Your Case Packer Manufacturer in China

JOCHAMP skillfully manufactures a series of case packaging machines. We provide the mentioned machines with heavy-duty rack structures, stable operation, and low noise advantages. All our offered packing machines specifications are open for customization to satisfy your needs. Negotiate with us now!

- Manufacture with compact designs

- Withstand various environmental conditions

- Provides reliable performance

- CE, ISO900, & SGS certified approved

JOCHAMP Case Packer

An automated machine known as a case packer puts up trays or wrap-around cases and loads items from the packaging’s top, side, or bottom. Following the loading of the goods, the subject is closed and sealed with glue or tape. It offers companies and manufacturers an all-encompassing solution for packaging and goods transportation.

Case packer can handle both variable and fixed-sized packages. It is also customizable between production runs to accommodate the different products’ sizes and shapes. Case Packaging Machines can automatically fold or erect the carton box. Depending on the design of the machine, it functions well with either blank cardboard or a pre-made carton case.

The purchase of case packing machinery is a significant business expenditure. Think about it: what if you wanted to know what equipment is accessible, what materials it runs on, how to operate it safely, and how to maintain it optimally? If that is the case, please shoot us an email right away, and we will promptly respond with all of the information you require!

Case Packer Type

The Side Load Case Packer is a specialized packaging equipment that loads products into cartons by pushing them sideways. This loading method is particularly well-suited for square regular products, such as small cartons and square soap.

The side loading process efficiently positions square products inside the cartons, ensuring a snug fit and secure packaging. This method is especially beneficial for products with uniform shapes, as it allows for precise and consistent loading.

The Side Load Case Packer is widely used in various industries, from food and beverages to consumer goods and pharmaceuticals, where square or rectangular products are common. Its versatility and efficiency make it an essential asset for businesses seeking reliable and cost-effective carton packaging solutions.

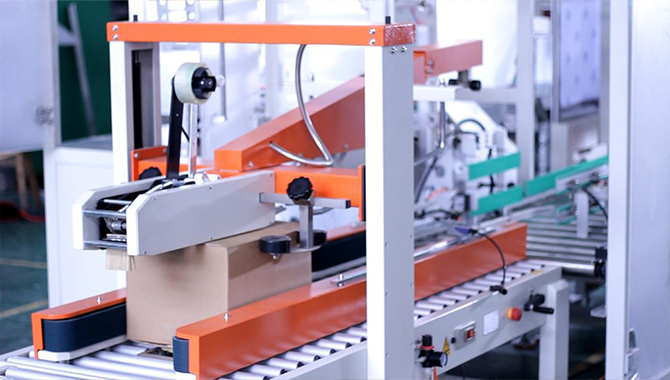

The Compact Case Packer is a highly efficient packaging equipment that combines the functions of unpacking, packing, and sealing within a single space. This integrated design optimizes the utilization of site space, making it a space-saving and practical solution for packaging operations.

By integrating multiple functions into one compact machine, it eliminates the need for separate equipment and reduces the overall footprint in the production area. This space-efficient design is particularly beneficial for facilities with limited space or those seeking to maximize their production floor.

The Compact Case Packer streamlines the packaging process, enhancing productivity and reducing manual handling. Its efficient operation ensures smooth and precise packing and sealing of products into cases, improving packaging efficiency and workflow.

This versatile and space-saving equipment is a valuable investment for businesses aiming to enhance their packaging operations while making the most effective use of their available site space.

The Wraparound Case Packer is an innovative packaging solution that utilizes a single piece of corrugated paper as the packaging material. This machine seamlessly integrates multiple functions, including corrugated box forming, feeding, and carton sealing.

Designed specifically for products that require wrapping, such as beverages, beer, and cans, the Wraparound Case Packer ensures secure and efficient packaging. Its ability to form the corrugated box around the products provides excellent protection during transportation and storage.

