China Automatic Cartoning Machine Provider

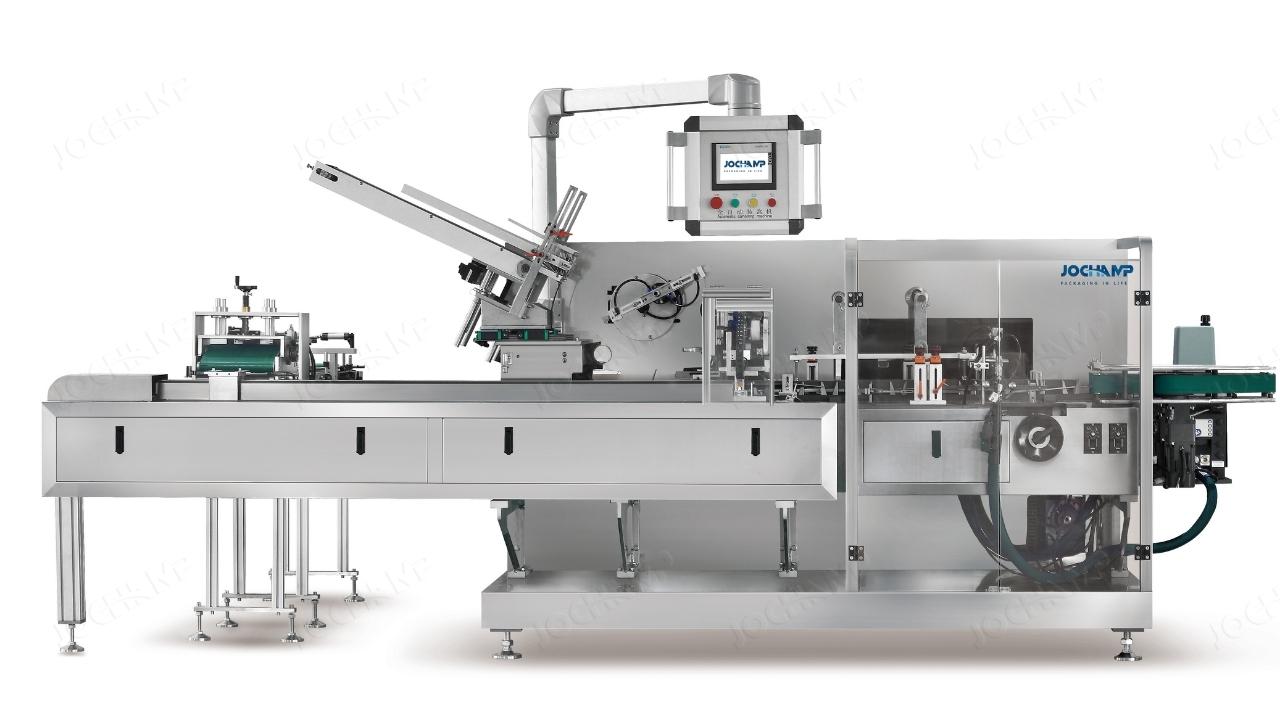

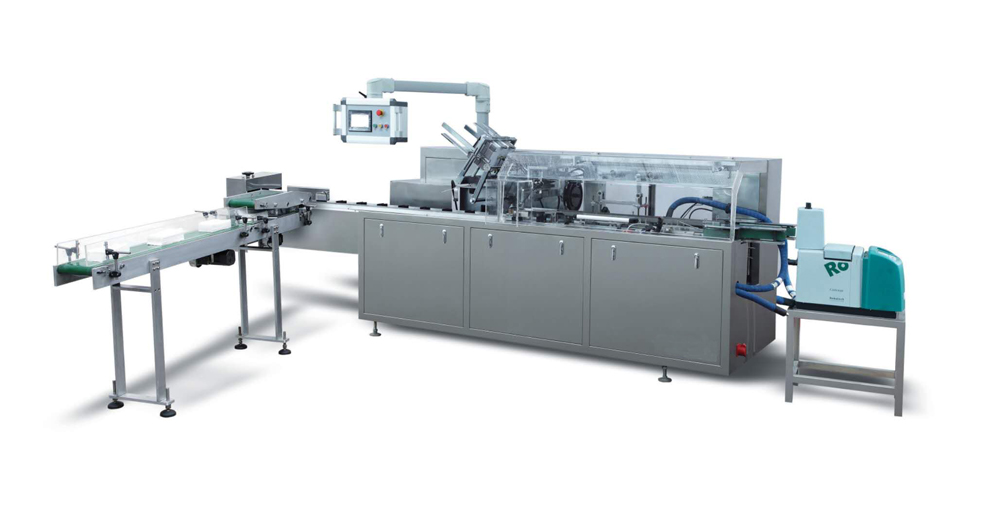

Jochamp is an industry-leading supplier of auto cartoning machines. A wide range of machine types, models, sizes, features, and other optional accessories are available. We can also custom-design, manufacture, and install cartoning machine production line solutions for you.

- Produce 50-500 PPM

- SGS, CE, and ISO9001-certified

- User-friendly HMI operating system

- Available with optional accessories

Jochamp Automatic Cartoning Machine

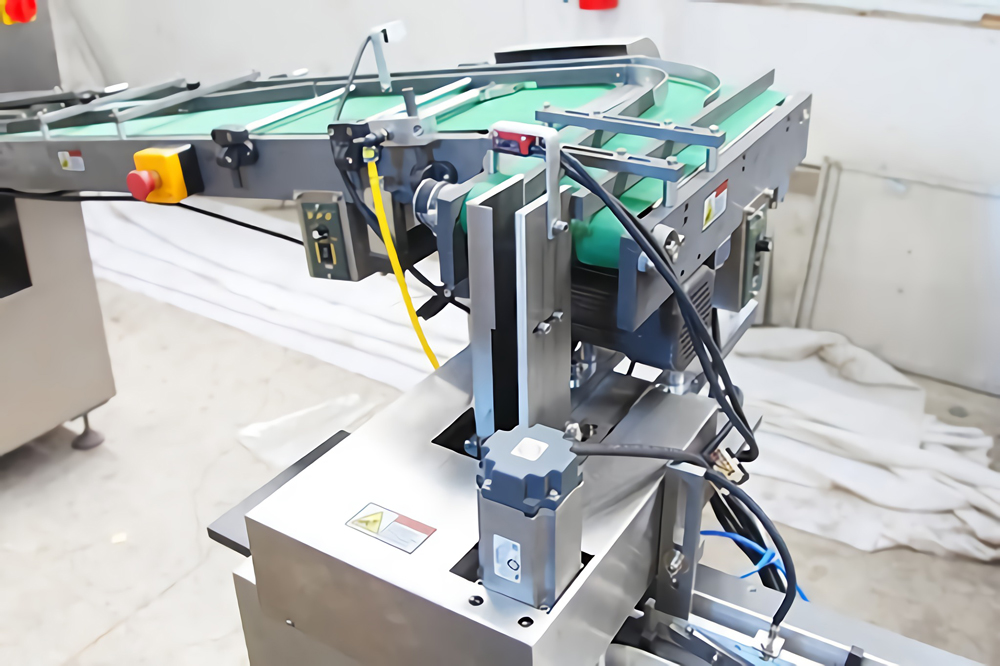

The automatic cartoning machine is a device that can produce custom carton containers. It is useful for a variety of products like cosmetics, food, toys, etc. The machine incorporates electrical, light, air, and mechanical design. Combined, they’re able to make cartons for different goods. Because the machine is totally automated, the major controls are managed by the PLC control system and HMI.

