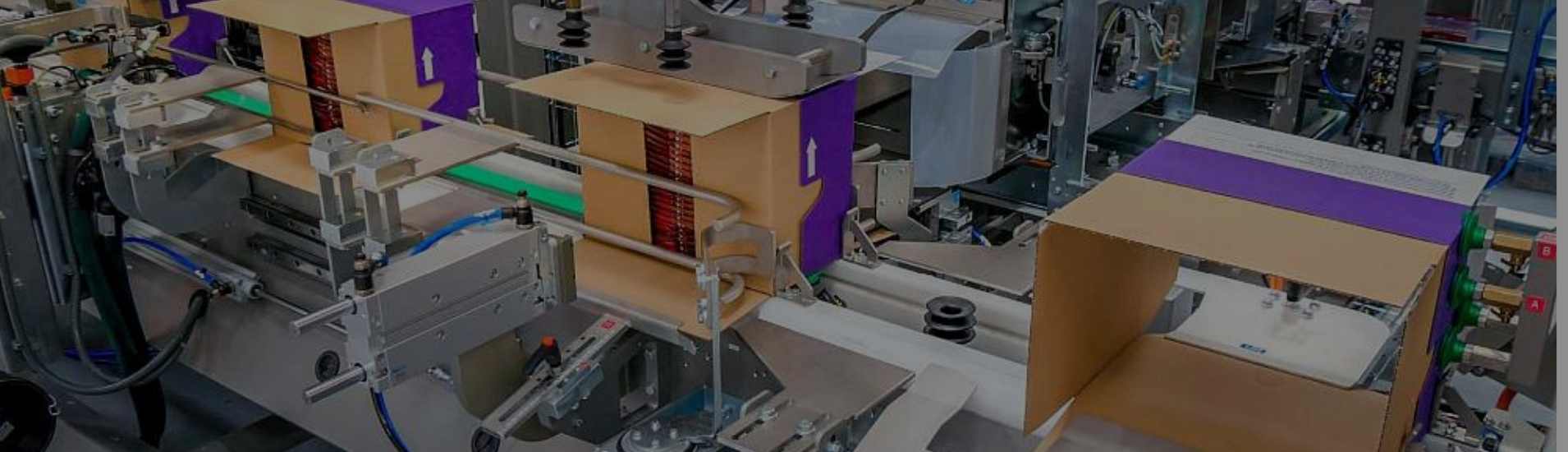

Case Erector Manufacturer in China

Jochamp is a professional case erector manufacturer in China. We supply all types of machines such as automatic case erectors, glue case erectors, tray erecting machines, and more. Message us today for your custom case erector design.

- Easy to operate

- Reliable and durable

- Heavy duty construction

- Adopt international advanced technology

JOCHAMP Case Erector

Jochamp case erector is an assembly line equipment that automatically transforms case blanks into fully erected cases. It unpacks large-scale cartons, folds the lower cover, and seals the lower bottom tape automatically. These machines have precise case management. It ensures complete case-control throughout the erection process. The cases work as intended and are manufactured with optimal performance.

Jochamp manufacture magnificent case erector machines for your project. Successful secondary packing requires square cases. Square cases are more efficient in terms of packing, stacking, and protection. Our machine can make your work very easy and very fast. Reliable and high-productive machines are available here.

Contact us now!

JOCHAMP Case Erector Machine Advantage

Our machines guarantee operators’ safety and health. Magazine infeed is simple to use and reduces loading stress. It has an open-frame design that allows for changeover points and sealing modules easily accessible.

Case erector frames are durable, dependable, and sanitary. These frames are made of quality tube and plate steel and constructed with hygienic requirements in mind. It can sustain up to 20+ years of packaging equipment life.

Jochamp case erectors are manufactured with neat, smooth motion, and noise-free operation. Our machines work without literal and figurative commotion. It accomplishes the task efficiently and perfectly.

All case erector machines are authenticated to CE, SGS, ISO, UL, and cGMP certifications. It is equipped with cutting-edge software that transforms the outer measurements automatically. Less maintenance and dependable performance.

