Overwrapping Machine Manufacturer in China

JOCHAMP is a well-established manufacturer with over 15 years of expertise. We make a variety of overwrapping machines, so you should have no trouble choosing one that meets your requirements and helps you meet your business and production objectives. We will be delighted to assist you in selecting the most appropriate option for your requirements.

- Passed CE, ISO9001, SGS certification

- Support printing film packaging

- Optional automatic film joining system, non-stop operation

- 304 stainless steel, PTFE, alumina material product contact surface

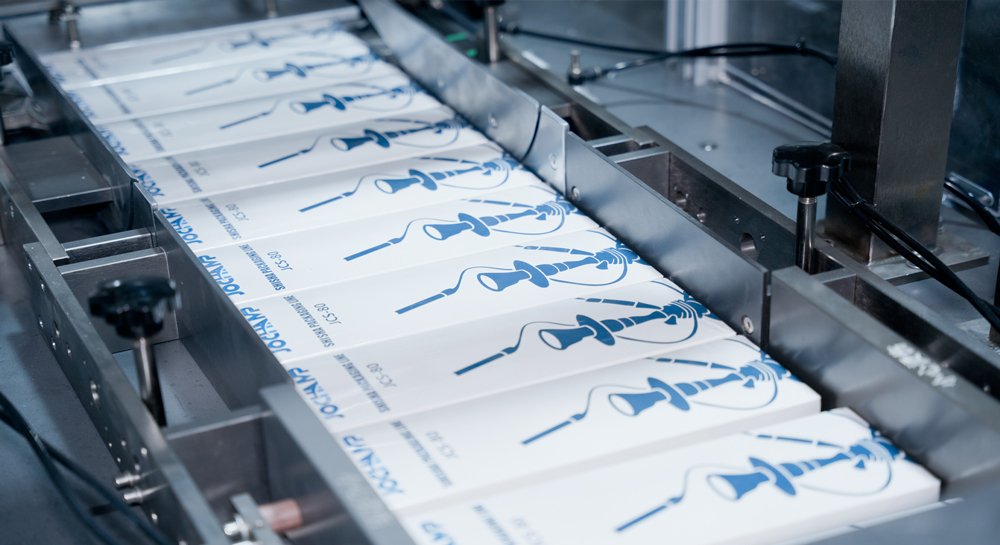

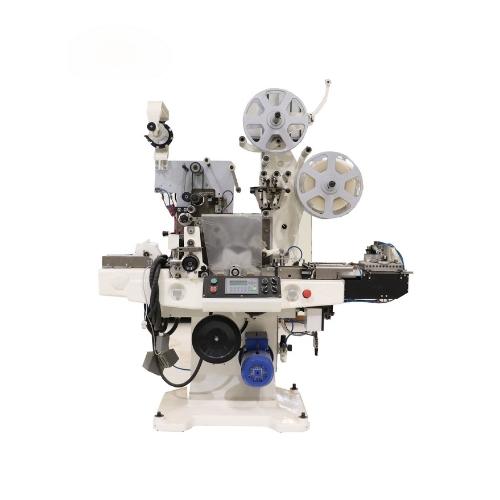

JOCHAMP Overwrapping Machine

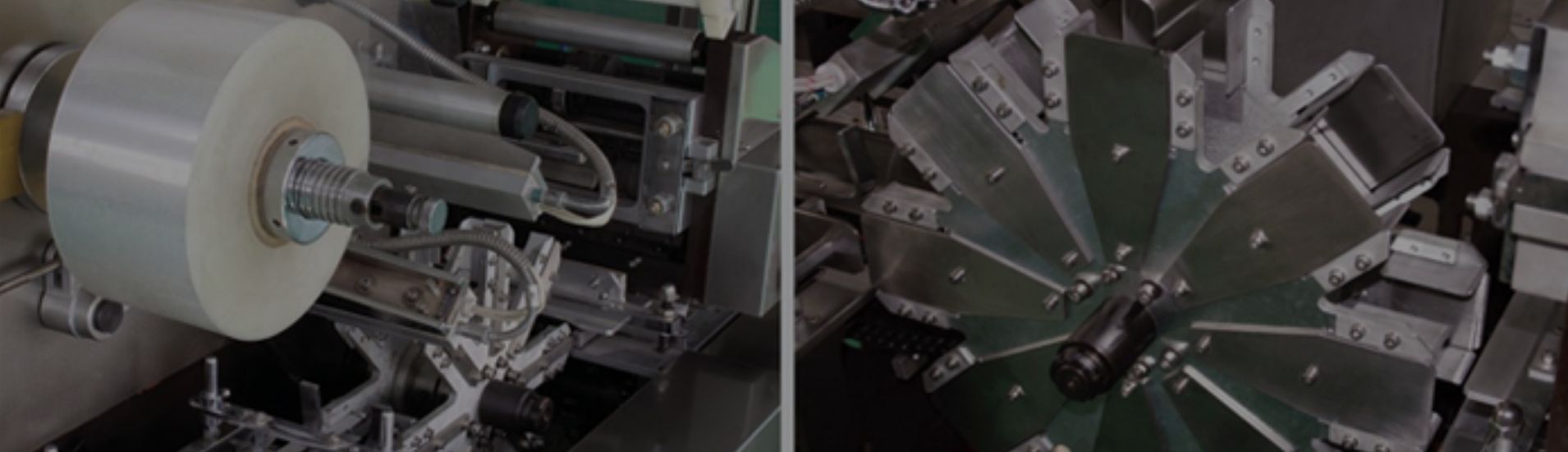

The overwrapping machine is the other form of packaging machine used to overwrap products by using flexible wrapping packaging materials. It has a simple construction, yet is capable of producing persistent and advanced performance. Moreover, the overwrapping machine brings zero-waste performance, safety, and consistency to any packaging. Wrapping is helpful to put all products in good condition.

Utilizing JOCHAMlP overwrapping machine maintains the good condition of all items and certainly protects them from dirt, dust, and other unpleasant substances. It is incomparable to think about the effectiveness of our overwrapping machine regardless of increasing the packaging rate. Its highlighting features and characteristics are widely applied in a wide range of industries. So in your need for a state-of-the-art overwrapping machine, JOCHAMP got your back. We can launch a series of machines—from manual to fully automatic that constantly meet market requirements.

JOCHAMP Overwrapping Machine Features

They can be customized to include thermal wrapping, moisture sealing, and other features that protect the contents of the boxes. Improve the product’s look, and increase customer appeal.