Jochamp has a comprehensive series of auto cartoning machines. JCZ-100 automatic cartoning machine, JCZ-120 automatic cartoning machine, JCZ-120J Robot Cartoner, JCZ-130 Automatic Cartoning Machine, to name a few. Also available in different designs are vertical cartoning machines, high-speed cartoning machines, and wrap-around cartoning machines. Jochamp has the right auto cartoner model for your production line needs. Feel free to contact us today.

Types of Automatic Cartoning Machines

A kind of intermittent cartoning machine with lateral insertion of products, which has a wide range of applications and has a good cost performance.

An intermittent cartoning machine with products placed on the head, more suitable for scattered products, such as washing powder, candy, milk powder, fasteners, etc.

A continuous running horizontal cartoning machine with fast speed and stable operation, which is more suitable for medium and large production enterprises.

Also known as a one-piece carton packaging machine. It is suitable for multi-pack carton packaging, yogurt, instant noodles, beer, etc.

The lowest cost cartoning machine. It uses manual loading of products. It is mostly used in small factories or laboratories.

Products are loaded by flexible robots, offering product positioning, defect product removal and lower requirements for production line docking.

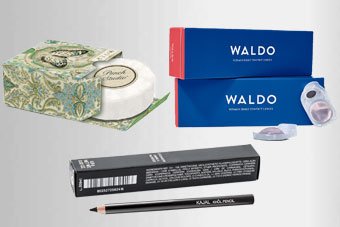

Jochamp Automatic Cartoning Machine Sample Package (6)

Auto Cartoning Machine Key Advantage

The fully automatic cartoning machine reduces labor costs and maintains speed, precision, and stability. According to on our case studies, you can save an average of 3-5 workers.

Jochamp automatic cartoner machine incorporates variable speed, multi-item collators, simple product size changeover, and more.

Auto cartoning machine is simple to operate and thus require less assistance. Mostly support a variety of tape thicknesses, and can be used for various products. It boosts operational productivity.

Since its fully-automated, the machine has a very low error rate. It features full over-burden assurance on all drives and stacking systems. That results in an overall increase in production.

Automatic Cartoning Machine Standard Features

Fully automated cartoning machine incorporates innovative technology. It contributes to smooth production operations and speed-up output efficiency.

- Rotary suction box way

- Auxiliary box opening device

- PLC control system and HMI

- Full 304 stainless steel cover

- Advanced overload protection system

- Size-changing structure with a ruler

- No product, no suction box function

Auto Box Packing Machine Series: Customize Solutions

The Jochamp automatic cartoner series is a great solution in the packaging industry. For particular business needs, we can design unique auto cartoning units. You can send us your design and check which of our models has a close image. Though we can build a new one, we try to modify our design first.

Automatic products feeding, glue sprayer, labeling machine, leaflet folder, check weigher are some equipment that can be built into. They can also adopt date codings such as laser coding, embossing, and inkjet. More features can be customized or added depending on your production needs. Please contact us today so we can assist you, specifically.

JOCHAMP MACHINERY- China Leading Automatic Cartoning Machine Manufacturer & Supplier

- 2 years warranty support

- Has an excellent team of 10+engineer, 15+ sales, 20+ after-sales

- All our cartons machines are CE, IOS9001, SGS certified

- Supply automatic cartooning machines to 1300+ customers in 100+ countries

Jochamp: Your Source for Automatic Cartoning Machine

Jochamp focuses on providing automatic box packing machine production line solutions. We serve different industries such as pharma, food, industrial, and household. There’s a range of unit classifications to choose from. You can source different functions, shapes, types, sizes, and other parameters.

If you’re undecided, our team can help you choose the right carton machine. You can discuss with us your factory floor pans, front-end production lines, budgets, etc. Rest assured Jochamp fulfills your business requirements. From initial call to delivery, we guarantee quality support. Send us an inquiry now so we can get started!

Jochamp Automatic Cartoning Machine Video

The JCZ-120 automatic cartoning machine manufactured by Jochamp Machinery is mainly used for 25g, 50g, 60g, 100g tobacco molasses. Its fastest speed can reach 100ppm, and it is mainly customized for hookah shisha tobacco in cartons.

This set of Automatic Wrap Around Cartoning Machine is specially designed and manufactured for large packaging of electronic cigarettes.

Multiply Automatic Cartoning Machines For Your Choose

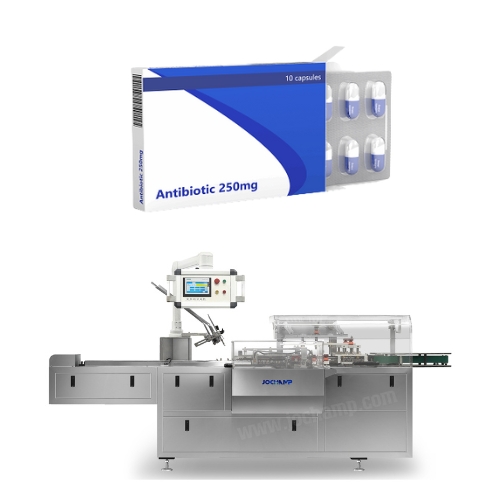

A type of fully automatic packing machine known as a blister cartoning machine is used to package capsules, tablets, patches, sweets, and other small goods in boxes. The machine may automatically carry out tasks including boxing, bonding, filling, sealing, printing, and forming of objects. It typically consists of an assembly line and a forming machine. By altering the mold, the blister cartoning machine can also achieve automatic packing of goods with various sizes and shapes.

The bottle cartoning machine is a fully automatic packaging machine that is ideal for packing bottled items. Beverages, shampoos, detergents, eye drops, electronic cigarette oil, and so on. The automatic feeding system allows the machine to be linked to front-end production equipment such as a filling machine and a labeling machine.

A tube cartoning machine is an automatic packaging device that can be used to package products such as toothpaste, lotion, ointment, and more. It can be utilized as a tube manufacturing line by connecting it to a tube filling machine, a tube capping machine, a tube labeling machine, and other pieces of machinery through front-end adaption.

Jochamp Machinery’s Food Cartoning Machine has several features tailored to the food industry. The machine’s stable operation can be ensured by the machine’s unique large carton suction box structure. Food safety is ensured by all stainless steel and food-grade contact surfaces. To ensure the stable operation of the equipment in the low-temperature cold storage, the entire system is equipped with low-temperature operating appliances as standard.

Jochamp Machinery has made a unique design for Pouch Cartoning Machine, which can guarantee the yield of pouch cartoning and reduce the defective packaging caused by uneven, bulging or too long pouch. By customizing the automatic feeding system, this pouch cartoning machine can be connected with vertical packaging machine, flow wrapper, and sachet filling machine as a production line.

The automatic cartoning machine is suitable for most products on the market. However, the top-opening carton requires different equipment.

According to the cartoning machine model, feeding method, product size, the speed is generally between 40-260. Before getting the exact speed, please provide product and carton information

Of course, We are a professional manufacturer of packaging solutions. We can design, manufacture and install packaging production line solutions for you based on your products, front-end production lines, factory floor plans, budgets, etc.

There are some differences between manual cartons and machine cartons. Before you place an order, we provide free testing services, and we will issue a detailed test report.

First of all, we will ensure that your carton is within the adjustable range of an automatic cartoning machine model. If it exceeds the range or has a different structure, your carton will not be able to be used on the same cartoning machine.

Usually, you need to spend 20-45 minutes to replace a carton and product with a similar structure. If your product structure has a large deviation, you may need to change machine parts, then you may need to spend more time.

Under normal circumstances, we have requirements for the material and thickness of the carton. White cardboard material and 250-350gsm weight cartons are the most adaptable.

