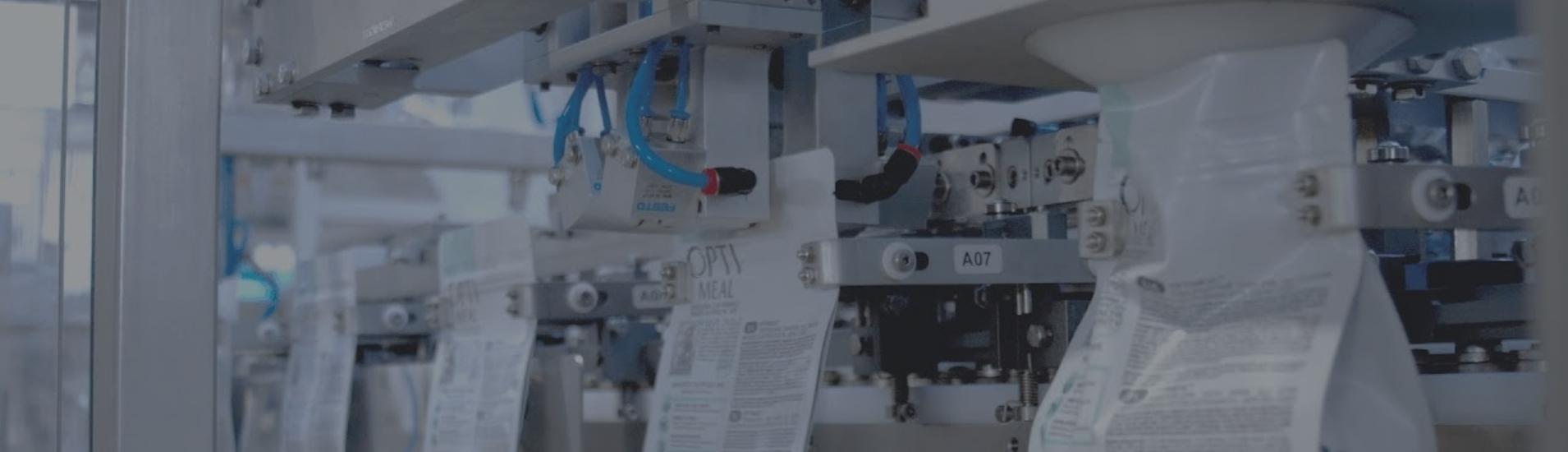

Form Fill Seal Machine Manufacturer in China

JOCHAMP offers automatic form fill seal machines for puffed food, pet food, frozen food, shrimp rolls, candy and more. We provide high-quality, reliable machines for your packaging needs.

- cGMP, ISO9001, SGS and CE certified

- Hot and cold double sealing system

- low noise operation

- Compact design with small footprint

JOCHAMP Form Fill Seal Machine

Form fill seal machines are typically baggers used to pack goods into bags. These machines allow bags to be formed from rolls. Afterwards, the product is bagged and sealed ready for shipment.

The JOCHAMP Form Fill Sealer is equipped with a secondary unfolding system and auxiliary bag opening. It also has an incomplete detection system to unfold and open bags to reduce waste. At JOCHAMP, our goal is to provide high quality machines for long life.

JOCHAMP is your trusted one-stop form filling machine supplier in China. We provide lifetime after-sales service and one-year quality assurance.

contact us!

Why JOCHAMP Form Fill Seal Machine

Our form fill seal machines is compatible with all types of bags, such as wide top bag, flat bag, block-bottom bag, zip bag, hem seal, etc.

JOCHAMP supplies hygienic design of form fill seal machine for packaging of meat, pasty, cheese, deep-frozen, powdery, liquid, and fresh products.

The machine can guarantee high performance in precision tubular bag form and pourable products or bulk material packaging.

We design a form fill seal machines to your specific needs and packaging requirements. Our machine features uncompromising quality and intelligent design.

Suitable Application

The form fill seal machine is widely used in almost all industries. They are economical, fast packaging solutions for the following applications:

- Rice Package

- Sugar Package

- Forage Package

- Nut Package

- Candy Package

- Coffee Bean Package

JOCHAMP works with famous brands in the world, including Siemens, Mitsubishi, SICK, Schneider, and international electric appliances brands.

