Chocolate Packing Machine Manufacturer in China

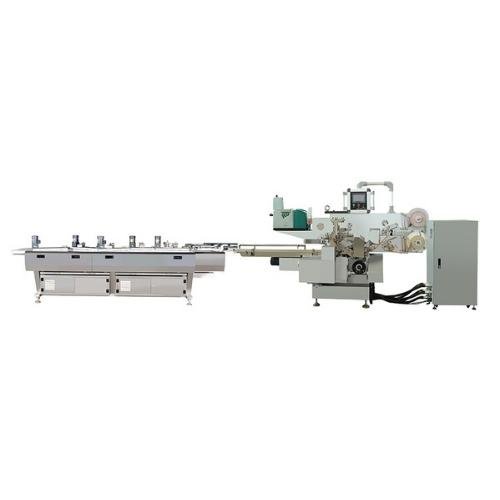

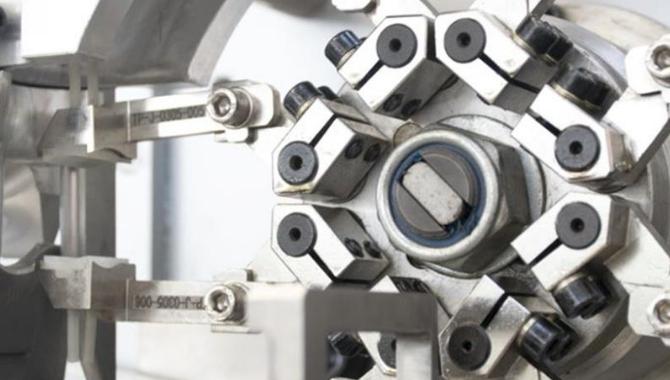

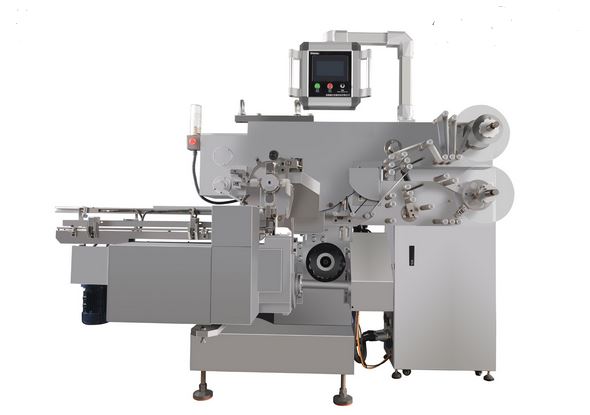

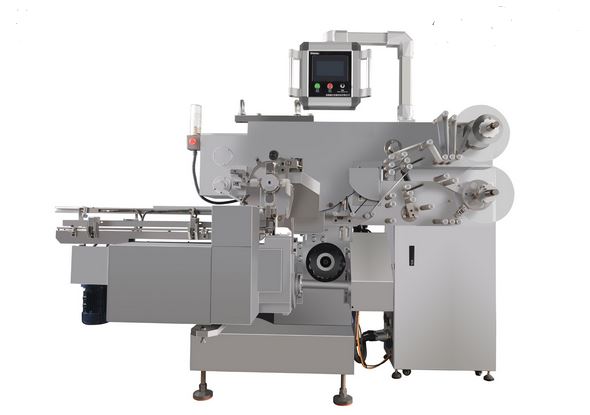

JOCHAMP is a leading manufacturer of chocolate packing machines that are used to flow wrap and coat chocolate products. It has a connected chocolate cooling tunnel which helps to save labor costs. Our chocolate packing machine is equipped with motions PLC and has a remote control device to make sure of stable working.

- Well equipped with a water cooling system

- Provide high accuracy color mark tracking functions

- Made from stainless steel and carbon steel frame

- Have HMI with memory function for easy use

JOCHAMP Custom Chocolate Packing Machine

The chocolate packing machine from JOCHAMP is equipment that uses for packing different types of candies and chocolates from bar to liquid chocolates. It has a water cooling system that provides a low-temperature packing process to maintain the chocolates in a perfect shape in the packaging process and not deform or melt due to external factors. We can offer reliable, efficient, and high-quality chocolate packing machines.

