Food Packaging Line Provider in China

All JOCHAMP packaging machinery has passed SGS, CE, ISO9001 and cGMP certification. We can supply all types of high standard food packaging machines to maximize your food production.

- Excellent quality and competitive price

- Simple and easy to operate

- High standard electrical control system

- compact design

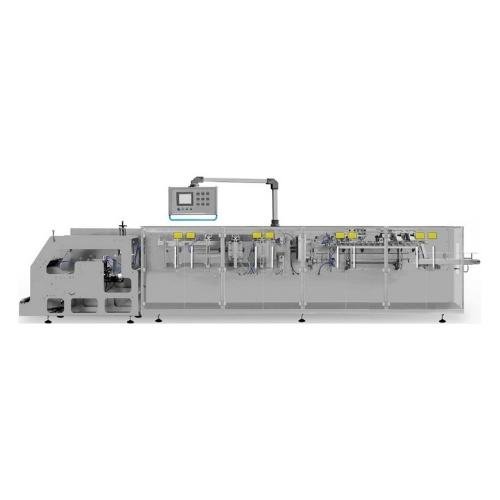

JOCHAMP Food Packaging Line

Packaging machines are very useful on production lines. This machine is responsible for packaging food items to protect and protect them during transport. We offer different types of food packaging machines according to the type of packaging you want.

JOCHAMP can provide you with two types of food packaging line machines, one is a semi-automatic man-machine combined work, and the other is a fully automatic machine to complete the entire work.

Food Packaging Line Features

JOCHAMP food packaging machines, especially semi-automatic machines, are very simple and easy to operate. Operators operating this machine do not necessarily have to be trained as it is very simple to operate.

All of JOCHAMP’s food packaging machines are installed with Siemens, Schneider Electric, Delta and other trusted brand electrical control systems, which make our machines accurate and safe to use.

JOCHAMP food packaging machinery has passed SGS, CE, ISO9001, cGMP certification. That’s why we make sure to provide you with quality and durable food packaging machines.

The packing line of our machine can pack according to the factory layout. This feature is sure to please you.

Why JOCHAMP Food Packaging Line

JOCHAMP food packaging machine structure and body covered with 304-grade stainless steel. It makes our machine become durable, has strong corrosion resistance, and lasts for a longer time. The size-changing structure of the machine with a ruler makes it to change different cartons easier. We can also customize the support of the mechanical structure depending on the carton sizes you demanded.

JOCHAMP offers great packaging solutions for many industrial manufacturing sectors. Our custom food packaging machinery can provide superior protection in any food product and can lower your cost as an owner. Our packaging machine can also have extensive expansion options like coding, labeling, conveying and manual folding, glue spraying, etc.

Food Packaging Line Application

JOCHAMP offers different food packaging lines for the following applications:

- For dairy products

- Food industry

- Beverage

- Biscuits

- Bread

- Vegetables

- Fruit juice

- Wafers, etc.

No matter what industry you are working, JOCHAMP provides excellent solutions for your food packaging needs.

Food Packaging Line for Different Materials

JOCHAMP offers high-quality food packaging lines for the protection of the food from damage, tampering, and contamination. Our food packaging lines are compatible with the following food packaging materials:

- Aseptic Processing: This packaging is made of aluminum and paper for packaging milk, drinkable products, liquid eggs, etc.

- Bags: Usually made from plastic material to block the food from air and environmental contamination. It is used to pack snacks, fruit, and vegetables.

- Boxes: Made from metal, fiberboard, or wood for packing cereal, frozen pizza, and snack crackers.

- Cans: They are the best packaging solution to preserve food such as vegetables, soup, meats, and gravy.

Why Choose JOCHAMP Food Packaging Line

As one of the leading companies, JOCHAMP can supply all kinds of packaging machinery including food packaging machines. We become a one-stop automated packaging provider that gives some industries the solution to their packaging line problem.

