Carton Box Packing Machine Supplier in China

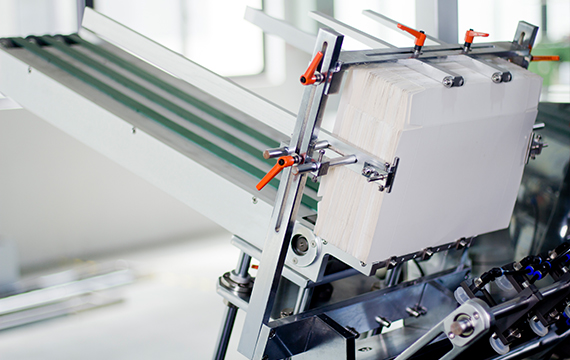

Jochamp supplies a complete variety of carton box packing machines. These machine solutions are precisely engineered for the demands of today’s packaging environment.

- Custom-engineered to your specific necessities

- Ideal for packing bottles, cosmetic items, etc into cartons

- Operates effectively, simple, and safely

- All machines meet ISO, SGS, and CE standards

JOCHAMP Carton Box Packing Machine

Carton box packing machine is an appropriate machine for packing various products (ex. soap, cosmetic products, bottles, sachet items, medicines, and more). These are the most demanded machines for the packaging needs of different industries. It is required for the food & beverage industry, pharmaceutical, industrial supply & logistics, and so on.

Choose Jochamp to supply your certain carton box packing machine requirements. We provide the most quality, multi-purpose machine solutions for your packaging needs. All are equipped with automated sensors and safety devices to guarantee effective machine operations.

Please send us your inquiries!

Types of Carton Box Packing Machine

The Cartoning Machine, a versatile and indispensable packaging solution, automates the process of loading products into cartons. Its advanced technology ensures precise and high-speed operations, enhancing productivity and reducing labor costs. With customizable features, it caters to various industries, from food and beverages to pharmaceuticals and cosmetics. By seamlessly integrating with existing production lines, it optimizes workflow and saves valuable floor space. From small cartons to large, this cutting-edge machine adapts effortlessly, empowering businesses to meet growing market demands while maintaining quality and consistency in their packaging processes.

The Case Packer, a revolutionary packaging marvel, efficiently loads multiple products into large cartons. Its automated system ensures seamless and precise packing, maximizing productivity and minimizing downtime. With adaptable configurations, it caters to diverse industries, including food, beverages, pharmaceuticals, and more. Customizable to fit specific packaging needs, it optimizes space and enhances operational efficiency. The Case Packer’s versatility and reliability make it an essential asset, streamlining production lines and delivering impeccable packaging solutions. From small cartons to complex setups, this cutting-edge machine empowers businesses to meet customer demands with unparalleled convenience and quality.

The Case Sealer, an innovative packaging solution, securely seals cartons with precision and speed. Its automated technology ensures consistent and reliable sealing, reducing labor costs and minimizing errors. Compatible with various carton sizes and types, it accommodates diverse industries, including food, electronics, and e-commerce. Easy-to-adjust settings make it versatile and adaptable, streamlining packaging processes and increasing productivity. With a compact design, it optimizes space and seamlessly integrates into existing production lines. The Case Sealer’s efficiency and durability make it an essential asset for businesses seeking reliable and efficient carton sealing, ensuring products reach customers in pristine condition.

The Case Erector, a cutting-edge packaging equipment, swiftly assembles cartons with precision and efficiency. Its automated system ensures smooth and accurate carton erection, saving valuable time and labor costs. Compatible with various carton sizes and styles, it caters to diverse industries, including food, beverages, and consumer goods. Customizable settings allow for seamless integration into existing packaging lines, optimizing productivity and workflow. With a user-friendly interface, it simplifies operations and reduces downtime. The Case Erector’s reliability and versatility make it an indispensable asset, enhancing packaging processes and ensuring products are prepared for subsequent filling and sealing stages flawlessly.

The Tray Forming Machine, an advanced packaging solution, rapidly constructs trays with precision and consistency. Its automated system ensures efficient tray formation, reducing manual labor and enhancing productivity. With versatility to handle various tray sizes and designs, it caters to diverse industries, including food, electronics, and medical products. The machine’s adjustable settings allow for easy customization and seamless integration into existing production lines, optimizing workflow and reducing downtime. User-friendly controls simplify operations, making it an essential asset for streamlining packaging processes. The Tray Forming Machine’s reliability and speed elevate packaging efficiency, ensuring products are securely and attractively presented in trays ready for distribution.