We provide global installation training services. But if it is a standard machine or you have a professional mechanical engineer, we recommend that you install it yourself through our detailed video and operation manual. Because the operation of the cartoning machine is very simple, if you only have one size carton, then you may only need to connect to the power supply to use it.

The most common optional configurations are:

- Glue machine

- Date coding machine

- Manual folding machine

- Automatic feeding system

- Air compressor

- Metal detector

- Weighing machine

You can choose the corresponding configuration according to your own needs.

We don’t produce cartons, but we have a dedicated cartons supplier. We can provide you with the corresponding carton structure design and the carton price for your reference. After you place the order, if you don’t have a paper box or it is not convenient to send a paper box, we can provide these paper boxes for machine testing. These are free.

Our automatic cartoning machine has passed mainstream certifications, including CE, ISO9001, SGS, etc. For other types of certification required by some countries, we can also provide.

Related Product

Automatic Cartoning Machine

Jochamp automatic cartoning machine can be connected to the production line to achieve online packaging. From 50 bags per minute to 500 bags per minute, our automatic cartoning machine allows you to experience the high-speed improvement of packaging efficiency with the naked eye. According to our case statistics, we can help customers save 3-5 labor on average!

Whether it is a batch packaging machine or a continuous packaging machine, their efficiency is fixed and controllable and can be seen clearly on their display screens. It means you can better manage your production.

You can also install the flyer folding conveyor, date printer, labeling machine, and lining parts on the cartoning machine, it will let you can handle different product packages. Different from manual packaging, each carton package of the automatic cartoning machine can be guaranteed to be exactly the same.

When the cartoning machine is used in line with the production line, all products can avoid contact with the human body, it can totally eliminate secondary pollution.

Cartoning Machine – Definitive Purchasing Guide

You can see carton packaging in the food, pharmaceutical, cosmetics, hardware, daily necessities, household, toys, and other industries. Of course, there are many kinds of cartoning machines on the market, which have different shapes, functions, prices, and quality.

1. What is Automatic Cartoning Machine?

The automatic cartoning machine is a kind of packaging machinery, which integrates Microcomputer, light, air, electricity, and mechanical configuration for packaging products. Simply put, it is a package machine that replaces manual labor and uses mechanical methods to load products into cartons and seal them.

Movement process of automatic cartoning machine

Fundamentally speaking, it uses mechanical operation to shape the folded carton, push the product into the carton, and finally close the carton.

2. Why Use an Automatic Cartoning Machine

Automatic cartoning machine has changed the entire product packaging market, and it has benefited from food packaging to cosmetics packaging to pharmaceutical packaging, etc. Here are some main benefits of using an automatic cartoning machine:

#1 Better Management

Whether it is a batch packaging machine or a continuous packaging machine, their efficiency is fixed and controllable. You can see everything clearly on their display screens. When the company has everything, including packaging efficiency, power consumption, and single package cost, it means that it is easier to calculate and control costs. In addition, the packaging efficiency of the machine is completely in your control, which means you can better manage your production.

#2 More Efficient

Not only packaging efficiency, but also the overall efficiency of the company. In most cases, the automatic cartoning machine can be connected to the production line to achieve online packaging. You no longer need to waste time and labor to transfer products, which allows your production line to improve overall efficiency.

From the automatic cartoning machine of 50 bags per minute to 500 bags per minute, you can experience the high-speed improvement of packaging efficiency with the naked eye. This not only means an increase in output but also your labor costs are declining. According to our case statistics, the automatic cartoning machine saves customers 3-5 labor on average!

#3 More features

The product packaging is different. Your carton may need to be sealed with hot melt glue, a folded leaflet needs to be placed in the carton, a label or date printed, product lining, etc.

You can rest assured to hand it over to the automatic cartoning machine, installing the flyer folding conveyor, date printer, labeling machine and lining parts on the cartoning machine are all optional items. And these can all be online.

#4 Precise Packaging

Different from manual packaging, each carton package of the automatic cartoning machine can be guaranteed to be exactly the same. The significance of this is that the recognition of the product will increase, and consumers can visually distinguish the authenticity through the product packaging.

#5 Eliminate Secondary Pollution

A large number of food, pharmaceutical, cosmetic and chemical products require carton packaging, and manual packaging cannot completely prevent secondary pollution.

It is completely possible to use an automatic packaging machine because all contact surfaces of the machine are used food-grade materials. When the cartoning machine is used in line with the production line, all products avoid contact with the human body.

3. Classification of Automatic Cartoning Machines

According to the movement mode of the automatic cartoning machine, it is divided into:

#1 Intermittent Cartoning Machine

You can also call it a horizontal cartoning machine. Due to its high adaptability and wide range of applications, this machine is very popular in the market. It is our most common type of cartoning machine.

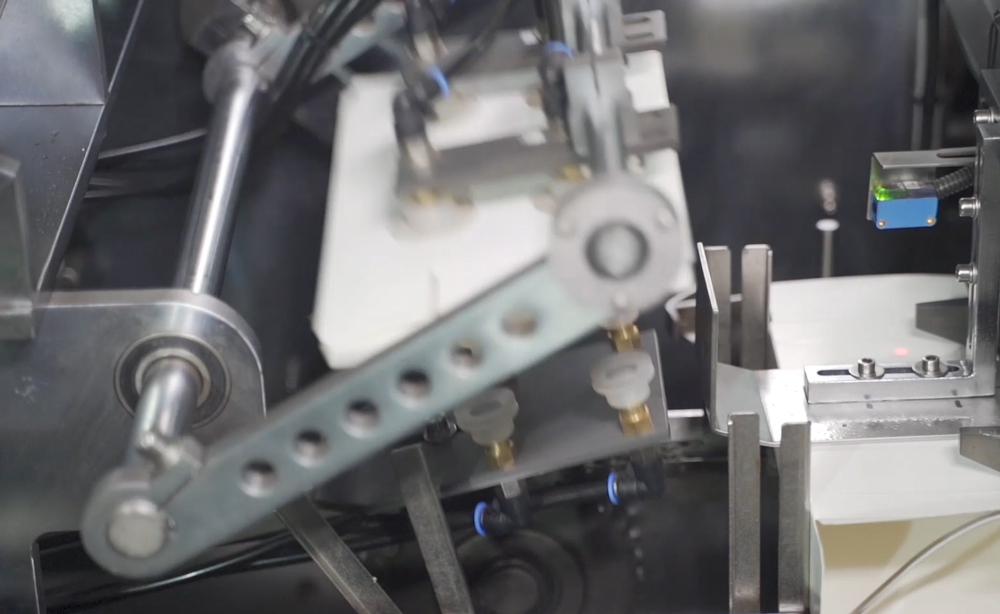

As shown in the figure, the suction box mode of the intermittent cartoning machine is up and down movement, and the pushing material is a single pushrod direct push, so the movement of the entire machine is restricted by the suction box and the material pushing parts. During the transportation of each product, It needs to be paused once, so we call it an intermittent cartoning machine.

#2 Continuous Cartoning Machine

Of course, you can also call it a high-speed automatic cartoning machine. This machine is generally only suitable for products with a relatively regular shape, and scattered products can easily make the machine unstable. It must be mentioned that its fastest speed can reach 100-500 bags per minute, which is not possible with intermittent cartoning machines.

Movement mode of continuous cartoning machine. As shown in the figure, thanks to the rotary suction box mode and the continuous operation of multiple pushrods, the working model of the machine can be continued uninterrupted, so we call it a continuous cartoning machine, and its speed is also Hence the benefits.

#3 Bottle Cartoning Machine

This is a cartoning machine suitable for bottles. Its front section has a bottle unscramble mechanism, which can sort bottles by rotating.

