Automatic Plastic Wrapping Machine Manufacturer in China

Automatic plastic wrapping machines are characterized by outstanding quality. JOCHAMP has grown to become a professional manufacturer in the wrapping machine industry. We have managed to stay flexible and customer-oriented. With JOCHAMP, you have a large choice of wrapping machines that meet your production requirements.

- Rich extension applications, applied to various devices

- Excellent quality and a competitive price

- One-stop plastic wrapping solution supplier

- Easy to use, high efficiency

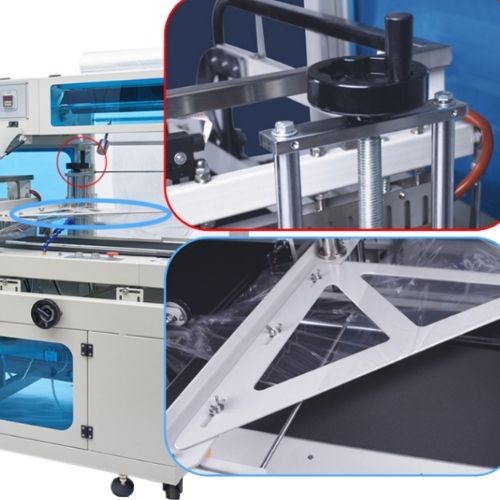

JOCHAMP Automatic Plastic Wrapping Machine

The automatic plastic wrapping machine is a high-powered tool used for wrapping and sealing products. It is a process that safely wraps good items from dust, dirt, and moisture and securely packs them ready and placed on a shipping carton. This machine is applicable for all sorts of products — either solid or liquid, bottled or canned.

JOCHAMP automatic plastic wrapping machine has a compact mechanical structure that guarantees reliable and high wrapping speed and performance. It lasts for more prolonged use and requires less maintenance. Besides, JOCHAMP has professional skills and knowledge in customizing automatic plastic wrapping machines. Whether you need it to pursue wrapping business and projects, reach us for your request. Every staff in our company is held accountable.

Types of Automatic Plastic Wrapping Machines

JOCHAMP Automatic Plastic Wrapping Machine Features

Optional remote system inspection, maintenance, and upgrading. Complete testing facilities and raw material inspection. JOCHAMP has over 50 technical patents.

We have an excellent team of high-quality talents and rich experience in product operation. Product contact surfaces that comply with food hygiene and drug safety.

JOCHAMP is an expert manufacturing company specializing in the production of R&D machinery with a wide range of products. Extensive industry support, suitable for all industries.

Automatic plastic wrapping machines feature a well-designed construction and provide accurate and long-lasting functionality. Equipped with a safety feature to avoid risks.

Automatic Plastic Wrapping Machine Ergonomic Structures

The automatic plastic wrapping machine is handy for packing and preserving plenty of industrial products. Due to its consistent function and firm productivity, it has become the sought-after machine for massive packaging production industries. Additionally, this machine comes with ergonomic structures that are suitable to wrap in any product, including:

- Foods and beverages

- Cosmetics products, medical drugs, tobacco

- Hardware parts, electronic and automotive components

- Electrical appliances, stationery products

- Magazines, notebooks, books

- Personal hygiene kits and essentials

- Fruits and vegetables

Automatic Plastic Wrapping Machine Performance

The automatic plastic wrapping machine is user-friendly and brings consistency and safety to the production line. All the mechanical controls of the machine are easy to use and maneuver. The operating performance will remain in good condition even with its long hours of use.

An automatic plastic wrapping machine is suitable for enormous product wrappings. It operates at its highest speed, allowing for the wrapping of plenty of goods in a single operation’s clean, zero-damage, and consistent wrapping output that will meet the different operational packaging requirements.

Automatic Plastic Wrapping Machine Feature Profile

The automatic plastic wrapping machine has a fully automated assembly line that adapts to the high-programmed configuration of machines. Below are the following that best describes our automatic plastic wrapping machine:

- Full cylinder drive.

- Synchronize and steady operation.

