Coffee Packaging Machine Manufacturer in China

JOCHAMP is your one-stop advanced packaging solution provider. We manufacture various coffee packaging machines professionally, ideal for your business and factories. Our company assures excellent machine qualities and performance with our skilled workers using automatic equipment.

- Easy to operate and maintain

- Come with a wide range of designs and capacity

- Fully equipped and automatic controls

- Increases business productivity

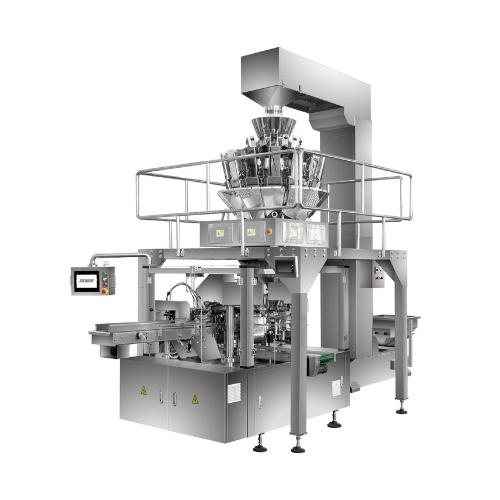

JOCHAMP Coffee Packaging Machine

The coffee packaging machines are automatic equipment that carries the vaccum packed coffee products out. They are beneficial for various coffee types’ packaging processes. These packaging machines feature handy and transport convenience. The coffee packing machines are designed to keep the coffee fresh and protect them from environmental effects. Compared to other devices, the mentioned machine has a more distinguished look.

JOCHAMP can fully provide your customized coffee packaging machines. We prioritize our customers’ requested specifications to achieve their desires and needs. Our expert designing team ensures accurate details and the performance you require for your coffee packaging factories.

Trust our satisfying services and drop your message now!

Coffee Packaging Display (5)

Why Need a Coffee Packaging Machine

The coffee packaging machines help keep the freshness of coffee products and prevent spoilage. Because coffee spoilage happens according to oxygen, heat, and light exposure, the equipment provides packing styles that maintain the best tastes.

Forming coffee packaging by automatic machines is essential for business sales. It enables your customers to identify your brand and the information for coffee products. The packing machines can produce unique packaging that attracts more customers.

Because the JOCHAMP coffee packing machines are durable, they are typically used for most coffee production facilities. These machines are made from high-end materials and construction, allowing them to operate for long hours.

The coffee packaging machines are designed with a one-way bag packaging process. They achieve packaging with pinholes that help eliminate the carbon dioxide from the packaging. That means the packed coffee is safe from cracking occurrences.

Coffee Packaging Machine Classifications

JOCHAMP manufactures different classifications of coffee packaging machines to suit various coffee types. They come with their functions and capabilities. Consider the following:

- Detachable Belt Coffee Packing Machine: This machine performs vacuum packing, sealing, cooling, and delivery. It is suitable for freezing, refrigeration, and sterilization products.

- Multipurpose Coffee Packing Machine: This machine provides productive functions. It is accessible in various series and accommodates items in bags of different sizes, contain, and shapes.

- Close Fit Coffee Packing Machine: A machine that uses two films, including the lower ones that carry the items and the upper films in the cardboard or trays.

How Coffee Packaging Machine Works

The coffee packaging machine functions first by placing the product into the bag and sealed. The material film must feature flexibility, be rigid, and resist heat. Coffee packing machines are designed with various functional parts, like vacuum pumps, heaters, and bags containing items that work with synchronization. That achieves productive and accurate coffee packaging.

Various packaging types are accommodated with automatic coffee packaging machines, including four sides-sealed, hem seal, pillow with a hole punch, three-sided seal bags, stick packs, gusset bags, etc. The coffee packing machines process removes the air from the inside of the packaging before being sealed.