This advanced machine streamlines the packaging process, reducing manual labor and improving overall productivity. By using a single piece of corrugated paper, it optimizes material usage, minimizing waste, and reducing packaging costs.

The Wraparound Case Packer is a versatile and environmentally-friendly packaging solution, making it an ideal choice for industries that require wraparound packaging for their products. Its efficient and reliable operation ensures consistent and high-quality packaging, meeting the demands of modern packaging requirements.

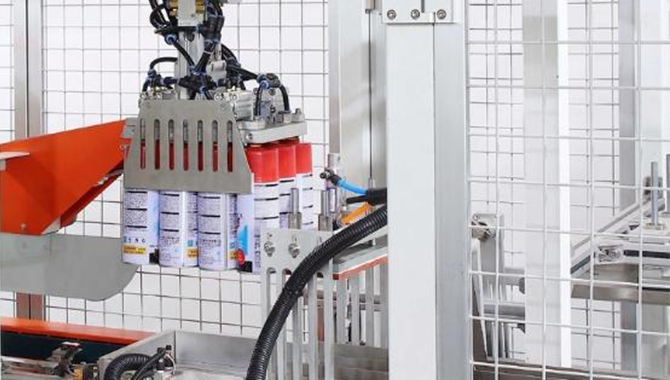

The Robot Case Packer is a highly versatile packaging equipment that incorporates a manipulator feeding system directly into the case packer. By utilizing a modified grabbing device, this machine becomes adaptable to a wide range of products.

The integration of a manipulator feeding system allows the Robot Case Packer to handle various product types and shapes with precision and efficiency. The grabbing device can be customized and adjusted to accommodate different product dimensions, ensuring a secure and precise placement into the cases.

This adaptability makes the Robot Case Packer an excellent choice for industries with diverse product lines, as it streamlines the packaging process for different items without the need for extensive reconfiguration or manual adjustments.

The innovative design and versatility of the Robot Case Packer contribute to improved packaging efficiency, reduced downtime, and enhanced overall productivity. Its capability to handle various products makes it a valuable asset for businesses seeking a flexible and automated packaging solution.

The Double Station Pick and Place Case Packer is an advanced packaging equipment designed for optimum space utilization and efficiency. It employs a straightforward servo-translational grabbing device to maximize the effective space during the packaging process.

The machine is equipped with two product feeding devices, allowing it to operate simultaneously on two production stations. This dual setup effectively doubles the packaging efficiency, reducing production time and increasing overall productivity.

With the servo-translational grabbing device, the Double Station Pick and Place Case Packer can precisely handle products and ensure accurate placement into the cases, optimizing the packaging process.

The combination of space-saving design and dual-station operation makes this equipment a valuable asset for industries seeking to enhance packaging efficiency and throughput. It enables businesses to streamline their production lines, improve workflow, and meet increasing packaging demands with ease.

The Case Packing Line offered by Jochamp Machinery is a fully customizable and tailored solution for packaging needs. With a focus on meeting customer requirements, Jochamp Machinery provides turnkey solutions, ensuring seamless integration and efficient operation.

The process starts with understanding the customer’s specific needs and site conditions. Jochamp Machinery conducts thorough planning and assessment to determine the most suitable equipment and layout for the packaging line.

Next, Jochamp Machinery matches the appropriate machines and components, ensuring they align perfectly with the customer’s desired output and production goals. This comprehensive approach guarantees that the Case Packing Line is optimized for efficiency and productivity.

Through their expertise and dedication, Jochamp Machinery delivers a complete and efficient packaging line, providing customers with a hassle-free experience and a fully functional packaging solution. With Jochamp Machinery’s turnkey solutions, businesses can focus on their operations, knowing that their packaging needs are in capable hands.

JOCHAMP Case Packer Advantages

Using automatic case packers offers an immense advantage by decreasing labor costs. Packing with prep processes using these automatic machines doesn’t require human labor, which means you can save money, and the employees would be more productive with other tasks.