Why Purchase a Case Erector for Your Business?

- Automated LxWxD path system – case erecting machine creates square corners automatically. Robust square corners on your boxes are critical in palletizing your products for transportation. These provide a solid base for weight distribution. It prevents pallet/load collapse or during shipping.

- Increases Throughput – Case erectors can convert cases more quickly than human workers. Human workers can assemble three boxes each minute on average. An employee might construct 1260 boxes in a typical day working an 8-hour shift without breaks. Machine assemble 2880 boxes in the same 8-hour shift, our fastest case erector could generate 9600 cartons per minute.

- Save Money on Carton Erecting – the case erector would save you money on the production and worker salary. It can also produce erected cartons efficiently.

Benefits of Case Erector

Jochamp case erector is made with advanced features to inspire trust. Our machines assemble and seal your box to the top quality requirements in a matter of seconds.

- Easy to maneuver, Reduces the need for manual labor

- Delivers a faster, more consistent performance

- Ensure all cases are squared before they are sealed

- Designed with an opposing-cup effector

- Easily integrate into the existing packaging line

- State-of-the-art photoelectricity induction control system

- Ideal for forming and sealing cartons of the same size

- Designed with a cutter safety system

- Robust steel construction

- Equipped with superior quality parts

- Stable performance and long life-using

Seal-Type Specifications

Jochamp manufacture both glue case erector and tape-seal erectors. Glue case erectors use hot melt glue in erecting corrugated cases and closing the bottom flaps. Direct application of glue to case flaps generates a powerful, firm adhesive that maintains the boxes intact and the goods inside are safe at all times.

Tape-sealing erector is reliable and high-speed. It is mostly a factory preference and use in various applications. It accommodates poorly corrugated and keeps on running. This erect and tape seal cases to 40 CPM. It delivers quick and easy tape roll replacement.

Why Choose JOCHAMP Case Erector

For your case erector needs, you can trust Jochamp. We are a reliable manufacturer and supplier of all types of case erectors and other packaging equipment in China. Our range of case erector machines are made from multi-channel spraying frame, and highly corrosion-resistant steel. These are hygienic, easy to clean and maintain in line with GMP, CE, ISO9001, and SGS certification standards.

You can choose whether tape or spray glue to seal your box. It has a smaller footprint and compact design, easy to integrate into your existing packaging line. These machines support various shapes of carton-forming equipment. It is easy to operate, and equipped with a human-machine industrial control system (HMI) precise control.

Our team is expert in supplying custom case erectors with your specifications. With Jochamp, you can be 100% sure of reliability, usability, and less maintainability case erector machine. Message us today.

JOCHAMP Case Erector

Our machines are designed with intelligent machine control for simple setup, and operations. You can choose the case size and speed in the touchscreen control center. It is easy and intuitive.

The case erector color display screen offers real-time operational data and enables all works, diagnostics, and changeover settings to be operated independently. It has step-by-step sequences, and non-contact sensors monitor machine performance and guarantee that each operational sequence is precisely timed.

No matter what your corrugated case materials, styles, specifications, speed requirements, tape-seal erectors, or glue-seal erectors, Jochamp is the right manufacturer in China that can satisfy your needs.

Our company has quality parts, components and advanced manufacturing processes to produce custom case erectors for your business. If you require something unique, as a professional packaging machine supplier in China, we are happy to serve you.

Use JOCHAMP Case Erector Machine for Various Applications

Jochamp is reliable in supplying case erectors for the food and beverages industries. These are built for long life and good stability. It provides solid performance and precision operation. Every box is created in uniform in size, shape, and accuracy.

Case erectors for hardware industries have durable structures and simple operations. It can be customized according to the customer’s need for carton size, speed requirements, and machine duration. We use high-quality electronic and pneumatic components for dependable usage.

A safe and hygienic case erector for medical industries is specifically-made at Jochamp to satisfy your requirements. The packing boxes are made always durable and perfect. It eliminates the risk of destroyed parcels and products.

