Packing Machine Manufacturer in China

Jochamp is your one-stop packaging solution provider. We supply all types of advanced machines including automatic packaging machines, carton box packing machines, high speed packaging machines, food packing machines and more.

- SGS, ISO9001 certified

- User friendly machines

- High-precision, high performance

- 2-year quality assurance

JOCHAMP Packing Machine

Jochamp packing machine is an equipment employed to put together unit loads from individual products. This machine is the final step in the manufacturing process. It is also the first step in the transportation method.

They are usually found as part of automated assembly lines. Due to its high-performance and efficiency, these can handle materials packaged in rigid, semirigid, or soft containers. Aside from that, this machine can work on items not packaged in containers, such as metal castings, lumber, sheet metal, rolled metal sections, etc. Packing machine can be automatic or semiautomatic, depending on your request.

As a leading packing machine manufacturer, Jochamp develops complete solutions to meet global market needs. Producing machines to industry specifications guarantee exact packing at efficient speed and greater protection of any product kinds.

Let Jochamp custom your packing machine now!

Various Packing Machine for Your Choices

The two main types are the automatic cartoning machine and the case packing machine, widely employed in the food, medicine, and cosmetics industries, among others.

Plastic blisters excel at product display, commonly utilized for food, daily necessities, and pharmaceuticals.

Flow wrap machine, shrink wrap machine, and overwrapping machine are widely applicable, serving various industries efficiently.

JOCHAMP MACHINERY specializes in tailored packaging lines to meet unique customer demands.

Jochamp Packing Machine Feature

Jochamp machines feature high efficiency that can pack 10 to 100 packets per minute. These allow for a streamline production process.

Our series of packing machines have a high-end construction and material allow for long working hours. Made under a strict quality control process.

Our machine can be specifically designed to fit your production environment. It is space-saving, cutting costs for renovating machines.

Packing machines are user-friendly, any person can easily operate them through advanced PLC controls. We provide training resources and onsite technical support.

Packing Machine Materials

Jochamp maintains long-term relationships with vendors who can supply our packing machinery on a consistent basis. Our raw material suppliers are subjected to a rigorous verification process. The quality of our processed parts, sheet metals, electrical components, and other materials is consistent. For specific packing machines, we ensure that they are food-grade and safe to use.

Our company can ensure a durable construction packing machine with a lengthy life span. We can manufacture racks or housing for the electrical component and wiring of our machines out of high-standard materials that are notably sturdy and stable.

Packing Machine Production

In China, we invested in high-end facilities and management systems as a professional manufacturer. We also have 50+ strategic cooperation machinery factories and 15+ mechanical engineers backing us. From raw materials inspection to machine assembly and testing, we ensure to follow strict quality control.

By incorporating our extensive market research, we can build packing machines that meet our clients’ expectations. Our packing machine can be design with a touch screen and operational panel accessible to each employee. These can increase worker productivity thanks to the ergonomic design of the control interface.

Packing Machine Applications

Jochamp packing machines are used for packaging bulk commodities in sacks or individual items in the printing, metallurgical, wood-products, food products, non-food items, etc. This machine can be made to assemble unit loads horizontally or vertically, or combine.

Depending on your applications or product type, Jochamp is your leading manufacturer that can satisfy your needs. Whether you require a liquid packing machine, pill packing machine, powder packing machine, or granule packing machine, we are glad to fulfill your specifications.

Why Choose JOCHAMP Packing Machine

Jochamp has 15+ rich experience in the packing machine manufacturing industry. We specialize in all types of packing machine that comes in different packaging materials, sizes, design, lengths, the weight of the unit loads and other configurations. Our CE and ISO-approved packing machines are widely used for various industries such as packaging food, toys, bathroom, furniture, engineering, electrical appliances, plastics, medical, lighting, hardware, electronics, hotel supplies, etc.

Our company develops packing machines according to materials and needs of our customers. We can recommend suitable packaging equipment and models for your projects. Below are some of the reasons why choose Jochamp as your packing machine provider:

- Use High Standard Material – all our materials are ISO and CE-certified. These materials reduce maintenance costs and allow machines to operate for a long time.

- 2-Year Quality Assurance – Our company provides a 2-year warranty and lifetime after-sales service.

- High Precision Machines – manufactured with the latest technology, servo-controlled film-tension system and intelligent system. Allow enhanced productivity and correct packing.

- Efficient production and lead time -fastest delivery time of 15 days

- Experienced technical team, engineers and staff satisfy your packing machine solutions and services

- Professional after-sale services – We have a 20-person after-sales team that can assist you with technical training and cost-effective maintenance.

- One-stop service – we offer overall packaging solutions worldwide.

- Strong R&D team – 10+ mechanical engineers with 10+ years of industry experience supports us. They are responsible for designing specific packaging solutions for customers.