Coffee Packaging Machine for Business

Using the advanced coffee packaging machines indeed improved production and business product qualities. These packing machines handle and pack coffee products even with different bag sizes and shapes. They are designed with de-aerating features and help maintain your packing coffee fresh. Most coffee packaging factories use these advantageous machines to improve their business productivity.

Moreover, the coffee packaging machines have minimum required capital, making them ideal for starting a business. It offers chances to start up your business with a small investment amount. Plus, the mentioned machines help your business grows faster, as they can produce bulky packaging items.

JOCHAMP - Your Expert Coffee Packaging Machine Provider

JOCHAMP is your expert packaging machine manufacturer that conducts strict quality controls. We are testing the qualities of raw materials, designing & planning, high-precision supports, parts inspection, etc. You can always count on our excellent services anytime you need assistance, purchasing multiple coffee packaging pieces of equipment. Customizing your desired specifications is our expertise.

As your constant supplier, we maintained excellent qualities and operation of our offered packing machines. You can send us the details of your needed coffee packing equipment to include during the production. We offer cost-effective and high-performing packaging machines, perfect for your factories and business.

Don’t hesitate to message us right here, right now!

JOCHAMP Coffee Packaging Machine

We are your trusted manufacturer that provides satisfying after-sale services, including the following:

- Repair: When your purchased machine will damage, JOCHAMP provides repair solutions. We have a mechanics group that is ready to fix any machine issues.

- Install: JOCHAMP also offers installation services for your newly purchased coffee packaging machines in particular facilities.

- Maintenance: The regular maintenance of packing machines is necessary to achieve longer life. You can also trust our assistance for that.

- Training: JOCHAMP has experienced staff that provides basic training on operation and running the coffee packing machines.

JOCHAMP specializes and focuses on the needs of particular buyers and understands the necessities of the customer groups.

For Industry Manufacturers, we provide:

- Customized coffee packing systems

- Equipment that suits your production environment

- Lower manufacturing costs

For Contract Packaging Factories, we offer:

- Flexible coffee packing systems

- Equipment that performed with high efficiency

- Multifunctional coffee packing machines

Coffee Packaging Machine: Coffee Product Types

Depending on the user’s preference, manufacturers may create coffee granules from either a coffee bean or a pre-made gold coffee. There are two ways to package granule coffee. The first option is to use quantitative volume containers, and the second option is to use balance filling devices to scale the goods.

The most widely used form of coffee is powder- a powdered coffee that is ready to brew. A screw filling technique may be beneficial to package ground coffee in various ways. The worker may modify the desired channel freely, making weight precision possible.

The items, which ranged from ground coffee to the necessary packaging grammage, were packed by the vertical filling machines. Depending on the coffee grind, a volumetric filling machine or a screw filling machine may be more appropriate for this situation. Ground coffee packets often come in the Quatro package design.

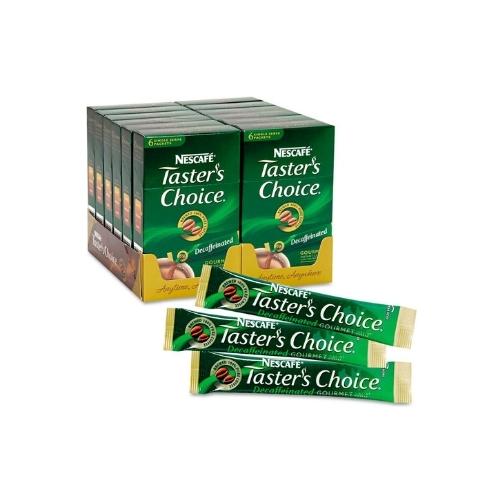

Tons of stick-pack coffees are consumed each day by consumers throughout the globe. We at JOCHAMP want to be a part of it. With our one-stop coffee packaging machines solution, our position is secure and stable. With over a decade of experience in the sector, we are a trusted supplier.

Related Product

Coffee Packaging Machine Buying Guide

This guide will help you choose highly efficient and reliable coffee packaging machine. Whether you wish to evaluate different types of coffee machines, specification, applications or understand the working principle – all information you are looking for is right here.