JOCHAMP provides chocolate packaging machines that are high corrosion resistant, support IP55 waterproof, are easy to clean, and can be directly washed. The whole system of our chocolate packaging machines is equipped with HMI industrial control system for easy operation and to be powerful. We can offer the standard machines in stock and can be shipped to you at any time.

Send us your inquiry now!

Various Chocolate Packing Machine for Your Choices

Chocolate Packaging Display (6)

JOCHAMP Chocolate Packing Machine Advantages

Our chocolate packing machine is equipment for the confectionery business. It is easy to operate, provide the best for chocolates, and handles delicately with a unique design that offers the best quality result for the products such as chocolates, candies, etc.

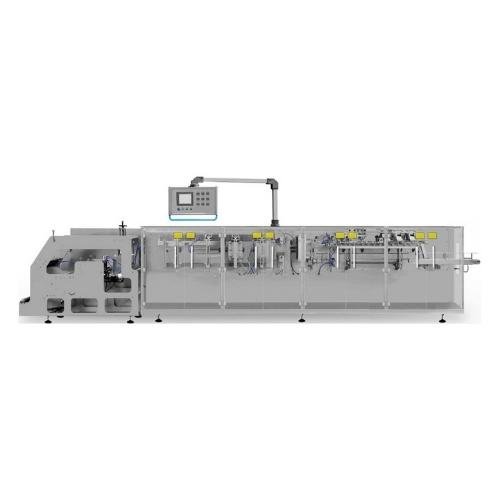

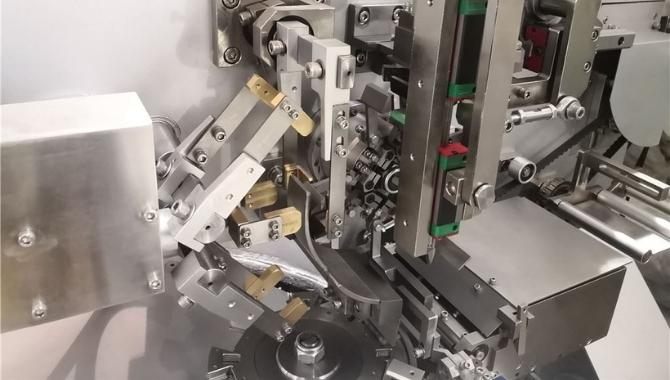

We manufactured a chocolate packaging machine that provides high speed and capacity for small and big sized for a business. The chocolate packaging machine has a touchscreen featured to provide an excellent tool for controlling packaging parameters.

Our chocolate packaging machine is user-friendly, easy to use, and requires minimal manpower. It has a conveyor chain with a flexible clamping design to prevent material from breaking and make it an ideal choice for different companies.

The chocolate packaging machines can increase productivity. It is capable to perform a number of tasks such as forming, edge folding, and lining up also it features various functions including case sealing, flow management, and palletization.

Certifications of JOCHAMP Chocolate Packaging Machines

To ensure that you purchase the best quality chocolate packaging machines, we adhere to different international quality standards upon the production. Below are the lists of different certifications that we have:

- SGS Certifications

- Approved by ISO, CE, and CO standards

- MSD or Machine Safety Directive

- PAD or Physical Agent Directive Certifications

- Approved by EMC or Electromagnetic Compatibility Certifications

- Certification from PUWER or Provision and Use of Work Equipment Regulations

Chocolate Packaging Machine Applications

Our chocolate packaging machine can perform different functions depending on your application such as:

- Can wrap a wide range of pure chocolate types such as cookies, wafers, inclusions, solids, and more.

- Can print labels accurately after packaging

- Offers a broad selection of wrapping styles such as double stage wrapping, folds, foils, and more

- Can package chocolates in different sizes and shapes according to your specifications

Features of Our Chocolate Packaging Machines

Our chocolate packaging machines are manufactured with optimal features such as the following:

- It can pack different types of chocolate with shapes such as rectangles, rounds, ovals, squares, hearts, and more. These are also suitable for a wide range of chocolate sizes ranging from mini to large.

