Side Load Case Packer Supplier in China

Jochamp supply side load case packer perfect for packing square regular items. It is reasonably priced. The way products enter the carton with the automatic palletizing function is side push.

- Stable and flexible machine

- Used for higher speed applications

- Solid machine concept

- Simple size change, quick, and require no tools.

JOCHAMP Side Load Case Packer

Side load case packer is a packing machine that is primarily used for bag in box packages. The packs are transported to the stacking unit, where each row is loaded into a holding plate assembly. After stacking the necessary number of rows, the collation is pressed into the open case, which is opened and kept in place by vacuum suction cups and guides, with the back wheel minor flap closed. Before case release, the case flaps are tucked and sealed.

As a one-stop automated packaging solution supplier, Jochamp provides all kinds of packaging machinery, such as side load case packers. We have more than 15 years of manufacturing and R&D experience. If you have a packaging business, this is a great addition!

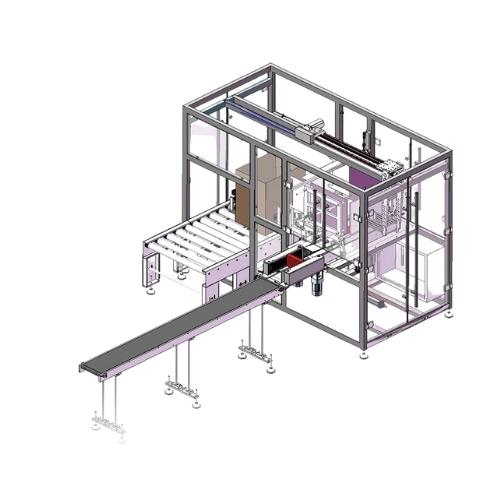

JC-500S Side Load Case Packer

This machine is suitable for packing square regular items. Its cost is relatively low. With automatic palletizing function, the way of products entering the carton is side push.

- Lack of material protection to prevent accidental injury to the product;

- The machine arranges the products by sinking or lifting, and uses the horizontal push method to complete the prescribed packing action;

- PLC control, safe and stable, servo-driven, accurate and efficient, no loss in packing;

- Digital man-machine interface, one-key operation to change equipment parameters, easy to operate;

- The equipment is equipped with a transparent safety door, which can monitor the operation of the equipment at any time. In addition, a door-opening stop system is designed to ensure safe operation;

- Quickly adjust the size according to the packing requirements. Adapt to different sizes of packing;

JC-500S

- Technical Parameter

- Features

- Optional

| Model | JC-500S |

| Power supply | 380V, 220V 3$, 50/60Hz, |

| Dimension | L2000*W1800*H1500mm(depend on design) |

| Packing speed | Max.5-15 carton/min |

| Product type | Boxed products (such as health supplements, oral liquids, biscuits) |

| Carton size | L200-450/W150-400/H100-350mm depends on design |

| Air compress | 6-8kg |

| Weight | 600kg, depending on design |

- Lack of material protection to prevent accidental injury to the product;

- The machine arranges the products by sinking or lifting, and uses the horizontal push method to complete the prescribed packing action;

- PLC control, safe and stable, servo-driven, accurate and efficient, no loss in packing;

- Digital man-machine interface, one-key operation to change equipment parameters, easy to operate;

- The equipment is equipped with a transparent safety door, which can monitor the operation of the equipment at any time. In addition, a door-opening stop system is designed to ensure safe operation;

- Quickly adjust the size according to the packing requirements. Adapt to different sizes of packing;

- The equipment has strong applicability and can be compatible with different products or products in different arrangements. One machine is multi-purpose and suitable for enterprises with many types of products;

- The equipment can automatically achieve hierarchical grouping, arrangement and combination of products according to the customer’s packing arrangement requirements, without manual labor, with a high degree of automation

case erector

carton sealer

Secondary packaging line integration

carton sleeve inner bag

Labeling Machine

printer

Glue sealing machine

Stainless steel

heavy duty casters

Leaflet Automatic Dispatcher

export conveyor line

Side Load Case Packer Benefits

The machine features PLC control which aids in more accurate operation and ensures no loss in the packaging.

Custom side load case packer designed with safe, stable, and efficient features. Given with manuals for easier operation.

As a reliable supplier of automated machines, Jochamp designed nonmanual machines. Operates without manual labor.

Every machine we offer ensures efficient operation. Ideal for packaging bags, bundles, cartons, sachets, and more.

How Side Load Case Packer Works?

- Auto-erect and construct a corrugated case

- Transport inbound products to the holding area (canisters, jugs, bottles, cartons, and boxes).

- We will automatically load the case from the side once the arriving product has been staged according to your pack layout to guarantee the most gentle transfer possible.

