Candy Packing Machine Manufacturer in China

JOCHAMP is a reputable candy packing machine manufacturer. We have significant technical skills and are equipped with cutting-edge equipment. We also have specialists that specialize in product development, design, production, and sales.

- PLC control system and HMI man-machine interface

- Full servo control, more stable and precise operation

- An optional automatic film splicing system

- GMP compliance, CE, and IOS9001 certification

JOCHAMP Candy Packing Machine

Candy packing machines are commonly used in the packaging business to wrap a variety of products such as toffee, hawthorn, bubble gum, candies, and other sweets. To keep their freshness and purity. JOCHAMP provides machines that are carefully produced by our skilled team of experts, utilizing cutting-edge technology and high-quality components. We also provide our clients with this equipment in a variety of configurations at an affordable price.

The JOCHAMP packaging machine can fill and seal candy items completely. Different variants are available to match customers’ needs for various bag kinds, speeds, and packing methods. Candy comes in a wide range of forms and sizes, necessitating the use of multipurpose packaging machinery. Are you seeking for a professional candy packaging machine to complement your existing equipment? Discover all the options for packaging hard or soft candy, wrapped candy, gummies, and more with JOCAHMP equipment.

Various Candy Packing Machine for Your Choices

Different Candy Packaging (6)

JOCHAMP Candy Packing Machine Advantage

Customers’ requirements must be met and exceeded, and chances for business growth must be developed. Pre-sale, in-sale, and after-sale service. 24/7 service hotline available at all times.

JOCHAMP has 15 years in the industry, constant innovation, and updating and improving production technology. Tool-less dismantling of maintenance settings for easy cleaning.

The firm provides long-term free technical consultation services and responds quickly to service requests. Specially customized end sealing system for candy, ensure 100% air tightness.

Customers save time and effort with customized service, which is also effective, high-yielding, and high-quality. Full food-grade product contact surface, to ensure food safety.

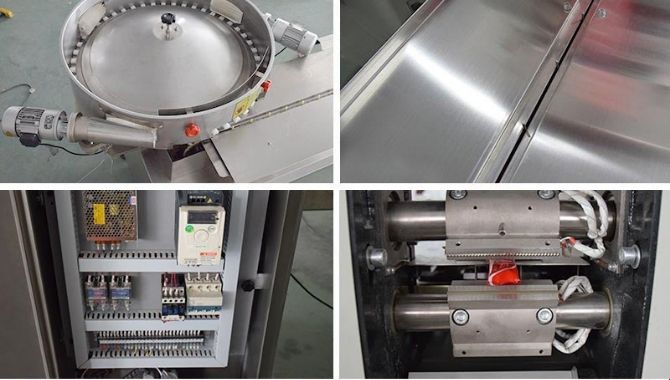

Candy Packing Machine Features

The candy packing machine is easy to use and maintain and saves time and effort. All parts are made of stainless steel, which is clean and hygienic. The completely sealed construction keeps materials out and is simple to clean. Candy Packing is a high-speed machine that can pack single or many pieces of hard candies, sugar jelly sweets, and other confections.

- Outstanding results.

- Maintenance is simplified.

- Strong construction.

- Standards for long-lasting finishes.

- Contains a variety of regular and irregularly shaped items.

Manufacturers with Strong Design and Production Capabilities

- Make your sweets more appealing: Your items will have a more appealing appearance with the use of a candy packing machine. You may personalize the bag’s cover with a lovely pattern to make it stand out on the shelf and grab buyers’ attention.

- Keep your sweets safe from contamination: A candy packing machine will protect your items from hazardous environmental factors by wrapping them. Moisture, sunshine, dust or dirt, and human sweat are all examples of these elements.

- Efficient candy packaging: Using a candy packing machine makes the process more uniform and efficient. You’ll be able to satisfy client requests while also increasing sales and earnings.

- Exceptional output: Candy packing machines allow you to complete more work in less time by packing more sweets than you could manually because they happen automatically.

Processing Equipment to Satisfy Various Client Requirements

Excellent Manufacturing Process: Polish product details, improve product quality, and ensure that every product offered earns customers’ confidence.

Customized Solutions: All good items have been accomplished after hours of processing methods and attentive production by the staff.