Packaging of coffee is a very important step in the supply chain. There are many types of coffee packaging machine, each with its own benefits and drawbacks as discussed below.

Form Fill Seal Coffee Packing Machines

The two primary types of form-fill-seal coffee packaging machinery are:

HFFS Coffee Packaging Machine

The key difference between them is that HFFS equipment performs packaging horizontally (occupying more floor area with minimal height). On the other hand, VFFS machines operate in a vertical fashion (occupying less floor area but need extra height).

VFFS equipment is among the most preferred packaging machinery in the coffee sector. The packaging machine can pack all coffee products including instant coffee, ground coffee, and whole beans.

Fill And Seal Coffee Packing Machines

This type of coffee packaging equipment just fills and seals the coffee packs; it does not create them. You insert premade coffee bags magazine into the machine, where they are picked out one by one.

Consequently, the filling and sealing packaging machine opens, fills with product and eventually seals the coffee packs. The machine can pack whole coffee bean, ground and instant coffee.

There are 2 major fill and seal coffee packing machine types:

i. Rotary Filling And Sealing Equipment

ii. Inline Filling And Sealing Equipment

Inline fill and seal machine executes its operations in a linear manner, with start and finish spots at opposite sides of the equipment. For this reason, the entire packaging system occupy more floor space.

On the contrary, rotary fill and seal machinery executes its functions in a circular manner. Therefore, the system needs less floor area since its starting spot is right close to the finish point.

Rotary Fill Seal Machine

There are 3 main types of rotary filling and sealing equipment: single lane, double lanes, and four lanes system. Coffee industry commonly uses rotary packaging machines due to these reasons:

- Lower investment cost

- Optimizes available factory floor space

- More operator-friendly ergonomic design

Stick Pack Coffee Packaging Machines

Stick pack machines are fairly basic; the major choice is how many lanes you need to satisfy your throughput requirements. The number of lanes can range from 2 to 20.

Speed And Operation Of Stick Pack Machine

With minor differences, stick pack machines work in similar manner as VFFS machines. A large packaging film roll is cut into strips and formed into stick packs using tiny forming collars. The machine then adds the coffee product into the stick packs before sealing them.

Volumetric fillers or augers help in the injecting the precise quantity of coffee products into the machine. Typically, the maximum speed of coffee stick pack machine is 80 bags/minute/lane. This translates to 1,200 packs per minute if your equipment has the maximum 20 lanes.

You can only process instant and ground coffee with this type of coffee packaging machine. Wholes coffee beans are too big for the equipment.

Coffee Bag Types

The machine limits you to just one type of coffee bag – stick pack. This may be a three-side seal, or stick pack with bottom and to seal. There are a variety of features available, including chain bags, pour spouts, tear notches, different seal designs, and various cut types.

Stick Pack Machine

The key reasons why you should invest in VFFS coffee packer machine are:

VFFS Coffee Packaging Machine

Broad Range Packaging Solutions

The VFFS coffee packer machine offers a wide range of packaging solutions that are suitable for any kind of coffee product. The equipment can produce both pre-formed and custom-shaped pouches. This means that it can be used to package different kinds of coffee beans without any hassles or problems.

Easy To Use

You do not require much effort or time to operate the machine. The unit comes with an auto-start feature that allows you to start it even when you are not close to the equipment.

Cuts Labor Costs

As the production process is more automated and optimized, VFFS coffee packing machines can drastically cut down on labor costs. This is due to their ability to produce multiple identical products with high speed and accuracy.

Easy Maintenance

Vertical form fill seal coffee packaging machine has an easy-to-clean design making it more hygienic than other types of coffee packaging machines. This reduces labor costs because you do not need employees to clean up after each use of this type of machine.

Enhances Efficiency

VFFS coffee packaging machine machines have a high processing speed. Because of this, you are able to produce coffee packages at an extremely fast rate without compromising on quality or consistency.