- The bottom and top flaps will be folded when the corrugated case is full.

- Case flaps will then be stuck or taped together.

- Tada! A final product that has been automatically case-packed is ready for delivery.

Why Would You Use a Case Packer with a Side Load?

Jochamp Side load case packer can be used for a selection of items. It is used to pack chemical products or liquids in sachets. Aside from that, you can use these case packers to load food items such as cheese, meats, and dumplings. These case packers come in a variety of shapes and trays, and you can use flat-surfaced bags in them.

Because of the sleek and flexible design of these machines, you have immediate access to the ground and can smoothly load and unload your goods. These case packers have plates that prevent your products from collapsing. As a result, you can keep your assets safe and avoid unnecessary loss and waste.

It also comes with speed and sensor adjustment settings. Adjust the speed using a remote-controlled system.

Differences Between Side Load and Top Load Case Packer

Side Load Case Packer: This machine is designed to pack square regular items. It is reasonably priced. The way products enter the carton is by side push. Cases can be used to pack food, sanitary items, or confectionaries with confidence. The machines are intended for continuous use in multi-shift processes.

- Extremely efficient

- Compact design

- Require no tools, quick, and easy size change

Top Load Case Packer: The top load case packer inserts the product into an RSC, wraparound, or harness style case through the top. It benefits manufacturers, retailers, and customers.

- Customizable in packaging size and configuration

- Consumes less shelf space

- Deliver positive environmental advantages

JOCHAMP – Side Load Case Packer Supplier for 15+ Years

Jochamp manufacture complete models of side load case packer. It is suitable machines for packing several goods. These machines have capacity to pack goods for maximum 5-15 carton per minute.

We are a one-stop automated packaging solution supplier in China. You are confident your custom side load case packer orders are safe with us and custom-built to your specifications. We have earned more than 15 years of R&D experience therefore, we can use our skills and knowledge in the entire customizing process.

For inquiries, directly email us!

- Material protection to avoid unwanted product damage;

- The machine sinks or lifts the goods and utilizes the horizontal push process to finish the prescribed packing activity.

- PLC adjust, secure and decent, servo-driven, precise and efficient, ensure no loading loss;

- Electronic man-machine connector, one-key action for changing equipment parameters, simple to use;

- The equipment has a seamless safety door that helps in monitoring the operation of the equipment at any moment. The door-opening stop structure is also included to allow the safe procedure.

- Instantly adjust the size to meet the packing specifications. Respond to various packing lengths.

Case packers are most often used in a multitude of sectors. Previously, it was used by food factories, but now it is used by a range of industries, including pharmaceutical, automobile, and toy production units, to load their product lines. You can stack your cases through the side when using our side load case packer.

Why would you select a side-loading case packer? If you want to expand your factory line, you must speed up the packaging process. Under this case, you can save energy/cost by installing an automatic side loading packer. These custom packers can pack approximately 100 products per minute. These systems will load your goods onto a conveyor and transport them.

Custom Side Load Case Packer for Business

The robotic side load case packer is custom-built. These packaging machines efficiently pick boxes of medical tapes and locate them into reared cases before safely sealing. The case packer benefits manufacturers, packers, and many consumers. It gently handles product packaging.

The industrial case packer functioned by moving the product quickly yet safely. They are designed for high packing speeds, and easy, fast changeovers. A trusted packaging system integrates accuracy and speed for a competent packaging solution.

Jochamp provides an automatic side load case packer that aids in reducing labor costs. It primarily benefits case packers in the packaging business. However, they utilize fewer packaging materials, and strictly monitor each case.

The traditional case packing machine is an automatically generated machine that fills up goods from the side of a traycase. Following the loading of the product, the case is closed and secured with glue or adhesive. It enhances employee efficiency, lessens labor costs, and gentle packaging operation.

Related Product

Side Load Case Packer: The Ultimate Guide

Before you invest in your next side load case packer, read this guide. It covers all information about side load case packer such as features, parts, working principle, specifications, etc. So, keep reading to learn more.

A side load case packer is a semi-automated or fully automatic machine fed sideways and used to pack products in corrugated boxes for transit or shipping.

The packs will then be delivered to the stacking unit, where each raw will be stacked into a holding assembly plate.

Following the stacking of the requisite row numbers, the collation would begin to push the packs into the open case.

side load case packer

Basically an open case with vacuum suction cups that guide the minor back flap closed.

The case flap will be ejected from the machine when it has been folded and closed.

With side lad case packer, it has the benefits below:

Reduce Labor Cost

Side load packer cases often offer significant labor cost savings since they eliminate or minimize human work in the operation.

It will reduce repurposed labor or costs by directing personnel to another task while the machine operates.