Reasonable Price: Remove moisture and overly high costs with an accurate quotation.

Time-Saving: When it comes to packaging items, a candy packing machine will save you a lot of time.

Why Choose JOCHAMP for Your Candy Packing Machine

For more than a decade, JOCHAMP firm has specialized in the manufacture of packing equipment. Therefore, we have a superior level of experience and technical staff. We’ve previously created a range of humanized candy packaging machines, so we’re familiar with this type of equipment, and we know how to optimize and correct it when issues arise.

Our company’s relevant personnel will continually monitor the order and report on the items’ logistical status at any moment. We provide the most thoughtful after-sales service. We are in charge of the goods’ later installation and maintenance. Send your inquiry now, for your next purchase.

When it comes to packaging candies, machines must use the correct equipment to preserve the products while also making them appealing. To protect the product, in particular, use a food-specific packaging material that is resistant, sanitary, tear-proof, and water-proof.

JOCHAMP candy packaging machines allow customers to pick the right film for their needs: polyethylene to polyolefin, macro-perforated to linked film, and biodegradable to printed films are all options. This variation allows you to have the best possible appeal.

All the candy packaging machines are controlled by a PLC to ensure long-term reliability and ease of use.

- Up to 500 pieces per minute.

- Optional automatic film splicing system.

- Independent PID temperature control system, precise temperature control.

- Full servo control, more stable and precise operation.

- Constant packaging material tension control system to ensure packaging consistency.

JOCHAMP Candy Packing Machine Advanced Services

JOCHAMP has a 15-year of experience in the candy packing machine sector and is dedicated to supplying high-quality goods and making relentless efforts for every customer. A candy packaging machine is a sort of commercial packing equipment that is designed specifically for packing candy and is commonly utilized by most candy producers.

The whole system is equipped with HMI man-machine industrial control system as standard, which is easy to operate and powerful. We have a full manufacturing line of machines and equipment capable of producing and packing equipment.

JOCHAMP has developed an independent technology research and development team that can supply consumers with total technological product solutions and fulfill the demands of varied users. The standard candy packing machine is in stock and can be shipped at any time. The fastest delivery time for customized machines is 15 days.

We have a service team made up of multi-functional departments such as sales, R&D, and production that is available 24/7. Customers save time and money by receiving real-time service. All candy packing machines have passed CE, SGS, ISO9001, cGMP certification.

Related Product

Candy Packing Machine: The Ultimate Guide

Candy packaging plays a pivotal role in candy manufacturing process. A reason this guide will help you choose the best candy packing machine – let’s dive right in.

Increased Quality

Investing in an efficient candy packing machine improves on the quality of the work done.

Unlike manual labor, though it is cheap, it is not guaranteed to produce quality and consistent results like the machine.

candy packing machine

An efficient candy packaging machine will be able to perform continuously perform tasks without quality degrade and slowing speeds.

Time Saving

Since there are high, stable and accurate speeds of production, an efficient candy packing machine saves on time.

At the same time, the machine upholds accuracy by ensuring there are minimal errors of operation despite the higher speeds.

Saves On Cost Of Production

Utilizing the machine reduces the labor task force thus reducing the cost of production that would have been used in hiring.

Only few operators are needed when it comes to machine operations thus there is no need of hiring more staff.

Improved Safety

Workers safety is enhanced as machine operators only use functions to operate the fully automated machine.

After instructions are commanded on the control panel, the machine is able to complete the functions as illustrated.

Through this, workers safety is guaranteed as they are not likely prone to work related injuries.

Customer Engagement

Customers find it engaged when they are left to make their own purchase decisions.

This can be achieved by including smart codes on the candy which provides information about the candy.

By doing this, it will lead to customer empowerment making them to stay loyal to your candy brand.

Positioned For Future Growth

Investing in an efficient machine, it will guarantee a long and useful performance.

Efficient candy machines are dependable as they are adapted in the business which will change the needs of the entire business.

The machine will is going to raise the business’s standards by making it grow through faster scales of productions.

Faster production scales means more products are created thus plenty in availability for purchasing.

High Speed Candy Wrapping Machine

It is a machine that wraps candies at higher speeds of around 600 to 800 pieces of candy in a minute.

