Tea Packing Machine Manufacturer in China

Jochamp offers all kinds of tea packing machines that have high packing speed, compact design, low power consumption, and low noise operation. Our tea packing machines are made from high-quality raw materials that comply with the GMP standards.

- Ultrasonic 3-side cutting and sealing of tea bags

- Precisely engineered stainless steel tea bag packing machine construction

- Reliable and safe operation

- Superior packing performance

Custom Tea Packing Machine from JOCHAMP

A tea packing machine is fully automated to function including tea bag filling, weighing, cutting, and sealing. It is also used for date printing, labeling, and more. These machines are integrated with a volumetric cup filler with high accuracy and precision in rotary style. The tea packing machines are used for packing CTC black tea, herbal tea, loose leaf tea, and more.

JOCHAMP is a professional manufacturer of tea packing machines that are fully certified by international standards such as CE, ISO, SGS, cGMP, and more. We have professional engineers to customize each tea packing machine according to your requirements. Our team will provide lifetime after-sales services, one-year assurance quality, and 24/7 fast response to inquiries.

Send us your inquiries today!

Packing Machine for Tea

Different Tea Packaging (5)

Jochamp Tea Packing Machine Advantages

The tea packing machines are equipped with safety features such as overload protection devices, safety door protection devices, and emergency buttons that improve safety during operation.

Our tea packing machines have a product contact surface that is made from stainless steel. Due to that, they have high corrosion resistance and are easy to clean.

The whole surface of the tea packing machines is safe for contact with tea products since they are manufactured according cGMP standards and other food safety standards.

Due to the advanced technology and our rich experience, we are capable of customizing the tea packing machines in accordance with your requirements.

High Production Rate Tea Packing Machine

JOCHAMP offers tea packing machines that are guaranteed to provide a high production rate.

- Can provide exceptionally shaped tea bags

- Uses an ultrasonic cutting and sealing

- Can pack up to 80 tea bags per minute

- Utilizes a pre-tagged filter material for producing tea bags

- One button adjustment for switching tea bag shapes

- Meets CE certifications

Produces Different Tea Bag Shapes

Our tea packing machines are designed to pack using different tea bag shapes such as the following:

- Triangular-shaped tea bag

- Triangle tea bag with string

- Rectangular tea bag with/without string

- Filter sachet tea bags

- Double chamber filter sachet, and more

You can also request specific tea bag shapes from us!

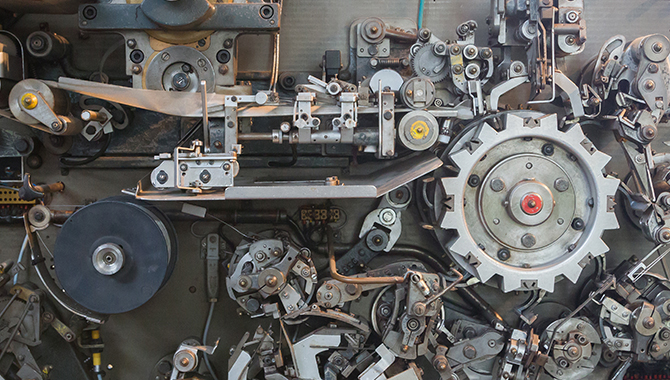

Tea Packing Machine Structure

We provide tea packing machines that are assembled with complete structural components including:

- Wide range of chute sizes

- Weighing systems such as auger filler or load-cell weigher

- Slide Doser vibrator

- Multiple feeding equipment

- Device for chute knocking

- Sub-hopper poking device

- Packaging material roll cover

JOCHAMP – Your Reliable Tea Packing Machine Supplier in China

The tea packing machines are driven by mature and advanced technologies to ensure efficient and fast packaging. These machines are guaranteed to have low maintenance costs, are easy to clean, and are easy to operate. Here in JOCHAMP, we have an in-house manufacturing and production facility for tea packing machine assembly. Our engineers can customize the tea packing machines according to your specific application requirements. Aside from that, JOCHAMP will provide you with excellent services and competitive prices.