After sorting by the bottle sorter, we usually use a more stable servo bottle inverter to pour the bottles into the bin of the cartoning machine. Bottle cartoning machines are more commonly used in cosmetics, medicines, and health products.

#4 Automatic Counting Stacking Cartoning Machine

Automatic counting stacking cartoning machine

This machine is mainly suitable for sheet-like products such as facial masks, eye patches, condoms, pregnancy test sticks, cards, etc. This machine is usually suitable for products of 3-20 pieces per pack.

It uses an automatic counting and unloading device to realize multi-piece stacked packaging of sheet products.

Sample of automatic cartoning machine for a beauty mask

#5 Cartoning Machine for Lined Products

In actual product packaging applications, we can often see some lined products to fix the product so that it does not shake in the carton and cause damage to the item, or some products use a removable carton to make users use it. More convenient.

Sample of Bulb Cartoning Machine with Lining

This machine is usually used for packaging products with special designs and lining for light bulbs, beauty masks, food, etc.

#6 Blister Cartoning Machine

The blister cartoning machine is generally suitable for medicines, health products, milk tablets, chewing gum, candy, and other products that use blister packaging. It realizes the stacking and packaging of 1-20 pieces of the blister through the servo splitting mechanism in the front of the machine.

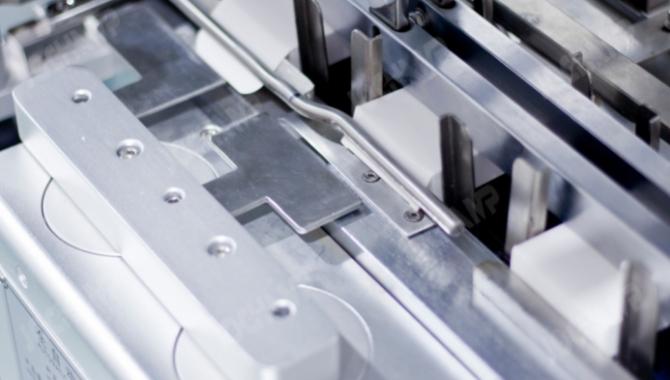

Blister feeding mechanism

Usually, the blister cartoning machine can be connected with the blister packaging machine through the transfer conveyor belt to realize the packaging production line function. To better understand this machine, please see the following packaging samples:

Blister carton pack samples

#7 Automatic Online Cartoning Machine

This machine is the most commonly used solution when connecting tissue-making machines, flow wrappers, face mask-making machines, or other production lines.

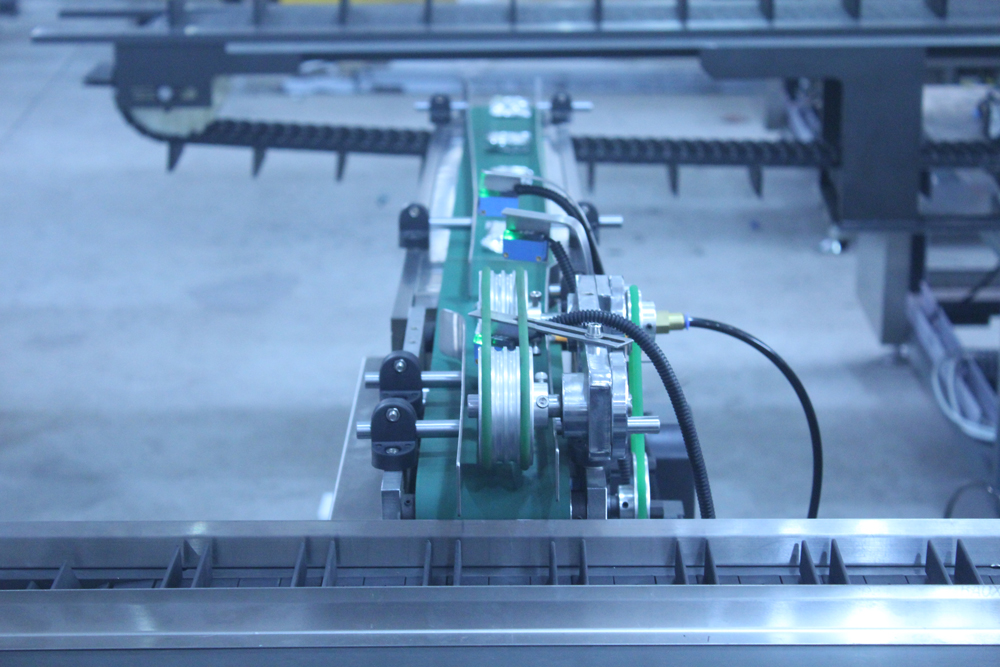

Conveyor Belt Feeding System

The transfer conveyor belt is used to limit the position of the product. There is a servo feeding mechanism at the back end of the transfer conveyor belt, which can make the products regularly arranged into the storage bin of the automatic cartoning machine.

Stacking Stockers

For some products that need to be stacked into cartons, we will configure a set of stacking stockers, which can stack multiple products and enter the automatic cartoning machine silo regularly. The machine has a wide range of applications, including napkins, cakes, shisha tobacco, surgical masks, bread, biscuits, etc.

Face masks stacked in a paper box

The product is packaged in carton after being packaged by flow wrapper plastic film

#8 Large Carton Cartoning Machine

Large carton cartoning machine

For some larger or thicker cartons, we usually recommend this machine. Because of the first point, the too-large carton is beyond the adjustable range of the cartoning machine and cannot be used. The second point is that for a single-tip suction box system, a box that is too large or too thick will be unstable. Third point, storage The depth of the silo is too small, resulting in frequent replenishment of the carton.

Carton Storage Bin

Larger and deeper storage bins are conducive to storing more folding cartons. The contact surface of the carton is equipped with a conveyor belt to make the carton fall more smoothly.

Larger Body Size & Box Outlet

The larger body size enables a larger adjustable size range. A wider outlet opening after the carton is sealed can help the carton to better fix its shape.

Double Suction Box System

The unique double-layer suction box design acts on both sides of the carton, making the carton easier to form and increasing the stability of the machine.

This machine is mainly suitable for large boxes of food and daily necessities packaging, or the carton is a special hollow type, or the carton is made of hard corrugated paper.

4. How to Select Right Carton for Cartoning Machine

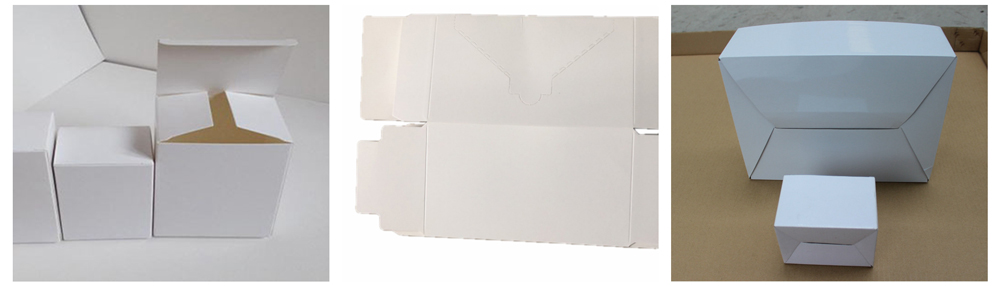

You should focus on the shape of the carton, the way of locking the box, the material of the carton, the difference between the manual box and the machine box, etc. This is not only related to the aesthetics of the product but also affects the selection of the machine and the stability of the machine in operation.

#1. Carton Shape and Lock Method

Usually, the cartons we see are quadrangular cartons, a small number of cartons are hexagonal or cone-shaped, and some cartons use a structure with hanging ears for more convenience.