- Conveniently adjusting sealing.

- Compact structure with complete safety devices.

- Uses the finest quality steel materials and adopts the man-machine interfaces.

- Gives high accuracy gear transmission and consistent mechanical speed.

- It can be moved upward or downward, depending on the working convenience, so that wrapping runs accurately and smoothly.

Why Choose JOCHAMP Automatic Plastic Wrapping Machine

JOCHAMP automatic plastic wrapping machine is a highly acclaimed wrapping machine due to its matchless mechanical versatility, strength, and endurance. For a decade, we have actively supported the automation development and innovation of all automatic plastic wrapping machines.

Moreover, an automatic plastic wrapping machine is concretely designed for extended industries needing a robust and highly functional machine. It contains high-programmed system controls, durable parts, good qualities, and features that ensure maximum compatibility and convenience, making it well-suited for immense wrapping processes.

JOCHAMP’s uppermost priority is to give satisfaction to all customer’s needs. For 15+ years, we have been in action in providing large numbers of fully upgraded, inspected, and certified automatic plastic wrapping machines. For customization, we can be trusted. We have our professional engineers who will understand your structural design and gives you the best quality machine.

JOCHAMP provides high-quality automatic plastic wrapping machine, which is available in different models, and each of them comes with unique qualities, such as:

- Sturdy design.

- High impact and corrosion-resistant.

- Excellent finishing.

- It has a high and low-voltage panel that prevents unwanted exposure to high voltage components.

- Accommodate different sizes of products.

- Prevent dust from entering the product. package and protect the operator to some extent.

The automatic plastic wrapping machine is worthwhile for wide-ranging wrapping operations. Its advantages have become highly demanded in different markets:

- Securely wrapped to avoid any potential damage.

- It prevents possible accidents and improves the safety of the employee.

- Considerably saves effort and time-consuming.

- Fast and increased production packaging.

- Efficient product wrapping.

- Ensure all software and components operate perfectly.

JOCHAMP Professional Automatic Plastic Wrapping Machine Services

Automatic plastic wrapping machines are widely used for all kinds of products of different sizes and shapes. Our products are extensively used in packing equipment. They are of good quality, have reasonable prices, and have stylish designs. To ensure long-term interest, the machine ensures optimum compatibility, which is advantageous for future usage as a packaging line. JOCHAMP can customize machines according to your business requirements.

To better ensure the safety of your goods, professional, environmentally friendly, convenient, and efficient packaging services will be provided. JOCHAMP can help increase your packaging efficiencies and reduce your packaging costs. Some products are in stock and can be shipped at any time. Customized machine with the fastest delivery time of 15 days.

Automatic plastic wrapping machines have an advanced design, stable and reliable performance, efficient power saving, good wrapping effect, novel and beautiful structure, convenient operation and maintenance, etc. The machine is easy to operate and has high efficiency. Machines are manufactured according to the characteristics of plastic film materials.

The whole series is equipped with an intelligent fault diagnosis system. The fault point will be clearly displayed on the screen, and the maintenance cost will be minimized. A unique temperature control system provides more precise temperature control and more energy savings. Patented sealing technology, 100% air tightness, and better aesthetics. Precise running parts make our machines less noise.

Related Product

Automatic Plastic Wrapping Machine: The Ultimate Guide

Automatic plastic wrapping machine will quickly and easily wrap large objects in plastic film. They will help realize efficient and profitable packaging solution.

Below, you will get detailed insights on automatic plastic wrapping machines. You will find information on benefits, applications, working principles, types, etc. Sounds exciting? Let’s dive in!

An automatic Plastic Wrapping Machine is often referred to as an automatic wrapper machine. This machine utilizes plastic material to wrap different large or small materials using plastic film. The machine does this without human intervention once set out for particular wrapping settings.

Automatic Plastic Wrapping Machine

Multiple advantages exist for automatic plastic wrapping machines that make them stand out. Some of the key advantages are as follows:

· Complete Protection

The automatic Plastic Wrapping Machine plays an important role in protecting the goods by wrapping and sealing using plastic film. This protects objects from moisture, debris, dust, and other foreign elements. It also contributes to the safety of goods by preventing harmful chemicals or gases.