Additionally, this equipment can contribute to improving the general effectiveness of your packing procedure. You can package more products in less time with the help of these machines because they can work at fast speeds.

Ultra-Simple Manipulation

The vertical form fill seal machines are equipped with a user-friendly touch screen that gives you complete control over the manufacturing line. This touchscreen HMI makes it possible for you to quickly select the pouch’s weight and dimensions in a matter of minutes. The effective interface reduces the amount of labor needed and the associated expenses for producing big quantities of packs.

Rapid Bag Size Changeover

The machine allows you to switch between different bag sizes and types quickly. This helps in increasing efficiency, reduces downtime and helps you increase your output.

When selecting an automatic coffee packaging machine, you will often have two options: Form Fill Seal machine and Premade Pouch Packaging machine. We will compare the two machines to help you determine which the better choice for your project is.

Speed

With regard to speed, both form fill seal and premade pouch packaging machine have excellent performance. Modern high-speed form fill seal equipment and premade pouch packaging machine can reach speed of up to 60 to 100 bags/minute.

Since the weighing and filling system dictates the final speed, the packaging material will largely influence the coffee packaging machine speed. It will not be helpful when the feeding speed is not able to match the quick sealing speed.

Another crucial parameter is the packaging bag style. Sophisticated packaging bags will impede the packing speed since there are more operations than basic packaging bags.

Premade Pouch Coffee Packaging Machine

Exterior Appearance

Premade pouch coffee packer machine is better than form fill seal equipment when appearance is a concern. The latter enables you to be noticeable in appearance and easy use features like zipper pouch, spout pouch among others.

Cost

Generally, premade pouch coffee packaging machine price is greater in comparison to form fill seal equipment. This is due to the more complex nature of premade pouch packer machines.

Packaging Materials

Premade pouch price is comparatively greater than rollstock used in form fill seal coffee packer machine. There will be more operations with premade pouch, but you will equally incur extra cost with rollstock, like higher labor expenses.

Nonetheless, utilizing rollstock in form fill seal packaging machine offers some benefits, like being more versatile. Rollstock gives you the flexibility to change the packaging design based on your requirements.

Moreover, premade pouch coffee packaging machine might leave you with too much inventory that may be useless. Therefore, the cost of operating the machine will be higher than that of form fill seal coffee packing machine.

Operability

With regard to operability, both types of coffee packaging machine are exceptionally easy to manage, and come with detailed guidelines.

The main coffee packing machine features include:

- Stainless steel built

- Touch-screen control panel

- Modular design

- Self-centering film drive down systems

- Compatible with most small-medium bag packaging, from 3″ to 15.5″, and 2″ to 11″ wide; larger machines can handle even larger bags