Characteristics

JOCHAMP provides a high-quality form fill seal machine with excellent characteristics to match your packaging needs. Below are the following characteristics of the machines:

- Full-automatic weight, simple, and efficient to work

- Excellent mechanical components wear out loss elimination

- Easy to install

- Optional heat transfer printer, anti-static device, and automatic film correction motor

- The advanced operating system for quick use and reprogrammable

Form Fill Seal Machine Capability

JOCHAMP form fill seal machine enables a diverse range of food-related product packaging. It includes but is not limited to frozen food and pet food. Our machines are easy to maintain and operate. Also, our form fills seal machine can reduce material and labor costs.

- With printers that can directly print onto the package

- Compatible with different printer brands

- Stores label programs

- Edge guide for waste reduction by adjusting and monitoring the film edge

More About JOCHAMP Form Fill Seal Machine

JOCHAMP form fills seal machines are available in a diverse range of ways and sizes with numerous features. These machines can be used with dry goods and liquids in a multitude of settings.

At JOCHAMP, you can get form fill seal machines that can operate at a very high speed. These machines provide up to 200 bags system speeds every minute on duplex lines. If you rely on our machines, you can save packaging costs since they can form bags from roll stock.

Being a leading provider of packaging solutions, we can provide standard packaging inventory and fast delivery time typically 15 days. You can always trust JOCHAMP since we comply with strict quality control from raw materials to shipping.

JOCHAMP Form Fill Seal Machine

- Flat Bag

- Wide Top Bag

- Zip Bag

- Block-Bottom Bag

- Gusset Bag

- Quattro Bag

- Hem Seal

- Punch-Hole Bag

- Chain Bags

- Three-Sided Seal Bag

- Low Noise Operation

- The fully enclosed operation, clean and safe

- High-strength structure

- Automatic feeding mechanisms like an elevator, weighing machine, etc.

- Unique sealing system

- Circulating lubrication system

- Double sealing system

- Automatic adjust fixture functions

- Powerful control system

- Friendly docking secondary packaging system

Custom Form Fill Seal Machine Based on Your Applications

It can guarantee affordability and high performance. These machines are equipped with many features like a servo-driven seal mechanism that produce stable seal strength.

These machines can be used to accommodate Quattro packs, three-sided seal bags, and handle flat-bag. It also accommodates different product shapes.

These machines provide exceptional sealing and film-feeding performance. When the machine operates, the operator can monitor pressure, temperature, and closure location.

These machines can fill different granular products quickly, including ground coffee and beans. Different product types in powder form like flour, instant soups, spices, and chemical powder.

Related Product

Form Fill Seal Machine: The Ultimate Guide

Form fill seal machines play an integral role in modern packaging industry.

A reason this guide will help you find the best and effective form fill seal machines.

Whether you want to know the features, working principle, benefits or classification criteria – read this guide.

This is a machine that is self-contained and can form the container, package and seal in an automated system.

It functions by getting a V-fold or flat roll material, forming it into a container or bag, filling the products and sealing the bag.

form fill seal machine

Film Pulling System

The system here is made up of a tensioner and an unwinding roller.

A film of roll stock is rolled on the back of the unwinding roller.

This film is laminated, particularly for vertical form fill seal machine, with PET or PE and aluminium foil on the inside.

The film on the roller is moved or controlled by servo motors within the system.

Printer

The printer is made with a photo-eye that can detect the arrival of the film at this station.

Again, the printer then automatically prints date and the batch code on the film.

Pouch Former

This is the part that makes the bags that will be used for packing the products.

It can form different sizes and designs depending on the size of the bag former.

Filling And Sealing The Bags

The bags are filled with products at this station and after filling, the sealing takes place.

Sealing can be done through either vertical or horizontal sealing jaws.

Pouch Cut

The overlaps or hanging materials are cut off at this stage and this is especially available for vertical form fill seal machines.

Control Cabinet

The control cabinet is attached at the side of the vertical form fill seal machine.

All electrical components emerge from this cabinet.

This is the part that is used for controlling all the processes within this system.

Form fill seal machine works in three stages;

Bag Forming

The film is fed to the forming tube which has the ability to make bags and seal them at the bottom.

Again, the vertical seam ensures that the edges of the film are also sealed together.

Sealing can be done through a lap seal or a fin seal.

There is also a possibility of a film being installed with a zipper before being loaded to the film roller.