Related Product

Case Erector: The Ultimate Guide

Without the right information, choosing an effective and reliable case erector can be an overwhelming task. A reason this guide explores all fundamental aspects about case erectors such as features, design, working principle and classification, among other aspects.

It is a piece of equipment designed to form, fold and seal corrugated cartons automatically from flat boxes.

Simply put, it takes collapsed cardboard boxes, builds them, and seals the bottom in readiness for packaging.

Often, it is easily integrated into an existing packaging line.

Choosing the most suitable care erector is fundamental in ensuring you experience cost savings and incorporating optimal machines for your output.

case erector

This article thus helps you to evaluate your needs and select the most suitable equipment based on your needs.

The decision to invest in a case erector needs planning and analysis to ensure its addition brings significant improvements to your throughputs and efficiencies.

Some remarkable benefits of using this piece of equipment include the following;

Improves Productivity

Manual case erection is time-consuming and quite tedious, with an average worker building about 2-5 boxes per minute.

However, this machine can build up to about 30 boxes per minute, which ultimately improves throughput instantly.

Quick Changeovers

The design of modern case erectors allows them to complete changeovers within minutes.

Hence, it reduces downtime when you require multiple different-sized cases for a specific line.

Reduces Backlog

Building cases manually is labor intensive since the workers must assemble adequate supplies of built cases.

Ideally, this adds production time and takes up considerable floor space.

On the contrary, case erectors can form cases on an as-needed basis, and this frees up floor space for other operations.

User-Friendly

This machine barely requires handling of corrugated cardboard blanks when forming cases.

Technically, it opens, squares, and seals the case bottom; hence all you require is an operator to load the blanks and enter dimensions for the machine to do the rest.

Reduces Shipping Damages

Hand-erecting cases can easily lead to unsquared boxes that are seemingly weaker when stacked on a pallet.

However, square boxes can endure heavier weights, making them less prone to shipping damage.

And this is attainable when using a case erector, which guarantees the product arrives undamaged and intact.

Minimizes Injury And Repetitive Strain

Repetition involved in manual case forming for long often creates strain and injuries in arms, tendons, hands, shoulders, and wrists.

Eventually, the repetitive strain reduces productivity, increases treatment and recovery time-off, and decreases satisfaction at work.

But using this equipment, employees’ exposure, and the business too.

Cost-Savings

Ordinarily, automation of this machine ensures you’ll reduce the number of laborers involved in forming cases.

In the long run, it enables you to reduce running costs significantly, which helps in increasing your profitability index.

The main function of a case erecting machine is to convert case blanks into fully-erected, bottom-sealed cases.

However, it also has other auxiliary functions in a packaging setting, such as the following;

- Increasing packaging speed to ensure you attain the right stock and deliver to the customers expediently.

- Gluing the bottom side of the case using tape or adhesive to enable product packaging.

- Enhancing box forming precision by ensuring each carton is identical and making sure they all have a uniform appearance.

- Increasing production throughput makes it a critical consideration, especially in industrial applications.

- Integrating into the existing packaging line to attain the desired convenience and efficiency as far as product packaging is concerned.

This carton erecting machine comprises a wide range of parts designed to perform different functions.

However, it is always imperative to know some notable parts of this machine to enhance operating efficiency and performance during case sealing.

The common parts of this machine worth knowing include the following;

PLC Touchscreen

It is a screen featuring an easy-to-read HMI interface designed to display various operational variables of the equipment during case forming process.

Control Keys

They assist in closing and opening different control circuits within the machine.

Conveyor Unit

It comprises various rollers and belts designed primarily to transport the cartons from one station to another within the equipment.

In-feed Panel

This part ushers the cartons into the machine for subsequent forming, shaping, and erection.

Emergency Control Button

It is a safety-measure key designed to protect the machine from hazardous occurrences by breaking the circuit and cutting power supply.

Electric Panel

This is an enclosure that houses several electrical components used in the operation of the case erecting machine.

Lubrication Unit

It lubricates all the contact parts of the machine to reduce friction and ultimately enhance parts’ and machine’s longevity and efficiency.