- Our chocolate packaging machines are fully automated. Therefore, it can pack a large number of chocolates faster than manual labor. It can pack up to 80 chocolate pieces per minute. Thus, increasing your business productivity.

- These machines are also equipped with digital counter features. With these features, you can monitor the number of chocolates that are already packed. Thus, keeping you on track with your production with ease.

JOCHAMP – Professional Chocolate Packaging Machine Manufacturer

JOCHAMP offers a wide range of chocolate packaging machines that can provide a high and accurate wrapping capacity. These machines can provide you an efficient and reliable chocolate packaging. It is also integrated with sensors and other safety features so the operators are safe during production and operation. If the sensor detects any problems, it will automatically stop the process. Therefore, protecting the equipment from any damage.

Here in JOCHAMP, we manufacture chocolate packaging machines that can increase your business productivity. Our factory has an expert R&D team with over 15 years of experience to provide you with customized solutions. Each machine is guaranteed to have one-year quality assurance. JOCHAMP also provides a one-stop solution from raw material inspection up to assembly and production.

For a customized chocolate packaging machine, don’t hesitate to contact us!

Difference Between Fully Automatic and Manual Chocolate Packaging Machine

- Fully automated chocolate packaging machines are used for large scale production

- Can provide high-speed chocolate wrapping capability

- Offers economical operation yet costly

- Needs little to no manpower operation

- Features flexibility to pack chocolates in different sizes and shapes

- Eliminates the human support because of its different parts

- These machines are only suitable for small scale chocolate wrapping operation

- Packaging chocolates with a manual machine takes a lot of time

- Manual chocolate packaging machines are easy to operate and are inexpensive

- Needs more manpower during the operation

- It has a particular chocolate size to pack

- Assembled with few parts thus, requiring more human support

Components of Our Chocolate Packaging Machine

This machine supports the chocolate packaging machine by heating, cooling, and mixing the chocolate. Therefore, you can achieve a crispy and smooth crystallization. It heats the chocolate a lot of time at a certain temperature.

This component of our chocolate packaging machine automatically deposits the chocolates into different molds. It can uniformly and accurately fill the chocolate into the molds eliminating the need for manual hand operation.

Automatic molding machines are typically used for molding and shaping chocolates. Thus, forming the chocolates into your desired shapes. With the help of this machine, you can also achieve assorted chocolate products.

This machine can homogenously and volumetrically mix chocolates and granules. Then, it will allow the flow of the mixture with its channel to the automatic chocolate depositor.

Related Products

Chocolate Packing Machine: The Ultimate Guide

There are many designs of chocolate packing machines in the market. This guide will help you choose a perfect machine for all your chocolate packing requirements.

Enhances Accuracy Packaging – The design construction and parameter specifications of this machine guarantee an efficient and accurate packaging process.

Easy To Maintain – It features stainless steel framing components and parts that are strong, easy to maintain, and clean.

Highly Versatile – You can use this equipment to package a wide range of products other than chocolate.

Increases Hygiene – This machine hardly contaminates chocolate since it features a corrosion-resistant stainless steel material that is easy to clean.

Improves Chocolate Appearance – The final packaged product is attractive, and this increases overall sales turnover.

chocolate packing machine

This equipment is available in different types, but the most common variants you will easily find in the market include the following;

Chocolate Beans Packaging Machine

It is a chocolate packing machine variant designed to specifically pack a wide range of chocolate beans into different packages.

This machine variant is commonly used in commercial and small-scale chocolate packaging applications depending on the actual desired capacity.