· High-Quality Wrapping

An automatic plastic wrapping machine ensures consistent and efficient wrapping. You will find no wrinkles on the wrapping. You cannot do this through the manual wrapping. Manual wrapping results in an uneven wrap, which spoils the packaging appearance. You can wrap pallets, boxes, and other products in your packaging vicinity.

· Save Wrapping Material

An automatic Plastic Wrapping Machine helps you to save wrapping material. It takes up the material just according to the object/ product dimensions. This results in zero waste generation. It also helps you save on material costs.

· High-Speed Packaging

High-speed packaging means you can increase the speed of packaging using an automatic plastic wrapping machine. It allows you to increase the number of products you want to wrap per unit time. It also varies depending on the product size and type of the product. But this is very beneficial in comparison to semi-automatic and manual wrapping machines.

· Reduce Space Consumption

An automatic Plastic Wrapping machine reduces space consumption. By wrapping consumable materials in rolls and bags, the machine saves space by minimizing storage space requirements. An automatic Plastic Wrapping Machine saves time, and energy and, most importantly, makes it easy to store.

Several differences exist between Manual and Automatic Plastic wrapping machines. Each one has its features and benefits. Some of the key differences that you must know are:

Automatic

- Manual plastic wrapping machines have low costs and are cheap. You don’t need a large investment in manual wrapping machines. On the other hand, automatic plastic wrapping machines initially have higher costs.

- You can package irregular or those products having odd shapes easily with a manual wrapping machine. This is not possible with a plastic automatic wrapping machine.

- An automatic machine requires no extra labor for its functioning besides setting specific product parameters. On the other hand, a manual wrapping machine needs manual labor to carry out tasks. This will add to labor costs.

Manual

- An automatic wrapping machine can wrap up more products with high efficiency and effectiveness per unit time. While manual wrapping machines, the efficiency depends on labor. You cannot compare a manual wrapping machine with an automatic one because its wrapping speed is unmatchable.

- An automatic wrapping machine results in a Good finish compared to a manual wrapping machine. Manual wrapping machine often results in wrinkles over packaging.

- The automatic plastic wrapping machine boosts your revue by increasing the overall productivity. On the other hand, a manual wrapping machine keeps your revenue constant.

The main function of an automatic plastic wrapping machine is wrapping the object or product. Doing this involves a series of functions. These functions are as follows:

Unroll Wrapping Film: Firstly, the automatic plastic wrapping machine unrolls the wrapping material wound on the roll. It unrolls the material as per commands fed to the machine.

Cutting: The second function is to cut the wrapping material. The machine does this with a built blade.

Wrapping: The object/ product you want to wrap passes through the material. In some machines, the machine overwraps the object/ product with the material film. The wrapping process varies from machine to machine.

Sealing: In the end, the automatic plastic wrapping machine carries out the sealing process. This process also varies depending on the machine. These mechanisms are heat, glue, and friction sealing.

These four different functions contribute to one function of wrapping. This ensures complete protection and increases the shelf life of various goods.