JOCHAMP manufactures case packer machines with safe and secured switches and components. They are designed with three-level tamper resistance that ensures certain functions. The packer machine doors come with safety sensors to maximize operators’ safety.

We can expect mistakes when we rely on human work, and if that happens, a lot of packaging materials are wasted. So it is a huge advantage to use a case packer to do the processes. They ensure the precise and required amount of packing materials and minimize mistakes.

Utilizing the case packer machines prevent wrong number or unintended item packaging. These machines will accurately pack the right items in every case rapidly. Moreover, they provide extreme versatility, reliable performance, and reduced total price of ownership.

How Does the Case Packer Work?

As the name hints, the case packer place or packs the products into the cases, like cartons, boxes, or bags. After placing, they are wrapped with film to keep the item secure. Knowing their smooth packing process makes them an excellent substitute for employees that manually seals and packs every case.

These high-quality case packer machines work in various ways, depending on their designs. But there are some primary processes they typically do, including:

- Forming items’ group, packed into the case

- Erecting, placing, or opening the case stacked

- Transferring the grouped products to the case.

- If necessary, sometimes they are secured with seals after packing.

Case Packer Categories

JOCHAMP manufactures numerous case packer designs with various packaging functions. Below are only three out of multiple case packer categories that might suit your applications.

- Top Load Case Packer: It is a machine that elevates the packed items through the top opening. The robot is typically used to pick up the products and put them into the case.

- Wrap-Around Case Packer: This machine forms and fills a corrugated shipping case. They are done by wrapping the grouped products and enclosing them with glue. This machine is ideal for wrapping carton-packed products into the shipping cases.

- Side Load Case Packer: The machine that pushes the products from the side for packing. It is suitable for high-speed utilization where products slide into cases easily.

Aside from that, case packer types include tray packer machines, compact, robot case packers, and more. Trust JOCHAMP to customize your case packing machines!

Case Packer Machine for Business

Upgrading your business using automated packing machines is an excellent decision to make. One of the most in-demand is the “case packing machines,” where filming, paddling, loading, and wrapping the products into the bottom, side, or top is processed.

Using them for business may improve your warehouse or distribution center’s productivity, safety, and accuracy. Having them in production or distribution factories provides numerous advantages. It minimizes the business’ bottom line and saves labor and material costs.

You can contact JOCHAMP anytime for more assistance choosing the most suitable case packer machines for your business. We consider your requested specifications during the production.

Why Choose JOCHAMP Case Packer

Today’s competitive industrial environment necessitates higher efficiency, utilization of human resources, and less downtime. Human resources are in short supply because of the economy’s rapid growth. Consequently, JOCHAMP provides the most creative series of case packing equipment suited to various products and packing techniques.

The model’s choices are compatible with various packing techniques with rates ranging from five to fifteen cartoons per minute. The case packer has mild steel construction for cost-effective alternatives, and stainless steel structures meet critical standards and clean, hygienic conditions.

The case packer machine enhances packing efficacy, dependability, and output. Our experts created an efficient and cost-effective packer for the most demanding applications. Please send us an email so we can assist you in selecting the case packer that best meets your demands and business objectives.

JOCHAMP - Your Case Packer Manufacturer in China

Several aspects to consider while purchasing packing machinery include studying machinery types, brands, and manufacturers. Their industrial and general uses, for example, were the same across the board.

- Music, Video, and Software

- Paint or Coating

- Pharmaceutical

- Stationary

- Tobacco

- Food or Beverage

- Garment

- Household Product or Merchandise

- more

All packaged goods benefit from case packaging technology because it serves a vital secondary packaging role.

Case erecting, case packing/filling, and case sealing are the three functions that the JOCHAMP case packer can do. Additional highlights of the packaging machine include the following:

- The case packer simplifies the transfer process. In some cases, changing components and a separate case erector is not quick because of the equipment’s design.

- Case packer stops making changes that cause problems after shift changes. Being electrically prepared also entails installing and operating your case packer system in under an hour.