The Case Packing Line is a comprehensive and efficient packaging solution that seamlessly integrates multiple machines to facilitate the entire packing process. It includes a series of automated equipment, such as case erectors, product loaders, case sealers, and palletizers, working in harmony to pack products into cartons or cases, seal them securely, and prepare them for shipping or storage.

The Case Packing Line is highly customizable to meet the specific needs of different industries and products. It optimizes packaging efficiency, minimizes manual intervention, and increases overall productivity. With its reliable performance and streamlined workflow, the Case Packing Line is an essential investment for businesses looking to enhance their packaging operations and meet customer demands with precision and speed.

Carton Box Packing Machine Benefits

Unlike other brands’ packaging solutions, Jochamp’s custom-built carton box packing machines are more efficient.

These custom-built machines include a labeling process on the individual box. You can print your label there, effective for brand advertising.

Using carton boxes than plastic can aids in reducing artificial waste and is not harmful to the environment. 100% Safe to use.

Our carton box packing machines offer fast-speed operations. Therefore, they can help meet your packaging deadline.

Different Types We Offer

Horizontal Cartoning Machine – This is a horizontal type of cartooning equipment. It is fully automated and runs in irregular movement. Used mainly for packing bottles, blisters, pouch products, and so on. These machines are also the first choice in the food industry, cosmetics, and pharmaceutical.

High-Speed Cartoning Machine – This series is perfect for packers that require a huge capacity for packing products. It is mostly associated with the blister packaging machine. These are great for cartooning bottles, hoses, and so on.

Vertical Cartoning Machine – It is one type of small cartooning machine that can conserve more space. These machines can be used for cardboard case packaging of sachet items, trays, glass bottles, tubes, etc.

Industries We Target

Our packaging machines are highly preferred in many industries due to their durability, smooth performance, and excellent qualities. Mostly targeted industries include:

- Plastic fabrication

- Sanitary ware

- Lighting industry

- Furniture industry

- Hardware screws

- Textiles

- E-commerce

- Food & Beverage Industry

- Pharmaceutical, etc

JOCHAMP Services

- One-on-one customer support, engineering solutions, and a free sample

- Create plans depending on the materials and necessitates, and identify relevant automatic packaging equipment and models.

- Coding, labeling and packaging, punching, cursor placement, and other development features can be added.

- Non-standard models can also be configured to suit specific needs with the help of an experienced R&D team.

- One-on-one service is provided by skilled professionals and after-sales experts.

Jochamp – Reliable Carton Box Packing Machine Supplier

As one of the reliable manufacturers and distributors in China, we cordially invite you to order high-quality carton box packing machines from our manufacturing site. We guarantee a wonderful system and reasonable price offers.

For more than 15 years in the business world, we have built trust from many clients worldwide. Once you order from us, our team thoroughly investigated your requirements and will thoroughly explain our services and solutions to you so that you fully realize our facility. Before shipment, we can also work with your collaborators to perform factory acceptance testing, or we can perform acceptance testing via live demo or teleconference.

If you have questions, please contact us directly! We provide 24-hour online technical assistance.

JOCHAMP Carton Box Packing Machine

Jochamp offers carton box packing machines along with multiple features, such as:

- Internationally recognized brands of electrical parts such as PLC touch screens, frequency rectifiers, and so on.

- Use a human-machine interface.

- Composed of a device that automatically displayed problems, speed, and delivers superior counts.

- Detection and dismissal device for missing items or leaflets.

- Stable quality, simple operation.

The custom-engineered carton box packing machines provide numerous advantages for the needs of multiple packaging landscapes. Some of its advantages include:

- Highly efficient, productive, and reliable packing machine

- Easy operation – no special training

- Solid machine structure

- Strong stainless steel designs

- Wide variety of formats, quick transition period

- Consistent production, even with a wide range of carton attributes

- Conceptual design versatility for a precision production

Custom Carton Box Packing Machine for Different Industry

The carton box packing machine is mainly required in the food industry. This is the best machine solution to pack frozen, dry food, baked, or fresh food. These machines perform excellently, cost-effective, fast, and efficient machines.

Cartoning is the best way to pack furniture products. From there on, packers mostly prefer carton box packing machines. All types ensures productivity, efficiency, and smooth packing performance.

In the pharmaceutical field, the carton box packing machine is used for packing medicines, tablets, and further pharmaceutical products into carton boxes. All the machines are efficient, ensure smooth performance and great quality.