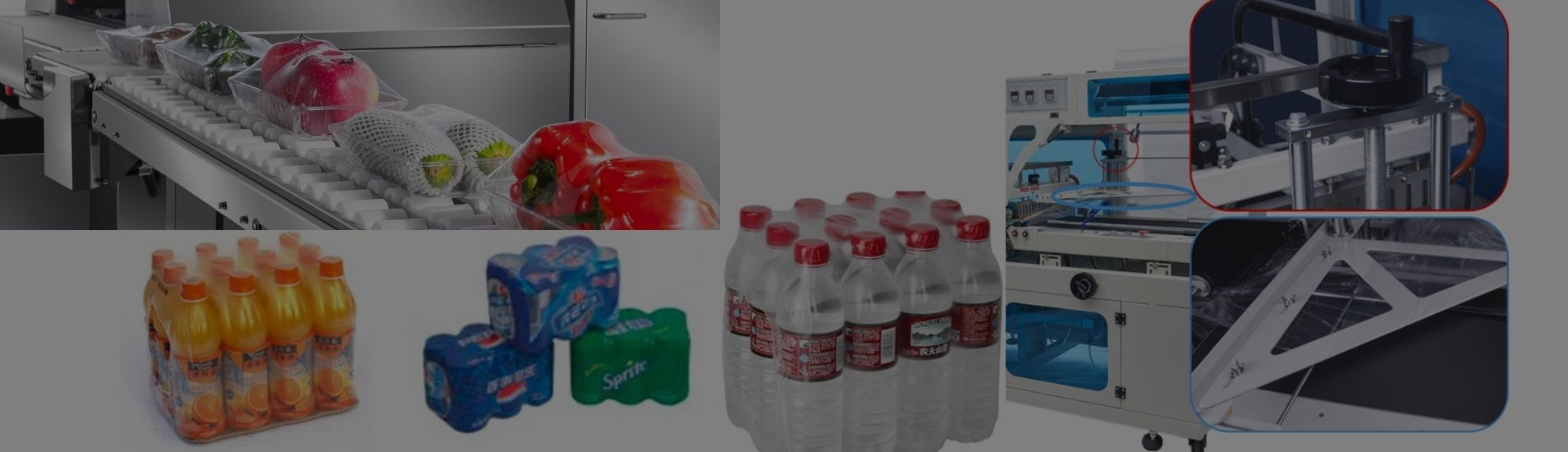

You can use an automatic plastic wrapping machine for various applications. Some of the main applications include:

· Logistics

An automatic Plastic Wrapping Machine is the key component of logistic processes. You can use it to wrap cartons, containers, pallets, and boxes in logistics. It wraps goods with good strength and protects them from crumpling, making them easy to store or ship. When labeled, this will lead to efficient management in logistics.

logistics application

· Consumer Goods

Automatic Plastic Wrapping Machine mainly applies to Consumer goods. It can wrap various products in bulk for shipment or transit. This can be anything from toothpaste to soda, smartphones to cars, cereal and milk, etc.

Consumer Goods

· Medical and Pharmaceutical

The automatic plastic wrapping machine plays a significant role in the medical and pharmaceutical industries. It helps to reduce costs by preventing any unwanted leakage, misuse, or spoilage of healthcare products. You can wrap bulk cartons or boxes of analgesics, vitamins, injections, drips, and other drugs that require special packaging.

Medical and Pharmaceuticals

· Food and Beverage

You can use this Machine in Food and Beverage industry to wrap food items and beverages. It will make them safer to store, transport, and sell. You can use it to wrap different products, such as fresh vegetables, bottles, cans, nuts, sweets, and other confectionery items.

Food and Beverage

There are different types of automatic plastic wrapping machines exist. Some of the most popular types are as follows:

· Automatic Plastic Shrink Wrapping Machine

The name automatic plastic shrink wrapping machine is because for two reasons. One is the automatic wrapping, and the second is the shrink sealing. Let’s discuss the benefits, limitations, and working principles:

Automatic Shrink Plastic Wrapping

i. Advantages of Plastic Shrink Wrapping Machine

There are several benefits of plastic shrink wrapping machines. Some of the main benefits include:

- It results in fine wrapping without crumpling your product in less time

- It guards your packaging against rain, dirt, or dust

- It makes perishable products last longer

ii. Limitations of Plastic Shrink Wrapping Machine

There are some limitations that you need to consider, too; these are as follows:

- If the temperature of the heating element increases above a certain level, the wrapping surface becomes wrinkled.

- If the temperature is below a certain level, the wrapping film becomes brittle.

- Keep in mind that plastic wrapping film releases harmful and hazardous odors.

iii. How Plastic Shrink-Wrapping Machine Works.