- A newly designed case packer increases bag speed. The case packer has a novel machine design to pack more than a hundred packages per minute.

- It takes less than half the time to install a case packer. Previously, this would take around seven minutes, but presently it just takes approximately four minutes.

Get in touch with us right now for further queries and information!

Why JOCHAMP Case Packers are Trusted by Thousands of Clients

We offer case packers that offer reliability and other benefits such as:

- Non-stop and continuous motions

- Accurate product placement

- Gentle handling and flexibility

With its versatile design, our case packers offer the following:

- Scalable design

- Ideal for simultaneous handling

- Can pack a different range of products

JOCHAMP manufactures case packers that are equipped with extensive usability such as:

- User-friendly interface

- Easy to operate and convenient to use

- Adjustable packing pattern

Related Products

Case Packer: The Ultimate Guide

There are many types of case packer machines in the market. Consequently, choosing highly efficient case packer requires careful analysis and evaluation of each equipment. So, if you want to learn more about case packing machines, read this guide.

It is a piece of an electromechanical machine designed to set up a tray or wrap-around case and loads items from the top, bottom or side.

The case closes, and it is sealed by tape or glue once the product is loaded.

Technically, this machine packs items into corrugated boxes, be it automatically or semi-automatically, for storage or ultimate shipping.

The essence of a case packer in a business setting is to facilitate faster packing of cases with the items for quicker shipping.

case packer

Hence, it is largely used in manufacturing and large production volume industries to enhance packaging process and efficiency.

In this article, you will learn a wide range of aspects surrounding case packer and case packing in general.

Typically, this equipment is made up of several integrated parts and components that form a single functional unit.

Each part plays a significant role in ensuring it delivers the desired result in the general case packing process.

However, some parts may vary depending on the specific mode of operation the machine uses.

For instance, you will find some parts in an automatic case packing machine that is not in a semi-automatic case packer.

Nevertheless, the notable parts of this machine include the following;

HMI Touchscreen – For displaying graphics and a wide range of functional parameters of the machine for easy selection and monitoring.

Control buttons – They are mainly for starting, stopping and pausing the operation depending on what is required.

Photoelectric eye – It emits a light beam from its in-built light-emitting element to facilitate color marking of the case.

Product conveyor – The essence of this component is to move products to different stations and from completion to assembly awaiting storage or shipment.

Safety interlock guard – It prevents or minimizes hazardous actions by ensuring the equipment is in a safe condition when unsafe manoeuvres arise.

Data printer settle – Prints different information or details on the packing case such as batch number, manufacturing and expiry dates etc.

Forming Systems – These may include a carton forming system such as bag former.

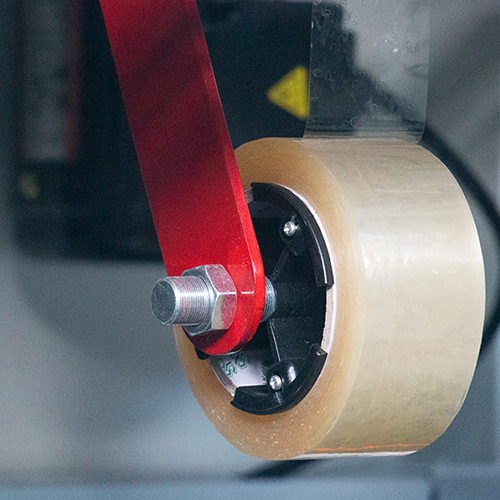

Setting roll film – Designed to deliver film for case sealing.

Electric unit – It contains different electrical constituents designed to supply, transmit and use electric power within the machine.

They include motors, transistors etc.

Loading systems – Most common options include multi-axis robotic systems, two-axis robotic system

Closing systems – Tri-seal, compact right angle, inline, inline top seal, tri-seal

Wheels – Facilitate easy movement of the equipment when used in case packing items in different locations within the larger warehouse.

Case packers are available in a broad range of types, all with unique features and specifications.

