Your Case Sealer Manufacturer in China

JOCHAMP specializes in manufacturing advanced packaging and sealing machines, including case sealers. We made them with sturdy and thick frames, last for a long time, and have maximized noise. Our complete manufacturing equipment ensures smooth sealing effects and stronger corrosion resistance.

- Designed with durable motor

- It comes with adjustable chassis

- High wear-resistant belt

- CE, ISO9001, and SGS certified approved

JOCHAMP Case Sealer

Seals produced by automatic carton sealers are incomparably more excellent quality than those made by hand alone. Putting tape on boxes by hand takes time and material waste. And does not guarantee a secure closure that will remain intact throughout the entirety of the supply chain. The frequently repeated actions that your staff does have the potential to result in strain injuries.

Square boxes are easier to pack, pile, and preserve. If the cases aren’t straight, they can’t be stacked well and are more likely to get crushed, hurting the product during shipping. Cases sealers lock in good shape to protect the time and money you put into making a square case and packing it well.

No doubt utilizing either a fully automatic case sealer or a semi-automatic carton sealer will benefit your business in the long run. It allows you to increase production, save money, cut down on material waste, safeguard staff, and other benefits. Get in touch with us right now to find out more!

Case Sealer Benefits

Having an efficient case sealer machine indeed increases productivity. JOCHAMP designs the mentioned machine that doubles the edges gauges. That decreases broken risks and increases the relative energy required for breaking the tapes.

Packaging processes that save materials reduce environmental footprints and costs. Increased and secured seal strength can consume about 72mm tape wide for typical applications. Using these machines for case sealing can save about 26% of materials.

JOCHAMP manufactures case sealing machines that are easy to install and set up. They have an easy switch plug to start the sealing product processes. These machines come with casters that provide greater mobility and reduce extra operator training.

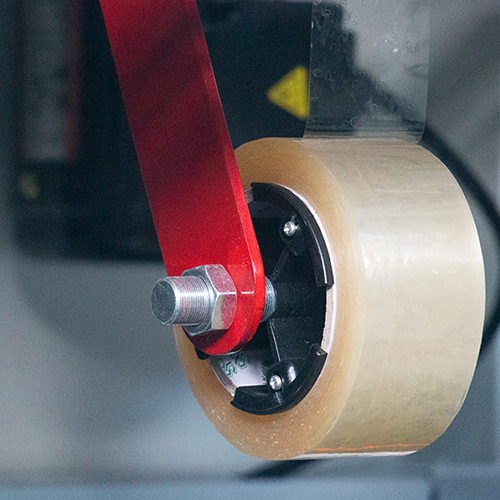

JOCHAMP designs case sealing machines with solid features with only a few wearable parts, including knives, drive belts, springs, and rollers. They are also accessible on our spare component kits with manuals for repair directions.

Case Sealing Machine Types

JOCHAMP manufactures and customizes your requested case sealing machines. Below defines some of the types you may need for your warehouses or production factories.

- Fully Automatic Case Sealer

-Uniform: Constantly moves the boxes of the exact sizes and doesn’t require an operator for folding flaps.

-Random: Starts and runs the boxes in random sizes. Setting up and folding flaps operators are not required.

- Semi-Automatic Case Sealer

-Uniform: It requires a worker to fold box flaps and then place the packed items in the machine. It seals the case both at the bottom and top. It also runs the case with the same sizes continuously.

-Random: This case sealer type is designed with automatic height and weight adjustments. An operator supports the sealing processes. Plus, it also seals the box or case the top and bottom.

Case Sealer Key Features

JOCHAMP case sealing machines’ typical features include the following:

- Major flap control: The high-quality case sealers require a mechanism to control significant flaps. JOCHAMP made them with standardized materials to prevent damage cases.

- Touch screen control: It helps increase work efficiency. This modernized feature delivers satisfaction for automatic system controls. They are placed at the proper fingertips.

- Guard doors: This guard door has full-length with secured switches. It provides the operator’s safety when stopping the machine in full access.

- Seals’ tape head: JOCHAMP designs the case sealer with easy tilt tape heads. It supports superior removal and access processes.

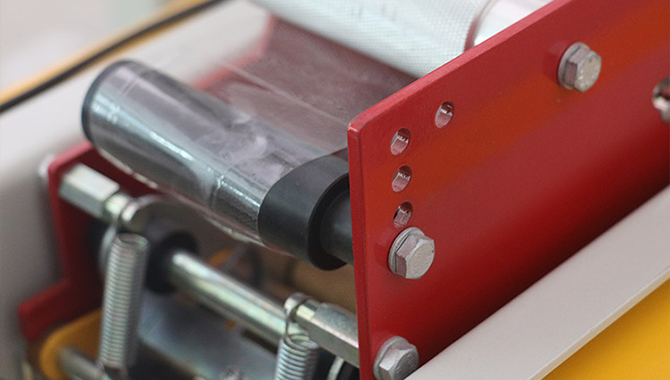

Spring-loaded side belts: This machine feature helps achieve a precise amount of grip. It allows the width variances case range all over the required production run.