Some notable features of a typical chocolate bean packaging equipment are as follows;

- Available in semi-automatic or fully-automatic functional options

- Features a highly simple and user-friendly design

- Photoelectric detectors for chocolate beans packaging accuracy

- Automatic variants feature a PLC touchscreen for regulating and monitoring the process

- Variable packaging speed controlled through an electric regulator

- Sharp zigzag knife of scissors for slicing the package once filled

- Stainless steel framing construction

- Can use different chocolate packaging materials

The main benefits of this chocolate packing equipment variant include high adjustable speeds allowing you to determine your packaging throughput.

chocolate beans packaging machine

Also, it is user-friendly, easy to maintain, and reasonably accurate, which are all vital in chocolate packaging process.

This machine works in simple steps that include; chocolate beans preparation in the machine, chocolate beans packing, cutting and sealing the package then discharging it.

The process is seamless and often based on the specific machine settings to deliver desired results.

Chocolate Foil Wrapping Machine

It is a chocolate packing machine variant that wraps chocolate products using aluminum foil without necessarily heating or glue sealing.

The design of this machine allows you to wrap a wide range of chocolate products.

It is relatively compact-size thus quite convenient to use in limited-sized floor spaces.

Besides, the body construction features stainless steel material making it stronger, more durable, and easy to clean.

This machine comes with control keys, including the emergency stop button, that enhances efficient machine operations and safety.

chocolate foil wrapping machine

Also, this equipment is user-friendly, and you do not necessarily require special skills to operate it.

Fully automatic and semi-automatic variants of this equipment feature a simple and easy-to-understand PLC touchscreen.

Besides, it comes with a powerful servo-motor that ensures all different elements that require electric power are efficiently powered.

This machine also has a roll film setting that seals the foil wraps once chocolate is fully wrapped.

However, the main advantage of this chocolate packaging machine variant is that you don’t need to use heat or glue sealing to wrap the chocolates.

Its major shortcoming is that it restricts you to wrapping the chocolate using aluminum foil.

The working principle of chocolate foil wrapping machine is quite simple and entails chocolate preparation, chocolate wrapping in the wrapping, sealing, and discharging.

Chocolate Fold Wrapping Machine

It is a chocolate packing machine variant designed to precisely fold the packaging material around the chocolate product in an envelope design.

This is important since the machine provides the flexibility to use any type of convenient packaging material to fold the chocolate.

Hence, it uses heat or glue sealing techniques, which enhances the strength of the packaging material around chocolate.

It features different elements, and the main ones include a roll film bar carrying the fold wrapping material.

chocolate fold wrapping machine

Vibrating tray in this machine is responsible for conveying the chocolate products one by one to the packaging and sealing section.

This equipment has a photoelectric sensor designed to detect the presence of a roll fold wrapper in the machine.

A simple PLC touchscreen with an easy-to-understand human-machine interface is also available to enable seamless control and monitoring of the different events.

It also features a conveying unit that transports the chocolate products from one station to another within the machine.

The first step in packing chocolate using this machine begins with preparing the products and placing them on the vibrating tray through the hopper.

Vibrating tray separates the products as it allows them to get into the sealing chute one by one.

While at it, the roll film setting bar releases the folding material from the opposite end of the vibrating tray, where they meet with sorted chocolate at the sealing unit.

Each chocolate bar is folded and wrapped inside the film wrapper, sealed accordingly, and moves to the dispatch section for other packaging processes.

Chocolate Coin Wrapping Machine

It is a type of chocolate packaging machine designed for packing a wide range of chocolate coins using aluminum foils and cardboard wrappers.

This machine is relatively compact-size, and some have universal wheels to allow easy and convenient movement when shifting it from one spot to another.

It features a roll film setting bar at the upper part that discharges the chocolate coin wrapping material accordingly.

The framing component of this machine features stainless steel construction with a steady vibrating table.

Besides, it comes with a control unit featuring a PLC touchscreen with an HMI system, control, and emergency buttons for enhanced safety.

chocolate coin wrapping machine

It also features heat-sealing and glue-sealing capabilities, thus broadening your options for a particular choice to consider.

Moreover, this machine has a production capacity of up to 60 pieces per minute

Chocolate coins go through this equipment for embossing aluminum foil and are covered using a similar pattern.

The roll film setting bar releases the film constantly towards the material pump that feeds the chocolate into feeding chutes.