Filling The Product

The system is automated such that immediately the bag is formed and sealed, the products are packed into it.

Besides, the stage is accomplished through a filling machine.

Sealing

The bag that has been filled is now sealed through an automated system.

Where the top of the initial bag gets to be the bottom of the next bag and the process is continuous.

After this stage, the bags are ready for distribution.

The packing rate for these machines is very high and they provide consistent results.

Bags made through these machines are very cheap reducing the general cost of the whole operation.

There is an increase in the rate of production hence reduction in the number of shifts to be run.

The cleaning and maintenance processes are easy to perform within the production shifts.

Printing of dates and batch codes within the machine system, makes work easier, accurate and efficient.

Machines are made up of very few moving parts which reduces tear and wear caused by friction.

These machines are automated and can perform all the work without the need for human labour.

There are two main categories based on the working principles of the form fill seal machines as discussed below.

Vertical Form Fill Seal Machine

The bags are formed through an automatic assembly line packaging system.

This type of machine can be used to fill products such as liquids, grains, powders and other bulk goods.

vertical form fill seal machine

Horizontal Form Fill Seal Machines

This type of form fill seal machine is preferred for packaging of solid products.

Additionally, the machine is designed with two sealing sections and other two moulding sections.

The doubled sections are meant to eliminate downtimes experienced during changeovers.

horizontal form fill seal machine

Moreover, the form fill seal machines can also be grouped into different types depending on the types of items they pack.

Bag Form Fill Seal Machine

This machine uses a flexible packaging film to form a bag which can be used for packing food products or confectionery.

bag form fill seal machine

Sachet Form Fill Seal Machine

Normally, this machine pack items into a four-sided sealed sachet and it also aids in forming of the sachet.

sachet form fill seal machine

Tubular Form Fill Seal Machine

The machine forms bags from a material that is tubular in shape which is formed and filled within the machine.

tubular form fill seal machine

Blow Form Fill Seal Machine

This machine is designed with the ability to melt plastic granules, extrude and blow to form hollow plastic bags.

blow form fill seal machine

Additionally bags are filled and sealed within the machine.

Thermoform Fill Seal Machine

A thermoformable material is heated and using pressure or vacuum, it is formed into bags which are filled, sealed and cut into smaller sizes.

thermoform fill seal machine

Stick Pack Form seal Fill Machine

It forms a three-sided sachet which is filled and sealed within the machine.

Design

The vertical form fill seal machine is designed to form a circular section tube from the material film provided.

On the other hand, horizontal form fill seal machine, forms a rectangular section tube from the film material.

vertical fill seal machine

Benefits

Vertical from fill seal machine is suitable for packing loose and free flowing items such as liquids, sugar and oils.

While horizontal form fil seal machine is suitable for packing single solid items like soaps, bakery products and toys.

Disadvantages

Vertical packing form fill seal packing machine is limited to products that are loose and can flow freely.

The horizontal form fill seal machine also cannot be used for packing products in the form of liquid.

Working Principle

Vertical form fill seal machines use a roll of film, forming it into a bag, filling the bag and sealing it in a vertical direction.

The horizontal form fill seal machine on the other hand, packs items horizontally into the bags.

horizontal form fill machine

Food & Beverages Industry

Here, the form fill seal machine can be used in this industry for packing food products cakes and beverages like soft drinks.

Food and beverage industry can use it because it is hygienic, has extended shelf life and it fully aseptic.

Electronics Industry

This machine is useful in this industry for packing electronics products like cell phones, tablets, computers, and many more.

Chemicals and Pharmaceuticals Industry

Here, the products from this industry like acid, alkaline solutions, drugs in the form syrup, capsules or tablets.

They are packed into bags or sachet or cartons through the form fill seal machines.

Consumer Goods Industry

In the consumer goods industry, the from fill seal machine is used to form bags, fill them with products such as toys.

The machine also seals the bags after filling them.

The machine has endless applications since any product can be packed into bags.

Below are some of the products that can be packed using the form fill seal machine.

Products in the form of grains like groundnuts, rice, pulses, beans green grams and many others.

Another set of products are granules such as fertilizers, detergents and many others.

Additionally, snacks like chips, dry fruits and namkeen are also packed through form fill seal machine.

Also, products in powder form like spice powders, milk powder and ground coffee are also packed through the machine.

Liquid products like water, milk, juices or liquor are also packed by the form fill seal machine.