Overwrapping machines process huge volumes of items while maintaining a uniform degree of quality. They’re great for the overwrappping industry, and they’re easy to incorporate into your present workflow.

Overwrapping machines provide accurate and long-lasting performance, as well as well-designed structures. During operation, there is no vibration. Effective overwrapping and safe operation.

The overwrapping machines are powerful, have safety door systems complying with CE standards, and are easy to use. It will be more durable and long-lasting. Purchase yours now at JOCHAMP.

Fast-Moving Overwrapping Machine

The overwrapping machine is a durable and full-powered packaging machine, which provides higher-speed operation. It provides an accelerated speed that accomplishes 40-300 or more product outputs in a minute, perfect for multiple and heavy-duty wrapping applications. The sealing quality of this machine is compact and sturdy enough, capable of protecting all solid and liquid products from theft, damage, wetness, and dust.

In addition, the overwrapping machine is accessible in different model options that suit certain applications. It is 99% safe for all operators and employees and only occupies less space in any working area. Every machine comes in a versatile mechanical structure, specifications, and operation capacity that lasts for years of use.

Different Types of Overwrapping Machine

The overwrapping machine is relatively easy to operate thus making it perfect for wrapping a variety of product sizes. JOCHAMP offers different types of overwrapping machines that ought to be an ultimate choice:

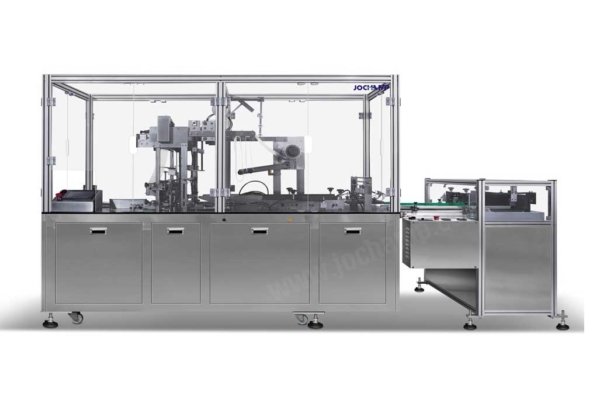

- Fully-Automatic Overwrapping Machine. This machine is good for high-capacity packaging. It considers the best wrapping packaging solution due to its level of automation, intelligence, labor cost-saving precision, and product output value.

- Semi-Automatic Overwrapping Machine. This is a wholesome improvement of the manual overwrapping machine. It is very efficient, practical, and useful to use for moderate wrapping packaging.