Send us your inquiries today!

Our tea packing machines are equipped with optimal features such as the following:

- Durable and strong

- Stainless steel plates construction body and frame

- Easy to clean

- Features volumetric cup to pack small tea particles

- Accurate measurement

- Easy to maintain and use

- Low noise, strong scalability, and good performance

- Safety operation

JOCHAMP tea packing machines can provide numerous benefits for your business.

- PLC touch screen controlled for user-friendly operation

- High weighing accuracy

- The touch screen can automatically display minute capacity

- Adjustable temperature control

- Pneumatic jaw horizontal sealing

- Safe, fast, and easy tube changing

- High performance and can increase your business productivity

- Provides maximum efficiency in all your packaging operation

Why JOCHAMP is a Trusted Tea Packing Machine Supplier

Jochamp has more than 17 years of experience in producing all kinds of tea packing machines. Our extensive experience enables us to be one of the leading suppliers in China. In addition, we have gained more expertise and capability to meet any customer needs.

We have implemented strict quality control in every production process of the tea packing machines. From verification of raw materials to assembly and inspection of the tea packing machines, every process is controlled by our QA specialists.

All of the tea packing machines we are supplying are produced in accordance with the international quality standards. They have ISO 9001, cGMP, CE, and SGS certifications. For that reason, you can rest assured that our tea packing machines have excellent quality, safety, and reliability.

Related Products

Tea Packing Machine: The Ultimate Guide

There are many tea packing machines for unique packaging requirements. This guide will help you choose highly efficient, and reliable tea packaging machine. Whether you want to learn about the classification criteria, design, parts or working principle; all information you are looking for is right here.

These are manual or automated machines you will use to pack tea.

It forms a single-type-use of a tea bag in aid of a filtering paper in a filling machine for industrial or consumable products for storing or shipping.

Some of the packing machines have a mechanism of including tags and strings on the packing bags.

tea packing machine

High Speed Level

It offers a very fast working speed hence saving on time management which results to high efficiency level.

Ease Of Operation

It is designed in a way that the human operation is easily achievable and accessible.

Complex work results to low work rate hence low efficiency level of the machine within a specific time limit.

High Quality Of Product Life

Chips which are imported are of high quality and capable of staying longer days when well managed and handled.

High quality products will also attract buyers and potential clients.

Speed Adjustment Level

Speed adjustment is of high level and done in a very advanced manner.

It creates a faster operational way that easily controls and alters all workings in the machine.

Cleaning System

Machine cleaning is computerized hence fast and less time consuming.

Waste Management

There is an overweight alarming which prevents overflow of the products during the process of filling.

It is also cost effective as waste is less produced and well managed within the working.

Protection System

It contains a stainless steel that feeds in hence no wasting of the materials.

Stainless steel also offers strength and durability of the machine.

Machine Structure

It has a number of shock absorbers hence offering a smooth running system of the process.

Control System

A touch screen controls all the systems during process for instance the speed, packaging length of a bag, and sealing through the heat process and temperature control.

Sensor Detectors

It creates accuracy in high efficiency and cutting.

Sensors also detect any deformities that may occur within the machine to prevent smooth machine running.

Emergency Button

Based on the machine rate or working conditions, an emergency button

Some of the most common types of tea packaging machines include:

Double Chamber Tea Bag Packing Machine

It is an automated with highly advanced technique.

Normally, it is suitable for all loose leaves of tea, red, black, green types of tea, herbs and coffee too.

It forms an inner kind of filtering tea bag and an outer type envelops which encloses the tea bag hence double chamber.

double chamber tea bag packing machine

Some of the main fundamental aspects you should note here include:

- Inner bag has a filtering paper cold-sealed.

- A tea tag and a thread are fixed on the bag for quick handling.

- Outer bag has paper components like plastics together with nylon and also aluminum foil.

- Outer bag is sealed either by cold type sealing or use of heat sealing.

- Hence, packaging is done to the boxes.

You can also learn more about tea bag packing machines.