The carton box packing machine used in the e-commerce industry is made from reliable, strong stainless steel construction. It packs a wide variety of e-commerce items safely and seals the cardboard boxes with tape. They are an excellent choice for your packaging requirements and businesses.

Related Product

Carton Box Packing Machine: The Complete Guide

Before choosing carton box packaging machine, you should know application, benefits, parts, working principle and classification, just to mention a few.

This guide takes you through all information you need about Cartoning machine.

A carton box packing machine packs products in cartons and seals the cartons.

Carton packaging has at least two main processes, packaging, and sealing of the coproducts in a carton.

Initially, the carton box packing machine erects a blank (flat carton) into a desirable shape and fills it with products.

carton box packing machine

The carton filling machine then flips and folds the carton flaps to close the carton and seal it.

You can use a carton packing machine in many different industries to pack extremely diverse product lines.

The following depicts the practical use of carton packing machines in diverse industries.

Pharmaceuticals And Cosmetics

You can pack your products, including but not limited to capsules, blisters, vials, sachets, bottles, etc, using a carton packing machine.

Food And Beverage

The design of your carton packing machine for use in food packaging has to accommodate the high sanitary, presentability, and quality standards required of the industry.

The carton packages for use in this industry must be of high integrity.

Your carton packing machine will come in handy in packing commodities such as pastries, biscuits, cereals, confectionaries, grains, and fast foods.

You can also use these machines to package bottles of wines, beer, and spirits. You can also use carton packing machines for non-carbonated beverages.

Consumer Products

You can package consumer products such as soaps, masks, toothpaste, paper towels mosquito nets, pads, etc. using either a horizontal or vertical carton packaging machine.

Electrical And Hardware Appliances

A vertical carton packing machine is more suitable for packing products such as chargers, sockets, bulbs, bearings, etc. which fall under this category.

Entertainment And Stationaries

You can use your cartooning machines to pack assorted goods including toys, staplers, playing cards, etc.

You can also use a carton packing machine in the textile, chemical, auto parts, and sports industries.

Carton packing machines have helped many industries and manufacturers to revolutionize their production processes.

The following are some of the benefits of carton packing machines.

Superior Product Protection

Automated packaging of products in cartons reduces risks of accidents in the workplace and product breakage thus also ensuring compact product integrity.

cartonor box packing machine

You can optimize the insertion of products into the carton using a carton packaging machine, ensuring their protection for long-distance shipment.

Fast Packaging

Compared to manual product packaging, the machine ensures optimal product packaging in the shortest time.

An automatic, non-intermittent carton packing machine will yield optimal results for your high demanding operations.

This machine guarantees high throughput production for long production runs without a stoppage in the course of production.

Unlike human labor, a carton packing machine does not fatigue thus ensuring faster and more efficient product packaging along with the line production.

Tamper-proof System

A carton packing machine has a unique and consistent carton sealing technique that cannot be achieved through manual human sealing.

You can easily distinguish the integrity of a carton sealed by a packaging machine and one sealed by a human being.

Should there occur any interference, there will be a distinct visual difference in a sealed carton indicative of consignment tampering.

This bolsters consumer confidence in the originality of your product’s brand.

Diversification In Production

Carton packing machines are highly adaptable to production requirements.

Some carton packing machine offers superior design flexibilities making it possible to pack multiple product lines in a single carton.

You can optimize your packaging system to facilitate dual or bunch product packaging.

This is critical for applications that require fast commodity upgrades to maintain profitable product marketing without incurring extra costs.

A carton packing machine is made of many different parts, by land large including mechanical, pneumatic, and mechanical parts.

These parts are further subdivided into tens and hundreds of smaller parts.

These parts include:

Control Panel

The control panel offers a design configuration for feeding in and monitoring carton packaging tasks.

You can specify the whole carton packaging process to your specific production needs using this component.

It constitutes the programmable logic controller (PLC) which has been integrated into a human-machine interface (HMI) and frequency converters.

Consequently, these three units will enable you to feed instructions into or invoke them from the carton packaging process.

The panel can also allow you to tweak packaging parameters to the needs of your production and send warning signals in case of faulty operations or breakdown.

Gear Systems And Electric Panel

The gear system, an electric motor, transforms the electric energy into the mechanical energy necessary for the operationalization of the machine.

The mechanical force produced by the electric motor facilitates the running of the conveyors, carton pressing, and transit along the rollers.

On the other hand, the electric panel contains the mains to the whole machine and provides energy to run the pneumatic system.