- Manual Overwrapping Machine. A type of overwrapping machine that is physically operated by hand. This machine shows robustness and is also the best choice for wrapping a single or less quantity of items.

Overwrapping Machine Technical Specification

The overwrapping machine is a very versatile machine that is built to last. JOCHAMP is well-pleased to introduce the technical specifications of our overwrapping machines:

- Low maintenance

- Fast and simple size alteration

- Servo or mechanical operation

- Organizing and multi packing

- Accessible in cold, heat, hot melt, or glue sealing

- Consist of a collating system that accepts thousands of cartoon or pouches in a single operation

- Extensive range of wrap packaging potentials

- Low capital outlay

- Customized specifications

Considering these unique specifications will give you enlightenment on how our overwrapping machine is distinct from other machines.

Why Choose JOCHAMP for Your Overwrapping Machine

Since its establishment, JOCHAMP considers the leading overwrapping machine expert and a manufacturer of massive and thoroughgoing state-of-the-art machines in the professional packaging world. JOCHAMP has consisted of engineers who continue to explore the clearest vision of excellence and brilliance in innovating overwrapping machines. We offer a complete portfolio of overwrapping machines which is extremely vast for powder products, dense products, granular products, and liquid products.

The unique mechanical and technical concept of our overwrapping makes it extremely demanded in all packaging markets and industries. Using these machines will make all packaging tasks easily and effortlessly accomplished. In need of a one-stop shop to provide your overwrapping solution? Check out JOCHAMP’s most popular overwrapping machines. We are the only existing manufacturer that offers excellent-quality machines that are best for all packaging applications.

JOCHAMP offers an extensive selection of overwrapping machine that holds explicit and outstanding features, such as:

- Superb packaging quality

- Fast change over facility

- Convenient flexibility during production

- Low-cost change parts

- Flexible size ranges

- Compact construction

- Friendly and powerful operation interfaces

- Intelligent malfunction diagnosis software

- Low risks of injuries and accidents

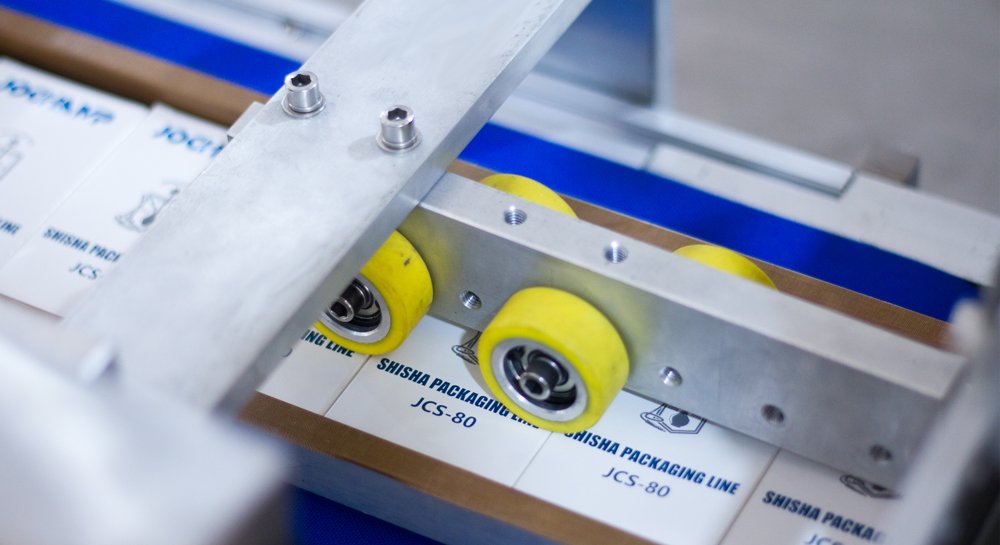

JOCHAMP is the only company in China that adopts the most advanced automation of all packaging machines. Besides, the overwrapping machine consists of sophisticated components, namely:

- PLC screen

- Motor

- Temperature controller

- Magazine

- Heat sealer

- Shrink tunnel

- Infeed conveyor

- Collecting chamber

- Multifunctional digital display

JOCHAMP Professional Overwrapping Machine for Your Different Application

Medicines, pharmaceuticals, and medical items require high-quality packaging and packing protection to assure the producer, merchant, and consumer’s trust. Pharmaceuticals overwrapping uses individual pack wrapping for goods including contact lens kits, pregnancy testing kits, and sutures. All of these items benefit from the use of an easy-open tear strip, which provides the consumer with the assurance of pack protection.