Pyramid Tea Bag Machine

As the name suggests, it forms a pyramid –kind of a shape of tea packaging.

Filtering bags can be made of nylon, non-woven types of materials or any kind of biodegradable materials.

It is a method that is commonly used in packing coffee, traditional type of tea and herbal type of tea to the filtering sachets.

It can contain a tag and even a string which are fixed automatically from the rolling stock.

Moreover, the packing bag can comprise of a technology that offers easy way o opening including a tearing notch placed on the tea bag.

pyramid tea bag machine

It has weight filler, has a sealer and a conveyor too.

Filtering of bags is done with the help of an ultrasonic sealing or a cold type sealer.

It is suitable for small businesses.

Manual Tea Packing Machine

It is a manual method.

The best part, it offers simple operation.

It can pack between 7-14grams, 30 bags at a single time.

Adjustment of the tea can pad for desired weight based on tea weight is done by addition or removal of the pad.

manual tea packing machine

Board is fixed with screws before use after addition of gasket.

Automatic Tea Packaging Machine

It is the latest design.

Remember, it fills seals by use of heat, threads, and labels and over wraps.

It is applicable in different industries types

automatic tea packaging machine

It uses sealing type pads instead of sealing rollers.

Transducer controls an actuating system.

Also, it is way flexible.

High Speed Tea Bag Packing Machine

Some of the main features of this tea packaging machine include:

- It is automated with a high speed level

- Packs 100 to 110 bags per minute

- Has a single phase

- Can fill, seal and fix tea bags and strings on the packing bags

- Has an outer kind envelope paper with a crimpling

- It lacks a heat outer seal

high speed tea bag packing machine

Tea Sachet Packing Machine

The main features of this machine include:

- Mostly fully automated machines

- They are mainly electrically driven

- On average, they can package 60 pouches per minute.

tea sachet packing machine

It works best with freely flowing substances too.

Green Tea Packing Machine

It is used in green tea packing methods.

Again, it is capable of weighing the green tea, filling it to the packing as it also forms the packing bags.

It seals and can as well print on the packing bags effectively.

green tea packing machine

Packing bags used varies from filtering bags to biodegradable packing.

It uses a human machine interface method in controlling the processes.

Herbal Tea Packing Machine

It appears in two styles:

Rectangular Style

It comprises of filtering paper having a cotton thread and tag

Sealing is done by heating the paper filter.

It can work up to 110 sachets per minute.

herbal tea bag packing machine

Pyramid Style

Some of the main features of this tea packaging machine include:

- Appears in a biodegradable manner

- It is environmentally friendly

- They are mostly automated

- Weighing, filling and also sealing is automatic

- On average, it can pack 45 bags per minute.

Herbal tea packing machine has two major parts: vacuumed elevators and tea filling and sealing machines.

Single Chamber Tea Bag Packing Machine

It has a heating system which seals a packing bag in a single chamber naked type bags.

Additionally, this machine is mainly electrically driven and can package 30-40 sachets per minute.

single chamber tea bag packing machine

In most cases, it has a servo model hence low machine maintenance.

It is flexible since it can pack various products like granules, spices and tea.

Brand Type Visibility

Different types of machines produce products which are of high quality and neat hence making a global brand.

Improved Work Efficiency

Due to the high speed working manner, the machine is capable of working on a lot of packing bags within a given time limit.

Reduced Labor

Since the machine is faster than the human labor force, it is essential to reduce the number of employees.

Improved Technology

Having a highly improved system offers a faster working mechanism which is highly improvised due to the use of modern high performing machines.

Flexible

It is suitable for non-sticky solid particles for instance seed feeds.

It can also pack granules, powder, nuts and even liquids.

Durability

Presence of a stainless steel offers durability of the machine in the long term.

Control System

Presence of a touch screen offers an easy way of controlling all the activities in the process at one point, hence easy to operate and detect any misconduct.

Efficiency

Machine operations are very fast and accurate, hence offering a high efficiency level.

Product Quality

Use of the tea packing machine maintains product quality as there is reduced mishandling since the machine does the entire process.