In terms of services, we can deliver your machine orders fastest as 15 days, we have a 24/7 fast response service, we give guidance on maintenance and regular after-sales care.

JOCHAMP is more than 15 years that focuses on R&D and manufacturing of packaging machinery, owns more than 50 technical patents, and employed more than 10 people working as professional technical sales with more than 5 years average of industry experience. Working on us also the 20 or more after-sales service teams and 15 mechanical engineers with high knowledge and capability.

JOCHAMP Food Packaging Line

Our series of food packaging lines are suitable for packaging food in different materials, such as:

-

- Wrappers

- Trays

- Pallets

- Flexible Packaging

- Cartons

- Cans

- Boxes

- Bags

- Aseptic Processing

- JOCHAMP designs food packaging lines with the following advantages:

- Simplify Cleaning

- Save Energy

- Improve Environment Work

- Increase Efficiency, Safety, Cut Costs, and Quality

- Waste Reduction

- Eliminate malfunction risks

- Enhances the health and safety of workers through automated palletizing

- Simplify streamline changeover

- Increase flexibility

Food Packaging Line Based on Your Applications

JOCHAMP provides fully engineered fruit packaging line solutions that deliver flexible workflows, highly efficient to maximize your line’s overall equipment effectiveness. Suitable for packaging vegetables, meat, and more.

JOCHAMP provides an automatic biscuit packaging machine. These machines are suitable for packing cookies, rusk, and wafers.

The tin packing machine can guarantee a large production capacity. It is made from high-quality materials to ensure durability.

Our food packaging sealing machine is manufactured from anodized aluminum or stainless steel. These machines are ideally suited for wet environments.

Related Product

Food Packaging Line: The Ultimate Guide

Packaging is an essential part of food production process.

Therefore, you need highly efficient, reliable and hygienic food packaging line.

This guide takes you through the vital aspects of food packaging line.

Take a look:

These are series of machines and equipment, which help in packaging food products.

Depending on the design, these machines may work independently or when integrated with other food packaging equipment.

Food packaging line

Some of the most common equipment in food packaging line include:

Check Weigher

The use of this machine is critical at the beginning and end of your food packaging line. Check Weigher are essential in getting the correct measurement for your raw materials and the final product.

These machines help get the right weight for the materials before shipping to the final consumer.

You can enhance the quality of your products by ensuring there is weight uniformity.

Check Weigher in food packaging

Vertical Form Fill Seal Machines

This automated machine helps in the packaging of your liquid food products. It generates a plastic package and fills it with your liquid content.

VFFS machine eliminates the use of human intervention, thus facilitating quality packaging. After filling the package with your liquid product, the machine then seals it preventing any leakage

The faster working rate of this machine allows for a high packaging speed which increases your production rate.

VFFS Machine

Vacuum Sealers

This machine facilitates the creation of an airtight seal for your food product. This enhances the safety and quality of your food product by preventing contamination.

Most production companies use transparent packaging materials to allow customers to view the content.

The advantage of this machine is that it can control your food product’s temperature. This enhances your product’s shelf life.

Vacuum sealer

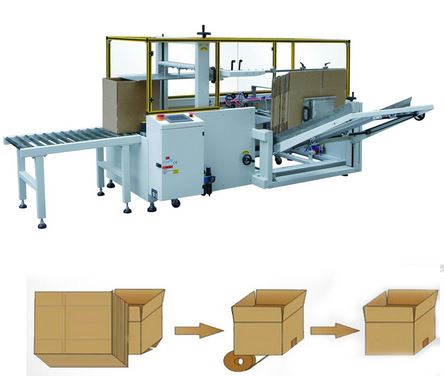

Case Erectors

Case erectors facilitate the folding of cartons into boxes for the packaging of your product. This eliminates the need for human resources, thus minimizing the overall cost.

The choice of which equipment to use depends on various factors. For instance, the type of product you want to package.

Liquid products usually use vertical filling machines, while solid food products use vacuum sealers.