Pneumatic control unit discharges the chocolate coins and as it embosses them on the moving wrapping film.

Each machine has a specially designed pattern based on your chocolate coins, which must be clear with a tightly wrapped edge.

Chocolate Bar Packaging Machine

This chocolate packaging equipment is designed to pack chocolate bars in different packaging materials.

You can use it to pack chocolate in plastic, pouch as well, as aluminum foil, depending on your preference and target market.

It is available in different sizes, but most feature a compact design for convenient usage and easy transportation.

The framing component of this equipment features stainless steel construction for strength and protection of delicate parts.

It also features a quantitative pouring mechanism determining the ideal material volume necessary for chocolate bar production.

chocolate bar packaging machine

The pneumatic control unit in this machine enables various hydraulic fluids to move to different stations.

Moreover, it comes with a robust vibrating table designed to align the chocolate bar into the right orientation for proper packaging.

The working principle of this machine entails a straightforward process of preparing the chocolate bars accordingly for subsequent packaging.

While at it, the roll film bar sets the pouch or foil to get into the sealing joint and where it wraps each particular bar before cutting it.

The process takes place relatively fast since each chocolate bar is packed in a different pouch or aluminum foil.

Manual Chocolate Packaging Machine

It is a type of chocolate packing equipment that does not necessarily use automated functions to pack chocolate into different packages.

As the name suggests, this machine variant requires a high level of human involvement in undertaking chocolate packaging.

Simply put, all operational aspects of this machine require manual input.

It is quite affordable and easy to maintain since it hardly entails any sophisticated systems and components.

This equipment is also compact but quite sturdy since the framing material is made of stainless steel.

The main advantage of using a manual chocolate packing machine is that it is quite cheap to acquire and maintain.

Besides, you won’t need large floor space for this equipment since it is relatively small.

However, the primary disadvantage of this machine variant is that it is quite slow since the operations are actuated manually.

Also, it lacks consistency as far as accuracy is concerned, and this is likely to affect overall quality of the package.

Essentially, the working principle of this machine involves manually picking and sealing the chocolate product into the respective container.

Semi-automatic Chocolate Packaging Machine

This type of chocolate packing machine has both manual and automatic functions enabling it to pack different chocolates in various packages.

One outstanding feature of this machine is a PLC and HMI control unit for easy operation and customization settings.

It features a simple design structure, which is quite easy to maintain.

Additionally, it has excellent adaptability to various packaging materials as well as a stable and stronger working performance.

This packing machine can also pack chocolate into different shapes and, at the same time, imprint labels on the material.

It is relatively accurate and faster though more expensive than a manual chocolate packing machine.

Touch-sensitive temperature regulating device is another fundamental feature of this particular chocolate packing equipment variant.

An outstanding advantage of this machine is that it is highly user-friendly, has a stability control system, and a computerized detection system.

This machine is versatile, meaning you can use it to pack different confectionery products other than chocolate.

Its working principle is quite simple and entails chocolate packaging preparation by integrating the machine with the production line.

Once you power the equipment, the production line delivers chocolate to the packaging machine.

Chocolate moves to the packing unit from the hopper via the assistance of a conveyor belt.

The packing material meets the chocolate at the packing unit, where it is cut to in right size and wraps it around the chocolate.

Once packed, the packaging material is sealed either by heat or glue.

Fully Automatic Chocolate Packaging Machine

It is a type of chocolate packing machine with all fully automated functional parameters.

This equipment barely requires any human involvement since the parameters are computerized.

One notable feature of this machine variant is high packing accuracy at relatively high speeds.

It also comes with a user-friendly PLC touchscreen integrated with a human-machine interface.

The stainless steel framing and contact parts material enhance hygiene and durability since it is easy to clean and corrosion resistant.

It comes with an effective material pump that ensures the product is served appropriately into the vibrating tray.

fully automatic chocolate packaging machine

You can easily integrate this equipment into a typical chocolate making machine as long as you get the right settings.

This machine also comes with a collection unit where the packaged chocolates are assembled.

Additionally, this equipment is highly versatile; hence you can use it to pack a wide range of confectionery products other than chocolate.