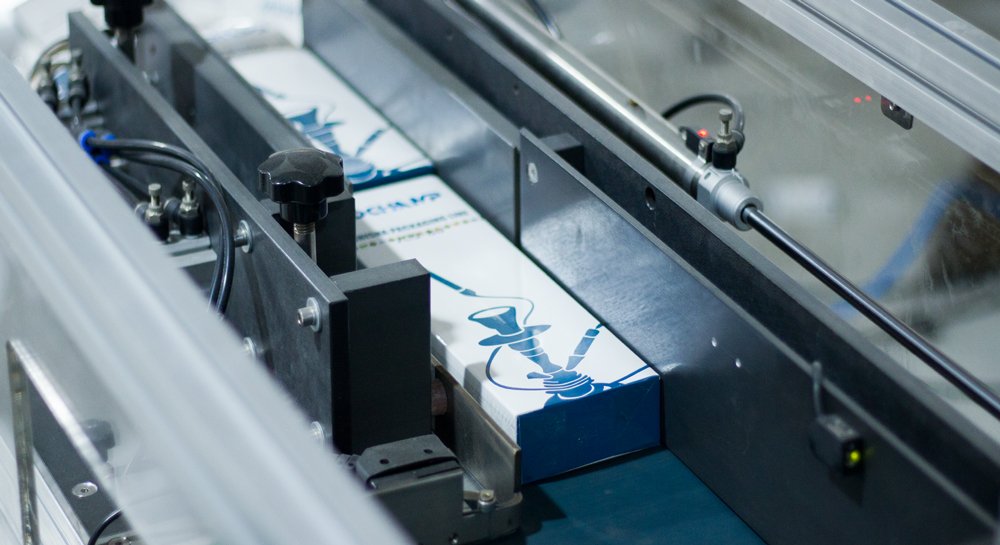

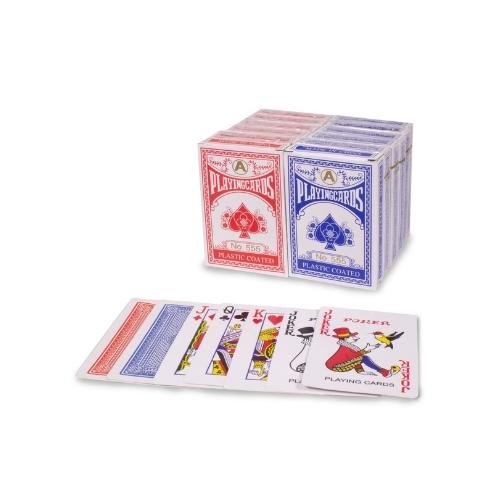

Tissues, napkins, serviettes, envelopes, paper reams, notes, notepads, playing cards, and other soft paper items are wrapped with flexible overwrapping machines manufactured by JOCHAMP. Any paper or card overwrapping application requires the proper automation of product feeding. All JOCHAMP machines can be completely automated and incorporated into the manufacturing process.

Overwrapping is also used in the food packaging industry to extend shelf life and provide multi-packaging ease. In addition, the box will be strengthened, including tamper evidence, and will be free of odor pollution. The ability to wrap a wide variety of products using a single piece of food wrapping equipment.

JOCHAMP is the industry leader in the design and manufacture of a perfume boxes and cosmetic packaging overwrapping machines. We understand the pressures placed on the cosmetics and fragrance industries to promote their products in the best possible light. The quality of the overwrap must match the quality of the goods within, and JOCHAMP can assist with your overwrpping machine requirements.

Related Product

Overwrapping Machine: The Ultimate Guide

If you are looking for high quality overwrapping machine, then read this guide. It will discuss what they are, how they work, the benefits of using one, etc. So, whether you’re just starting in packaging or are looking to upgrade your current system.

Read on for all the info you need to make an informed decision.

An overwrapping machine is a highly specialized piece of equipment.

It applies a layer of film to the product’s outer surface to create crisp, durable edges.

Overwrapping Machine

You can overwrap individual products or batches using the overwrapping machine.

The overwrapping machine offers several advantages. Some of the main advantages are as follows:

Offers Products Protection

Product protection is very important for both the company and its customers.

The process of wrapping a product to create an airtight enclosure helps in three ways:

1) It prevents dust from entering inside.

2). Moisture cannot enter because there’s no way it can get through these barriers

3); Heat won’t harm most products, thus increasing their shelf life.

