Blister Card Packaging Machine Provider

Jochamp is an expert blister sealing machine manufacturer in China. Blister card packaging machine is one of our top-of-the-line products. Ideal for small consumer goods, auto parts, hardware, foods, and pharmaceuticals.

- Greater processing capacity

- Stainless steel 304 surface material

- Automatic stop and alarm when no card

- Custom-design model as per demand

Jochamp Blister Card Sealing Machine

Blister card sealing machine is a technology utilized to package small products. It creates a mold around the product. That protects it during transportation and safely stores it. Jochamp blister card machine is a very flexible packing machine. It has a greater processing capacity. Commonly used in batteries, syringes, scissors, razors, and other product packaging.

Our complete line of blister card packing machines comes in a full range of sizes. It is available in various stations with standard and unique features. Additionally, customize options are welcome to meet your market needs. JCB-350 and JCB-600 are among the two-model range. Jochamp has the right blister card sealing machine to handle your production requirements.

Types of Blister Card Packing Machines

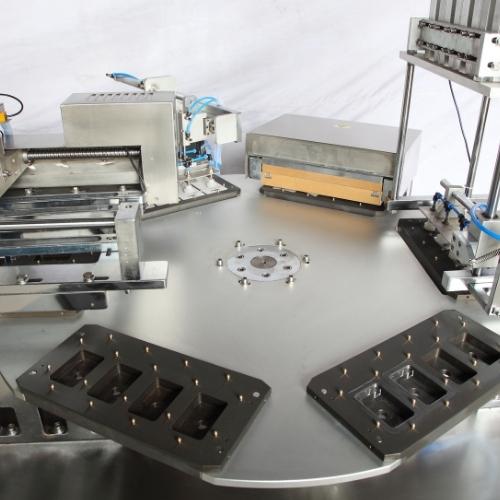

The JCB-350 Rotary Blister Card Packing Machine offers a space-saving operation mode, effectively minimizing the equipment’s footprint, making it ideal for facilities with limited space. Its ingeniously designed mechanical structure simplifies operation, reducing the learning curve for operators and enhancing overall productivity. This user-friendly machine allows for seamless blister card packaging, ensuring products are securely displayed and protected. With its compact design and straightforward controls, the JCB-350 ensures a smooth packaging process, allowing businesses to meet production demands efficiently. Whether for small or large-scale operations, this versatile machine proves to be a valuable asset, delivering high-quality blister card packaging with ease and precision.

The JCB-600 Blister Card Packing Machine operates in a straight-line manner, enabling additional stations for increased equipment speed and versatile functional expansion. This mechanical structure optimizes the packaging process, accommodating various products and enhancing production efficiency. With more stations, it can perform multiple tasks simultaneously, such as forming blisters, filling products, sealing cards, and ejecting finished packages. This versatility enables seamless integration with different packaging requirements, making it an ideal choice for businesses seeking improved productivity and flexibility in blister card packaging. The JCB-600 offers a robust and scalable solution, empowering manufacturers to meet growing demands and adapt to evolving market needs effectively.

Blister Card Packaging Machine Advantages

Jochamp blister card sealing equipment permits quick and simple product changeover. It accommodates small batches to large production and frequent format changeover.

Blister packing machine setup is easy with a human-machine interface (HMI). Minimal training is required. Extremely user-friendly and intuitive. Reduced extra labor costs effectively.

Our blister card machine is suitable for small-scale to large-scale production batches. It produces up to 300 blisters per minute and around 150 cartons every 60 seconds. Precise and efficient.

Jochamp can customize any blister card packing machine design. Regardless of its shape, size, features, and number of items like tablets; it can be custom to fit your production needs.

Jochamp Blister Card Machine to Maximize Revenue

The Jochamp automated blister card sealing machine permits smooth and active workflow. It improves and grows production operations. This leads to a rapid return on investment. Following are the unit’s high-performance features:

- Omron PLC and touch screen control system

- Omron stepless frequency converter

- Three sets of Mitsubishi servo motors

- Rotary circulation sealing structure

- Automatic Stop and Alarm when no cards are detected

- Stainless steel 304 surface material

- Special oxidation on the surface of a mold

Blister Card Packing Machine Optional Features

Aside from standard features, Jochamp also provides additional feature options as per customers’ demands. We offer innovative design conceptions to fulfill ever-changing customers’ needs. Below are some optional details that can be added.

- Dispensing machine for tablets and capsules

- Liquid filling machine

- Robotic automatic feeder

- Nitrogen flush

- Sealing texture

- Punching mechanism

- Date printing

Custom Machine Technical Specifications

Jochamp is producing custom-made solutions for blister card packaging machines. For years, we’ve been working with companies, laboratories, pharmaceutical factories, and more. We produce a variety of specialized packaging systems for the various market. Blister card sealing machine main parameters that can be specified are:

Size of a card, Forming area, Forming depth, Packing capacity, Air pressure, Air consumption, Forming material, Machine shell material, Power voltage, Power consumption, Overall dimensions, etc.