Of course, this is integral because it implies you can get the specific one that suits your needs accordingly.

The prominent types of case packers you will find in the market include the following;

Drop Case Packing Machine

It is a type of case packer that packs the product by vertical case packing, often referred to as drop packing.

This case packer variant is suitable primarily for a wide range of rigid containers such as bottles of different shapes such as oval, cylindrical or rectangular.

It presents an efficiency ratio of 99%, factoring in high line speeds.

The design of the case packer allows it to attain maximum reduction of resetting, maintenance and changeover times.

As such, it guarantees highest efficiency to the line.

Its basic working principle involves getting pre-erected cases and items from the filling line.

Then, the equipment splits the products into rows depending on packing pattern and places them in shipping containers by drop.

drop case packer

A major advantage of this machine is that it features a compact design hence convenient to transport and install in various settings.

Besides, it requires little maintenance but guarantees efficient speeds in taping or glueing corrugated cases.

Side Load Case Packing Machine

Also known as an end-load case packer, it is a machine that packs products in a case by forcing them in from the side.

Essentially, the packs attain the stacking unit where every row is stacked into a holding plate unit.

Collation is then pushed into open case, which is opened and held in position by vacuum suction cups and guides while the rear minor flap remains closed.

side load case packer

Case flaps are, in turn, folded and closed before case discharge.

Ordinarily, the side load case packer features an intelligent layout for one side operation and allows for easy changeover.

It features a compact and ergonomic design, and it’s easy to manipulate infeed products depending on required ultimate packing matrix.

Moreover, it offers direct access to the machine at floor level and minimizes product retention zones.

The working principle of side load case packer involves feeding of products by a single-layer simple transfer or by servo-driven elevating or lowering stacker.

Compact layout of this multi-function equipment facilitates easy access and operability.

Tray Case Packing

This case packer variant is designed to solve backbreaking task of loading multiple packs in trays.

It loads pre-formed trays with cases of cans and bottles at different speeds of up to 15 trays per minute.

You may also consider an optional configuration that packs trays with ringed cans.

Some notable features of this equipment include; balcony design, precision in each application and automatic and semi-automatic operations.

tray case packer

Besides, you can adjust it to 11 different configurations, and it offers an easy tool-free changeover.

This machine also has easy case clear-out, which is an imperative feature because it easily releases problem cases to maximize machine uptime.

Horizontal Case Packer

Top Load Case Packing

This equipment loads items through top of an RSC, harness or wraparound style case while offering the best footprint and packaging size range combination.

Simply put, it packs products into an erected, corrugated box via an opening in the top.

Its design features an entirely modular mechanical and control-system architecture.

Hence, it offers the choice of sequential or continuous technology to handle a wide range of product handling systems.

top load case packer

Top load case packer comprises a compact and positive vertical case-forming system featuring several servo-motors.

It seals the top flaps using adhesive tape or glue and guarantees the case squaring.

This machine also has a cantilever structure for walk-in access to the core elements through human interventions.

Ordinarily, it also features a 2-axis pick and place assembly with a gripper pick head or vacuum with quick-change tooling offering precision product handling.

It is flexible and durable since it has quick change-out heads.

Besides, the loading funnel guarantees precise product loading into the case.

One benefit of this equipment is that it offers case forming, loading and sealing operations in one compact unit.

Also, it is fast and can attain high speeds of up to 40 cases per minute.

It is versatile thus can handle a wide range of products such as stand-up pouches, pillow bags, bottles and a wide range of difficult-to-handle items.

You can integrate this unit with an existing case erector or tray former.

Some of its optional support equipment include bar code readers, labellers, a vision camera, and customized infeed conveyors.

Robotic Case Packaging

It involves opening, filling, shipping, palletizing, sealing, coding, and labelling product packaging.

Technically, a robotic case packer offers versatility, accounts for product irregularities, and solves the orientation difficulties easily due to its vision-guided robotics.