Time-Saving

Investing in an overwrapping machine is one of the smartest decisions you can make.

It will cut down on tedious labor and save time.

The manual task of palletizing, boxing and other products can also be tedious, consuming plenty of time.

This is good for businesses that don’t have enough employees or cannot afford them!

Reduce Film Expenses

Hand wrapping your product with high-quality film can be expensive.

However, there are overwrapping machines that will save you money in the long run!

One example of this would include automatic stretch-over wrappers.

It utilizes two different speeds to create tension on film material by pulling at certain points.

This increases tensile strength, which reduces overall pricing per unit length utilized.

Improve Productivity

You will save time and money with the automatic overwrapping machine.

Your operators no longer have to wait for each cycle of wrap!

The placement or pulling on a pallet starts an immediate set process which means you don’t need any extra manpower either.

With the overwrapping machine, you can operate your business at full capacity without worrying about anything else.

Consistent Wrapping

Hand-stretching is a time-consuming and laborious process that often leads to the inconsistent wrapping of products.

With an overwrapping system, you can ensure that all your bulk or individual packaging requirements are fulfilled.

They always meet the same strict quality standards with consistent efficiency–a huge win for both retailer and customer!

Better Inventory Management

When you place similar products together, this leads to better inventory management.

The overwrapping machine can reduce inventory counts and time-consuming product separation.

However, if your package is clear or consistent, you can easily scan them through at the very instant!

Multiple things you need to consider when buying your overwrapping machine. Some of the main considerations include:

Overwrapping Capacity

The capacity of an overwrapping machine is the number of products you can overwrap in one minute.

Capacity determines how easy it is to keep up with your production needs.

The capacity varies for different overwrapping machines.

Additionally, the most common production line capacity is 50-60 overwraps per minute.

It’s considered a good one.

Pallet Size

The pallet size for your overwrapping machine depends on the type of materials that you are going to be wrapping.

Different machines can wrap pallets of different sizes.

Point out the package dimensions you want to overwrap in length, width, and height.

Conveyor Size

Conveyor size greatly affects the performance of your overwrapping machine.

The conveyor is responsible for transporting your product to an over the wrapper.

If the conveyor size does not match your product’s dimensions, then it will be all in vain.

On the other hand, if the product size is too large, it will affect the conveyor performance.

The conveyor will also be unable to handle this product.

Pallet Load

Check if the pallet load is within specific standards of your overwrapping machine conveyor.

If the conveyor cannot handle the pallet load, it will affect the conveying speed and productivity.

Machine Size

Machine Size is a crucial factor when making any business decision.

It depends on the number of products you want to wrap and the space available for machine accommodation.

Numerous types exist for the overwrapping machine. Some of the widely used types are as follows:

Carton Overwrapping Machine

Carton Overwrapping Machine is a piece of automated machinery that can overwrap and seal the carton.

You can use it to overwrap various cartons, from small to large.

Carton Overwrapping Machine

The Carton Overwrapping Machine has multiple engineered design benefits such as superior performance, excellent repeatability, and better ROI.