Jochamp: Your Trusted Blister Card Packaging Machine Supplier

Jochamp focused on blister sealing machine production for 15+ years. Our 3000 m2 workshop guarantees smooth manufacturing operations. By integrating innovative technology and an expert team, you can assure the best packing machine solution. We can provide all support you need for your production needs.

We test each machine to meet CE, SGS, ISO9001, and cGMP standards. We also provide free sample tests. Our specialists supervise every step of production. From raw material selection, machine assembly, and testing. At Jochamp, you can rely on meticulous quality control of your unit. On top of that, we provide a 12-months warranty plus lifetime after-sale service. Worry no more. Jochamp got your back with 24/7 fast responsive service. Need a custom solution? Contact us right away!

Jochamp blister card sealing machine shares technology and techniques to enhance production output. Utilizing a blister packaging machine for your production offers various advantages.

- Flexible pack design

- Increased visibility and accessibility

- Best model to save packaging materials

- Fast set-up and the minimal training required

- Improves product shelf life and protection

- Durable and clean oxidation on the surface mold

- Custom design mold according to requirements

- Sealed molds for easy changeover from one product to another

Jochamp packing equipment is an extraordinary solution for common applications. Each blister card packaging machine can package any blister application for a wide range of industries.

- Nutraceutical

- Pharmaceutical

- Consumer Industries

- Medical Device

- Animal Health

- Confectioneries

- Electronic

- Automotive

Why Choose Jochamp to OEM Blister Card Packaging Machine

Jochamp owns state-of-the-art equipment and production technology. Our lines of automated units make unique blister card machines. We utilize high-grade materials to assemble machinery. Quality production guaranteed.

An experienced team controlled every step of your machinery production. We have more than 20 personnel in the after-sale department and 10+ in the technical sales department. Also, we have more than 15 mechanical engineers.

All blister card sealing machines are meticulously tested to different industry standards. Our QC team makes sure it met cGMP, CE, SGS, and ISO9001-certifications. Aside from, we provide one-year quality assurance after the unit has been shipped out.

Jochamp blister card packing machine is more cost-effective compared to other suppliers. Without compromising quality, we guarantee to provide economical packing units. European quality, but Asian price.

Jochamp provides life-time after-sale service for your blister card sealing machine. Our team performs regular after-sales care and training support. Through giving guidance on maintenance.

Related Product

Blister Card Packaging Machine: The Ultimate Guide

Blister card packaging machine plays an integral role in modern packaging. You will use these blister packaging machines across many industries. In this guide, you will find all information about blister card packaging machine.

Blister card packaging machine is an equipment that creates, fill and seal blister cards containing various products.

A blister card packaging machine creates a reliable protection from external contaminants for products that are light-sensitive, fragile or water-absorbent.

blister card packaging machine

Blister card packaging is made up of two parts;

The pocket normally takes the shape or the design of the product, for instance, how toys are packed in plastic covering with the same shape.

Other times, the pocket can be circular, rectangular or square depending on the kind of product being packaged in it.

Backing

The backing can be referred to as the support system of the whole packaging.

Backing offers stability from the back of the pocket and the material used is usually a paperboard.

However, any other material can be used to make this part depending on the needs of a company.

Coating

Coating material should be one that is compatible with both the backing and the pocket.

Content

Blister card packaging has its content placed in the pocket part, which is clear and is visible even before opening it.

Content refers to the product that has been packaged, for instance, a pair of batteries or a makeup kit.

Paint Layer

Painting is done to reflect the color that represents a company or the application of the content of blister card packaging.

The painted section becomes part of the backing component to give the whole package a beautiful and attractive appearance.

PVC Roll

PVC roll is the material required for making the blister card pockets.

The roll is moved into the system through a PVC feeding roller to get it ready for blister packaging process.

Pre-Heating System

Preheating system consists of a heating box whereby the received materials are heated to a temperature suitable for forming.

Heating box is made up of a turning cycle, forming die holder, adjusting bolt and heating plate to aid in heating.

Blister/Cavity Forming Station

Blister forming section is made up of a tooling system with different configurations and designs to perform functions like;

-Thermoforming or cold forming of blister card packaging.

-Intermittent or continuous creation of blister card packaging

-This tooling system helps in giving shape to the blister card packages.

Size requirements of a given blister card package can be adjusted at this section through the touch screen interface.

Traction System

Traction system consists of an electric motor which aids the movement of the mobile parts like rollers, rails etc.