The machine is suitable for top load pick and place for different products such as bottles, bricks, jars, pouch bags etc.

For product handling, robotic case packer performs pre-collation, batch forming, product flow management and assortment.

It features lightweight tooling hence provides a significant weight reduction on average in relation to conventional gripping heads due to smart association of composite materials.

A wide range of gripping tooling can be utilized to preserve different products while loading arm selection is optimized to save energy.

The loading arms perform accurate movements to safeguard products irrespective of their contents and features.

It has a modular design that enables it to be scaled depending on desired speed and product contents or weight.

Robotic case packaging comes in handy in guaranteeing product packaging consistently, precisely, and with high quality to enhance product integrity.

Moreover, it speeds up cycle times and enhances productivity in various packaging applications.

The main benefit of robotic case packaging is speed, accuracy and productivity in different material handling operations.

As such, it offers a real and durable impact on overall production process.

Many manufacturers implementing packaging robots are guaranteed boosted throughput since production speed is hardly hindered.

It also streamlines production in the sense that they can lift more products at a time and feature far higher uptimes than manual input.

High Speed Case Packing

This case packer variant is designed to offer ultimate case packaging solutions to a wide range of products in different industries.

It is available in different sizes, which is integral since it broadens your choice options in ensuring you get the most suitable one for your case packaging demands.

The engineering of this machine has been from the ground up to guarantee the highest reliability and efficacy levels.

Besides, it also focuses on providing best quality packaging solutions while delivering exceptional throughput speeds.

high speed case packer

It features a traditional mechanical walking beam that offers a robust and easily maintained transport system.

The film servo system guarantees smooth and faster packaging and accuracy of packing several cases within a minute.

This machine automatically takes corrugate blank and feeds it into the equipment.

What follows is the erection and positioning for loading, after which lower flaps are closed.

The design of this machine features a quiet and low maintenance operation.

Besides, it has a vacuum generator, which opens the cases for relatively high production rates.

High-speed case packer features all-servo motion control with a wide range of case media styles.

It also has multiple closure options with magazine options for durable continuous run times.

This machine also features a recipe-driven interweaving capability within a layer or by layer.

As such, it permits a multitude of load pattern alternatives.

Wrap Around Case Packing Machine

It refers to an innovative intermittent running case packing machine with an output upwards of 30-cycles per minute.

The equipment envelopes a group of products into cardboard or paper packaging.

This equipment forms end of the line packaging styles and can wrap a wide range of products.

As items move along the conveyor belt, the equipment wraps protective packaging around the bundle.

It results in secure, tightly packed, awaiting shipping, thus suitable for plastic containers and bottles.

The stability and security which wrap around case packaging provides keep the products safer and easier for end-users to handle.

wrap around case packer

Furthermore, it guarantees product data recording, line control communication and product traceability throughout the process.

The notable features of this machine include a grouping station for different pack sizes and a folding station designed for multi-layers formats.

It has add-on modules for labeler, metal detection, check weigher and rejection station.

This equipment allows product indexing by side chains, timing screws, smart belts or starwheels.

It offers product protection with layer or partition-board as an option.

Moreover, it features sloping plates instead of product retention zones; thus, products fall directly on the ground at infeed collation and loading stations.

It can carry out loading operations by a “pick and Pack” gripper where speed and smooth handling requirements are of concern.

Nonetheless, this case packaging machine offers a wide range of benefits.

One is that it offers forming, side loading and sealing operations on a single unit for three types of packaging.

Also, it portrays advanced accessibility and ergonomics in addition to its compact and uniform unit design construction.

You can optimize changeover times in this equipment due to the centralized setting points and changeover assistance integration.

As such, the automatic changeover features allow the machine to simplify the process and reduce unnecessary downtime.

Wrap-around case packing machine is ideal for packing relatively rigid products such as cartons into shipping cases.

As the name indicates, this case packer variant features automated functions with little or no human intervention in packaging solutions.