Guard Assembly

This component consists of different units designed to minimize and protect the equipment and operator from potential damage or injuries during case formation.

Flap Folder Assembly

It is triggered to ensure the flaps of the cartons are folded appropriately and accurately depending on the dimensions.

Servo Motor

This is a small programmable motor operating the robotic components of the case sealing machine.

Ordinarily, it actuates precision and repeatability within this equipment by receiving feedback on component’s positioning and directing their motion and positioning.

Tape Applicator

It applies the sealing tape at the bottom of the carton to ensure it is securely attached to hold the products safely.

Vacuum Cups

They are used as grippers within the machine and often secure and assist the cartons in moving.

The working principle of this machine often varies depending on its actual mode of operation.

Ordinarily, there are semi-automatic units and automatic units, which use relatively similar working principles with slight variations.

Nonetheless, the overall design of this equipment has exclusive features working to keep your packaging line running seamlessly.

Here’s how a typical case erector works;

Case Loading

In this phase, cases are loaded against squaring rail to allow easy alignment and infeed.

The machine has a horizontal stack-squaring magazine, which facilitates proper case alignment.

Once stacked, they automatically index into position and provide a steadfast and continuous case feed.

Floating Grippers Adjusting To Case Variations

Here, there is a need for proper case feeding into the machine.

Thus, the floating grippers are triggered to adjust to the case variations accordingly.

Primarily, the upper section feed magazine runs warped and band-marked cases smoothly.

Double-floating grippers then lift case from the top of the stack to ensure reliable feed whether case feed is uneven due to corrugated variations.

Case Opening

The lower and upper suction cups trigger positive case opening.

Hence, the case is sealed from the bottom by vacuum grippers, whereas mechanical opening arm lowers to grip and pull it open resolutely.

Vacuum grippers deliver reliable case formation even on cases with excess manufacturer joint adhesive, which can deter opening.

Inner Flap Closing

Overhead grippers are activated to over-open the case flaps to allow smooth minor flap closing.

It is a design allowing adequate space for minor flaps to fold inwards and remove the usual jams encountered during flap closing.

Ideally, this usually arises when running cases that have misaligned scores.

Squaring The Cases

Walking beam squares cases during transfer facilitates error-free sealing using tape or adhesive.

Technically, the better the carton gets into the sealing section, the better it comes out.

Hence, you need to control cartons tightly throughout the process to get top-high-quality cases irrespective of potential challenges.

Primarily, that’s the basic working principle of an ordinary case erecting machine.

Ideally, case erecting machine is relatively versatile hence can be used in different packaging applications across various industries.

Some common industries where the use of this particular machine is quite dominant include the following;

Food And Beverage Packaging

A wide range of food and beverage products are packed in various case sizes that need to be formed using this equipment.

Of course, it is important in this industry since it guarantees high speed and accuracy, which are vital in attaining desired market results.

Automotive Parts Packaging

Various automotive manufacturers and assembling plants often use case erectors to build cartons in readiness for packaging of their products.

It is essential equipment in this industry since uniformity, speed, and precision are quite fundamental concerns.

Pharmaceutical Products Packaging

Case erector comes in handy for pharmaceutical products manufacturing companies since they are used for effective packaging of such items.

Ordinarily, this machine forms different case sizes suitable for packaging a wide range of medicinal products such as tablets, capsules, vials, ampoules, etc.

Personal Care And Hygiene Products Packaging

Different products used for personal care and hygiene are also commonly packed in cases erected by this equipment.

Such products require uniformity and accuracy, thus the need for this equipment to guarantee best results.

Confectionery Products Packaging

Many confectionery items are normally produced in large masses, thus the need for a packaging mechanism that guarantees efficiency and consistency.

Case erector is speedy, accurate, and can form different cartons for a wide range of confectionery products packaging.

They are available in a broad range of types based on different factors.

The common ones you can find in the market include the following;

· High-Speed Case Erecting Machine

As the name indicates, this is a type of case erecting machine offering ultimate speeds of up to 50 cartons per minute.