Motion is achieved through components like shafts, belts and gears.

Speed of the machine is also controlled through the traction system.

Rollers And Guide Rails

During the blister card packaging process, a traction system or a guide rail is employed to guide the material from a given station to the next.

Traction system is made up of various parts including turning roller, guide rail and others.

Waste Material Collection Area

After the blister card packaging has been completed and cut, the waste material collection section collects the waste materials from the system.

Blister Cutting Station

A fully processed blister card package is cut from the original material at the cutting station using a specified cutting mechanism.

Every package has its own set of cavities and this number determines the size of the cutting mechanism used.

Picking up section

Picking up station is responsible for filling the already formed blister pockets with products.

The machine can detect whether a given cavity has been filled or not.

Paper Board Station

Paperboard placing section is responsible for loading the paperboards that are used as the backing part of the blister card packaging.

Heat Sealing Station

Once the blister cavities are ready and are filled with the content, the heat-sealing mechanism is enabled to seal the pockets.

Various components including bearing seat and cam case aid in heat sealing process.

Output Area

Output area is also referred to as the product chute

This is the part that aids in moving the blister card packaging out of the machine once it is ready for shipment.

PLC And A Touch Screen

A PLC with a touch screen interface allows the operators to control, feed in parameters and monitor the whole packaging process.

Another function is that it allows the operator to troubleshoot machine problems arising from components.

Lubrication System

In an automatic blister card packing machine, the moving parts are lubricated automatically using grease and oils.

Lubrication is achieved through an inbuilt lubrication system which reduces friction on the moving parts.

Tow Mechanism

The mechanism responsible for moving the already sealed blister card packages to the sealing station.

Switching on the Blister Card Packaging Machine

Once the machine has been switched on, every part is put in motion.

The unwinding system gets ready with packaging materials and the control panel is ready for feeding in the desired parameters.

Material Heating

Once the machine is on, the heating station starts heating up in readiness for material arrival.

Heating box is only available in thermoforming blister card packaging machines and not cold forming machines.

Material within the heating box is heated to a temperature suitable for forming.

In order to achieve a consistent heating process, this machine uses both lower and upper heating plates.

Forming Pockets On The PVC Film

At the pocket forming station, die plates or compressed air can be used to form the pockets as desired.

This is followed by a cooling process to get the pockets ready for filling with products.

Filling Of The Pockets

At this stage, the pockets are ready for filling and the machine automatically fills the blister pockets with products.

Empty cavities can also be identified by the machine.

Sealing The Blister Card Packages

Blister card packaging machines uses paperboards to form a sealing and a back for the already filled pockets.

Pockets with no products in them cannot be sealed, this being part of the machine design.

The temperatures are raised a bit to aid in sealing while pressure is exerted to ensure a tight seal.

Printing Of Information On The Package

Once the packages are filled and sealed, the machine will print the required information on the backing section of the package.

Information such as expiry date, manufacturing date and batch number is necessary.

Trimming The Blister Card Packages

Waste material is removed at this stage to give the blister card package the desired shape.

Thereafter, the package is removed from the machine through the product chute.

Yes, it is possible to integrate a blister card packaging machine with a cartoning machine in the same production line.

Once the blister cards have been formed, filled and sealed, they are automatically moved to the next station which is the cartoning station.

The already packaged blister cards are then packed into cartons before the cartons are sealed and transported.

Integrating the two machines in the same production line offers various benefits including efficiency, cost-effectiveness and high throughput among other benefits.

Another factor that should be noted is that both the machines use a cardboard as one of the materials for packaging.

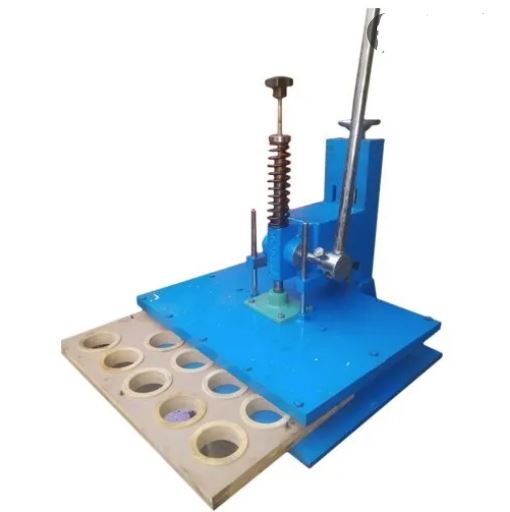

Hand Operated Blister Card Packaging Machine

Hand operated or manual blister card packaging machine is a small table top machine used for handling small scale production lines.

Most pharmaceutical industries are employing the use of manual blister card packaging machine for creating and releasing new drugs.