Lubrication System

A carton packaging machine has an automatic parts lubrication system that protects its gears, bearing, and belts from rust and subsequent failure.

You have to replenish a high-quality lubricating media into the system during maintenance to avoid machine breakdown and downtime in the course of operations.

Pneumatic System And Carton Pack Tooling

This system constitutes the carton storeroom where blanks are stored and the vacuum suction system which erects blanks for further carton packaging operations.

The carton storeroom has mobile mid-plates attached to the back and front sections. The mid-plate will shift to ensure the carton parameters adjust accordingly.

Printer

A carton packaging machine also contains an add-on component, the ink-jet printer, which is critical in writing necessary wordings in the carton for identification and branding.

Safety System

A carton packaging machine must have a safety button that is strategically placed in an easy-to-access part of the machine.

The safety button cuts off the power supply to your carton packaging machine, causing it to stop operations in case of an emergency.

The area of operation must ensure the operator’s optimal safety.

Further, proper grounding and earthing of your machine are also vital in minimizing shock cases in the course of operation.

Locomotive Components

The locomotive components including guide rails, conveyors, carton chute, and rollers are also vital parts of the carton packing machine.

They facilitate the movements of the carton along with the packaging system.

These parts are interlinked to facilitate a smooth flow of cartons from one section to the other and are all controlled by the HMI in the control panel.

parts of a cartoning machine

When you turn on the carton box parking machine and set the desired parameters in the control panel, the push plate opens up the blank which is already positioned in the rail.

The vacuum suction suck on the front and rear parts of the carton.

It erects it at 90 degrees before reaching the loading bay where goods are gently loaded into the carton.

The carton is then conveyed to the folding area where the carton flaps are concurrently folded by the cam which is powered by the push plate motors.

After the carton flaps have been folded, the carton tongues are sealed by the front covers and then moved to the next section that secures the lock by bending the lid.

Also, the final sealing involving the application of adhesives for closure of all cartons ends is then performed for full closure.

Additionally, the carton packing machine then scrutinizes the integrity of the sealed cartons and forwards the non-damaged cartons to the carton chutes.

There are two main types of carton packaging machines, a horizontal carton box packing machine, and a vertical carton box packing machine.

Vertical Carton Box Packing Machine

This type of packing machine takes in cartons from the in-feed system in a vertical orientation, mostly from the top of the machine.

You can use this type of packaging machine for a wide range of products.

However, these machines are more suitable for supplying products whose prices are dependent on weight or volume and hence must be supplied by gravity.

vertical carton box packing machine

You can also use this kind of carton packaging machine for products that are suitably handled in vials or bottles.

The design of a vertical carton packaging machine offers a compact dimensional flexibility which widens its scope of use and range of application.

Compared to its counterpart, a vertical carton packaging machine has a faster product in-feeding system and a lower product damage rate.

Horizontal Carton Packaging Machine

Horizontal carton packaging machines accept and pack products into the cartons from the side.

These carton packaging machines are ideal for use in high-speed, high-throughput applications because they can operate continuously.

This type of carton packing machine also has an intermittent option/model.

Besides, the products must have a very stable base for them to be packed using a horizontal packaging machine.

As such, this carton packaging machine is frequently used in packaging food products such as cereals, pizzas, coffee, etc.

Horizontal carton packing machine

There are both automatic carton packaging machines and manual carton packaging machines. Both types offer advanced flexibility in carton sealing and conveyance.

There are automatic and manual variants of this type of packaging machine.

Remember, the design of their conveyor networks and carton sealing techniques should offer more flexibility, either through accessories such as flap insertion or hot melt glue.

The selection process of a carton packing machine is highly dependent on your packaging requirements and has to be made to your business model.

Again, the following factors outline the basic processes involved in the selection of a carton packing machine.

Project Budget

Your monetary allocation for the acquisition of a packing machine will considerably influence your selection process.

Though this needs a one-time justification, the process should ensure that the machine yields optimal returns to the investment cost in the long run.

The cost of your machine will depend on the level of machine automation, safety measures in place, the type of product being packaged, and the production capacity of the packaging machine.

When budgeting for a carton packaging machine, the cost of acquisition and other engineering procedures involved with operation should be justifiable to the current line labor cost.

Type Of Product

The type of your product is a critical determinant of the type and model of carton packing machine you settle for your packaging needs.

Granular products such as detergent powders and products constituting loose pieces are best packaged using a vertical packing machine.