JOCHAMP Packing Machine

Jochamp manufactures one-solutions packing machines for a wide range of products. We can modify machines to industry specifications. These guarantee right, efficient packing and greater protection of any product type such as:

- food & beverage

- healthcare & medical parts

- pet food & treats

- furniture and bathroom accessories,

- hotel supplies,

- masks, bread, biscuits

- toothbrushes, toothpaste, soap,

- switch sockets, casters, rubber strips, etc.

To improve your business productivity, Jochamp produces the latest technology, accurate packing machines at fast speeds to reduce costs and reach business quotas. Some are the following machines we offer:

- Multilane Packing Machines

- Automated Packing Machines

- Pouch Packing Machine

- Blister Packing Machine

- Flow wrapping/packing machines

- Over wrapping/packing machines

- Auger filler packing machine

- Linear weigher packing machine

Custom Packing Machine Based on Your Applications

Jochamp can manufacture advanced and efficient food packing machines. You can request specific food types to manufacture your machines. We can add this packing machine to the existing packaging line. It is built durable, long-lasting and user-friendly.

Our range of pharmaceutical packaging machines can pack tablets, capsules and powders. It is easy to operate and provides efficient solutions for preparing pharmaceutical items. Designed for healthcare plants, small pharm factories, food plants and preparation rooms.

Get a cost-effective flour packing machine at Jochamp. It is rigorously manufactured under CE and ISO standards. We can combine this machine with other load securing, palletizing, and data processing systems.

Our company offers a series of coffee packaging machines used in packing a variety of coffee such as coffee beans, instant coffee, drip coffee, etc. Our extensive skills and knowledge allow us to design accurate and fast machines for your business.

For your vegetable packing machine need, Jochamp manufactures high-efficient, latest technology, and versatile machines for all kinds of veggies product packaging purposes. These are ideal for all types of large-scale and small-scale industries.

Related Product

Packing Machine: The Ultimate Guide

Before investing in your next packaging machine, read this guide.

It gives you a detailed insight on what to look for when buying packaging machine.

Whether you need a packaging machine for your pharmaceutical industry, food packaging or other products – you will find all the useful information right here.

A packing machine is a piece of equipment used to package products or components.

It is used in the entire packaging operations, which involve primary packages to distribution packs.

You can hardly accomplish certain operations without a piece of packaging machinery in some packaging settings.

As such, it means packing machines are available in wide varieties in the markets to cater for different packaging needs.

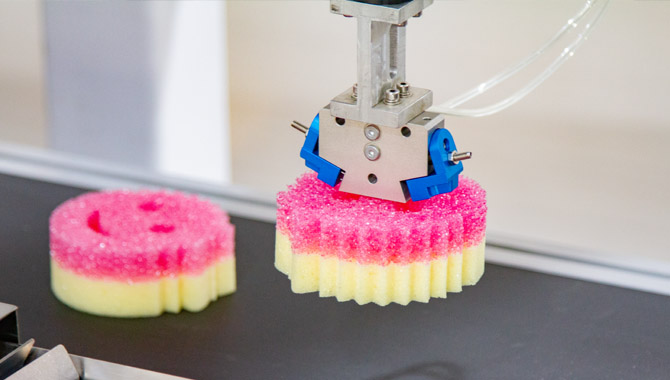

packing machine

Besides, this type of equipment is also available in different sizes, from small to large and in different design construction.

However, it is imperative to note that packing machines can vary in size but still perform the primary functions effectively.

Furthermore, you can find this equipment in standard and custom designs; hence the choice is based on your specific application demands.

This machine is used extensively in different packaging applications across various sectors.

Mostly, you will find them categorized on many grounds but often based on type of products or components.

You can classify packing machines in various ways, and the main ones include the following;

Packaging Machine By Application

Of course, most packing machines are determined by the specific type of product or component they pack in different industries.

These machines are in hundreds, but the most common ones include the following;

Accumulators – Available in different sizes and configurations but often put at the end of packaging line for sorting and gathering finished products.

Bag sealers – Designed to enclose packing bags made from different materials entirely.

Bagging machine – It is used to pour products into respective packing bags after opening.

Cappers – Capping machine is used with bottles, jugs and jars to apply lid caps once the product fills the container.

Carton sealer – It uses tape to close top and bottom sides of the box to reduce product damage during transportation.

Case erectors – This unit is used to form and fold flat boxes to insert products easily before moving to the next phase.

Checkweigher – It is designed to confirm weight accuracy of the product as it passes by a conveyor belt and stops if the product is not within the required weight.

Conveyors – They transport products to different stations within the packaging line for appropriate packaging operation.

Filling machine – Mostly used with liquids and gels to control a consistent amount of product placed into the container, bottle or jar.

Flow wrappers – Often used in food processing industries, especially where high-speed food packaging is a concern.