It can also pack various types of chocolate packaging materials, including foil, pouches, and plastics.

However, it is a bit expensive to procure and requires professional maintenance to maintain its production reliability and efficiency.

Its working principle mainly revolves around receiving an adequate amount of chocolate, which moves to the packing unit with the help of a conveyor belt.

Packing materials moving from the roll film setting bar meet the chocolate at the packing unit, where it is cut according to the right size.

The machine wraps or folds the cut chocolate using the material and moves to sealing point for either hot or glue sealing.

Upon sealing, the packed chocolate moves to the collection tray awaiting next process.

Single Twist Chocolate Packing Machine

This chocolate packing machine variant is designed to wrap and fold chocolate products from one end.

It is versatile; hence you can use it to wrap and fold different chocolate types, such as round type, rectangle type, and cone types.

The principle features of this machine include a special design structure that delivers chocolate firm and relatively fast to the wrapping process.

It uses a servo motor to send wrapping film, which is more stable and comes with a feeding conveyor capable of making chocolates in line before sending to wrap.

This machine also features a PLC touchscreen control unit for easy and smart operation.

Besides, it has a high and adjustable packing speed of about 20-350 bags per minute, depending on the preferred settings.

single twist chocolate packing machine

It is generally compact size, but you can find it in different sizes depending on the customized specifications.

The working principle of this machine involves conveying the chocolate products into the packaging unit.

Here, they meet wrapping films coming from a roll film setting bar where the chocolates are wrapped and folded one by one.

They move to the sealing unit to strengthen the wrap and ensure it remains strong.

Double Twist Chocolate Packing Machine

It is more or less similar to a single-twist chocolate packing machine.

However, this specific variant is designed to wrap chocolate products from two ends, making the package stronger.

Essentially, you can set a single twist chocolate packing equipment to provide a double twist on chocolate products.

The main features of this machine variant include stainless steel framing material and high packaging speeds.

double twist chocolate packing machine

PLC touchscreen control unit for intelligent and convenient operation and a more stable servo motor are other notable features of this equipment.

Ability to wrap chocolate in different materials as well as stable and durable working performance also come out as its outstanding features.

As far as its working principle is concerned, the chocolate products are conveyed into the packing unit using the conveyor belt.

The wrapping films from roll film setting bar meet the chocolate at the packaging unit for wrapping and folding.

At this stage, the machine wraps the two ends of the chocolate package accordingly.

Once wrapped, the chocolates move to the next sealing stage to enhance the strength of the wrapped ends.

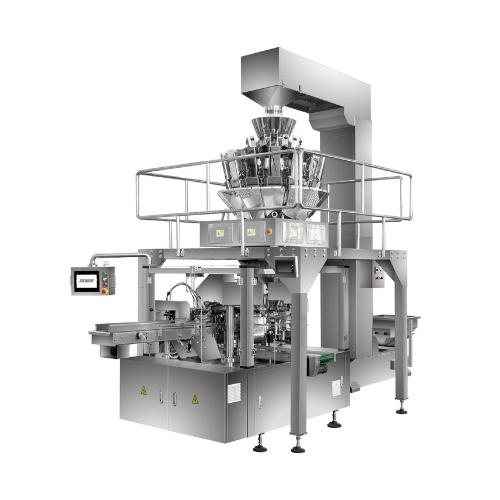

Chocolate Pouch Packing Machine

This machine is designed to pack chocolate products into pouches of different sizes.

Often, this machine features faster case packaging speeds with hot glue or tape sealing abilities.

The changeovers are quick, simple, and repeatable, in addition to synchronized handling of different chocolate products.

It comes with a PLC screen user interface that is easy to understand and an auto-pouch management mechanism.

chocolate pouch packing machine

The framing material features durable stainless steel that guarantees high hygiene levels.

Moreover, it allows different metering and infeed mechanisms with a continuous motion for accurate product placement.

This machine starts the process by chocolate pouch feeding and pouches erecting.

Conveyor unit moves each pouch as it prepares them for chocolate feeding as the machine assembles the pouches using race track collation system.