You also have to check the packaging condition you want for your food product. A vacuum sealer machine helps preserve the food from microbial contamination, which enhances its shelf life.

Case erector

In addition to these, you can classify these machines according as:

- Horizontal form fill packaging machine

- Stick packaging machine

- Filling and packaging machines

The common packaging you can use for your food are:

Food packaging

Metal Tin An Containers For Food Packaging

There are various packagings that you can make using metals. They include containers, cans, caps, films, and tubes.

Metals like aluminum are ideal for fabricating cans for packing liquids and beverages. The advantage of metal is you can recycle them, which reduces the operational cost and facilitates the conservation of the environment.

The choice of which metal to use depends on various factors. They include rigidity, pressure resilience, temperature tolerance, and corrosion resistance.

You also have to check on the ease of cleaning the metal to facilitate reuse.

Having a proper design easily attracts your customers, thereby enhancing your sales.

Paper For Food Packaging

You can use paper to pack your dry foods and wet fatty foods. Common paper types for packaging are corrugated boxes, folding cartons, sacks, and paper plates.

Others are bags, wrapping paper, and leaflets. When selecting an ideal paper packaging, you should consider fold durability, ease of folding, and level of stiffness.

You can use lamination to increase the durability of your paper material.

Glass For Food Packaging

Glass is a durable material, dependable, and does not contain any toxic material. This makes it safe for use in food packaging.

Plastic For Food Paackaging

The different types of plastic packaging for your selection are bowls, foils, bottles, pouches, trays, and bags. Durability and affordability are the main advantages of using plastic.

Plastic, however, is not recyclable, which negatively impacts the environment.

You have to consider the following when selecting your food packaging material:

Functionality And Safety

Functionality is essential in offering conducive handling of your food product. The material should not negatively affect the food product therein.

The functional aspect of your packaging should include containing your food product and preserving it safely.

You also should check on which product to use a particular packaging material. For instance, you cannot use glass for hot food packaging.

Convenience Of Using

Your food packaging material should be convenient for the final user. You have to consider the dimension of the packaging material and any adverse reaction when using it.

Design And Marketing Aspect

The ease of marketing and designing your packaging material is of importance. Proper marketing attracts clients to your food product.

The designing and marketing process should be compatible with your material.

Price Of A Packaging Material

The different packaging materials cost differently due to their different properties. The primary materials are glass, paper, and plastic, each having a different price.

The suitability of your packaging material should match its price when selecting. This is to minimize selecting a material with a cheaper price alternative.

Ideal features that you should check on your food packaging systems are:

Section of food packaging line

Convenient

An ideal food packaging system should be convenient for all those handling it. Such a system should allow easy movement of your food product from one stage to another.

Convenience should include the dimensions of your food product.

Flexibility And Ease Of Use

This feature can minimize your operating cost while maximizing your output.

If a food packaging system is easy to operate, you may require minimal personnel to help you in its operation.

You also need to check on the level of flexibility of the machine. That is, the machine needs to package different food types without replacing them.

This removes the need to have different packaging machines, which reduces the overall operating cost.

Guarantee Hygiene

Food is sensitive to both the consumers and those handling it. An effective food packaging system should allow easy cleaning of all the elements.

Checking on the material of your food packaging system is also vital—elements like anti-corrosion and ease of cleaning help in enhancing the hygiene levels.

Consumer Requirements

An effective food packaging system should cater to various consumer requirements. Such requirements include the dimension of the packaging material and design uniqueness.

This helps in the personalization of your food packaging and its content.

Sustainability

A proper packaging system should include sustainability. This allows for the reuse and durability of the packaging material.

Sustainability reduces cost and environmental pollution.

The best practices you can apply to your food packaging line are:

Recycling

Using packaging materials more than once helps reduce the overall packaging cost. Recycling helps in reducing environmental waste and in conserving the environment.

Environmental Friendly Packaging

Choosing a packaging material that does not degrade the environment is the best practice in food packaging lines. This is because you can easily dispose of the material without worrying about the environment.