It features a production proven design and comes with quality specifications to deliver peak production on packaging line.

Regarded as a workhorse machine, it has heavy-duty steel framing construction powered by a powerful motor drive.

high speed case erector

It features a servo-powered sealing ram that guarantees square and well-sealed cases and a large capacity, easy-to-load case magazine.

This variant is the ultimate choice for dependable, high-speed case erecting applications.

· Small Case Erector

It is a relatively compact case forming machine with a capacity to build up to 12 cartons per minute.

This machine features an HMI touch panel control unit and is equipped with no tape detection and tape cutting failure.

small case erector

Besides, it ensures precision for each operating sequence via non-contact sensors.

Also, the color operator panel displays real-time operating data and allows independent operation of all functions, changeover settings, and diagnostics.

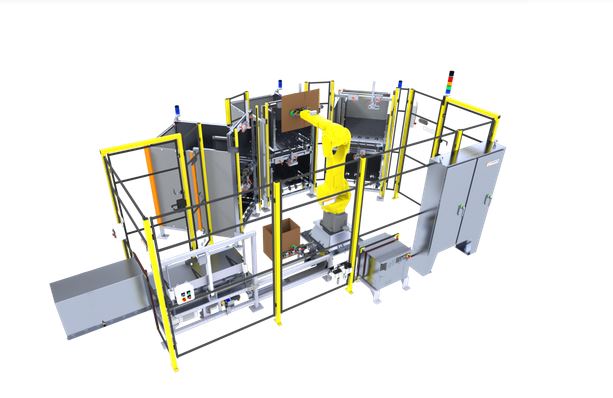

· Robotic Case Erector

It is an automated end-of-line packaging solution solving ergonomic concerns with employees handling repetitive tasks.

This unit includes an interactive color touchscreen for an operator to use in a manual mode and quickly change case size being erected.

It also comes with additional case magazines, Ethernet connectivity for auto-case size selection, and hot melt glue closure.

robotic case erector

Moreover, it has high-speed bottom sealing abilities with servo adjustable side belts for enhanced speed.

Generally, this unit combines a six-axis robot with multiple case magazines and a bottom flap folder with an integrated case sealing head.

· Glue Case Erector

This type of case erecting machine folds two bottom minor flaps a case blank before applying glue to both minor flaps and fold over major flaps.

The build case is held for a while to ensure glue dries and hardens to provide a strong seal.

It is efficient since it assures less change-outs hence saves time during production runs.

glue case erector

This equipment can use either cold or hot melt glue.

Semi-automatic Case Erecting Machine

It can handle a wide range of box size, but it requires some operator involvement for the cases to move across the machine.

Generally, it is fast and somewhat accurate, thus ideal for small and medium-scale production.

semi automatic case erector machine

To attain high packing efficiency, this unit can work with case sealers.

Fully Automatic Case Erecting Machine

All the operating variables of this unit are automated thus hardly require operator involvement at any case erecting stage.

Essentially, the design of this machine allows it to form, fold, and seal the bottom side of corrugate boxes automatically.

It features an ergonomic, easy-access magazine with retainers that ensure a clean release of each blank from the magazine.

automatic case erecting machine

Also, it has flap folders and a pusher bar that maintains the pusher during transition to sealing.

Case Erector With Bottom Taper

This variant has a side belt drive that forms bottom seal cases at varying speeds of up to 15 cartons per minute.

It is designed with strongest framing component ideal for the quite demanding 3-shift settings and easy to integrate within an existing line.

case erector with bottom taper

The unit allows flat case blanks to stand vertically in the walk-in magazine that is easy to load.

Its minor flap is folded using a pneumatic mechanism, while the major flaps are folded up using a rotary actuator mechanism.

Case Erecting Machine With Bottom Sealer

It offers case erecting and bottom sealing abilities guaranteeing optimum durability, reliability, and value.

The design construction of this unit features a strong frame ideal for most demanding 3-shift environments.

case erector with bottom sealer

It provides a 2-minute changeover without tool adjustments using scales and cranks.