Common carton shapes

Generally, the shape and size of the carton affect the part of the structure and operation of the automatic cartoning machine. Generally, the cone or hexagonal carton structure needs to use a non-standard structure.

In addition to the shape of the carton, what affects the structure of the machine is the way the carton is locked. Usually, our common lockbox methods are the self-locking structure, insert box structure, and paste box structure.

Common lockbox method

In fact, the method of locking the box affects the part of the structure of the machine and directly affects the price of the machine. For some special carton structures, such as the top-opening carton or the carton that requires particle filling, the structure of the machine will be completely different, and the price will be 2-5 times higher.

face mask Top open carton packaging

#2. The Material of the Carton

There are three main types of boxes on the market, white cardboard, corrugated paper, and unusual PET plastic boxes.

Carton of various materials

Generally, under the premise of the limited shape and lockbox method, the material of the box does not affect the structure and operation of the machine.

#3. The Difference Between Manual Box and Machine Box

The human hand is the most adaptable. Compared with the human hand, the machine is inevitably somewhat unsuitable, so some cartons must meet the requirements of the machine, otherwise, it will cause the machine to become unstable.

First of all, where the carton is marked in red, we must have a certain arc so that the blade will not generate friction when folding and cause waste. This applies to almost all types of cartons.

When using the ear lockbox of the carton itself, we need to pay attention to the place marked with a red line. This will not cause waste caused by the ears of individual boxes not being locked.

For the stability of the machine, ask your carton supplier to pre-fold your carton, and the folded carton will open better. This will benefit the stable operation of the machine. This step is usually free.

5. Automatic Cartoning Machine works in different industries

The application range of automatic cartoning machines is very wide, and it can be designed in almost all industries. Here, we show some of the more common products.

# 1. Food Industry

Trending towards environmental protection, more and more foods have begun to use carton packaging. Usually using carton packaging can also make food more hygienic and beautiful. Automatic cartoning machines began to play a pivotal role in the food industry.

- Frozen food packaging

For frozen food, traditional film packages cannot effectively produce brand effects to attract consumers, and carton packaging has significantly improved its appearance and cleanliness.

Pizza carton packaging

Steak carton packaging

Frozen seafood carton packaging

- Baking industry

For baked goods that are easily damaged, cartons can undoubtedly protect them better.

Biscuit carton packaging

Chocolate Pie Carton Packaging

- Chocolate and candies

For the carton packaging of granular candy or chocolate, we can use an automatic weighing feeder to achieve automatic packaging.

Candy Carton Packaging

Chocolate Carton Packaging

- Powder carton packaging

Milk Powder Carton Packaging

Corn Starch Carton Packaging

#2 Cosmetics Industry

For cosmetics, compact and beautiful packaging can increase the favorability of consumers and can also serve as a basis for anti-counterfeiting.

Beauty Mask Carton Packaging

Perfume Carton Packaging

6. Safety & Technical Compliance

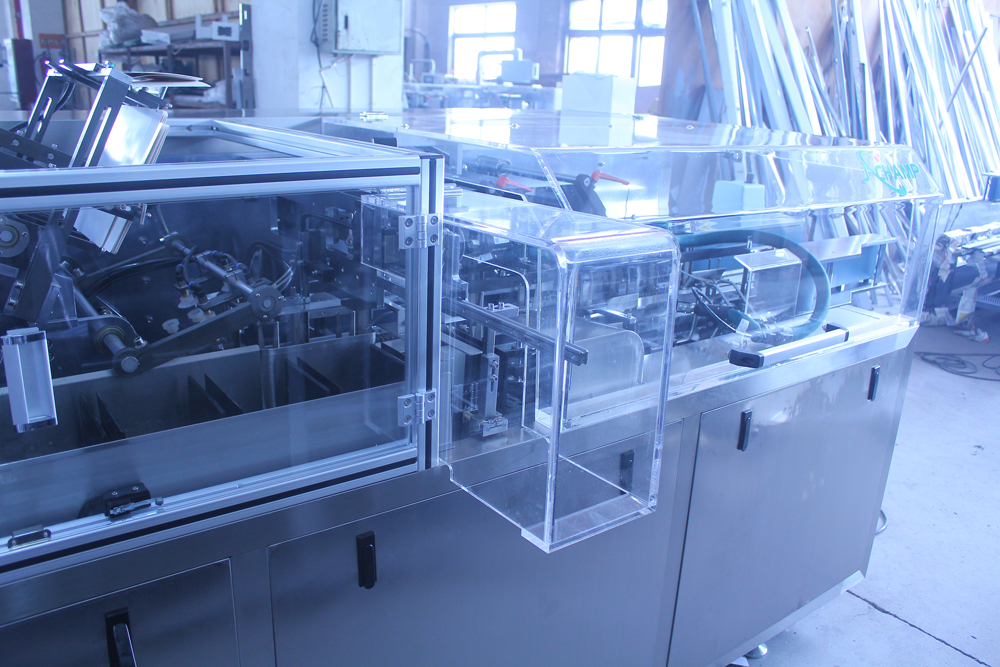

While the automatic cartoning machine helps you, the safety of using a small and medium industrial machine is also valued by us. The most obvious point is that we have installed safety shields as much as possible in all operating areas.

Safety Guard for Automatic Cartoning Machine

In the main operating area of the machine, we have installed an acrylic transparent shield, which will improve the safety of the machine operation and will not affect the operator’s observation of the machine.

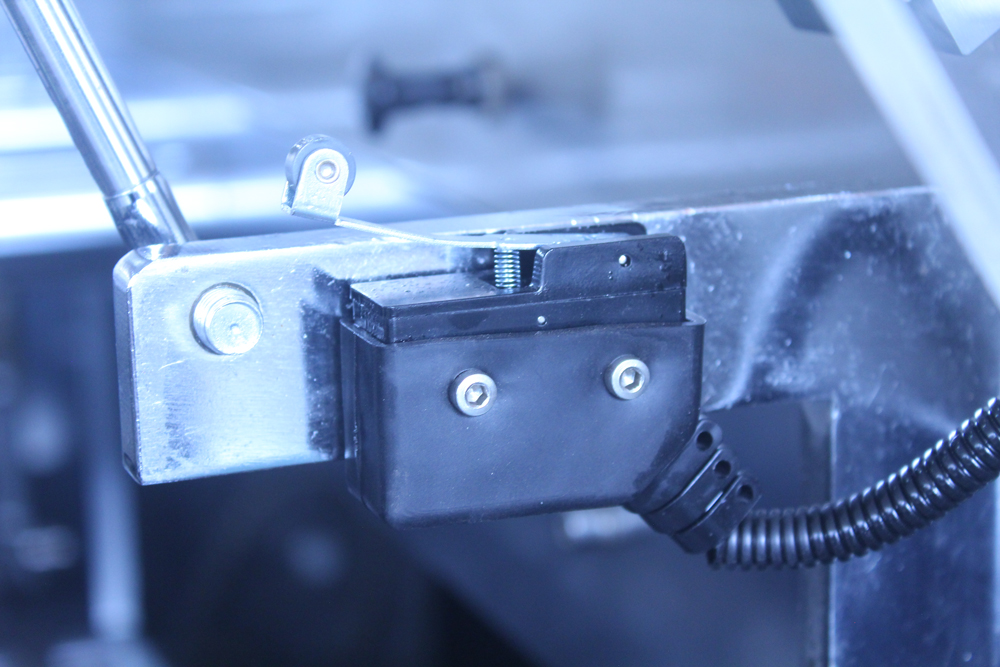

Limit Emergency Stop Switch

At the same time, we have installed limit switches on all openable shields. When the machine is turned on by mistake, the machine will stop running in a short time to better protect the operator.