Case Sealer Buying Factors

Consider the following factors when purchasing a suitable case sealer for business.

- Case size: Check all case sizes you utilized, from small to large. Make sure you buy a case sealer that suits all your used sizes.

- Case weight: Find a sealing machine that can handle your case weight capacity. You can consider your products’ weight and industry necessities.

- Types of cases: Think about your product cases; they may have different sizes. Random type is advised if you seal different case sizes, while the uniform one is ideal if sizes are all the same.

- Sealing Environment: You can also choose a suitable case sealer, depending on the working environment. The stainless steel case sealer is ideal for working in a high-humidity environment. And enameled steel is perfect for typical sealing surroundings.

- Production Volume: Make sure you have case sealers to seal 150 or more cases per day. You can also check the maximum volume to improve your production.

Why Choose JOCHAMP Case Sealer

Too much work is one of the worst challenges a business can have. Business owners can improve a company’s efficiency and throughput by automating some of their warehouse’s tedious and time-consuming duties. It allows team members to focus on the essential tasks that demand additional attention or participation. Carton sealing is an excellent example of this concept.

A case sealer is a piece of packaging equipment that is not overly complicated in its operation. During the application, it transports a case or box through a conveyor and then through two cartridges. A tape dispenser occupies one of them. The tape is then applied to your item by the cartridges as it travels down the line, doing away with the necessity for any manual tape application.

As an alternative to personally taping each box before shipping it out, you may have your employees do something else. Workers can enlist the assistance of an automatic case sealer, which completes the task in a more timely and accurate manner. The first step in achieving this goal is to select an appropriate case sealer. If you need help, don’t hesitate to contact us.

JOCHAMP - Your Expert Case Sealer Manufacturer in China

The following are some of the reasons that will assist your company in being more effective, operating more securely, reducing expenses, and maximizing profits.

- Improved packaging

- Improve product safety

- Reduce product damage

- Reduce workplace accidents and downtime:

- Reduce workers’ compensation premiums

- Remove inconsistent tape lengths and positions

Daily, businesses are under growing demands to accomplish sustainability objectives and generate better revenue. Decreasing packing materials may have a substantial impact, especially for those that ship in large quantities. In addition to seeking equipment that assists in achieving their sustainability objectives, many businesses also want efficient, dependable, and adaptable equipment.

The JOCHAMP case sealer, with its Total Control System, can provide flawlessly squared and sealed items despite the fragile corrugate and case manufacturing differences.

Custom Case Sealer for Various Industry

The automatic case sealer machines are in-demand in the food and beverage fields industry. They seal the packaging of various food products. These machines transfer the packed goods into the conveyors that reconfigure and deposit the case into a second belt. Using these machines, your business food and beverage products maintain packaging stability and hygiene.

JOCHAMP ensures the built-in modular steel structure with corrosion resistance and lightweight, heavy-duty case sealers for medical products. Different case sealer types are ideal for this industry, including the uniform for the same case packaging sizes and the random one for various pharmaceutical packaging dimensions. Using these advanced machines enhances medicinal productivity.

The machine and hardware industry use case sealers to transfer goods efficiently and achieves secured sealing solutions. Various packaging processes are performed for this industry, including shrink wrapping, skin wrapping, case sealing, stretch wrapping, etc. This heavy-duty machine indeed lessens material costs and operator injuries.

JOCHAMP manufactures flexible versions of case sealing machinery that seal the huge textile boxes. This machine utilizes gummed paper, hot melt glue, or adhesive tapes. We supply well-established and high-quality case sealing machines that represent the long-term business investment. Multiple models are available to suit the cases’ sizes and capacity.

Having a specific model of case sealer machines for raw materials optimizes power consumption. They are in demand for sealing the goods with high efficiency, low investment cost, and easy operation. JOCHAMP assures fast and convenient case sealing processes, which improves productivity.

Related Products

Case Sealer: The Ultimate Guide

At times, choosing an efficient case sealer can be an overwhelming task. A reason this guide explores all vital aspects of case sealing machine such as design, features, working principle and classification, amongst others. So, keep reading to learn more about case sealing machine.

It is a machine that closes the carton lid tops after case packing.