- Human-Machine Interface that support bilingualism

- Bag speeds exceeding 150 bags per minute

- Automatic edge film tracking and guidance

- Integrated temperature control

- Minimum energy and carbon footprints

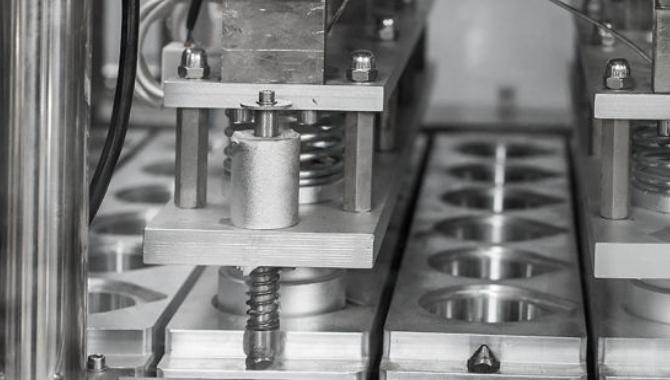

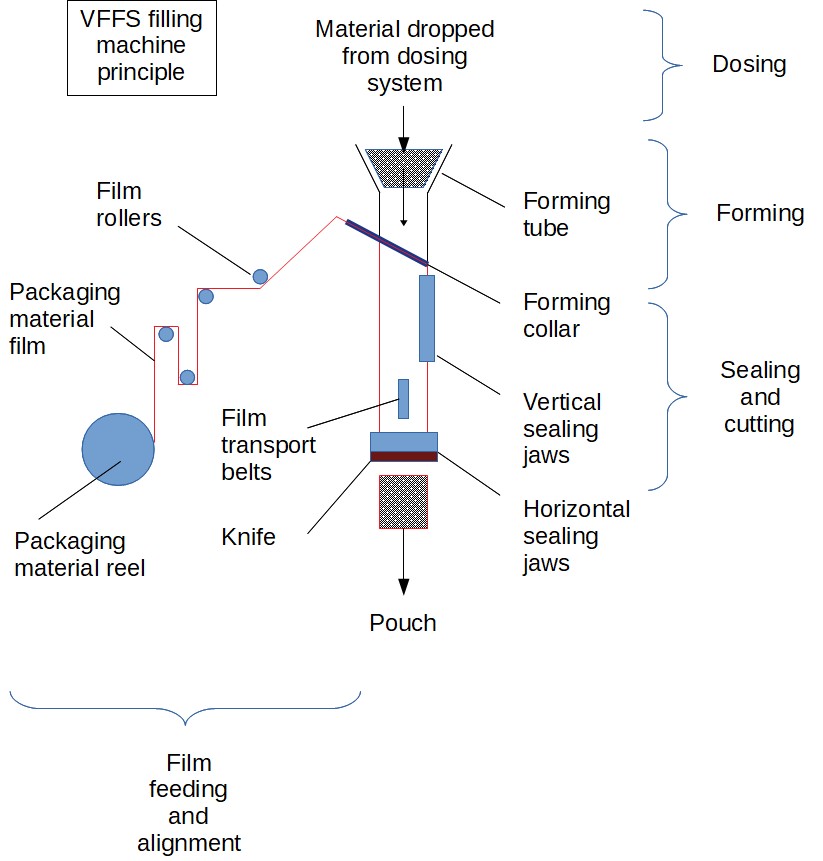

You know that there are various types of coffee packaging machine available in the market. However, we are going to look at the parts of VFFS packaging machine since it is the common one.

The major parts of VFFS coffee packaging machine include the following:

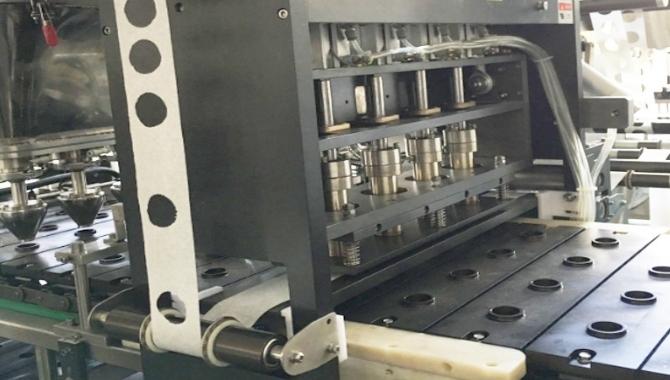

Film Pulling System

The key components of this system are tensioner and unwinding roller that unrolls the film roll used for packaging. Furthermore, the film pulling system features servo motors that help in driving and pulling the film on its reels.

Printer (Optional)

The printer is critical in printing the production batch code and date on the packaging material. Often, there are two types of printers used: normal printer that utilizes black color ribbon and Thermo-Transfer Overprint (TTO) printer.

Pouch Former

Here is where the coffee packaging machine forms the pouches or bags. You can form different bag sizes with short changeover time. Additionally, the stainless steel bag former also fills the pouches/bags with the coffee product.