Advantages High Speed Candy Wrapping Machine

- Higher precision of packaging

- High accuracy levels

- It has a more range of adjustment

Working Of High Speed Candy Wrapping Machine

Preparation stage

Before starting the machine operations, you need to ensure the machine is in its rightful performing status.

Feeding stage

During this phase, the candy material is loaded into the machine.

Other needed raw materials should be available before starting the machine.

high speed candy wrapping machine

Wrapping stage

Wrapping foils and candy are fed by the hopper.

Candies are supplied, wrapped and wrapping film accurately cut.

Wrapped candies are then sealed by glue, heat or friction.

Discharge

Candies are now discharged for storage after they are wrapped and sealed completely.

Features Of High Speed Candy Wrapping Machine

High speeds of product packaging.

Frequency speed regulation that is variable.

Additionally, it has a tracking system is photoelectric.

It has a faster computer programing.

Flow Wrap High Speed Candy Wrapping Machine

It is a flow wrap machine that is automatic which;

Completes the process of forming bangs

- Filling of the candy

- Sealing of the product

- Does discharging of the completely packed product

Working Principle Of Flow Wrap High Speed Candy Wrapping Machine

To start the process, you need to have a roll film that is cylindrical.

The film from the roll is transferred to the forming collars by the machine.

By this time, the conveyer will have lined up the candies which should be wrapped.

flow wrap high speed candy wrapping machine

Through the collar, the film is fed and candy wrapped thereafter into the film, sealed and cut.

The completely wrapped and sealed candy is discharged ready for packing in cartons or bags.

Advantages Of Flow Wrap High Speed Candy Wrapping Machine

Easy adjustments are a changeover that reduces waste of candy and film.

Easy to operate

Features Of Flow Wrap High Speed Candy Wrapping Machine

- Easy to use touchscreen

- Independent temperature control systems

- Automatic rotary fin wheel assembly

- Have rotary seal jaws with logics of jam detecting

- Adjustable bag former

Fold Wrapping Machine For Candy

The machine is designed to fold and wrap different shapes and types of candy that have square bottom, flat, rectangular and much more.

The machine is able to wrap and fold an average of 120 pieces of candy in a single minute.

Working Principle Of Fold Wrapping Machine For Candy

The machine works by putting and folding a cover over the candy.

The conveyer helps in moving the candy.

On a single sheet or paper with specifications like name and logo, the machine presses candy against it.

The optoelectronic print recognition enables accuracy during printing and cutting.

Then, folding and wrapping takes place on the candy.

Advantages Of Fold Wrapping Machine For Candy

- Speeds are adjustable hence flexible speeds of production

- Higher hygiene levels are upheld hence minimal likely contaminations

- There is easy accessibility to parts hence easy maintenance

Features Of Fold Wrapping Machine For Candy

- Transmission parts have fully automated lubrication system

- Wrapping options are flexible

fold wrapping machine for candy

Utilizes specific sealing techniques hence candy is sealed and wrapped easily.

Candy Foil And Band Wrapping Machine

It’s a wrapping equipment that wraps candy in a foil then applying a paper band to make the pack complete.

Most used foil during wrapping is Aluminium foil.

The machine can achieve wrapping around 300 packs in a minute.

candy foil and band wrapping machine

Working Mechanism Of Candy Foil And Band Wrapping Machine

A foil band loop is created around the candy which is intended to get wrapped.

The foil band loop is then tightened using a tightening device which has a rotatable roller.

The rotatable roller has to be parallel to the axis of the roller.

Since the roller is rotational, the foil band is automatically binded on to the roller.

Then, the foil band loop is tightened up.

Advantages Of Candy Foil And Band Wrapping Machine

The foil reduces chances of contamination to the candy.

There is high output by using this machine.

Human labor costs are reduced since the machine is automated and thus performs all functions.

Features Of Candy Foil And Band Wrapping Machine

- Automatic lubrication system

- Heat sealing system is thermostat

Overwrapping Machine For Candy

The equipment is used in wrapping of candy or several groups of candies to make a packaging that is enclosed completely.

Candy is overwrapped by the equipment as it uses a packaging material that is flexible.