Rocker Controller

The standard rocker arm controller improves the safety and ease of use of the machine.

The Sensor

The ubiquitous photosensitive probe is an important part of the machine’s intelligence. It can make the machine handier, while also protecting the safety of the operator. While safety is guaranteed, the quality of the machine is also an important point, which is related to the service life of the machine. The basis of quality is the use and handling of materials

The ubiquitous photosensitive probe is an important part of the machine’s intelligence. It can make the machine handier, while also protecting the safety of the operator. While safety is guaranteed, the quality of the machine is also an important point, which is related to the service life of the machine. The basis of quality is the use and handling of materials

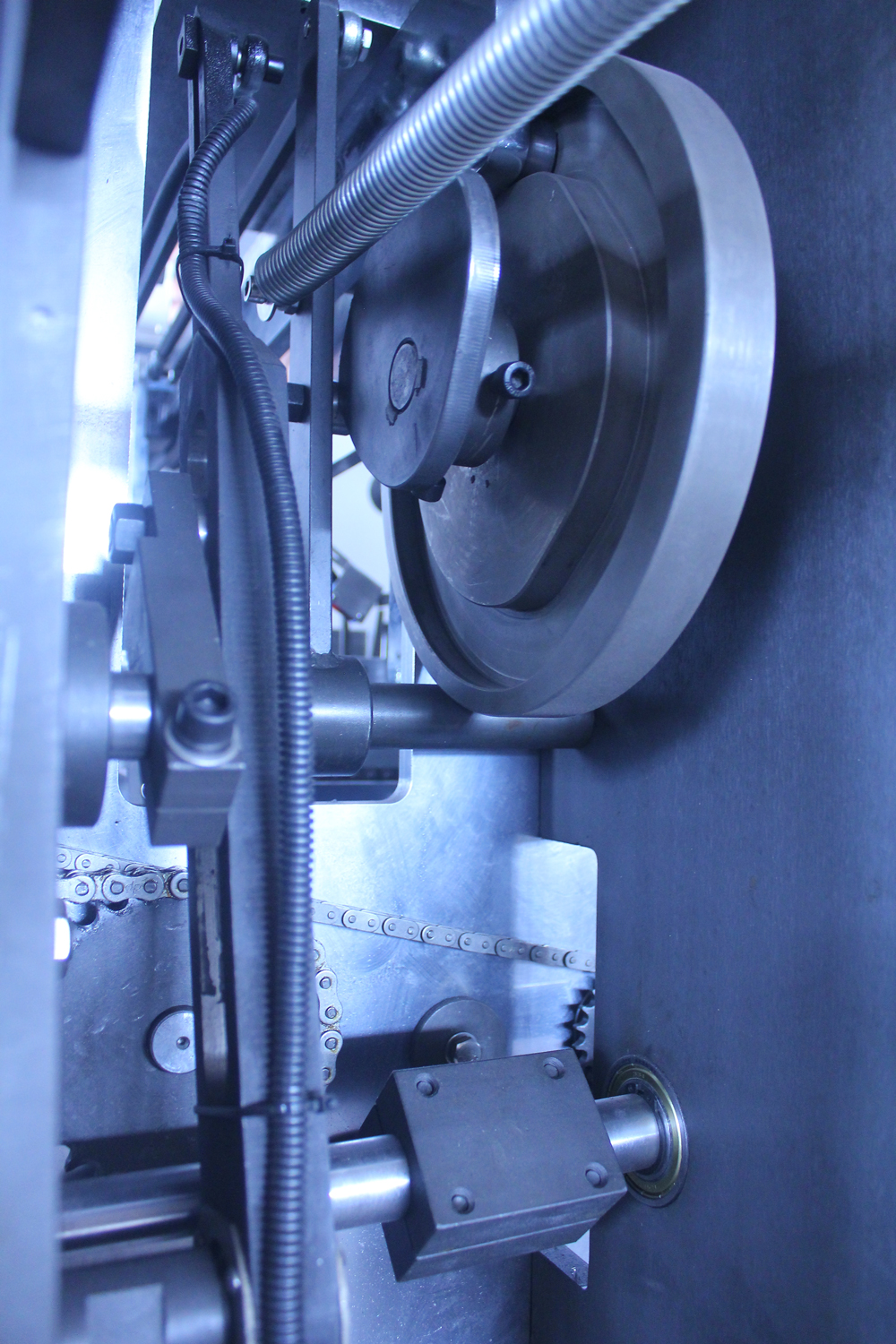

Cam structure of automatic cartoning machine

We use high-strength hardened carbon steel on the most easily worn cam and transmission structure, which can make the machine have a longer life.

Frame steel plate of automatic cartoning machine

When buying a machine, people’s focus is usually on price or function. A very important point supporting the fuselage structure is often ignored. That is the rack. Reasonable body structure and stable body can help reduce noise when the machine is running, and at the same time reduce resonance between components.

At this point, we also attach great importance to our fuselage facade using a 16mm thick chrome-plated steel plate with plane correction, which can effectively resist corrosion while ensuring the coordination of the fuselage structure.

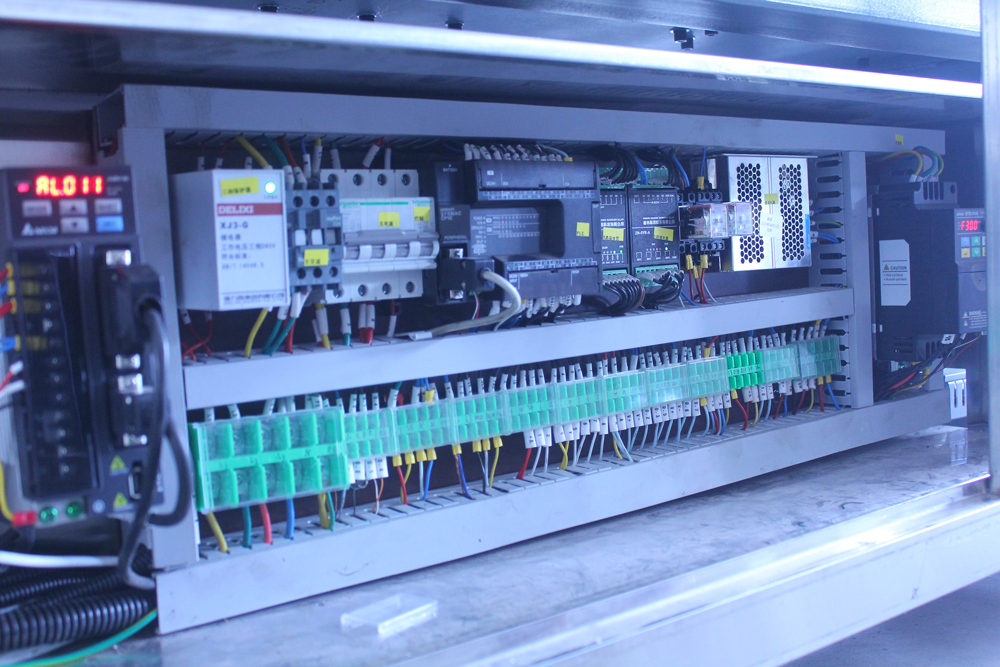

Electrical part of automatic cartoning machine

Electronic appliances are the soul of automatic cartoning machines, and a high-quality cartoning machine should be driven by stable appliances.

In the core part of the whole machine: PLC intelligent control system, we usually use the internationally renowned Omron or Siemens industrial control system. For some customers who are more concerned about cost performance, we would recommend Delta industrial control systems.