These products require direct carton packing and would be less suitable for use alongside horizontal carton packing machines.

On the other hand, some products are best suited for side packing and are therefore best packed with a horizontal carton packing machine.

Considering the type of product as the first step helps you conduct a focused search, saving you a lot of time that you would have otherwise wasted in looking up irrelevant packaging machinery.

Packaging Speed

The speed of your carton packaging machine is equally as critical and has a direct influence on the efficiency of your line packaging.

Packaging speed is dependent on whether you will be using the carton packer online or offline.

For either of the two, take into account the potential for a future increase in production and packaging needs.

Company Needs And Capabilities

The technical know-how capabilities of your company’s workforce will also influence the model and type of carton packaging machine you select.

Settle for a machine that is simple to use if your company’s technical workforce is not experienced in using a high content carton packing machine.

Other factors such as time to delivery, part availability, time to changeover, and ease of maintenance are also critical in selecting a carton packing machine.

Suppliers

Selecting a supplier is another daunting task and is probably the last category you will consider when purchasing a carton packing machine.

The final supplier you settle for must bring on board attributes that give you a competitive advantage in product packaging.

You could consider proximity to plant, experience with your types of products, ease, and flexibility of product changeovers, and offer of aftersales services.

The design of the carton you package your goods in is critical for product marketing and can play a significant role in the consumers’ preference for your product.

Also, the following carton designs are among the most widely used alongside automatic carton packing machines.

- Folding cartons: They come in assorted sizes, shapes, graphics, and colors. They are ideal for packaging consumer products.

- Rigid cartons: These are very strong cartons and are used for packaging high-end, luxurious products.

- Shoulder cartons: These are specialized rigid cartons where the top and base do not intersect.

- Regular slotted and half slotted cartons: The folds of slotted cartons are symmetrical but the half-slotted cartons have openings on a single face making them ideal for stacking against pre-packed boxes.

They are ideal for packaging smaller products.

- Full overlap cartons: These cartons are very strong and resilient because the flap overlaps its whole width.

- Telescope type cartons: These cartons have their top and base separated. You can use them to package your high-end products.

- Mailer cartons: These boxes are specifically manufactured for delivery of post and letter packages.

- Shelf ready cartons: These types of cartons are specifically designed for product exhibition and shelf retailing purposes.

- Custom cartons: As the name suggests, this type of carton offers unmatched versatility.

It also enables you to form them into unique shapes and sizes that will deliver a memorable experience to your customers.

These two carton packaging machines rely on the extent of the independence of operation.

A semi-automatic machine requires human intervention in supplying products/cartons which does not apply to a fully automatic carton box packing machine.

semi automatic box packing machine

The semi-automatic machine requires close human monitoring when in operation.

It is also slower than a fully automatic machine.

Fully automatic carton packaging machine has additional tooling.

These tooling enable it to initiate the process of product packaging and follow-through up to sealing with minimal human intervention in the control panel

automatic carton box packing machine

These following tips will help you ensure optimal carton packing machine maintenance.

- Regularly clean the packaging machine offline for the removal of dirt.

- Tighten all loose parts and repair any visual or otherwise worn-out parts as soon as you notice them.

- Schedule regular checks and replenishment of lubrication oil.

- Schedule machine overhaul on regular basis to ascertain efficient operation and enhance its longevity.

You can increase the effectiveness of your carton packing machine through:

- Ensuring timely maintenance and repair of worn-out parts.

- Optimal integration and synchronization of the carton packaging machine to the production line and other auxiliary equipment.

- Maintain a skilled set of machine operators.

- Eliminate all processes and procedures that may cause miniature stoppage along the production and packaging line.

The following operational conditions can cause the failure of your carton packing machine:

- Extensive operation of the carton packing machine at high speed can result in machine instability.

- Sucker tubing leakage or blockage of air pathway.

- Poor suction positioning.

- Inappropriate machine operation, poor maintenance, and loose fasteners fault the system transmission.

- Fault blockage in the transmission channel can cause failure in product and packaging material delivery.

The following are the new technological developments in carton box erecting and sealing machines.

- Increased attention to detailed development in carton packing machine’s structure for enhancement in overall product quality.

- Designing and constructing the carton packaging machine to the alignment of the back packaging of the production line.

- Development of carton packaging machines that are highly adaptable to the packaging of inner packages with diverse packaging conditions.

- Digitalization of carton packaging machine.

More Resources:

Automatic Cartoning Overwrapping

For all your carton box packing machine, contact us now.