Ideally, it integrates several case packing systems with its case erector and sealer range to pack a wide range of products automatically.

You can modify fully automatic case packer or bespoke to meet the specific desired case packing specifications.

It is built with a compact footprint ideal for tight production workshops and includes full sensing kits to alert the operator when cases or tape are low or empty.

Automatic case packaging machine

The robust construction of the case packer with different components housed in a sturdy chassis ensures less maintenance and minimal servicing.

Ordinarily, it features systems designed for rigorous typical end-of-line packaging needs.

Besides, the design of this machine gives you best value for your investment through optimum productivity with reduced stoppage time.

Essentially, fully automatic case packer is built to operate 24/7 and needs little maintenance but offers extended life expectancy.

Moreover, it offers excellent quality control, high efficiency and flexibility.

Hence, it has systems designed to enhance the loading process of products into cases, thus increasing speed and reducing costs.

It is highly versatile thus allows you to run multiple designs through the same equipment, and it is fundamental since it maximizes efficiency.

Semi-automatic Case Packer

This type of case packer is automated but also has a few of its aspects that require human intervention to accomplish the process.

In other words, most of its operating parameters are automated, but a few are put manually through human labor.

It combines case erecting, hand packing and adhesive or tape sealing into a compact and efficient work cell.

This unit is ergonomically designed and features automatic indexing systems, positioning cases and products for maximum operator safety and comfort.

As such, it minimizes unnecessary repetitive arm and wrist motions.

semi automatic case packer

It also provides ultimate flexibility through on-demand case presentation and variable speed product infeed combined with different operator stations.

Besides, it packs a wide variety of product materials, weights, sizes and shapes into a different range of case sizes rapidly and easily.

The working principle of a semi-automatic case machine is quite straightforward, and it starts by automatically erecting and forming a corrugated tray or case.

It then conveys incoming cartons, pouches, bags, boxes, widgets, or containers to the staging area.

Immediately after the product is staged, the operator conveniently transfers the product from conveyor into the case or tray.

After loading the incoming product based on your pack pattern, the case is then transferred to the sealing station and process repeats.

Next, the top flaps of corrugated case will be folded and glued or taped.

The case is then ready, and finished products inside await shipping to the respective destinations.

This equipment is economical, and since it only consumes a small volume of compressed air and change can be conducted within shortest time.

Bottom Load Case Packaging Machine

It is a compact, all-in-one case machine designed to eliminate need for manual labor entirely from case loading and sealing.

Primarily, it loads products from the bottom while maintaining the vertical orientation of the case or RSC.

This equipment supports the product fully and provides the bottom load design with extra servo technology to offer a small footprint.

Hence, this allows for a simple transition from hand packing to automated case packaging.

The design of this equipment guarantees durability, safety, productivity and efficiency, which are all critical in the case packaging process.

It is flexible and manufactured to meet your specific production demands and can also handle different products while increasing productivity.

This equipment carefully controls product positioning during collation, forming and loading of the cases.

Besides, its operation allows it to transfer case from one station to another smoothly and accurately due to the servo-driven trolley.

It has lower movable elevating guides that guide the products during packing phase, thus a suitable solution for a low product infeed.

Primarily, after picking and erecting case, it gently elevates collated product upwards into the case.

The machine features a loading funnel, ensuring precise product loading into the case.

The operator zones of this equipment are visible and accessible while it gives a moderate speed depending on the set cycles per minute.

Vertical Case Packer

It is a case packer that handles different products gently with great support from its bottom-loading technology.

This machine features new open designers that allow operators increased access to its internal workings.

Of course, this is important because it allows the operators to easily detect and diagnose maintenance requirements faster and efficiently.

Essentially, it features “Pick & Place” monoblock designed to pick an item from the infeed conveyor and insert it into cases by vertical movement.

vertical case packer

This machine offers vertical case packing, which is the most suitable choice for unstable products with higher slipping chances.

Some notable features of this equipment include; a servo-driven pick and place system and a sturdy framing component.