Chocolate is loaded into the pouch at different speeds then closed by heat sealing or glue sealing.

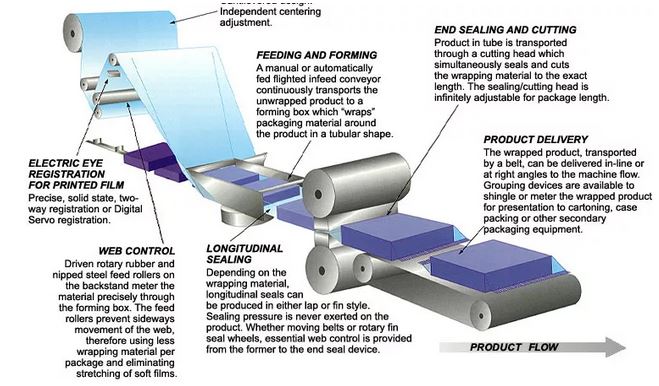

A standard chocolate packer is designed with several parts integrated to form a single functional instrument.

Of course, different machines may have different parts depending on the exact model and customization needed.

But here are the main parts you are likely to find in a typical chocolate packing equipment;

Hopper – It is a funnel-shaped component used for holding chocolate products before moving to the subsequent packaging stage.

Vibratory Table – This part facilitates transfer of chocolate product from the hopper to the feeding tubes.

Feeding Tube – It aligns the chocolate product you are packaging with the film to guarantee adequate sealing.

Roll Film Unit – This component has several links that help to pull the specific packaging material in a seamless rolling mechanism.

Conveyor Unit – It moves the chocolate product from one to different stations within the packaging machine.

Control Panel – It displays different packaging process parameters to allow easy control.

Sealing Jaws – They are parts that cut and seal the specific packaging material, often come with a serration pattern or heating element.

Sensors – These are devices within the machine designed to detect different operation anomalies and alert for response accordingly.

Dancer’s Arm – It is a free-moving roller positioning itself depending on the packaging material. It often maintains a neutral position if the packaging material has right tension.

Electric Unit – It consists of different electrical components and devices such as wires, fuses, and switches used in driving this equipment.

Discharge Chute – This is the section where the packed chocolate products are collected, awaiting the next stage in the process.

chocolate packing machine parts

They are quite a several but usually vary from one type of machine to another and the exact type of chocolate product being wrapped.

The notable wrapping methods for different chocolate products include the following;

Twist-Wrapping – This technique involves sealing chocolate products by twisting the ends of the wrapping material.

Banding – It is a wrapping method that entails wrapping chocolate around and sealing with heat or glue.

Sleeve-Wrapping – This method involves enrobing a web around chocolates by applying single or double film reels and sealing with heat.

Foil Wrapping – It is a method that entails sealing the ends of cylindrical chocolate wraps.

Foil And Band Wrapping – It involves wrapping chocolate products with aluminum foil and using a paper material to wrap around aluminum.

Pleat Wrapping – This wrapping technique entails the machine folding the wrapping paper like an accordion around the chocolates.

This process conforms to different stages, which ensure careful packaging of chocolates in readiness for distribution.

Here are the highlights of the main phases involved in chocolate packaging;

1) Preparation

It is the initial stage in this process and entails assembling and ensuring all materials required for packaging are in place.

The packaging machine must also be ready and free from any malfunction.

At this stage, all safety precautions are put in place to avert hazardous occurrences when using the machine.

2) Package Formation

After placing the packaging material on the roll film setting bar, the machine begins forming the package.

There is a conveying unit that delivers the chocolate product to the packing zone.

The machine’s dancer’s arm and forming collars play critical roles in helping chocolate packaging formation.

Packing process thus starts once the forming collars come in contact with the packaging material.

3) Chocolate Packing

Upon receiving enough chocolate from the main production line, the product moves swiftly to the packing unit.

It is at this stage that the formed packaging material meets the chocolate product.

However, it is imperative to note that different chocolate packing machines can use various wrapping methods and mechanisms.