Using Fewer Packaging Materials

Compared to humans, who are prone to making mistakes, employing a side load case packer allows you to use less material and waste less.

You may rest assured that the number of errors will reduce, and you will save time.

Production Speed

Side load case packers often have a high production capacity, allowing you to meet your packaging needs on time.

It can pack many packs per hour, which benefits producers.

Flexible

The advantage of side load case packers is that they can be used to pack a wide range of packing bag shapes.

You may easily swap out the parts to obtain the case of your choice for your packs. To handle fragile products, you can use the side load case packer.

Consistency of Products

Side load case packers will guarantee that the correct material is used and the correct volume and weight of the product before it is packed.

It will benefit producers because they can maintain product uniformity without worry.

Some of the applications of side load case packing are:

- Nuts

- Crisps

- Grains

- Capsules

- Sugar

- Sauces

- Rice

- Pet foods

- Pills

- Bread

- Greeting cards

- Cakes

- Tea bags

- Phone cards

- Condiments

- Sweet and confectionery

- Preservatives

- Jams

The side load case packer’s sealing mechanism varies depending on the product type, but it is an important feature because it prevents product spillage.

The heat-sealing technique is the most frequent mechanism for sealing case packs.

Normally, the appropriate temperature is used to seal the bags, with the temperature being precisely controlled by the control system.

After the bag has been sealed, the machine will cut the sealed bag to the needed specifications using the input digital cut position.

Another sealing mechanism is the hot glue closure, which involves applying hot glue to the flap to form a permanent seal for the side load case packer.

It is most commonly used by producers who deal with heavy objects, particularly near the bottom.

A combination of the truck in closure and hot glue closure is another sealing method that usually improves the sealing case’s strength.

The truck in a closure is usually put to the top of the case pack, with hot glue applied to the bottom to make it more sturdy.

Forming Systems

It is a part of a side load case packer that allows the cases/boxes to be molded into various forms as specified by the manufacturer.

The manual loading of bank cardboard for the cases to be constructed is done in this section.

Loading Systems

These are a type of side load case packer in which manufacturers use choices such as a two-axis robotic system and a multi-axis robotic system to put the product into the case.

Because the procedure begins here, the case packer is usually a vital section.

Sensor Unit

The sensor unit system is one machine component that identifies any system problems. It also aids in determining the number of correct cases.

Electric Unit

The portion of the machine circulates electricity throughout the entire process.

It also aids in the connection of the control panel, which may be adjusted according to the process specifications.

Closing Systems

Inline top seal, tri-seal, compact right angle, and inline are some designed parts with side load case packers.

The side load case packer cannot operate without these closing systems; they are responsible for closing the box flaps of the cases.

The manufacturer’s requirements will use this component for the case packaging of their items.

Discharge Unit

When you’re finished with the closing system unit, the cases will be discharged through this section and put into a carton for transportation.

side load case packer

Side load case packer works in various steps, which include:

Step One -Product Collation

It’s the first phase, where product flow and orientation happen. Depending on the product, you can choose from various collation system casings.

Step Two -The Case Loading

This stage mostly entails case feeding and opening lay down with the side load case packer’s flaps completely open.

Optional multiple case feeding is also offered.

Step Three-Product Loading

The products are loaded at this stage to be cased packed; typically, this is driven by a high speed of 90 degrees on infeed, with the case loaded through the sides.

Then tilted upright or in any other orientation you desire to be packed.

Step Four-Case Sealing

The product is already cased at this point, with all flaps closed and the case sealed with tapes or hot melt glue, depending on the manufacturer’s preference.

Make sure to utilize the proper sealing mechanisms at this point to avoid any spills while the products are in transportation.

Step Five- Case Upright

This stage, normally optional with a side-loading case packer, is where a unique mechanism raises the horizontal laydown cases.

If your case packaged products are unique and require these criteria, you might choose this step as a manufacturer.

Step Six- Case Transition

The cases are packed at this phase and normally depart the side load packer machine through the conveyor.

You can begin a new procedure by returning to stage one and feeding after the casing exit.

Top Load Packer Case

A top load case packer is usually ideal for products requiring vertical casing. Typically, the product is loaded by the top harness or wrap-around types.

Top load case packer

Advantages

- With the right collating system, bags, cartons, trays, cups, cans, bottles, and more can be collated.

- The Delta robot features cartesian and vision-guided setups for optimal loading.

- Use flat and vertical pack casing for high-impact shop displays.

- You can build, load, seal, and cap your cases in one tiny machine.

While

Side Load Case Packer

The side load packer inserts products into cases by pushing them in from the side. With the flap open, the case is essentially built horizontally.