Case sealer machines are typically the best and most dependable for manufacturers who work with carton packing.

case sealer machine

It is suited for systems that produce products in large quantities and is fast and accurate.

Carton sealing or gummed tape is standard adhesives used in this process.

Frequently, corrugated cartons made from flat boxes are shaped, folded, and sealed using case erector machines.

It typically has advantages like simplicity of use, fast speed, labor cost savings, and waste reduction.

While the upper lids of the cartons are typically sealed using case sealer equipment after the cartoning process.

case erector machine

Its key benefits include increased output, decreased labor costs, decreased material waste, and excellent precision.

Semi-automatic Case Sealer

It is high productivity and efficient case sealer machine that uses a human interface to shut the significant and minor top flaps.

semi automatic case sealer

The machine has self-adhesive tape and can seal both top and bottom casings. It has a high speed and is ideal for a high production process.

Fully Automatic Case Sealer

This case sealer machine folds the flaps without using a human interface. Gum and carton seal tape adhesive is appropriate for these designs.

One of the top case sealer machines for manufacturers with high range output, it comes highly recommended.

fully automatic case sealer

Although it is relatively pricey, this machine constantly runs with various case sizes.

Case Sealer With Automatic Flap Closure

With this machine type, the human interface is not needed to close the flap on the boxes.

The machine is often configured to do each task independently once the loading process is done.

Usually, this kind of case sealer machine will seal the top and bottom of the case quickly, increasing productivity.

It is one of the sorts that manufacturers are advised to utilize globally.

Automatic Sealer With Automatic Flap Folding

This kind of case sealer machine eliminates the need for human intervention. Until the very end, the sealing and the flap folding will function independently.

While sealing the cases, it does it with excellent productivity, accuracy, and speed. It is a better solution if you deal with massive volume production.

Random Case Sealer

It is a machine requiring no operator and typically adapts to arbitrary case dimensions.

Before sealing, a random case sealer automatically sequences and modifies the width, height, and length.

random case sealer

Additionally, it is quick, accurate, and perfect for small and high-volume production.

You can also learn more about random case sealing machines.

Uniform Case Sealing Machine

The top flaps are folded, and the top and bottom cases are both tapped, making it a machine that requires no operator and is often compatible with boxes of the same size.

uniform case sealing machine

Uniform case sealing machines are always needed when using an automatic case or when processing must be done more quickly than by hand.

Water Activated Case Sealing Machine

This type of case sealer machine works mainly with bulky, pricey, and delicate cases that must be carefully sealed for security and protection.

This technique of case sealing typically forms a lasting bond with the case, providing a tamper-evident seal.

The machine often offers a high speed, accurate, and dependable sealing that helps manufacturers ease.

Adjustable Case Sealer

These case sealers were created to close-packed cartons of the same size throughout lengthy packing operations.

adjustable case sealer

Before putting a box into the case sealer machine, an operator must first adjust the head tape to fit the height of the box and manually close each box’s flaps.

Bottom And Top Case Sealing Machine

It is a style of sealing case device that generates a consistent seal on the cartons and may seal the top and bottom of cases.

The best machine for cutting tape costs and waste is the bottom and top case sealer machine.

bottom and top case sealing machine

They have a high production capacity and are fully customizable for quick and easy format adjustments.

Pressure Sensitive Case Sealer.

With this type of machine, top flap sealing will be produced with tight butting and no gaps.

Most of its characteristics involve a powerful drive mechanism that guarantees that carton cases leave the pressure-sensitive case-sealing device in a square shape.

Some of the main parts include the following:

Sealing Plug

One of the significant components of the machinery that help the machine seal the cases. Depending on the case that needs to be sealed, they come in various sizes and shapes.

Electrical System

You need an electrical system to supply the unit with power for a case sealer machine to operate. Since it links circuits to generate power, this component is essentially the machine’s heart and keeps it running.

Pneumatic System

This section typically aids the machine pressing while the sealing process is underway and helps the machine move other parts, such as lubricant fluids.

Blade

After sealing is complete, this component of the case sealing machine is mainly used to cut the tapes.

The cases gain from having the same closure cut after the entire operation.

The Springs Handle

The case sealing machine’s spring handle component aids the automatic movement of various components, such as sealing plugs.

Once the sealing plug plunges in a different direction, it typically causes a return movement in that opposite direction.

Lubrication System

It is one of the components that assist in greasing the moving parts of the case sealing machines for more straightforward use.

It lubricates components such as bolts, gears, and rails. It will make it easier to maintain and less likely for the machine to break down.

Conveyor Belt System

In essence, it is a mechanism that helps move cases to and from the case sealing machine. Without such a system, the machine will never be able to function.

