to ensure biscuit feeding is easy and done at very high speeds.

- All the contact parts of the machine are made using stainless steel to counter rusting and extreme environmental conditions.

- They contain a Human Machine Interface (HMI) that displays the speed of operation, shift and total output.

It also displays errors and can be used to set the parameters of operation.

Both Biscuit Packing Machine and the Candy Packing are essential processing parts in confectionary packaging process.

Both candy and biscuit products packaged by these two machines are considered as sugar confectionaries.

This means that the biscuit packing machine can be considered as one of the different types of confectionary packer’s same way as the candy packing machine.

Their mode of operation is usually similar with slight variations with the major difference being the type of product being packaged.

Modern advancements in technology have brought about packaging machines having cutting-edge automation making them multifunctional.

Most of the modern Biscuit Packing Machines have upgraded systems like auto-correction in the event of a jammed film.

Such advanced systems in the Biscuit Packing Machine also include its auto-adjustment of packaging dimensions in terms of product shape and weight.

This allows the Biscuit Packing Machine to be able to package Cookies after parameter adjustments have been made to suit the cookie conditions.

This is very convenient for very many manufacturers who carry out multifunctional packaging of products.

Short product runs are made possible depending on market requirements with the changeovers being very precise and fast.

For all your biscuit packing machines, contact us now.