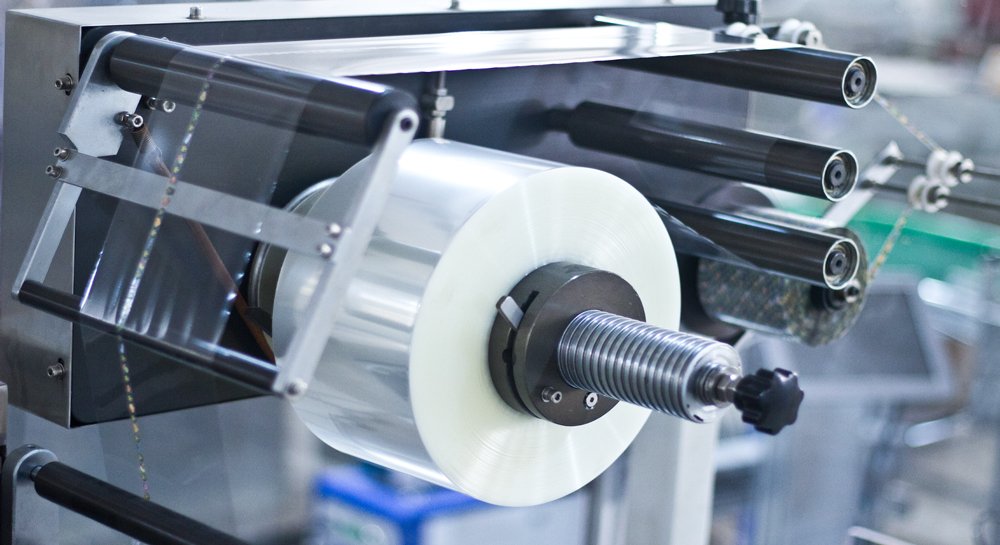

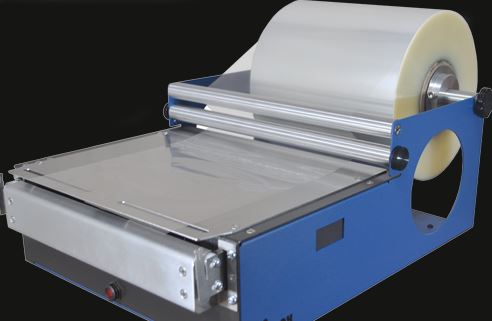

Servo Heat-sealing Film Overwrapping Machine

Servo Heat-sealing Film Overwrapping Machine is used to heat seal the flexible film. The film is stretched during the sealing process and heated to a degree where it is softened and sealed.

Servo Heat Film Over wrapper

Servo film overwrapping machine helps businesses get the most required and reliable wrapping quality in minimum time.

Automatic Overwrapping Machine

Fully Automatic Machines are the best choice for businesses that need to wrap their product with minimal effort and time.

The fully automatic machine has better automation than other wrapping programs, which also saves you money on labor costs!

Automatic Overwrapper Machine

When considering the characteristics of a particular situation and how they apply, it becomes clear that this type has the edge over previous ones.

This is because its economy-oriented design allows for more flexibility when applied at larger scales.

Some benefits of this machine include zero error, zero waste, fully automatic, no labor needed, and cost-effective over others.

Manual Overwrapping Machine

The manual overwrapping machine is a complicated piece of equipment with many parts.

The major parts include stripping, heat sealing, wrapping material loading, and external structure.

Manual Overwrapper Machine

While this is an inferior method of producing a film, which requires some manual labor.

You need a person to drag out wrapping paper, followed by cutting and folding manually.

After folding, the person needs to seal it with the heating mechanism.

This is the perfect machine if you’re looking for an economic choice that can handle small or occasional production runs.

But this is not appropriate for large-scale production.

High Speed Overwrapping Machine

This high-speed overwrapping machine enables you to overwrap your products in record time.

It will outperform any other machine on the market with its speed. This machine is suitable where productivity is a major concern.

High Speed Overwrapping Machine

Semi-automatic Overwrapping Machine.

When it comes to semi-automatic machines, some functions have been automated. These include sealing and folding, but the operator must still drag out wrapping material from the roll.

Later the labor cut off excess material using a blade!

Semi-Automatic Overwrapping Machine

The machine has been designed to provide a helping hand in the crafting process rather than taking over.

In situations where people use semi-automatic over wrappers, they spend more on labor due to its lack of ability for automation and speed.

To produce high-quality output with the semi-automatic overwrapping machine, the operator must master their craft.

This means there will be some errors in what they produce.

There is different wrapping mechanism used in the Cellophane wrapping machine. The popular mechanism is as follows:

Dot Sealed Overwrapping

When it comes to overwrapping, you can’t beat the elegance and beauty that arise from a dot-sealed design.

In this type of sealing, process heat or thermo is used. In just one small area at nib end against wrapping film with them atop one another!

Dot Sealed Overwrapping

Fin-Sealed Overwrapping

In the case of Fin-Sealed Overwrapping, both ends are folded and thermostatically shaped to seal it tightly.

This is a rather stable form that can be trusted in most situations!

Fin-Sealed Overwrapping

The aesthetics are not appealing in comparison to Dot Seal Overwrapping.

Fin-Sealed Overwrapping is better in offering Moisture and airproof functioning.

Overwrapping With Tear Strip Tape

In this type of overwrapping, the strip of tape is placed on a tearable overwrap.

Strip Tape overwrapping

Overwrapping with tear strip tape offers benefits, including ease of opening, good aesthetics, and advertising.

You can use it for cosmetic products, cigarettes, and gift packs.

Heat Shrink Wrapping

In this process, the wrapping material is pulled out to make a covering around the product.

Then heating element then shrink the entire wrapping film to the product. Later on, the film material is sliced over and sealed.

This is the least expensive type of wrapping available.