You must set the parameters through the user interface for a particular product. The wrapping material unrolls as per product size and is cut into the desired length. Then the products pass through the wrapping film and move on the conveyor toward the heating unit. At this stage, the wrapping film loosely covers the product or object. The heating unit then shrinks around the product, thus finishing the wrapping process.

· Automatic Overwrapping Machine

As the name reflects, the automatic overwrapping machine wraps the wrapping material in all surroundings of the particular product.

Automatic Overwrapping Machine

i. Advantages Of Overwrapping Machine

The key advantages that make your automatic overwrapping machine stand apart include:

- A good and attractive finish is the main advantage of the overwrapping machine. Diamond seal or strip tape seal plays a great role in this regard.

- You can use this method to overwrap individual items or overwrap items bundled over one another.

- The overwrapping machine protects your products from contamination.

ii. Limitations Of Overwrapping Machine

The limitations of the overwrapping machine are:

- You can only use this method of wrapping for products having a cubic shape or cuboid shape

- This method of wrapping is expensive as compared to shrink wrapping

- Not suitable for large size objects

iii. How Plastic Overwrapping Machine Works.

The first step is to drag out the wrapping material film from the rollers. The next step that this machine follows is cutting the film with the help of a cutter. In the end, the heating element within the automatic overwrapping machine seals the overwrapped film.

· Automatic Flow Wrapping Machine

In an automatic flow wrap machine, the product gets wrapped by flowing into the wrapping material.

Automatic Flow Wrapping Machine

i. Advantages Of Flow Wrapping Machine

A variety of benefits are associated with a flow wrapping machine. The key benefits include:

- It helps you package with less cost

- The machine results in the efficient management of wrapped products

- It protects the item/ product from foreign elements and improves shelf life

- The growth of your business experiences a boost

ii. Limitations Of Automatic Flow Wrapping Machine

This machine has a few limitations. The major limitations include:

- You cannot wrap the products that are in liquid or powder form

- Only solid products viable with an automatic flow wrapping machine

iii. How Flow Wrapping Machine Works

The working principle of the flow wrapping machine is remarkable. On one side, it unrolls the wrapping material and converts it into a container shape by rolling it into a cylindrical form. On the other side, the product/ item flows into the cylindrical container. Then the product moves to the sealing section. The heat seal process then seals the cylindrical product.

· High-Speed Automatic Shrink-Wrapping Systems

The only difference between automatic shrink wrapping and high-speed shrink wrapping is speed. It rapidly shrink-wraps various products.

High Speed

i. Advantages of High-Speed Automatic Shrink-Wrapping Systems

The benefits of these systems include:

- It minimizes space consumption

- Offers improved protection of goods

- It is sustainable and affordable

ii. Limitations of High-Speed Automatic Shrink-Wrapping Systems

The wrapping issue results in the wrong setting regarding time, pressure, and temperature. Other limitations are similar to that of the Automatic Shrink-Wrapping Machine.

iii. How High-Speed Automatic Shrink-Wrapping Systems Works

It works by wrapping the material and then shrinking it using heating filament. The working principle is the same as the Automatic Shrink-Wrapping Machine, except it uses horizontal and vertical detectors. This is good, especially when it comes to high-speed machines.

· Continuous Motions Shrink Packagers

This is an incredible product. It keeps moving the item one after another and shrinking the material film with heat. The process never stops.

Continuous Motion Shrink Wrapping

i. Advantages of Continuous Motions Shrink Packagers

The main benefits that you can enjoy are:

- High productivity associated with these machines

- They are affordable

- You can package bundles or in bulk materials

ii. Limitations of Continuous Motions Shrink Packagers

The only single limitation is that if any parameter is at a faulty setting, it will ruin the whole wrapping process. Other limitations regarding hazardous gas and wrinkles because of high temperature are the same as shrink-wrapping machines.

iii. How Continuous Motions Shrink Packagers Work

It utilizes dual direction horizontal and vertical motors (servo motors) to ensure the cross seal. This machine operates continuously regarding sealing and wrapping. In the end, it uses a heating seal mechanism to end up wrapping process.