Comply With Quality Standards

Ensuring the packaging materials you are using meets the quality standards set helps in adequate packing of your products. Quality standards minimize the chances of using substandard packages that can contaminate your food product.

The easy way of getting quality standards is by purchasing from reliable manufacturers.

A food packaging line offers the following benefits:

Food Protection And Preservation

A food packaging line offers protection to your food product against various elements. Protection is mainly against three critical factors, biological, chemical, and physical

The protection is mainly by packaging your food product using an appropriate packaging material. Such material ensures your product retains its quality till it reaches the final consumer.

Reduces Food Waste

A proper food packaging line ensures your product is safe and of the right quality till it reaches your customers. Lack of external interference of your product means it remains safe.

The freshness of your food product means you reduce food waste. This saves you money while increasing your profit margins.

Enhances Marketing Of Your Food Products

A proper food packaging line helps in marketing your product. You achieve this by adequately labeling your packing material.

Adequate labeling has the effect of attracting customers, which increases your sales and profit margins.

Traceability

A food packaging line allows for easy traceability of your food product. This is from sourcing your raw materials to the various preparation stages and your customers.

Traceability increases the quality of your product since it is easy to detect any bad quality even after the food has reached the market. You can request the removal of a specific batch number if you note bad qualities.

Proper maintenance of your food packaging line involves the following:

Food packaging system

Frequent Lubrication Of Moving Parts

Friction can hinder the smooth operation of your food packaging line. It is, therefore, essential that you use the right lubricant to lubricate the various moving parts of your packaging line.

Always ensure you lubricate as per your manufacturer guidelines. This is to enhance the productivity and durability of your machine.

Cleaning Your Food Packaging Line

Contamination is a major issue when dealing with a food packaging line. This is because of the sensitivity of the food product.

You, therefore, have to clean the packaging line after every process. This is to minimize remnants of the food particles from contaminating the next packaging batch.

You have to use an appropriate cleaning agent as per your manufacturer’s recommendation.

Using The Right Materials

Using suitable raw materials on your food packaging line enhances productivity and durability. Raw materials include the food product you are packaging and the packing materials you are using.

You also have to use the correct quantity of these materials.

Replacement Of Worn-out Parts

Food packaging line, like other machines, tends to break down, reducing their efficiency. When such happens, you must replace these parts.

You have to replace these parts with genuine spare parts. This is by purchasing from a reliable dealer or your manufacturer.

The following specifications are ideal for your food packaging line:

Chocolate packaging machine

Packaging Speed

Packaging speed determines the output of your machine. When specifying this, you need to check your expected output and any future increase.

Packaging speed enhances efficiency and can significantly reduce the operating cost by eliminating the human resource.

Food Packaging Line Type

Food packaging lines are available either as manual or automatic. The choice of which one to select depends on cost and the type of food you are packaging.

Packaging Flexibility

The ability of a given food packaging line to use different packaging materials enhances its use.

Such a machine can facilitate food packaging in different packaging materials, which reduces the overall operating cost. You also need to check if the machine can package different food types.

Price Of Food Packaging Line

The price of a particular food packaging line determines if you are to purchase it or not. Such a price should complement the services you are getting from it.

Always ensure you get the price factors correctly. This includes the purchasing, maintenance, and installation cost.

You can improve the efficiency of your food packaging processes by practicing the following:

Automating Food Packaging Line

Automation reduces the need for human intervention. Human intervention has the effect of slowing down the packaging processes.

It also leads to machine downtime due to human energy exhaustion. This impacts negatively on your output and profit margin.

When you automate the processes, you do away with this aspect. The machine operates continuously, which increases the production process and your output.

Hygiene Packaging Processes

Food products are sensitive, and a small mistake can result in huge losses. Such mistakes include contamination and expiry of your products.

Modern companies incorporate hygiene measures in each of the packaging processes. This enhances efficiency while minimizing contamination.