Sealing Jaws

VFFS coffee packaging machine has two groups of sealing system: horizontal and vertical sealer. You can perform various sealing patterns with different sealer types. The weighed coffee products are filled after sealing the bags.

Pouch Cutter

After sealing the products, the pouch cutter cuts the pack at the bottom seal, completing the packaging cycle.

Control Cabinet

The control cabinet contains the PLC, Human-Machine Interface and key electrical controls.

Vertical form-fill-seal machine is used for coffee packaging for good reasons. The VFFS equipment is an economical and fast packaging solution which conserves your valuable factory floor space.

Let’s now look at the main steps during operation of VFFS coffee packaging machine:

Working Principle of VFFS Coffee Packaging Machine

Step 1: Transporting And Unwinding Of The Film

Vertical form, fill, and seal coffee packing equipment utilizes a single film sheet material rolled about a core. The film roll is put on a spindle unit found at the back of the machinery.

Often, film transport belts pull off the film roll from the magazine. On some coffee packaging machine brands, the sealing jaws hold and pull the film downward, conveying it through the equipment without using belts.

Step 2: Tensioning Of The Film

The machine unwinds the film from the roll and moves it above a dancer arm that incorporates a sequence of rollers. The arm maintains an up and down movement as the film moves across the machine. This maintains the film material under tension ensuring that it does not go off track as it moves.

Step 3: Optional Printing

From the dancer arm, the film then travels across the printing unit, in case one is integrated. The printer puts on the film the desired codes, dates, registration labels, logos, or graphics.

Step 4: Tracking and Positioning Of Film

After passing through the printer, the film goes through the registration photo-eye that spots the registration label on the printed film. Consequently, this guides the pull-down belt connecting to the film material at the forming duct.

The registration photo-eye ensures correct positioning of the film to make sure the coffee packaging machine cuts it at the right spot.

Subsequently, the film goes through film tracking sensors, which spot the film position as it moves across the machine. If the film moves out of position, the sensors cause an actuator moves the whole film carriage to return the film to its right position.

Step 5: Bag Forming

Here, the film crests the collar onto the forming tube assembly and gets wrapped about the tube. As a result, you form a piece of film material having the 2 outward film edges overlapping one another. This marks the start of the bag creation process.

Step 6: Filling and Sealing Of Bag

On Intermittent VFFS coffee packaging machine, the film will momentarily pause to allow vertical sealing of the formed bag. The hot vertical seal bar shifts forward and touches the vertical overlay on the film, binding the film layers together.

With continuous VFFS coffee packaging machine, the system does not stop to give the film its vertical seal. The vertical sealing system stays in touch with the film constantly.

Subsequently, a series of hot horizontal sealing jaws close to create the upper seal of one pack and bottom seal of subsequent pack. In intermittent VFFS coffee packer machine, the film stops to get the horizontal seal from sealing jaws with an open-close movement.

However, in continuous motion VFFS coffee packer, the jaws employ open-close and up-down movement to seal the packing film as it moves. The machine fills the products whilst the jaws are shut.

Step 7: Bag Discharge

After releasing the products into the coffee pack, a sharp knife inside the sealing jaws shift onward and cuts the pack. The jaw gets opened and the packed bag drops, marking the completion of a single cycle on VFFS coffee packing machine.

Often, coffee packaging machines feature friction pull belts. These type of belt utilizes friction between the rollstock and belt to clutch and move the film across the system.

Nonetheless, when processing oily/dusty product like coffee, particles may hinder the gripping operation and lower the service life of the belts. Because of this, you should opt for vacuum pull belts to clasp the film material for transport. Particles will not hinder film movement or result in needless belt wear when utilizing vacuum suction.

The various types of coffee packaging machine can create different types of bag styles. VFFS coffee packer can form a variety of bag styles, the highly popular ones include:

- Bag-in-bag style that is used for small fractional packs enclosed within a large exterior wrap.