Reliability

Tea packing machine can pack different products apart from tea leaves and powder like granules and liquids.

Safety

Stainless steel offers a safer working environment due to its durability and strength.

Accuracy

Tea packing machine offers accurate results as all the processes are well managed and controlled.

This is by using a sensor that detects all the defects of the machine in collaboration with the alarm system.

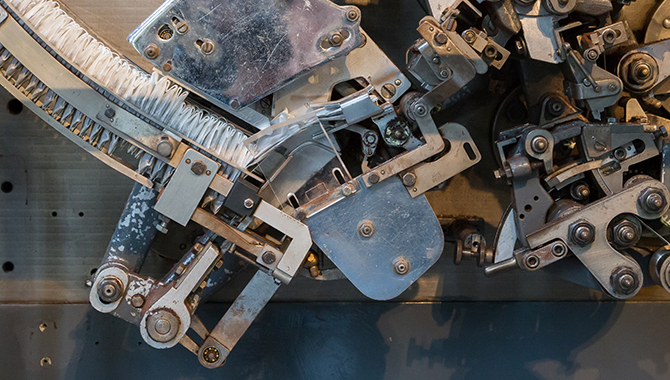

Some of the main components of tea packaging machine are:

Linear Weigher

It fills the sachet with tea leaves or powder.

Filling Hopper

Uses an electric weighing style to determine the level of the tea leaves measured.

Control System

All activities happening in the system are mainly controlled by the touch screen in collaboration with the alarm system.

Sensors

They detect any deformity in the system.

Feeding Point

It contains cups that are used as weighing bags or feeding points to the packing bags which are introduced to machine for filling.

Filling Point

At this point, packing bags are filled and moved to the sealing point by use of conveyor.

Sealing Point

It is a point at which heat is slightly applied in order to offer a seal to the packing bag.

Stainless Steel

It offers protection to the machine and other machine components.

Discharge Point

It is a point at which a machine expels a packing bag after being sealed and ready for shipping.

Conveyor Belt

It is a moving part which helps in moving the packing bags from one point to the next as the process is carried out systematically and effectively.

Pyramid Tea Packing Machine

Tea is filled into pyramid bags by use of filler.

Filling hopper is used to detect the level of tea filled in.

Containers are moved to the filling device by a conveyor system, later to the sachets acting as tea bags.

A paper roller makes triangular tea bag sachets, which are filled and weighed.

Tea bags are cut and sealed in a pyramid shaped paper like sachet by use of an internal type of a bag sealer and cutter.

pyramid tea packing machine

Based on the machine, the shape can as well be rectangular.

Envelops are formed from foil rolling stock, as tea bag links up with the bucket elevator, comprising of external bags.

External bags are cut and sealed accurately by use of optoelectronic kind device.

External cutting of bags devices counts the tea bags to pack in one outer bag before being expelled by use of a conveyor.

Double Chambered Bag Tea Packing Machine

It is a very quick method.

Packing starts at tube formation point.

It uses a dosing type mechanism to the feeding hopper part.

Tea bag is made at the machine core, which has a moving wheel hence making a bag. It winds the folding of the head and the bottom of the tea bag.

It lastly fixes the tag and also the thread to wind up the packing process.

Faulty bags are expelled from the machine while in use.

Filtering Paper Type Tea Bag Packaging Machine

Just as its name suggests, it has a filter paper, made from rolls of filter papers.

Due to the stretching of the filter paper to the device forming part, it id filled automatically.

All these is done accurately as the tea has been weighed accurately.

Knives are used to cut the already sealed paper filtering bag by use of heat.

Counting of packed bags is done hence conveyed away.

Labels and even threads can be used to pack tea bags.

Outer Bag System For The Doubled Chamber Tea Bag Packing System

It packs tea products in an outer type of plastic sachets.

Despite it working like the outer mechanism, it forms bags horizontally, as it fixes bags horizontally too.

A computer is used to control operations like weighing the tea, filling to the bags, sealing of bags and even cutting them accurately.

Counted is done automatically.