These features will determine the type of form fill seal machine you choose for your operations.

Machine Frame Construction

The stability and support for the machine during operation will be determined by the frame construction.

Additionally, the choice should be robust and strong in order to offer the best results.

It means the machine frame should be heavy enough and welded frames are a better choice also for ease of maintenance.

Film Tracking

The form fill seal machine should feature an automatic film tracking to avoid having to track the film manually.

Manual tracking may lead to faulty results, and it is also time consuming and labour intensive.

Then, machine is therefore equipped with a sensor meant to detect the film edge.

Then it will shift the film automatically to regain the centre.

Machine Noise Level

Noise level of the machine will determine the amount of wear and tear in the machine components.

More noise indicates a lot of friction taking place within the machine parts and this means frequent replacement of worn-out parts.

The modern form fill seal machines are made in a way to minimize the kind of friction that produce too much noise.

Before you purchase a form fill seal machine, test it or get a video and gauge the noise level.

Ease of Change Over

Here, the modern form fill seal machine are designed with an easy and also too free change over procedure.

The procedure takes less than 45 minutes to be complete and ready for another session of making new bags.

However, rotary premade bagging machines takes less than 5 minutes to change over.

Also, the toolless and easy change over procedure reduces the downtime of the machine hence high output.

Machine Controls

Here, the form fill seal machine is equipped with a brain like control system.

The operator only has to feed in instructions through a monitor and the machine does the rest.

It comes with a programable logic controller to control the whole operation and a human machine interface.

Besides, the human machine interface allows observation, adjustments, and displays feedback.

Sealing Jaws

Form fill seal machines are designed with heat sealing jaws to aid in the sealing of the bags.

These sealing jaws work in pairs to seal bags with a defined combination of pressure and heat.

In order to ensure consistency in the sealed bags, the jaws should be fogged from the same piece of material.

Servo Driven Mechanisms

The form fill seal machines made with servo driven mechanisms are much more superior and offer precise control.

Each form fill seal machine has its own set of instructions on the cleaning procedure as provided by the manufacturer.

Before anything is done on the machine, the power should be turned off and disconnected.

The cleaning process should be carried out before every packaging session.

Use an air nozzle to blow off any residue left within the machine; the nozzle should have low pressure.

Remove the tube and clean it and do not clean it while it is still attached to the machine.

Moreover, the film feed belts should be replaced and the slide mechanisms lubricated.

The heat-sealing jaws are cleaned by first removing the knife and then cleaning both sides of the jaws with cloth and water.

Stainless steel guards are cleaned using hot soapy water.

Clean the film rollers by wiping and drying them.

Connecting rods, air cylinders and guide bars are wiped using a piece of cloth and water.

Now fit back the forming tube followed by loading the film roll.

Follow the process of threading the film roll and rethread it.

Use an FDA approved mineral oil in wiping down the slides and the guides.

Some of the common issues may include:

When Machine Does Not Power Up

It could be because the main switch is off or there is an issue with the incoming power.

Machine Does Not Reset

It maybe because there is low air pressure or guard doors are opened or faulty wiring or safety circuit has not been reset.

Low Air Pressure

This can happen if the machine or safety circuit has not reset.

It can also happen if the incoming air pressure is low.

If the air pressure during the run mode is low then the machine can experience low air pressure.

Temperature of The Jaw is Not Within Range

This could happen if the sealing jaws are not warmed up or a faulty PLC, temperature sensor, heater or fuses.

Consider checking all the wiring connections within the system.

Sealing Jaws Not Working

This could be caused by the jaws assembly not working freely or there is low air pressure or there is faulty air cylinder.

Other causes could be a faulty piston position sensor, air distribution or an e-stop.

Printer Not Working

Could be because printer was not set ready to work or the printer has been switched off or faulty printer.

Another cause could be if the ribbon is broken or printer is damaged.

Film Cannot Track Properly

Confirm if the film carried is able to move properly.

This can be caused when the film webbing is wrongly done, or rollers and dancers’ levels are similar.

It can also happen if the break roller is dirty, or if the pull belts are faulty or if the auto film tracking has failed.

Jaw jam

This can be caused by low air pressure in the jaw or if the jaw is not set up properly.

Related Resources:

Automatic Shrink Wrapping Machine

For all your form fill seal machines, contact us now.