Working Principle Of Overwrapping Machine For Candy

The overwrapping machine has various working mechanisms;

The equipment has a mechanism of wrapping, a device of transport that is responsible of receiving, moving and unloading candy.

Furthermore, it has rolls of materials used for wrapping with labels, device for gluing and a device for counting sometimes.

The candy is then either wrapped on a line or a turn table regarding the machine’s type of construction.

overwrapping machine for candy

Advantages Of Overwrapping Machine For Candy

- Shelf life of candy is enhanced

- Low costs on materials

- The wrapping process demands low energy

- Ease of operation

- Low maintenance

Features Of Overwrapping Machine For Candy

- The machine is fully automated in its operations

- Water and moisture proof

- Anti-infectious

- It has centered electric systems of control on PLC programmable controller

Small Scale Candy Wrapping Machine

This is a candy wrapping machine that is used in wrapping of low candy volumes.

Working Principle Of Small Scale Candy Wrapping Machine

At the beginning of the process, you need to ensure you have a roll film that is cylindrical shaped.

The film from the roll is transferred to the forming collars by the machine.

By this time, the conveyer will have lined up the candies which should be wrapped.

Through the collar, the film is fed and candy wrapped thereafter into the film, sealed and cut.

The completely wrapped and sealed candy is discharged ready for packing in cartons or bags.

Advantages Of Small Scale Candy Wrapping Machine

It significantly reduces the cost of packaging hence saving money that can be used for product maintenance and developments.

Protection of candy from moisture and possible damage

Features Of Small Scale Candy Wrapping Machine

- It’s constructed using a stainless steel body

- It has a self-diagnostic feature in case there is a malfunction

- The feeding system is automatic

Single Twist Candy Wrapper Machine

This is equipment that is used in twist packing of different shapes of candy at a single end.

The common shapes that are twist wrapped include cylindrical, rectangular, square and spherical.

Working Principle Of Single Twist Candy Wrapper Machine

The machine works by encompassing the following;

- It contains a hopper using for sorting and an automatic feeding system.

- The orienting plate for candy

- Candy transfer section

- The twist wrapping section

single twist candy wrapper machine

Advantages Of Single Twist Candy Wrapper Machine

Faster rates of production since the machine can produce around 350 pieces of candy in a minute.

- Saves on labor costs since a single operator is able to operate the machine

- It has a simple design that eases cleaning and maintenance

- Due to the automatic sensors, there is reduced material wastage

- It is easier to operate

Features Of Single Twist Candy Wrapper Machine

- It has a simple design

- Fully automated hence few operators can work with several machines

- The machine’s lubrication system is automatic hence no need of manual lubrication

Double Twist Candy Wrapper Machine

The machine automatically feeds candy into the twist wrapper aided by the feed plate at a specified set rate.

The machine then produces candy with double twist wraps.

Working Mechanism Of Double Twist Candy Wrapper Machine

The equipment either consist changeover of reels that are speedy or holders of double paper feed reels.

Its feed belt has sensors which control the feeding and it moves in a continuous motion.

The machine is put into standby mode when the product is low; shows a beacon light and the operator becomes aware.

After commencing the product, the machine starts over again automatically.

Advantages Of Double Twist Candy Wrapper Machine

- It can handle different variations of shape and sizes.

- It is simple when it comes to changeovers from one product to another

- Ease to maintenance and cleaning

- Easier to use

Features Of Double Twist Candy Wrapper Machine

- Length of wrapping film is controlled by the stepper motor and a keypad

- Automatic lubrication system

- Fully automated thus requiring minimal intervention of operator

Automatic Pillow Type Candy Packing Machine

It is a type of packing machine that is used in the packaging of different types of candy shapes.

Working Mechanism Of Automatic Pillow Type Candy Packing Machine

The stepless motor of the machine gears the transmission to rotate through the triangular belt.

Different speeds are adjusted in the gear box through a transmission chain which enables adjustment of the paper film.

The gearbox’s output shaft conveys the roller to rotate driving the paper film into the chain drive.

Here, the length of the out paper is operated manually on the gear chain.

At the same time, it is monitored by photoelectric sensors during the process of packaging.