Manufacturers who require high-speed product application should use side load case packers.

side load case packer

Advantages

- Side lade case packer is simple and easy to operate

- It is flexible

- It can handle a high capacity of products

- Saves time and labor cost

- It is suitable for any application

Below are some of the important features of the side load case packer :

- It’s usually made of painted heavy-duty steel structures.

- All tubular welded framework steel is guaranteed for a long time.

- Stainless steel is used for all product contact parts and the casing.

- It also offers a straightforward switching method, which is a plus.

- It’s also sealed with tape and hot melt glue.

- It has a positive carton collation system that allows you to load the case at a 90-degree angle before loading.

- The compression case is squaring device, which maximizes case squareness.

- Major and minor positive flap folding.

- High volume vacuum with two-panel positive case opening

- Another feature is the integration of the labeling process.

The available options for side load case packer include:

Lane Divider With Grouping

It is an in-feed option that has multiple lanes divided into groups in a small footprint and can handle a wide range of case packings.

In most cases, this infeed option is appropriate for jugs and bottles.

High-speed Rotary Up The Stacker

It’s a side load case packer with a feed option, as the name implies, packs cases quickly.

It is commonly used by manufacturers with high production levels and is well-known for its suitability for cartons.

Low-speed Bump Up The Stacker

It is suitable for carton box packing but at a slower pace for low-speed bumps.

If you have small production, you can save money by using a low-speed side-load case packer feeding system.

Flood Feed

Manufacturers dealing with high volume carton case packing or any product can typically employ this in the feed option.

Racetrack Feed

It’s another infeed option for the side loading case packer that’s good for sleeved products and cartons. It’s also noted for being quick and inexpensive.

Indexing Paddling

It’s also a side-loading case packing solution that’s great for cartons and sleeved items.

It can handle high- and low-volume production depending on the company’s needs.

The RSC bottom load case packer commonly loads products from the bottom while retaining a vertical posture.

It usually provides full support for things since it handles them carefully.

Besides, it is usually a good alternative for heavier products that are tough to choose and place during the loading process.

bottom load case packer

Also, it has an active flap folding system that uses servo action.

The top load case packer, on the other hand, usually loads the products using a top wrap-around, harnesses, or RSC case type.

It is easy to use and can be used to pack any production case. It is also one of the most commonly utilized case packers by manufacturers.

top load case packer

The product is normally placed in an open case on its side.

It Works with an in-feed system. The goods will be collated in the correct pack and cased packed.

Wrap-around case packers pack corrugated products into cases by wrapping corrugate around the product and sealing it tight.

Wrap-around case packers often pack stiff products, such as large cartons, into shipping cases.

By Testing The Material Case Consistency

Packaging quality is critical because out-of-spec case packing can generate plenty of issues. Regardless of how good the side load case packer is, the efficiency of the side load case packer will undoubtedly grow by assuring improved quality control of the incoming material.

Have A Maintenance Schedule

Regularly lubricating bearings, cleaning the belts, and checking for adverse sprocket and belt wear will prevent large amounts of downtime on your case packer machine.

By this resulting in increased efficiency. It will be able to assist in the detection of any malfunctions that may develop on the equipment.

By Watching The Hot Melt Unit

Load your hot melt tank with adhesive to be within one inch of the top, but don’t overfill it.

Allowing the tank’s level to go too low and then refilling it with cold glue causes the tank to be thermally shocked.

Ensure that filter system is changed regularly (annually or semi-annually), that the tank is cleaned, and that all hoses and guns are flushed with fresh adhesive.

By Double-checking The Vacuum System

In most cases, the engineered system is well worth the investment.

Check your vacuum cups frequently to ensure they are not clogged with dust, which could cause a malfunction while working.

wrap around case packer

The ideal cup usually has a little filter on the face and can be cleaned easily with a blower every hour.

A drop case packing machine is a top-loading case packing system that can handle various rigid containers.

Fast changeover with adaptable side in packing heads, heavy-duty welded tubular steel construction, and quick clamp product guide lane are all hallmarks of this system.

On the other hand, side load case packers are intended to load and push products via the side of the machine.

drop case packer

The packing pattern specifies the direction in which the product must be packed into your case.

Case sealers are packing machines that seal and fold the top lid of the cartons.

They provide quick and dependable methods for sealing cases following the packing process.

Semi-automatic and automatic case sealer devices are available; most case sealers eliminate the need for dirty hand-held tape guns.

case sealer

While case erector refers to a forming machine that automatically forms, folds, and seals corrugated cartons from a flat box.

They are also available in semi-automated and fully automatic configurations.

They are often high-speed case erectors that eliminate the need for workers to stop packaging products to assemble their cartons.

case erector

For all your side load packer machines, contact us now.