- Quad seal or flat bottom bags for bulk or retail packs

- Pillow bags for single-serve or fractional packs

For stick pack coffee packaging machine, you are restricted to one major bag style: the stick pack. This bag style can be a 3-side-seal or sealed on the bottom and top. Moreover, you can go for features such as chain bags, pour spouts, tear notches, different cut types, and seal styles.

Based on your specifications, you can apply one of these 4 most common MAP packaging technologies:

Gas Flushing

Among the most common active MAP techniques, gas flushing technology achieves 3 things:

- Oxygen displacement to delay oxidation

- Reducing the development of aerobic spoilage organisms

- Serving as a filler to preserve coffee package conformity

In gas flush procedure, you actively pump a harmless gas (normally nitrogen) into the pack before sealing to replace ambient oxygen. You do this to reduce the oxygen amount within the package. Consequently, this will reduce the spoilage rate since oxygen is among the primary killers of freshness.

Barrier Packaging Films

Selecting particular packaging films that offer enhanced protection forms part of pass MAP. You can realize this by utilizing barrier packaging materials which offer reduced oxygen and moisture permeability, like PVC, PP and LDPE. Moreover, there are new “smart” packaging films on the market that can feature indicators of coffee quality, leakage, temperature among others.

Desiccant Or Scavenger Pack

Another MAP technique you can apply is adding a desiccant or oxygen scavenger pack to the coffee package. Typically, these tiny sachet-type packs comprise of a blend of ascorbic acid and iron powder, and at times activated carbon.

These constituents serve as activators or catalysts, absorbing ambient oxygen and moisture, thereby eliminating it from inside the package.

On-package Valves

Adding one-way valves to the package exterior is another type of MAP. You can incorporate these special valves to the film material during coffee packaging process or to premade bags.

One-way valves facilitate the escape of specific gases from the pack without permitting any external gases in. This is usually carried out to release pressure due to off-gassing that results when coffee product releases gases or additional compounds. You can equally use one-way valves to permit escape of air from the packages to enable excellent stacking and palletization.

Coffee packaging machine is specially designed to meet all your coffee packing requirements. You can use the packaging equipment for a variety of coffee products including:

- Whole bean

- Ground coffee

- Coffee powder

As already discussed, some of the solutions comprise of premade pouches for packaging whole coffee beans within zippered pouches. Also, you can use bag-in-bag or brick packs to package whole bean or ground coffee.

Here are some general coffee packaging machines maintenance guidelines:

Routine Cleaning Of Coffee Packaging Machine

The first thing that you need to do is to clean your coffee machine on a regular basis. Cleaning will help in removing any dirt or dust that may have accumulated over time. This is important because it will prevent any damage to the machine.

Lubrication Of Moving Components

You need to lubricate all the moving parts of your coffee packaging machine to prevent wear and tear of these parts. Moreover, it helps in ensuring smooth functioning of all these parts, which in turn ensures efficient operation.

Oil needs to be replaced from time to time as it may get contaminated with other substances such as water and dust particles over time. This can in turn affect its performance negatively if left unchecked for too long. You should replace oil at least once every six months depending on how often you use your machine.

Check The Cables

Cables are prone to damage and wear, so make sure that you check them regularly for signs of wear, such as exposed wires or broken connectors. If you notice any problems with the cables then get them replaced immediately before they cause more damage to your machine.

Inspect Any Loose Parts or Leaks

Another important aspect of the coffee packaging machine maintenance is checking if there are any leaks in the system or not. If there are any leaks in the system then you need to fix them immediately as they can cause serious problems.

You should also check if there are any loose screws or nuts that have come off due to vibrations during operation. Replace them accordingly so as to ensure smooth functioning of your coffee packaging machine.

Change The Filters

The filters on a coffee packaging machine should be changed once every two months, or when they appear worn out. This ensures smooth operation and prevents the build-up of impurities in your coffee products.

You may also like:

Coffee Capsule Packaging Machine

Drip Coffee Bag Packaging Machine

For all your coffee packaging machines, contact us now.