PLC Control System

It is a system that often includes a full touch screen that allows you to program, monitor, and control all case sealing machine activities from a single location.

Speed Motors Transmission

Typically, this section will regulate and control the overall speed of the case sealing mechanism.

Below is the process of how the machine works:

- The machine is counter-checked to make sure it is in better working order during the first stage of preparation.

- Attaching the tapes to the case sealing machine is the second step.

- The third step is to check that every component is in its proper location, set various parameters, and start the case sealing machine.

- Place the cartons on the conveyor for the fourth stage with the cases already loaded.

- The carton box sealing machine’s fifth stage will automatically push the cartons inside.

- The machine will automatically tape the cartons’ top and bottom in the sixth stage before pushing them out and preparing them for storage or transportation.

carton box sealing machine

Case Sizes

You need to list all case sizes, from the smallest to the largest, to determine whether the case sealer machine can handle them.

It’s crucial to remember that the capacity varies significantly from design to design.

Case Weight

The weight that the case sealer machines can handle typically has a maximum capacity.

To get the perfect sealer machine for you, always consider the product weight and your industry’s needs while choosing the machine.

Work Environment

It usually makes a difference where you want to use the machine, whether in a typical working atmosphere or with excessive humidity.

Consider stainless steel case sealer machines if they will be utilized in the food production business or an area with high humidity because they are made for these conditions.

However, enameled steel will operate quite acceptable in a typical working setting.

Production Volume

The ideal case sealer machine should typically be able to seal 150 cases or more daily.

Choosing the machine with the biggest production volume is typically advised to meet your future needs as a producer.

Additionally, it will aid in raising your daily production output.

Space

As a manufacturer, you should consider this before building the machine because case sealer machines often come in several sizes.

By choosing the machine depending on your available area, you can avoid buying a larger machine that might not fit.

Output Increase

You will be able to accomplish more in less time because of the machine’s speed.

Sealing more cases per minute than the manual sealing procedure will automatically increase your production output.

Reduces Tape Usage And Eliminates Double Taping

Employing a case sealer machine may quickly stop cases from being tape sealed more than once because the machine typically applies one strip of tape in a reliable seal.

Your tape costs will be reduced, and the sealed case will look perfect.

Increase Product Security

Better security will often accompany more consistency. It is simple to identify whether a case has been tampered with when one piece of tape is used as a case sealer machine.

It will undoubtedly allow for a reduction in theft rates and an increase in security while transporting cases.

Damage Of Product Decreases

There is a greater risk of product damage and potentially personnel harm when sealing cases using glue, staples, or straps.

Additionally, the machine used to apply the staples and glue requires expensive maintenance.

But with a case sealer machine, you can be guaranteed fewer product defects during shipping and lower equipment maintenance costs, which benefits the producer.

It Reduces Downtime And Employee Injuries

Your employees may get wrist, back, and neck problems due to repetitive body motions.

Case sealing equipment facilitates the procedure and relieves workers of this particular task. Downtime, weariness, and strain injuries are reduced.

Most case sealer machines use a tape sealing mechanism, typically the best option because it stays detached throughout shipping or transit.

For security and theft resistance, it generally provides a permanent bond. However, alternative removable tape solutions are still available if you need them.

We often follow a few maintenance procedures, including:

- During the case sealing process, it’s crucial to monitor the mechanical parts to see whether rotation and lifting are regular or if there are any faults on the screws that need to be tightened.

- Regularly examine the case sealer machine wire to ensure the contacts are reliable and look for leaks in the pneumatic system.

- The case sealing machine’s fundamental parts are manually adjusted monthly to check for dependability and performance quality.

- It is a very sensitive, highly sealing, and exact part of the machine by ensuring the sensor is not touched while being used.

- Ensure that the lubricant you use to oil the case sealer machine parts is approved.

- For hygienic reasons, the case sealer machine should be cleaned frequently.

Below is how to troubleshoot the machine:

- When the case sealing machine’s pinching action is prolonged, it usually means the front buckle or inner component of the machine is worn out or the bolts are loose.

At this stage, the bolts need to be tightened, and you should also pay attention to the front buckle shaft’s proper position or replace them.

- If the case sealer machine does not start, connections to some components may be wrong, or there may not be enough electricity.

Verify that the power supply is connected correctly and that all connections are made properly.

- The leaking piston rod indicates that the main body’s bottom is broken and must be replaced immediately.

- Where there is no movement after the loaded cases on the machine become stuck at some point, check the position of the conveyor belt and replace it if necessary.

- If the machine cannot be reset, you should press the emergency stop button to bring it to a complete stop before starting it up again.

You May also like:

For all your case sealer machines, contact us now.