Frequent Maintenance

Maintenace involves having all your parts ready for functioning. This includes frequent cleaning and removing particles which can reduce its performance.

You also have to replace worn-out parts frequently. This should be as per the recommendation of your manufacturer.

High speed food packaging machine

Balancing between speed and flexibility in your food packaging industry facilitates the efficiency and durability of your machines.

To balance these two, you have to understand the dynamics of your food product.

That is the dimensions of your product in terms of size and condition in terms of liquidity.

Flexibility reduces the operating cost by minimizing the machines you need to have. You can easily package different food products using a single machine.

Areas where you can apply food packaging machines are:

Food And Beverages Industry

There are different food products you can package using a food packaging machine. The choice of which machine to use depends on the type of food product.

Main food products are liquid, semi-solid, and solids. You also have to consider special conditions like temperature and preservation requirements.

Medical Industry

Packaging various medical drugs and equipment is essential to maintain their quality and avoid poisoning. A food packaging line facilitates this by using an appropriate packaging material.

Other industries that use a food packaging line are chemical, hardware, and machinery industries.

Evolving technology necessitates improving several aspects of food packaging process designs. Such considerations include:

Automation

Reducing the number of human interventions is essential for your food packaging line. By automating your processes, you enhance quality by preventing contamination.

Automation reduces the overall operating cost of your processes. This is done by reducing human resources and machine downtime due to the exhaustion of human labor.

You also increase your output by ensuring there is continuous food packaging.

Traceability

Traceability helps understand the origin of various elements of your food packaging line processes. The knowledge gained helps you track any errors that arise during the process.

Common factors that necessitate tracking include the source of various raw materials and the final destination. Such materials include food products and packaging materials.

Consumer Trends

Suppose you align your food packaging line with what your final consumer needs can help in increasing sales. Aspects you can check here include shifting the packaging material to recyclable ones and bulk packaging.

You may also consider breaking the bulk to suit small-scale consumers.

Sustainability

Making your food packaging line sustainable towards meeting the various client requirements is vital. Sustainability attracts your customers and makes them brand loyal to your products.

Installation And Maintenance

Having a food packaging line that is easy to install is vital in your operation. This is in terms of the installation space and procedure.

A proper installation should consider all the cables and different parts of your machine. This allows for easy test runs before the actual commissioning of the machine.

You also have to consider the ease of getting the spare parts for your food packaging line. These spare parts should be from your manufacturer or an authorized dealer.

Original spare parts reduce the chances of getting counterfeits which reduces the efficient operation of your machine.

Modern food packaging technology aims at reducing environmental waste and increasing durability. This has an impact on reducing your overall packaging cost and enhances efficiency.

Such technologies include:

Edible Packaging

Edible packaging involves using a packaging material that you can easily consume and digest.

This reduces environmental waste by ensuring you dont throw the packaging material after eating your food.

The advantage of this type of packaging is it is easy to manufacture. This is because it uses readily available materials.

Recyclable Packaging

Reducing environmental waste is of great importance in modern living. You can achieve this by recycling your packaging material.

You can easily recycle all the packaging material types. This includes glass, plastic, and paper packages.

Recycling reduces your overall packaging cost by ensuring you have the raw material.

Smart Packaging

Innovative packaging is a technology-based aspect that you can integrate into your food packaging line.

This type of packaging aims at giving detailed and accurate information to the final consumer.

It involves embedding your food package with technology chips that your customers can scan for real-time information.

Such information includes the temperature, pH levels, flavor, and fermentation levels of your product.

The packaging aims at reducing the toxification of your food products which can harm your consumers.

Real-time information can also help you minimize loss due to customers abstaining from your products.

Transparent Packaging

Transparent packaging entails using a packaging material that allows your customers to view the content of your package.

Such a package increases your sales and profitability. This is because customers are sure of purchasing what they can see.

You can compliment transparent packaging with clear labeling on your food package. This way, the information on the label relates to the content of your food package.

If you have any question on food packaging line, contact us now.