It has easy-to-adjust devices for rapid changeover tool free.

Furthermore, this machine has a digital HMI for setting production variables, parameters and alarm display integrated into machine design.

The case infeed conveyor of this equipment is motorized with a somewhat low friction slat chain conveyor.

Ideally, a vertical case packer is beneficial to a wide range of food packing applications, especially those with lay-flat or rectangular cartons.

It is also ideal for applications with gable-top cartons, industrial cans, and gallon jugs among others.

Mechanical Case Packer

This is a versatile and robust machine used in a wide range of case packing applications.

It is designed for simplicity, making it quite easy to use with a high automation level.

Access to this equipment is quite easy, which is imperative for cleaning and maintenance operations.

Also, it features a simple operator interface making it easy for efficient control and monitoring of different operating variables.

mechanical case packer

This equipment carries out various operations in automatic mode, including product collection and preparation, product placement inside, waiting for cartons and filling cartons discharged from machine.

The case erection section of this machine has a mechanically driven positive unfolding unit and device for a squaring case.

It has compact dimensions, which is fundamental and convenient for operating.

The notable advantages of using this machine for packaging solutions include the following;

- Reduces operating cost

Since this machine is automated, it means you will eliminate the need for human labor in the case packing process.

This is beneficial because it makes the entire process cost-effective and increases your business’ profitability for growth and sustainability.

- Reduces wastage

Case packaging machine eliminates material wastage since it uses the exact amount of material needed each time.

- Saves time

Automation operation of this machine makes the process faster.

You can also set it to match your time requirements, and this is advantageous since it enhances convenience and reliability.

- Enhances safety

Manual case packing exposes the operators and employees to different hazards, which can be costly in the long run.

However, using this machine ensures the operator is protected from inevitable disasters likely to arise during case packaging process.

- Speedy Return on Investment

This machine guarantees faster ROI from increased output, performance, reliability and efficiency.

Therefore, you can be certain of achieving better returns from your investment when using this case packaging machine.

- Easy to Maintain

Most case packaging machines feature simple design constructions making them relatively user friendly and easy to maintain.

Hence, you are certain of getting the best service from using this machine in offering packaging solutions.

Ordinarily, case packing has been part of packaging industry for quite a long time.

Of course, it was traditionally used to pack food and beverage products.

However, several diverse modern industries are using and benefiting from this machine considerably.

Notably, though, different case packing machines benefit each industry.

For instance, horizontal or vertical case packers are used in different industries from wrap-around case packing systems.

In essence, it implies each machine can perform multiple user-friendly operations to improve cost-effective production in different industries.

Some common industries that use case packer include the following;

- Automotive industry

- Furniture and hardware

- Pharmaceutical

- Clothing and textiles

- Electronics

- Children games and toys

When buying this machine, it is always imperative to consider different elements to ensure you attain the best results possible.

Ideally, this equipment comes in several variants suited for different applications.

Of course, most of them are versatile enough to use across several sectors while maintaining a high customizability degree.

Some businesses also install auxiliary components for increased efficiency based on specific business needs.

Nevertheless, when choosing this machine, the first thing to consider is the production demands.

Ideally, a fully automatic case packer can be suitable for considerable production amounts.

However, some businesses realize that their product demand is merely inadequate to recover the investment faster.

For instance, a semi-automated unit would be ideal for production that needs about 10 units per minute.

In a nutshell, understanding the business production needs should be a fundamental consideration before investing in this unit.

You should also consider the cost of purchasing this equipment.

Of course, this would vary depending on several factors like the brand, design construction, material, size, the software etc.

Even so, you should ensure the ideal choice fits within your budget.

And importantly, check the usability and user-friendliness of this equipment when choosing one.

The essence of using this machine is to attain efficiency and performance in providing case packaging solutions.

Hence, it would be ideal to go for a simplified unit that can be operated by different people quite easily.

For all your case packing machines, contact us now.