Besides, it also comes with a walk-in case magazine that loads cases in the equipment while running.

Hot Melt Case Erector

It has a case erecting capacity of up to 30 cartons per minute with a low-level magazine for loading knockdowns without lifting.

The exclusive walking beam case shifts square cases as they move from opening through sealing.

Moreover, it has unique mandrel square cases during sealing and mainly uses adhesive to seal the cases.

hot melt case erector

It guarantees reliable performance at low-cost operation.

Case Erecting Machine With Automatic Changeover

This variant features servo motion technology and brushless EC motors, which eliminate fine-tuning needed when changing to a different size case.

It saves case size recipes in HMI and triggers automatic case repositioning when selected.

The operator needs to load new corrugated case blanks, and this unit is quickly back to forming and sealing.

It is suitable for businesses that struggle with high turnover or those that use unskilled employees.

Case Erector With Servo Sealing.

This unit features a positive opposing vacuum-case opening, walk-in powered case magazine, and lug drive case transport for forming and sealing up to 20 cases per minute.

It has a single-piece welded tubular steel framing component and heavy-duty driveline components.

The system has a safety-interlocked guarding and an intuitive operator interface for easy and safe equipment operation.

You can accomplish tool-less changeovers in under 5-minutes for various case sizes.

The common features of a typical case erecting machine include the following;

- Automated path generation

- Opposing cup case opening

- Active case squaring

- Robotic pick and pass

- Sturdy and sanitary frame design

- Tape/adhesive seal type

- Compact footprint

- Bottom flap sealing

- PLC control system

- Automatic size adjustment

- Output motorized conveyor

- RSC, CSSC case ranges

- Emergency stop switch

- Fault detection and warning light

- Low voltage control circuit transformer

Ideally, a case erector and case sealer sound more or less similar, but in a real sense, they are entirely different machines.

Granted, both machines work with boxes, but that’s where the similarity ends.

Each can speed things up while simultaneously allowing you to save money, making them incredibly useful.

Moreover, they can be used separately and together to attain maximum cost-effectiveness.

Nonetheless, here is how these two machines compare;

Case Erecting Machine

It is essentially designed to build boxes by folding cardboard box and erecting it accordingly.

This machine squares up the box and seals the bottom to make it ready for packaging.

Case erector is accurate and makes perfect boxes every time.

case erecting machine

Some variants can also assemble recycled, corrugated, used, or poorer quality boxes to save on using new stock every time.

The case erector applies a single layer of adhesive tape on the bottom of the box, with the total length of tape fluctuating.

Case Sealing Machine

The design of this machine allows it to glue the erected boxes accordingly correctly.

It works with any type of box but guarantees better results when sealing better-constructed boxes.

That’s the reason a case sealing machine works best on cartons coming from a case erecting machine.

case sealing machine

Case sealing machine applies the same amount of adhesive tape on each box without any variation.

Ideally, this assures you that each case is sealed correctly and securely.

Tray erector is a piece of equipment used for erecting trays from flat sheet blanks.

The sheet blanks are put manually in the magazine, and the tray erector picks up a blank then feeds it to the machine.

Adhesive is applied on flaps before blank is pressed via a forming tunnel that erects the tray.

This machine is compact, flexible, and offers easy changeover of format.

On the other hand, a case erecting machine is specifically designed to convert case blanks into fully-formed, bottom-sealed cases.

tray erecting machine

You can find it in various sizes and designs suited for a wide range of case erecting operations.

Majorly, case erectors can build any type of box with perfect 90-degree angles irrespective of its construction.

The notable maintenance practices for case erecting machines include the following;

- Conform to preventive maintenance schedule – It allows you to avert minor and major problems from happening hence reducing unscheduled downtime.

- Always inspect the machine to determine the worn-out parts or potentially faulty components.

- Lubricate all the moving parts using recommended lubricants to reduce friction, likely to lead to faster parts wear.

- Have an elaborate plan for upgrading the case erector to ensure it meets the respective application and design demands.

Related Resource:

Packaging And Labeling Machine

For all your care erector machines, contact us now.