7. Conclusion

We have learned a lot of professional knowledge about automatic cartoning machines. I also understand what the cartoning machine can bring us. You can choose a standard or customized cartoning machine according to the production needs of the company. You can even add an automatic cartoning machine to your existing production equipment as a production line.

Automatic Cartoning Machine: The Ultimate Guide

There are a number of factors to consider before buying automatic cartoning machine. You should know the features, classification, working principle, components, safety feature and troubleshooting procedure, amongst others.

In this guide, you will find all information about automatic cartoning machine.

This is a machine that automatically packages products in a carton by erecting a blank carton and placing the products inside it.

The machine is high tech and combines air, light, mechanical and electrical properties in its operation.

automatic cartoning machine

Automatic Cartoning Machine has drastically changed the packaging way of finished products all over the industry.

Additionally, packaging demand for products in majorly the food and pharmaceutical industries has greatly been met with improved efficiency.

Furthermore, the need for improved efficiency and productivity has been brought about by the benefits that come with an Automatic Cartoning Machine. They include:

Time Saving

Production lines that operate under very high speeds tend to waste a lot of time during packaging due to backlog.

This is different with the Automatic Cartoning Machine because it guarantees a dependable and continuous cartoning output.

Because machines are not prone to fatigue unlike human labor, the production process can go on for hours on end.

When unnecessary breaks are eliminated, the output is usually high with great efficiency.

Safety

Operating an Automatic Cartoning Machine is very safe compared to manual packing of products.

Automation has ensured that risks such as pinching of hands have been eradicated for safe production.

Improved Quality

The packing quality of the product is greatly enhanced and the box cannot be easily damaged. Manual carton packing involves the risk of damaging the carton appearance but Automatic Cartoning Machine follows a definite packing procedure.

Automation

The control panel of an Automatic Cartoning Machine has an intelligent display panel that operates using PLC.

This facilitates easy monitoring and trouble shooting in the event of a breakdown.

There are various types of Automatic Cartoning Machine available in the market. The main types include:

Intermittent Mode

This is an Automatic Cartoner Machine whose method of operation involves an intermittent motion.

Such machines are normally of a lower intermediate or intermediate speed with their cost very pocket-friendly.

Intermittent Automatic Cartoning Machine are usually ideal for cartons of very big sizes with stability being a major advantage.

Since it handles large boxes with their containment area being big, operating it on very fast speeds is literally impossible.

intermittent mode

Continuous Mode

This type of Automatic Cartoning Machine contains several barrel cam loaders that are used to insert the boxes.

Their motion is horizontal to facilitate the forward motion of the boxes insertion and their backward movement.

Their design is configured in such a way that maximum speeds can be achieved in their operations.

Additionally, the price is relatively higher compared to intermittent cartoning machines with their design being more complex.

continuous mode

Vertical Automatic Cartoning Machine

The operating mechanism of this type of Automatic Cartoning Machine involves the loading side of the erected box facing up.

Also, the front and rear panels are made to be horizontally positioned.

This type of machine is recommended for products that do not require vertical loading into their packaging.

vertical automatic cartoning machine

Such products may avoid vertical loading to evade production flaws like abrasion on their surface in the process of loading.

You can learn more about vertical cartoner machine.

Horizontal Automatic Cartoning Machine

This type of machine is highly recommended for cartoning products having regular shapes like medicine or biscuits.

Products are fed automatically and carton flaps closed with batch numbers printed and sealing done with hot melt glue.

horizontal automatic cartoning machine

You can also learn more about horizontal cartoner machine.

Top-Load Cartoning Machine

This type of Automatic Cartoning Machine resembles the vertical cartoning machine in the manner in which the boxes are fed into the system.

However, instead of a single unit, it contains a combination of machines integrated into it including components like carton closers, robotic loaders and tray formers.

top load cartoning machine

Here is more information about top loading mechanism.

The main parts of an Automatic Cartoning Machine are as follows:

PLC Control Panel:

This is the cartoning machines Human-Machine Interface (HMI) and is fully automated.

It is used to control and observe processes such as carton placement, product per carton and their placement.

All process parameters are set here with the option of the machine stopping in the event of a failure.

Automatic Lubrication System:

The Automatic Cartoning Machine is an electromechanical device with very many movable parts.

To ensure the lifespan is increased, all these parts must be regularly lubricated.

Sufficient lubrication is automatically provided to components such as conveyors, bearings and gears.

Guide Rails, Carton Chute and Conveyors

The Guide rails function is majorly creating a pathway for the conveying of the cartons.

An electric motor runs the conveyor that carry the cartons from one point to the next and is inclusive of rollers.

The carton chute ensures that once products are packed in the carton, it passes through it for further packaging.

Besides, this will be in bigger boxes for easy transportation and storage.

Inkjet Spraying Mechanism

An Inkjet printer comes with the Automatic Cartoning Machine and is used for labeling purposes on the carton.

Details such as the products expiry date, manufacture date and any other indications are printed for the consumer’s knowledge.

Carton Feeding Mechanism

This is a pneumatic system that uses vacuum to suck blank cartons in preparation for the cartoning process.

The cartons are contained in the carton storage room with can be adjusted to accommodate different carton sizes.

Leaflet Feeding System

This mechanism ensures that leaflets are fed into the cartoning process by placing them on cartons via pins.

The products then proceed to the conveyor belt for the next process.

Electric System

The Automatic Cartoning Machine gets its operating power from its electric system including powering the pneumatic system.

It is composed of the electric panel combined with electric motors providing the gearing system.

There are various types of Automatic Cartoning Machine in the market but all their working principle is basically the same.

Generally, blanks of cartons are erected and the product is automatically inserted into the carton and then sealed.

Automatic Cartoning Machine can be utilized individually and product loaded or they can be integrated to an upstream system where products are introduced.

An example is an automatic Cartoning Machine connected to a tray-sealer that seals trays with a film and placed into cartons by the machine.

automatic cartoning machine

Based on the type of machine, cartons are pushed into the machine using different types of inserters.

A continuous cartoning machine contains several pushers with a cam barrel that continuously pushes them individually until products are inserted.

Intermittent Cartoning Machines have just one inserter that is either mechanically driven or has a servo-motor to drive it.

The Cartoner then discharges the loaded cartons after they have been inserted and secured in a collated style.

The cartons then pass through a several guides that assist in folding the tuck end of the carton. Also, the tuck and dust flaps are then folded and tucked by the tuck folder and flap folder respectively.

Immediately the cartons have been sealed by the machine, they are ejected from the cartoning system. They are then taken to a downstream packaging system such as a case packer or an overwrapper that completes the packing process.

Some very important features of an Automatic Cartoning Machine include:

i. Guaranteed Safety: when products don’t conform the preset parameters, an alarm is raised and operation suspended for rectification.

Pressure and vacuum are also well protected to automatically ensure effective and quality cartoning.

ii. Automatic Diagnosis: the cost of maintenance is greatly reduced when faults are diagnosed in advance and rectified.

The machine automatically indicates faults and ceases to operate to avoid further damage.

iii. Operational Synchronization: the Automatic Cartoning Machine has product and carton continuously fed with all other functions working simultaneously.

All these operations occur with high stability and are very reliable.

iv. Operational Convenience: adjustments can easily be made depending on the size of the product being cartoned.

Speed is controlled via variable frequencies with PLC and HMI devices easy to operate.

Some of the limitations of using an Intermittent Mode Automatic Cartoning Machine include:

a) Acquiring the machine is quite expensive especially in the early operations after purchase and when installing it.

b) It has a very slow mode of operation compared to other types of Automatic Cartoning Machine therefore reducing output.