The machine is mostly used for trials to test the ability of a blister card package to hold and keep products safe.

hand operated blister card packaging machine

Products like tablets, toys, toothbrush and burning torch can be packaged into blister cards through a manual blister card packaging machine.

One limitation is that this machine is very slow and cannot be able to handle large quantities.

Semi-automatic Blister Card Packaging machine

Semi-automatic blister card packaging machine is mostly used for packaging of tablets, ampoules, toys, toothbrushes and other products.

Semi-automatic means it is partly manual and partly automatic and is a table top machine just like the manual one.

Blister card forming process is automatic while processes like filling the pockets or loading material into the machine are done manually.

semi automatic blister card packaging machine

Just like manual blister card packaging machine, this machine is also used for small scale productions like in trials and tests.

Semi-automatic blister card packaging machine works faster compared to the hand operated one, however it cannot handle large scale packaging.

Fully Automatic Blister Card Packing Machine

Fully automatic blister card packaging machine can perform all the functions listed below on its own, without the input of labor.

-The machine can load the material into the system

fully automatic blister card packaging machine

-Heat and form the pockets needed for packaging

-Pack the products into the pockets

-Seal the pockets using paperboards

-Reject pockets that have no products in them.

-Print information on the packages

-Finally eject the packages from the machine.

Compared to the other two, fully automatic blister card packaging machine operates on a very high speed.

Large scale manufacturers usually go for this machine for high production output of almost all blister card products.

Some of the applications of a fully automatic blister card packaging machine include pharmaceutical, consumer goods, electronics, chemical and food industries.

Speed Of Blister Card Packaging Machine

A blister card packaging machine of choice should have speed limits that are changeable and easy to control by operators.

A slow machine will slow down your operations and a speed which is very high can be hard to control.

Productivity Of The Machine

In the manufacturing industry, there are large scale and small-scale companies and the choice of machine will depend on production size.

Go for a blister card packaging machine that will be able to accommodate the output needs of your company.

Travel Range

Travel range describes the amount of time the blister card packaging machine will last before it ends a cycle.

Consider going for a machine that will run for as long as the production process is one and packaging is needed.

Dimensions Of Machine

Every company has specific product sizes that a blister card packaging machine must handle because each machine has specific dimensions.

Therefore, it is very important to check if the machine of choice will match the dimensions of the specified product.

Air Pressure And Power Requirements

Operational cost is an important factor to consider when looking for any machine, a blister card packaging machine is no exception.

Consider the amount of energy the machine will use for operations and the amount of force needed for sealing.

Material Specifications

Some machines are highly versatile and can be used with almost all types of materials.

However, other machines are limited to certain types of materials.

Consider going for a packaging machine that can handle all materials in your production line.

Level Of Automation

A blister card packaging machine can be manual, semi-automatic or fully automatic.

The level of automation will also determine the price of a packaging machine.

Your choice will be determined by the needs of your company and what is affordable.

PLC With A Touch Screen Control System

For an automatic blister card packaging machine, a PLC is necessary for easy operation and control of the whole process.

Other blister card packaging machines may not have this feature, so ensure to go for what suits your packaging operations.

Durability

Different packaging machines are available in the market and knowing the duration of your production operations is very important.

With such knowledge, it is easy to choose a blister card packaging machine made from a strong material like stainless steel.

Pharmaceutical Industry

Blister card packaging machine is used in the pharmaceutical industry for functions like packing tablets, syringes.

Another function is to print information on the backing section of the blister card.

Consumer Goods Industry

Products like toys, padlocks and many others are produced in this industry and are packaged through a blister card packaging machine.

Blister card packaging machine also prints information on the packaging.

Food Industry

Various food products can be packaged through the use of a blister card packaging machine.

The blister card packaging is able to display the contents of the package to attract consumers.

Chemical Industry

Various types of chemical products can also be packaged into blister cards through a blister card packaging machine.

The packaging type will keep their integrity intact and provide security.

Cosmetics Industry

Beauty products like makeups, hair products, body products and items used for applying them can reliably be packaged into blister cards.

A blister card packaging machine is a good choice for such functions.

Sealing is usually done by application of heat and exertion of pressure.

At the sealing station, the lidding material, which is a paper card coated with a plastic material, is put in place.

Heating will raise the temperatures to a level that is suitable to achieve sealing.

However, the temperature level should not be too high because there are products like drugs that are affected by heat.

Blister card packaging machines are designed with a pressure exertion mechanism.

Once the backing parts and the pockets have been heated to the sealing temperature, the machine exerts pressure to create seals.

Heat is meant to melt the sealing material while the pressure is exerted to create tight and secure seals.

For all your blister card packaging machine, contact us now.