Label applicator – It applies labels to various packages, containers and products.

Lidding machine – This unit is used for sealing a tamper-evident lid over products to assure end-users that the product has never been opened before.

Over-wrappers – It uses a thin PVC film, tray and heat pad to wrap different consumables and protect them from dust, insects and other external elements.

Shrink tunnel – This packaging machine uses a conveyor belt to move products through a heated chamber to shrink and enable them to conform to a product.

Shrink wrap sealer – It uses heat to mend shrink wrap materials and cut excess film for visually appealing seals.

Skin packaging equipment – It is designed to use heat and vacuum to pull a clear facing onto a backer-board.

Strapping machine – This unit is ideal for bundling multiple items together to enhance strength, particularly during transportation.

Stretch wrap machine – It is used for applying stretch film to product pallet by pulling it tightly around the pallet and holding products in place during shipping.

Vacuum sealer – Mostly used for modifying the air within a package and helping extend shelf-life of the consumables by reducing oxygen content.

Stamping machine – It uses stamping dies or heated image molds to transfer pre-dried inks onto surface of packaging material.

Air pillow machine – It inserts air in various pouches designs to form an air pillow for cushioning products during shipping.

Wrapping machine – Used for bundling multiple pieces of luggage to consolidate and minimize tampering while in transit.

Metal detector– It is used with conveyor belts to identify unwanted metals in products

Vegetable packing machine – It is designed to pack specific fruits and vegetables into defined packaging materials.

Spice packaging machine – This unit is used for packing a wide range of spices in different sizes.

Sterilization machine – It is used in packaging line to sanitize the products and treat them to suit the specific intended setting.

Packing By Working Principle

It is also another category for determining the types of packaging machines used in different industries.

Ordinarily, these machines have different working principles based on the design, size and the product it is designed for.

Mostly, packing machinery based on working principle exhibit multiple functions.

The common types of this machine under this category include the following;

Liquid filling machine – It is a type of machine used for filling and packing a wide range of liquid and semi-liquid products.

Horizontal packing machine – Products in this machine are configured horizontally for efficient packaging.

Rotary packing machine – This machine packs products by rotating or revolving around a central axis.

Teabag packing machine – It is designed for packing and wrapping tea leaves in different designated packaging bags.

Bag packaging machine – It is used for conveying packaging bags to different stations in packing line for various product packaging functions.

Powder packaging machine – This unit is designed for packing a wide range of powder products such as flour.

Packing Machine By Production Capacity

In packaging setting, speed and handling capacity are core elements that determine the type of machine used.

Small and medium scale production does not necessarily require high speed hence can use particular packing machines designed for such capacities.

However, industrial production requires high-speed packaging machines and lines that can match the high production volume efficiently.

Thus, when picking a packing machine based on production capacity, it is fundamental to establish whether the specific choice offers desired results for your production needs.

The notable types of packing machines under production capacity include the following;

Manual Packing Machine

Like the name indicates, this unit is operated manually and hardly needs a reasonable power source or electricity.

It is a suitable choice in applications or areas where power source is not a meaningful concern or where compressed air is unavailable.

manual packing machine

You can use it for packing products in a small scale volume.

Semi-Automatic Packing Machine

This packing machinery requires an operator to place containers, bags, or products manually and start the packing process via a switch.

The operator then performs a few functions manually, such as moving the containers to succeeding stages of packaging process.

semi automatic packing machine

Semi-automatic packaging unit may require the operator to refill some products or packaging materials accordingly.

Automatic Packing Machine

All packaging operations of this unit are automated; hence rarely require operator’s input.

Ideally, this type of packaging machine involves a wide range of integrated units combined to provide packaging efficiency in different stages.

It has a PLC control unit where different operating parameters of the packaging processes are regulated and monitored.

Automatic packing machine

Besides, this machine guarantees excellent efficiency, high speed and precision, thus suitable for large volume and industrial applications.

Notably, packaging in a typical manufacturing business is fundamental since it enhances the efficiency of the production process.

Buying a wide range of packing machines for your business is an upfront investment that can be costly but worthy in the long run.

Hence, the main benefits of investing in this machinery include the following;

Easy To Meet Rising Demand

Technically, when your business is experiencing rising demand, it indicates you are on right trajectory.

It means you are receiving more orders and your clientele is satisfied, and you look forward to making more profits.

Even so, rising demand can be a challenge if your business cannot cope.

Thus, using packaging machines, in this case, enables you to scale up rapid production, especially if you buy upgradeable units.

Hence, you will hardly miss delivery deadlines, encounter bottlenecks or compromise accuracy and speed in your operations.

Lowers Running Costs

Labor is quite an expensive element in a manufacturing setting, especially where you have to hire a reasonable number of staff.