There are different types of sealing mechanisms used in the Overwrapping machine. Some of the widely used sealing methods are as follows:

Glue Sealing

Glue Sealing is an effective method of protecting your product from water damage. The adhesive layer creates a leak-proof seal around all sides, preventing any liquid or air penetration by chance!

Heat Sealing

Heat-sealing, also known as heat welding or fusion, is the process of making water and airproof seals.

You can rest assured that these seals are non-shrinkable.

The widely used heat seal processes are as follows:

- Hot bar sealing

- Induction sealing

- Hotwire welding

- Impulse welding

- Continuous heat sealing

Friction Sealing

The friction sealing process uses two materials that generate heat when they contact each other.

As this happens, it causes less material to be used and saves energy.

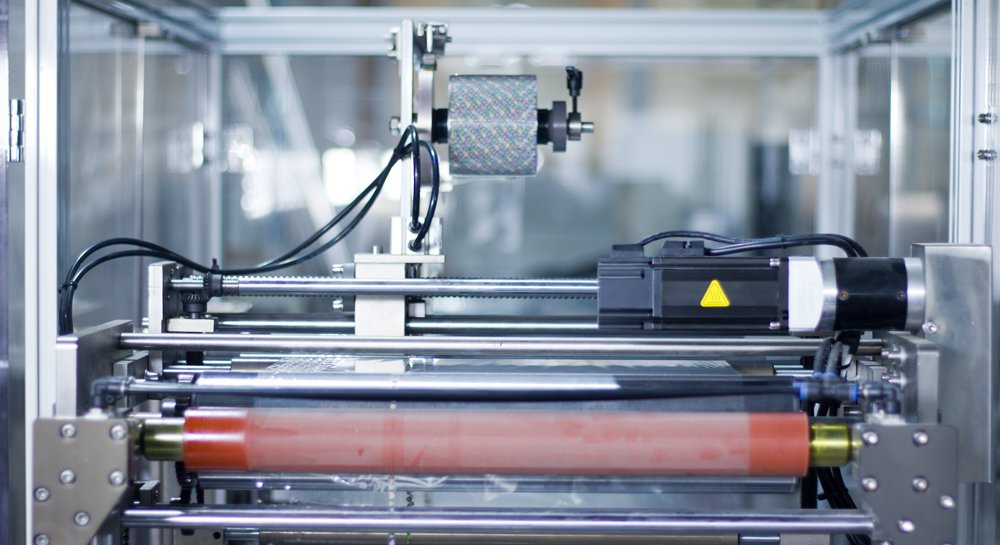

The main parts of an overwrapping machine are as follows:

Motor

The motor is the beating heart of your phaser system.

The function of the motor is to transform electrical energy into mechanical energy that aids in driving your overwrapping machine!

PLC and HMI

The PLC is a high-tech device that controls and monitors manufacturing processes. It’s an interface between the operator and machinery.

On the other hand, you can program with instructions to configure or maintain it accordingly with HMI.

This allows for more precision than ever before!

Temperature Controller

The HMI panel is where you will find all the controls to control the temperature unit. This machine does your work for you when the temperature is just right.

It reaches an appropriate level and then maintains it so that each piece comes out perfectly shaped without human interference!

The working principle of the overwrapping machine is as follows:

Additionally, the packaging process starts with the cutter cutting out all of your required films. The products are conveyed using a conveyor.

Moreover, the cylinder is what pushes the stack as per your requirement. It’s also responsible for wrapping and folding film around your package.

In the end stage, the wrapping material is subjected to sealing.

The sealing device seals the material to protect it from external humidity, dust, and moisture content.

Several applications exist for an overwrapping machine. The major applications are:

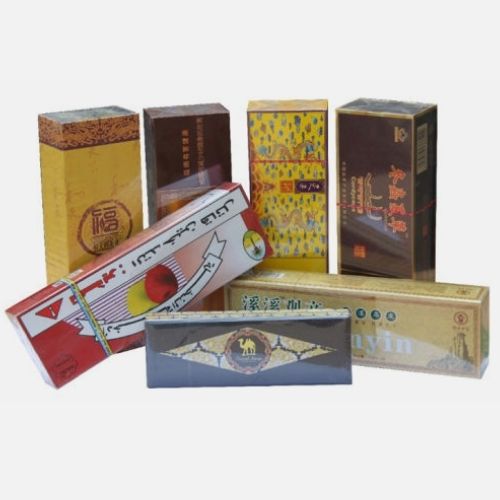

Cigarette Overwrapping Machine

Cigarette Overwrapping Machine is a production line that simultaneously wraps cigarettes in a complete package according to the customer’s specific requirement.