Advantages Of Automatic Pillow Type Candy Packing Machine

- The machine offers an excellent performance

- It ensures that there are high speeds in packaging

Features Of Automatic Pillow Type Candy Packing Machine

- Equipment is computer programmed control

- It has photoelectric sensors hence there is no packing when there is no candy

- It has a frequency converter which ensures stable operation and speed control

Cut And Twist Wrapping Machines For Candy

It is a machine that is mainly used in the cutting and wrapping of candy at the same time.

Works at high speeds since it completes 500 pieces of candy in a minute.

Working Mechanism Of Cut And Twist Wrapping Machines For Candy

In the feeding section, a rope like candy is fed into the cut and wraps equipment.

There are intermittent sizing rollers which are responsible for feeding and sizing the long candy into the wanted thickness and width.

The intermittent sizing rollers are always two pairs.

Additionally, the machine has sensors which detect the candy rope and also the engagement of paper feed is detected by PLC signals.

The rollers ensure the require paper length is cut using a rotary knife that is detachable.

Also, candy rope is cut to correct length by nipping knives then driven together with cut wrapper in the wrapping section.

Advantages Of Cut And Twist Wrapping Machines For Candy

- Reduced maintenance

- Health and safety guaranteed

Features Of Cut And Twist Wrapping Machines For Candy

- Versatile

- Automatic operations

cut and twist candy wrapper machine

VFFS Candy Packing Machine

This is automated packaging equipment that is used in the packaging of candy.

The equipment is has a continuous flat roll made of plastic film that makes the candy packaging bags.

Working Principle Of VFFS Candy Packing Machine

On the rolls, films are installed for tensing and unwinding it.

The film is the drawn forward aided by a conveyor belt.

The machine is now set on the control panel where bag lengths, language, sealing temperatures and packing speed are determined.

Start the machine.

It runs the whole process since it has been set and it is automatic.

Advantages Of VFFS Candy Packing Machine

- It offers a wide range of packing hence reducing time needed to package products

- Labor costs are cut as minimal labour is required to operate the machinery

- Efficiency is enhanced due to the high packaging speeds

Features Of VFFS Candy Packing Machine

- The machine is fully automated

- It utilizes rollstock film which is not expensive

- It’s made of stainless steel thus health safety

Table Top Candy Packing Machine

The machine is large equipment that is used in the packaging of wide candy quantities within a shorter time.

Working Principle Of Table Top Candy Packing Machine

The machine uses programmable PLC to attain its packaging solutions.

Candy supposed to get packed is weighed and cut to the desired weight by the machine.

On the next step, candy enters the packaging bag.

The packaging bag is sealed under computer control.

The packaging bag is then cut by the cutting device.

Advantages Of Table Top Candy Packing Machine

- The operations are simple making it is easier to use.

- Large candy quantities are packaged in the shortest time

- The machine is flexible since it can be adjusted from time to time.

- It’s reliable and easy to maintain.

Features Of Table Top Candy Packing Machine

- Cutting arrangements are adjustable

- The machine is fully programmable using the programmable logic controller

- Simple control automatic functions

- The machine has a self-checking functionality which enables the operator to realize when there is a malfunction.

Semi-automatic Candy Packaging Machine

It is a packaging machine where bags are loaded manually.

The machine can complete around 250 bags in an hour.

Working Principle Of Semi-automatic Candy Packaging Machine

The bags are set on the outlet and the feeder switch is turned on.

After the required quantity is attained, the bag is manually sent to the closed bag track.

Thereafter, the machine is going to complete the remaining processes of packing

Advantages Of Semi-automatic Candy Packaging Machine

There is safe operation because the entire operation system is equipped with safety measures to ensure the operators are safe.

There is stable operation as the semi-automatic packing systems are consistent compared to the automatic systems.

Besides, the machine is less expensive thus it does not require large amounts of capital to purchase one.

There is good productivity as the machine meets many productivity requirements.

Features Of Semi-automatic Candy Packaging Machine

Filling speeds and volumes can be adjusted at anytime

The machine is of small size, reasonable design and convenient operation

Candy Premade Pouch Filling And Sealing Machine

It is a type of single or multilane automatic machine that has eight working stations to package candy.