When it comes to wrapping, the final stage is sealing. Different machines make use of different types of sealing mechanisms. Some of the very popular sealing mechanisms are:

- Heat Seal

- Glue Seal

- Friction Seal

Heat Sealing

Heat sealing is a mechanism in which wrapping film is heated up at a point where it fuses or melts. It leads to the formation of a non-shrinkable and airtight seal.

There are different types of heating that an automatic plastic wrapping machine use. Some of the popular ones include:

- Induction Sealing

- Hot Wire Welding

- Impulse Welding

- Continuous Heat Sealing

- Hot Wire Welding

Glue Seal

This type of sealing uses a layer of glue or adhesive to form an air and water-resistant seal.

Friction Seal

This process works when two materials come into contact with each other and generate friction. This mechanism is better than heat sealing as it uses less energy.

You need to consider several things while looking for an automatic plastic wrapping machine. Some of the key things include:

Wrapping Speed

This term specifies how fast it can wrap up a certain object or product. The greater the speed associated, the greater the ROI you enjoy because it will wrap up several products at once.

Sealing Mechanism

Another feature to look for while selecting your automatic plastic wrapping machine includes sealing. Ensure the sealing lasts longer while preventing foreign material from getting inside. The foreign materials are chemicals, dust, dirt, debris, etc.

Working Life

Check for the working life of your automatic plastic wrapping machine. Keep in mind the frequency of usage. If you use this machine most often, select one with longer working life and low maintenance associated.

Wrapping Dimensions

Some machines can wrap up big objects while others are suitable for smaller ones. If you select the wrong automatic plastic wrapping machine, you will not be able to wrap a particular product. Make sure to select one capable of wrapping your product with particular dimensions.

You can use some materials in your automatic plastic wrapping machine. Some of the main materials include:

Polyolefin

Polyolefin possesses high molecular weight components of ethylene and less than 1 percent olefins. Polyolefins have extended properties, including:

- Low moisture absorption

- High tensile strength

- Stiffness

- Good thermal stability

- Ability to stand a wide range of blends with other polymers

The high-quality film prevents direct contact of the product with the outer surface resulting in improved product protection and longer shelf life.

Polypropylene

Polypropylene is a synthetic plastic that is transparent in color and has good mechanical properties. It has low thermal conductivity and high strength and rigidity. It possesses excellent barrier properties. You can use it as a shrink-wrapping film for different products and appliances. The polypropylene film offers great protection from contamination and moisture.

Polyethylene

Polyethylene is a material that forms a plastic film that is strong and resistant to impact and heat. You can use polyethylene to wrap goods as it has excellent tensile strength. It also offers a low friction coefficient and can apply it even at high temperatures.

PVC

PVC is a synthetic material made from polymer polyvinyl chloride (PVC). It has several advantages over other plastic materials, including durability and cost. PVC is a thermoplastic material with outstanding mechanical, optical, and thermal properties. The high flexibility, good chemical, and low-pressure resistance make it best for shrink wrapping machines.

The maintenance measures are the key to the longer life of your Automatic Plastic Wrapping Machine. Some of the key maintenance measures include:

- Conduct periodic lubrication of all parts to avoid heat generation because of friction. Otherwise, this will lead to wear and tear of several components. Clean your machine daily to keep it efficient.

- Maintain the level of oil in the reducer. Make sure to change the level of oil after every 2500 working hours.

- After the end of the working shift, inspect the peeling agent or blade and see if there are material residues. If yes, then clean it using a wire brush.

- Maintain the appropriate power levels, and keep the power supply above or up to the point where needed.

- Operate your machine in the environment under recommended standards. For instance,

a) the working temperature range should be: -100C to -500C,

b) relative humidity not above 85%,

c) No dust and corrosive chemicals in the air.

These preventive measures result in longer life of your automatic plastic wrapping machine. It will also lead to an increase in efficiency and effectiveness.

Related Information:

For all your automatic plastic wrapping machines, contact us now.