Printing can as well be done.

Weight of bag, its length and speed is fed in directly.

The main filling mechanism are:

Powder Filling

It has a hand wheel used to adjust height.

Additionally, it offers an easier way of tracing can type filling.

It is a very quick method.

Packing starts at tube formation point.

It uses a dosing type mechanism to the feeding hopper part.

Tea bag is made at the machine core, which has a moving wheel hence making a bag. It winds the folding of the head and the bottom of the tea bag.

It lastly fixes the tag and also the thread to wind up the packing process.

Faulty bags are expelled from the machine while in use

Powder filling method can also use auger filling method.

Granules Filling

Auger method of tea powder filling

It is well suited for fine kind of tea powder.

Also, it is highly accurate.

A can is used for measuring of the tea powder level and size.

Volumetric Machine Filling Mechanism

Pump Machine Mechanism

It uses different pumps to lift tea from one tank of even a vat to the packing bag.

Pumps which are peristaltic have tubes flexible as well as rollers that isolate rotating pump parts from the tea being packed.

Tubes can be replaced after every activity for accurate sanitary level maintenance.

Gravity Method

It uses gravity to feed the system with the product for packing.

Piston Method

It uses valves to fill the powder into the packing bags.

Sealing is done in different ways or different methods;

Thermal-bond Method or Use of Heating Method

It uses pressure and heat for its performance.

Filming surfaces are always stuck together due to the heat flow through the given material from bars as sealing is done.

It is the mainly used method due to its reliability in mass productivity.

It is fast, quite efficient and also less costly.

Filtering papers, aluminum type foils films and laminating film are suitable materials to be used in the method.

Ultrasonic Method of Sealing

This method joins two rolling films together.

It is generated through different components.

Higher level frequency of the energy vibrations moves to the interface in between the two films making a frictional generation inside the film causing films to melt.

You should note the following about this sealing technique:

- It does not cause curling of the packing bags

- Fast and also efficient

- The technique is suitable for nylon type pyramid packing of tea bags effectively

- It is suitable for non-woven kinds of fabric materials, nylons and also PLA materials

- Process is accurate

- Offers smoothness and tightness in packing bags

- Applicable to sensitive temperature kinds of products

- It has also a very advanced seal success rate.

Staple Stitching Method

Sealing is done in a form of cold seals.

Cold sealing method retains freshness of the tea bag contents

It is achieved by putting a tea bag in a selected point after which the machine is run onto the tea bag.

A label is put on the filtering paper.

Thread is then past though to the placed label and the around the tea bag opening.

An automated machine will then link the hard type label and the thread with the staple.

It offers products that are more durable due to lack of possibility of bag tearing.

Moreover, it is a very fast method and cost effective.

Rusting of the staples over time way affect product quality.

Vacuum Method

It is well suitable for sealing tins after the product is put into the tin.

Using high level pressure, air is compressed out of the tin to create an air vacuum tank.

It completely prevents microbial activities from the bacterial activities.

Use Of A Taping Method

It is commonly used in sealing boxes.

After folding the box flaps properly, a tape dispenser is used to distribute the tape along the box edges and bottom parts of the box.

After packing products are put in the box, the box top is sealed by enclosing the top using a tape sealing.

Foil Type Stand up Pouches

Well suited for loose tea leaves.

Its lower gusset offers a vertical standing nature.

It is very common in tea packing process.

Found in many colors.

Sealing is done using an aluminum foil together with a zip type lock for loose tea.

Foil Type Gusseted Bags

Are in many color types

They are very common in storing of tea.

They are of various types like center type seal gusseted bag, side type seal gusseted bag and quad type seal bag.

For a good base, side types have holes at the corners.

Paper Type Pouches

They are in different colors.

Due to their square bottom, they are capable of standing well to the shelves.

Products in these packing bags have a shorter life span since they lack an airtight type seal.

Barrier Type Bags

They are of different layering hence having a well protection system of delicate tea leaves against ultraviolet rays.

It is a method that is preventive against harmful elements.

For all your tea packing machine, contact us now.