Working Principle Of Candy Premade Pouch Filling And Sealing Machine

Pouch loading: Premade pouches are manually loaded into the in feed magazine.

Pouch Gripping: Grippers grab the bag consistently during its movements.

Printing and Embossing: Dates and codes are printed and embossed at this station.

Detection and Bag Opening: The fitted zippers on the bag are detected and opened for the bag to get filled.

Product Filling: Determined quantities are put into the bags.

Dust Collecting and Settling: Unwanted materials are removed at this station.

Sealing and Deflation: Deflator plates are used to squeeze the bag removing remaining air.

Sealing is done using hot bars on the top side of the bag.

Cooling and Discharge: A cooling bar is passed over the heated seal to strengthen and flatten the seam.

Advantages Of Candy Premade Pouch Filling And Sealing Machine

- Speed

- Less costly

Features Of Candy Premade Pouch Filling And Sealing Machine

- Colored touchscreen

- Adopts stainless steel

There are lots of candy packing ideas that can be used in their packing, includes;

Custom Printed Wrappers

To easily getting noticed on the shelf, you ought to use a customized candy wrapper for your product.

The candy wrapper at this point is going to take the candy’s color hence it will be noticed from a far distance.

Also, the color of the wrapper sets a tone whether you need to create fun or have a serious atmosphere.

For instance, a serious atmosphere can be achieved by dark shades while fun can be achieved using brighter colors.

Using Foils In Packaging

Using a gold or silver foil in packaging of candy is a unique and brilliant idea one can use.

The packaging looks great as it does not only feature the appearance but also the foil’s thickness thus creating a luxurious feel.

This idea makes it ideal for gifting purposes on special occasions like birthdays, weddings and other events.

Using Candy Bags

The visual appearance of candy bags can be improved to a way better level.

For instance, the candy bags can be given tags that illustrate their ingredients and their nutritional values.

Also, creativity can come in by arranging your candies in a certain way like wrapping and stacking them in certain manner.

It will be more appealing to your customers making them purchase more thus sales improvement.

Using Cardboard Boxes

As a way of efficient marketing, you can use unique customized cardboard boxes when marketing candy.

The boxes are usually an efficient way of representing your candy creations since they are made of great qualities.

The boxes are more appealing and attractive to the buyers because of their unique look.

Furthermore, during their manufacture, several factors like water proof, durability and strain resistance are put into consideration.

Candy can be packaged into the following materials;

Foil wrappers which can be either gold, silver and much more.

- Candy boxes

- Stretch loops ribbons and ties

- Candy boxes

- Candy containers

- Lollipop sticks

- Candy cups

- Candy pads and trays

Applications of this machine include;

Wrapping of different products

Filling of liquids into their desired measure

Protecting products from storage and transportation as they can be packed when they are needed

The following are ways on how to choose this equipment;

Health And Safety Needs

When choosing a candy packaging machine, you need to focus on the health and safety needs you require as per standards.

Through ensuring that, this will be a boost in your selling since health and safety of the consumers is upheld.

Furthermore, the machine should be one that exposes staff to minimal injuries during its working operations.

The health and safety of employees will also be upheld due to minimal risk exposure.

Shape, Size And Candy Types

It is an important factor to predetermine the exact information about your candy before acquiring the packaging machine.

Therefore, you need to focus on the type of candy, shape and size of candy you are intending to package.

There are different machines but the best option becomes the universal that can package different lengths and harness of candy.

Accuracy And Performance Requirements

Depending on the production rate you need for your business, you need to be in apposition to choose the best machine.

Therefore, the machine you are choosing should be stable and consistent in its operations.

Also, you need to make sure the chosen machine spare parts are readily available in the case of breakage or maintenance.

Additionally, the machine should be simple to use and less expensive during maintenance.

Quality

You need to conduct a proper research for the best machining company before settling on a certain company.

The chosen machine model should be one that embraces modern technology.

Modern technology ensures consistent quality, reasonable consumption of energy and improved production speeds.

Low quality machines will not uphold your packaging quality and consistence due to many issues it will bring by.

Therefore, you also need to pay details to the smallest qualities as they have a huge impact in the machine’s quality.

For all your candy packing machines, we are here to help.