Besides, it can reduce profits significantly since major part of the sales returns is channeled towards employees’ needs.

Packaging machines are beneficial since they can pay for themselves, given the machines require a few operators.

In general, packaging, especially with automation machinery, cuts costs but increases quality and production.

Guarantees High Quality

Manual packing is prone to several inconsistencies such as overfilling, misapplying labels, damaging the package or failure to tighten caps.

Ordinarily, such inconsistencies often waste the products and easily upset the customer.

Ultimately, it is a costly affair trying to trace the recurring issues and prevent them from occurring.

However, packing machines deliver consistent results and guarantee quality results all the time.

Relieve Employees From Repetitive Tasks

Many employees dislike repetitive jobs, and this reduces productivity significantly.

Using packing machines in highly industrialized settings frees workers from unnecessary monotony and gives them fulfilling tasks.

In essence, this improves overall productivity within the production setting.

Minimizes Waste And Product Rejection

Manual packing often leads to several errors, resulting in additional waste from overfilled containers and overusing material.

It adds up over time and tends to influence profits considerably.

When you use filling machines, in such instances, you are guaranteed high precision, which lowers wasteful overfilling and underfilling.

Increases Business Sustainability

Ordinarily, many companies in manufacturing sector are investing in automatic packaging machines.

Of course, this is important for business sustainability and competitiveness in that particular industry.

With limited efficiency in parking, your business may be locked into lower productivity than competitors.

In essence, this may affect operations and possibly lead to closure of the business.

Efficient Use Of Floor Space

Ideally, floor space is costly, and production increases require more space.

This may eat into your profits since you want to manage and increase efficiency.

However, using modern packing machines means you can use them where space is limited.

You can find some that are relatively compact but delivers efficient performance and reduce footprint of your production line.

Increased Production Speeds

Notably, one major reason for investing in a number of packaging machines is to increase overall production speeds while lowering costs.

This equipment also allows you to scale production up and down depending on how demand fluctuates.

Hence, it means adding suitable packaging machines guarantees better efficiency and improved production speeds.

Improves Social Distancing

In the wake of Covid 19 pandemic, supporting social distance at workplaces was the major practice that businesses adapted.

Of course, spacing workers slow down production across various manufacturing industries significantly.

However, the use of automatic packing machines ensures that production is maintained since most need fewer employees to operate.

This is advantageous because it means you will maintain your business operations accordingly.

Enhances Product Care

Using the right packaging machinery for your goods guarantees safety.

For instance, an ideal stretch wrapping machine ensures the items are properly wrapped and are safe from contamination.

In essence, this increases the overall durability and shelf-life of the respective products accordingly.

Boosts Customer’s Confidence

Most customers and consumers of different products purchase them easily if they are pleasing to the eye.

Using automated packaging machines implies great packaging with accurate details.

Hence, it creates an ideal impression and helps in promoting your brand.

Besides, consumers can keep machine-wrapped products longer than by refrigeration only.

As such, it increases the overall demand for products packed by machines.

Different packing machines are priced differently based on a wide range of factors.

The main cost-determinant elements of these machines include the following;

Specific Type Of Machine

Packing machines are available in hundreds of varieties, each designed to perform a designated packaging role.

Some offer single-function, whereas others are multi-functional.

Ordinarily, the former tends to be cheaper than the latter in many instances.

Hence, the actual price will depend considerably on the particular type of packaging machine you are buying.

Capability

Various packaging machines are designed to offer different handling capacities.

In essence, it means you will find some manufactured to handle large volumes and others low volumes effectively.

Ideally, packing machines with high handling capacities are usually more expensive than those designed for small volumes.

Mode Of Operation

This type of machinery is available in three main types as far as operation mode is concerned.

Fully automatic unit is the most efficient, reliable and fastest of all the available options.

All its operational parameters are automated hence the most expensive of all the packing machinery.

Semi-automatic unit uses automated functions but partly utilizes human input in some functions.

It is also faster and relatively accurate but more affordable than the automatic unit.

On the other hand, manually operated packing machines are the most affordable units in the market.

Type Of Application

Some packing machinery requires integrating at least two different units into the production line to fulfill the process.

Such equipment are expensive since they involve many individual units combined to provide the ultimate packaging results.

However, buying single-use packaging machines is cheaper.

Brand

Ordinarily, packaging machines are manufactured by different companies.

Each company has a specific price range for its various units, depending on a wide range of factors.

For instance, a highly-rated brand in the market is likely to be pricey since it has built a reputable name in the industry.

On the other hand, less known brands may be cheaper since they do not have a larger market share.

Material Quality

These machines are usually manufactured using a wide variety of materials.

Of course, some materials like aluminum and copper tend to be more expensive than others.

Hence, specific material used for making a particular machine determines its actual cost.

packing machine

For all your packing machines, contact us now.