It can wrap 1-3 cartons per second of cigarettes. It employs high wrapping speed and excellent quality of packing as the main features.

Cigarette Overwrapping Machine

Paper Overwrapping Machine

A Paper overwrapping machine is used to wrap and protect the items. It places the paper in all facings of the item.

The result is a tight, durable, and professional-looking cover. It contributes greatly to both your brand image and your marketing efforts.

Paper Overwrapping

Perfume Carton Wrapping Machine

The perfume Carton Wrapping Machine is also called a perfume packaging machine. It is a packaging machine that can wrap the outside of the carton through different wrapping films.

Perfume Bag overwrapping

This process also protects the product from dirt and dust that may be present in the surroundings.

This machine is automatic and has a time-saving feature. You can use it in the pharmaceutical or cosmetics sector.

Soap Carton Overwrapping Machine

Soap Carton Overwrapping Machine is an important machine used to wrap small or large soap cartons.

It provides security from tearing and pinching. It is capable of overwrapping using various wrapping materials.

It allows you to wrap different types of cartons quickly and efficiently.

Soap Bag Overwrapper

There are several maintenance measures for cellophane overwrap machines. Some of the main measures are as follows:

- To keep your machine running smoothly, it’s important to ensure all parts are clean and free from debris.

With a compressed air tool, you can get rid of all the dirt and debris from the seals.

Make sure they stay in good shape for as long as possible.

- If there are still pieces of packaging material left over on the cutting knife, this will affect packaging effectiveness and aesthetics.

If you want to keep your knife in peak condition, use the steel wire brush for film removal!

- The heating element is a crucial part of your overwrapping machine.

It helps maintain the temperature you desire, so if it gets damaged or breaks down, there can be major consequences!

A circuit breaker might burn due to an electric couple breaking down, leading to no heat.

In this case, the only solution is a replacement.

- To keep your machine in top form, you must practice oiling your overwrapping machine.

Friction slows down various components of your overwrapping machine with time.

Oiling minimizes this slow-down process and assists you in keeping up with speed.

Keeping your machine running smoothly is key to profitability.

The more maintenance you do, the greater your chance of increased profits for yourself!

Flow Wrapping is the process where you take one long piece of film from the roll. Then you convert it into a horizontal sheet roll.

The material flow into this horizontal sheet roll. As the material gets in, both open ends get sealed.

This method is known as flow wrapping or Horizontal fill and seal wrapping.

The process of overwrapping begins when a length from the roll is removed and folded around one product or bundle.

The ends then pass through a heating device that seals them closed!

Several limitations exist for the Film Overwrapping machine. Some of the major limitations include:

- You can only use it for products having cuboid or cubic shape

- The overwrapping machine’s expenditure is much more than the shrink-wrapping machine’s.

- The size tolerance of a product’s packaging is often an issue regarding large items.

Multiple differences exist between pouch packaging and overwrapping. Each has its features and benefits.

Some of the major differences are as follows:

Flexible packaging that can be used to package any product with liquid content is known as Pouch packaging.

Pouches come in many different sizes and shapes. Ensuring the consumer has access no matter what they need.

In pouch packaging, one end is sealed while the other is capped.

In the overwrapping process, no button or cap is involved, unlike pouch packaging. The overwrapping process is good for handling semi-solid and solid products. Overwrapping first covers the entire product with wrapping film and then seals it.

Several issues may happen while working with overwrapping machines.

Some of the main issues and their leading causes are as follows:

Machine Not Functioning

It may be due to a lack of power. In this scenario, you need to check the following:

- If there is an issue with the power supply

- Check the power cord and see if any damage exist

- Observe the circuit breaker and see if it is open or close

- Replace the blown fuses if any

Turntable Unable To Stop

- Turntable and Mast have a poor connection

- Examine the limit switch for debris and dirt causing blockage

- In case of zero blockage, replace the limit switch

No Working of Film Carriage

- Ensure that plug is fine and working properly

- See if the transmission system works properly

- Check if the wrapping material carrier is within the working limit

Wrapping Material Breaking Most Often

- Check if you are using the right wrapping material. Some material has enough stretchability

- Cross-check if the machine correctly threads the material

- Minimize the tension level and speed of the turntable for the solution

So, if you are having over-wrapping problems, this troubleshooting can help you.

It will improve your efficiency on a day-to-day basis. So, troubleshooting the Overwrapping machine is necessary.

This way, you can test elements and check whether they are working properly or not.

For all your overwrapping machines, contact us now.