Automatic Cartoning Machine have operational challenges like:

a) Poor carton quality can lead to difficulties in packaging due to continuous stoppages.

b) In the event of a system error occurring, wrong diagnosis and debugging can reduce the production quality.

c) The cost of spare parts for the complex machinery is usually high with most parts not being interchangeable.

d) The complex nature of the Automatic Cartoning Machines makes its maintenance very costly and tedious.

In terms of operation, the feeding system of a semi-automatic Cartoning Machine is not automated therefore its operations are not simplified.

This tends to reduce the overall output of the machine and the production speed.

For efficient production and considerable output, many operators have to be employed to make up for lack of automation.

Some designs of the Semi-Automatic Cartoning Machine may also be sophisticated enough to allow inclusion of accessories such as box conveyors and carton magazines.

Some of the benefits of a semi-automatic Cartoning Machine include the reduced cost of maintenance. It can also be easily used with other safety devices like the Human Machine Interface (HMI) that safeguards the unit’s integrity.

semi-automatic cartoning machine

A fully automatic Cartoning Machine is very intricate and requires very little physical human input for its operations.

It is considered one of the most efficient cartoning machines that can carry out all the cartoning machine operations.

The fully automatic Cartoning Machine has the ability to verify the quality of the packaging carton being used.

This ensures that the correct quality carton material is utilized.

Some of the accessories that come with the fully automatic Cartoning Machine include folding systems and ink jet printers.

They can also insert brochures in the packaging and apply a system of hot melt glue used fir sealing.

All the operations carried out on the fully automatic Cartoning Machine are controlled from a central point using a computer.

This control unit is responsible for regulating, controlling and managing the operations with minimal labor required.

When sourcing for an Automatic Cartoning Machine, the results it can yield and the operational comfort greatly influence the decision.

Some of the vital factors to consider include:

Size

The Automatic Cartoning Machine should be economical in the space that it will occupy in the final premise.

Also, the design should be made as slender as possible but without compromising any of its performance capabilities.

Flexibility

Due to the high capital input cost of acquiring an Automatic Cartoning Machine, its flexibility should be diverse.

The design should be aligned in such a way that it is adjustable enough to package various box designs.

It must also be able to be easily configured into a variety of packaging lines and work well after installation.

Level of Output

An Automatic Cartoning Machines efficiency plays a role in influencing the number of products it can package in a day.

The product manufacturer should be consulted widely regarding the maximum output of the Cartoning Machine.

Safety Precautions

Due to the nature of their operation and complexity of design, operators of Automatic Cartoning Machine are exposed to many risks.

Any operational mistake can prove to be fatally costly and severely catastrophic.

Emergency precautions such as a shut-down function that is automatically emergent combined with a shut-down manual button are recommended.

This together with other auxiliary precautions should be factored in during design.

Automation

Based on the end-user’s level of demand for automation, the manufacturer makes an informed decision to avail the most appropriate machine.

In the event of a system error, the Automatic Cartoning Machine must have a trouble-shooting system.

This ensures that the machine ceases operation immediately to evade further damage and to allow for rectification.

Project Budget

The cartoning process should be clearly understood for the firm to arrive at the correct budget estimates.

Some considerations include the efficiency of the product being packaged, how the ergonomics is improved together with package aesthetics.

The current or initial cartoning process should be clearly analyzed together with future improvements of the process.

Some improvements to consider include making the cartons tamper proof or reducing the labor involved to bare minimum.

Machine Serviceability

A machine that requires a very limited change of parts in between carton adjustment changes is mostly recommended.

The cartoning machine should be able to seamlessly have changeovers when different cartons are applied.

Picking Mechanism

The picking method of the Automatic Cartoning Machine should be fully compatible with the product being packed.

For the entire cartoning process to run flawlessly, the blanks need to be correctly picked by the machine.

The Automatic Cartoning Machine has many industry applications including:

Pharmaceutical Industry

Products in the pharmaceutical industry such as ointments, oral liquids and others are packaged using an Automatic Cartoning Machine.

Its major gain in the pharmaceutical industry is preventing counterfeiting by having the cartons safely sealed.

Food Industry

Packaging food in cartons assists in the prevention of dust and microbial pollution while preserving its quality.

This also eases the foods transportations, circulation and its storage extended.

Cosmetics and Commodities

Cosmetics and other commodities can be easily packed using either vertical or horizontal Automatic Cartoning Machine.

They include products like facial cream, cosmetic cotton, soaps and toothpaste with abnormal products removed by the PLC.

Electrical Appliances And Hardware

The best option for packaging electrical appliances and related hardware is the vertical Automatic Cartoning Machine.

Such appliances may include devices like chargers, power sockets, electric bulbs and bearings.

Safety concerns in the Automatic Cartoning Machine have been addressed in the following ways:

a) Sensors: a variety of sensors using multi-pulse technology are used in the designed and linked to the control program.

When they detect an error or empty carton, the machine is automatically stopped by the safety controller.

b) Automatic Sealing: burns and cuts experienced by operators in manual Cartoning Machines have been eliminated by automatic sealing.

c) Critical Motion Control: there is a coordinated motion control in the decentralized drives with product variance controlled by automated adjustments.

d) Programmable Logic Control (PLC): it provides a fail-safe for all the processes with worker’s safety guaranteed by automatic diagnostic error stoppages.

e) Light Curtains: these are optoelectronic sensors capable of detecting something within proximity of an area.

They bring the Automatic Cartoning Machine to a stop when a worker accidentally comes into contact with them.

In the process of utilizing an Automatic Cartoning Machine, many challenges may be experienced.

Some of the problems encountered in the operations and their possible solutions include:

a) The vacuum suction may be poorly positioned. This requires a total refit of the whole vacuum system and calibrating it to the right position for efficient cartoning.

b) The infeed of the carton magazine may sometimes draw a flat blank into the machine.

This can be rectified by using multi-pulse equipment such as a photoelectric sensor that warns and stops the machine in the event of a malfunction.

c) Sometimes the carton blanks cannot be automatically separated when the machine is picking them.

This requires an entire shutdown of the machine and physically separating the blanks while swapping them with operational ones.

d) When the Automatic Cartoning Machine temporarily runs on the manual mode, it tends to have reduced operational speed.

The immediate solution is to alter the design of the drugging board adaptable to adjusting the machines speed.

e) On selected occasions, the carton store room can sometimes be improperly adjusted.

This calls for immediate adjustment of the carton store room to ensure seamless delivery of the cartons.

f) When the Automatic Cartoning Machine continuously operates at very high speeds, it becomes physically unstable.

Servo Motors and other servo stabilizing techniques can be applied to smoothen the operations of the machine.

g) The sucker tubing can sometimes have some leakage or get blocked thus leading to a malfunction of picking cartons.

The sucker tubing with a leakage should be replaced immediately after being unblocked with a new one.

Based on the working technique of the Automatic Cartoning Machine, black cartons are sucked using the pneumatic system from their stack.

Powering the pneumatic system before machine operation since the air will be used in the suction system.

The advantages of using a Continuous Mode Automatic Cartoning Machine are:

i. It is fully automated enabling all process and control parameters to be set and observed from a single point.

ii. The carton packing has a very high output because the machine operates at very high speeds.

iii. The packaging procedure is easily executed due to the progressive nature of the chain.

iv. The cost of production is significantly reduced due to the handling provisions that are very little or sometimes non-existent.

v. The carton efficiency is greatly improved due to the accuracy of the procedure.

vi. A lot of production time is saved due to the machines high speed compared to other machines.

For all your cartoning machine needs, contact us now.