This often depends on the actual type of chocolate product you are packaging and your preference.

Banding, twist-wrapping, pleat-wrapping, foil wrapping, sleeve wrapping, foil, and band wrapping are among the notable wrapping styles you can attain from this machine.

Nevertheless, other types of chocolate products, such as chocolate coins and chocolate beans, have unique wrapping styles.

Once chocolate is wrapped or folded accordingly, the machine slices the wrapping material awaiting the next product.

4) Package Sealing

It is the next stage after chocolate is wrapped in particular packaging material.

The wrapped or folded chocolate is pushed into the sealing stage through a conveyor unit.

Different wrapping materials have various preferred sealing techniques but most commonly heat or glue sealing.

Heat sealing primarily uses heat to secure chocolate packages, whereas glue sealing uses adhesive to stick the package.

Immediately after sealing process is over, this equipment inspects the package and seal integrity.

5) Discharge

The packaged chocolate product then exits the machine through the discharge chute to the collection section for next process.

manual feeding chocolate packing

As you write this section, please note that there are different wrapping techniques and methods

Occasionally, you may encounter a few technical errors when packaging chocolate using this equipment.

Some notable errors and ways of troubleshooting to enhance the efficiency and reliability of this packaging machine include the following;

Misaligned Packaging Film

In this case, it means the wrapping material appears misaligned on the chocolate product.

Usually, it indicates the film is not centrally placed, or the belts are improperly positioned.

Troubleshooting this error requires using a film with suitable threading and aligning the role centrally at the spindle to enable wrapping film to track properly.

You may also replace the film feed belt as you adjust the tension upon noticing inconsistency in bag length.

Packaging Bags Not Forming

This error shows that the machine fails to form packaging bags as desired.

It means the forming collars or dancer’s arm are worn out or broken.

The ideal way to handle this problem is by repairing or replacing the dancer’s arm and the forming collars.

You need to look into several aspects to ensure you pick the right equipment suitable for your needs, which include the following;

- Technical Features

Different units come with various specifications for chocolate packaging.

Always ensure the specific machine you are picking exhibits the ideal specifications that would meet your packaging demands, whether standard or customized.

- Model

Chocolate packaging units are available in a wide variety of models from different manufacturers.

When selecting right one, it is ideal to go for a model from a manufacturer with an outstanding reputation as far as quality and customer service are concerned.

- Versatility

Typical chocolate packaging machine can package different confectionery products.

But some are limited to specific shapes of chocolate products they can effectively pack.

It is, however, important to ensure you pick one that offers as many versatile features as possible, especially if you have to pack chocolate in different designs.

- Ease Of Integration

Mostly, these machines have to be integrated into the main chocolate production line.

It is thus advisable to choose one that is user-friendly and requires simple settings to integrate into the line accordingly.

- Cost

This is a fundamental element you should never overlook when choosing chocolate packing machine.

Of course, they are available at different costs based on various factors surrounding the specific machine.

But it is recommended to ensure you always get value for money whenever you select this machine.

- Production throughput

When picking suitable chocolate packing equipment, it is ideal to consider your projected packaging volume.

It guides you in making the right choice based on your packaging volume projection.

Primarily, there are two main types of sealing mechanisms used in chocolate packing machine, and they include the following;

- Cold Sealing

It mainly entails using a wide range of techniques that do not involve any form of heating.

In other instances, it is referred to as glue sealing since the packaging material is secured using adhesive substance.

- Heat Sealing

This sealing mechanism entails use of heat in sealing the chocolate packaging material.

In essence, you apply heat up to a certain temperature to melt and subsequently bond the package to create a strong seal.

These generally refer to the type of packaging material used outside the main packaging material.

They are vital in chocolate packaging since they facilitate easy handling of relatively smaller chocolate products by consolidating them in single packs.

Some notable types of these packages include the following;

- Plastic crates

- Corrugated cardboard

- Separators

- Shrink wraps

- Paddings

- Box

- Trays

- Bags

- Paper

Other Packaging Machines:

For all your chocolate packaging machines, contact us now.