Small Case Erector Manufacturer in China

JOCHAMP is a leading manufacturer of automated and semi-automatic small case erectors with 15+ years of experience. Our small case erector is great for e-commerce product cartons that need to fold.

- Ergonomic blank loading

- Precise case forming

- Heavy-duty design

- Long life use and stable performance

JOCHAMP Small Case Erector

The small case erector is a type of machine that is great for erecting all kinds of boxes or cases for packaging. Whether you want to expand the efficiency of your business, JOCHAMP can provide you with a small case erector in a different setup to match your needs. These machines can be operated on compressed air or electric power. They are all easy to maintain.

JOCHAMP has friendly & knowledgeable sales, technical staff, and excellent customer service to help you find the best small case erector that suits you. You can guarantee reliable machines from us since they are fully certified by SGS, cGMP, ISO9001, and CE.

Message us right away!

Why JOCHAMP Small Case Erector

Faulty equipment can make you disappointed. Here in JOCHAMP, we ensure all our case erector overcomes case variations that provide unique design and reliable performance.

Our small case erector comes with a simplistic design that makes them quick to change over and easy to use. For that reason, these machines can create square cases each time.

Our team manufactures a small box erector with safety in mind. You can guarantee safety machines from safety shields, and curtains to ergonomic magazine loading.

Our company is the best among others. We have driven equipment solutions and rich knowledge in packaging that makes us an expert in this industry.

Small Case Erector for Numerous Sizes of Box

JOCHAMP small case erector is great for different sizes of boxes. It has a little footprint that can glue and fold any size of simple cardboard into top loaded cases.

We manufacture the latest and state-of-the-art small case erector that can be adjustable. It ensures a precise process of boxes in low and high mix volumes. JOCHAMP case erector can accommodate different shapes, sizes, and low quantities of boxes.

Effectively Saves Material Costs

Besides reducing labor costs, and speeding up production, our small case erectors can also limit the material costs. Yes, it can save the material costs as it precisely uses the same tape amount to seal every box.

In addition to reducing waste, the small box erector can deliver more-professional looking boxed product appearance. It also allows the user to predict material costs.

Capabilities of Small Case Erector

JOCHAMP supplies different speeds of small box erectors ranging from 12 – 50 boxes per minute. For instance, case erector can create 18 boxes/minute and can accommodate different box sizes, ranging from 8-inch x 6-inch x 4-inch to 16-inch x 12-inch x 13.5-inch. The machine is accessible with a left or right-side exit to arrange them to your space.

We can also design a small case erector with a running speed of 50 boxes per minute and carton storage of about 80 pieces. These fastest machines can handle boxes ranging from 10.5-inch x 7-inch c 4.5-inch to 17.5-inch x 13.5-inch x 13.5-inch.

JOCHAMP – Your Trusted Small Case Erector Provider

A small case erector is essential to maintain the integrity of the item or product inside it. Whether you need to promote your business through your packaging or need a reliable machine to pack something, you’re in the right place. JOCHAMP provides you with an option for a customized small case erector to meet your needs. These machines are built for reliable and sturdy performance that can prevent the product from being damaged.

JOCHAMP small case erector is fabricated according to our strict quality control. These machines have passed various international quality standards like cGMP, ISO9001, CE, and SGS certifications. Besides, JOCHAMP has more than 20 professional after-sale service teams and more than 15 mechanical engineers to assist your product development.

JOCHAMP Small Case Erector

JOCHAMP covers a solution for high-speed small box erectors and develops a modifying, advanced horizontal-type case erector. These machines allow the folding of different sizes of cartons, ideally suited for the following applications:

- Hardware Accessories

- Personal Care Products

- Logistics

- Express

- Cosmetics

- Alarm for failed pick carton box

- Alarm for failure carton molding

- Failure alarm for sticking tape

- Alarm for running out of adhesive tape

- High safety standard

- Automatic warning if the machine needs to supply a carton

- Safety cutter system

- Fits with a case sealer, bag inserter, label machine, and cartoning machine to benefit from an automatic packing line.

Why JOCHAMP is Trusted By 1000+ Clients

JOCHAMP can manufacture a small case erector that suits your budget and needs. Our range of standard case erectors can accommodate about 10 boxes/minute. Our high-speed box erector allows to erect up to 30 boxes/minute. These machines can be customized to fit your application needs.

JOCHAMP provides top-notch small case erectors among others. These machines are reliable, safe, and easy to use.

We designed a small case erector with total control system that enables each box to erect with great 90-degree angles, no matter what the design is. This system allows every box to pack, protect, and stack product better.

Related Product

Small Case Erector: The Ultimate Guide

For small scale production, you may consider investing in small case erector machines. This guide will help you choose highly efficient case erector machine for your packaging needs. So, keep reading to learn more.

It is an automatic machine that is designed to fit in areas that have less space or where large machineries can not fit.

small case erector

The machine forms, folds and seals given flat cartons into boxes of different dimensions.

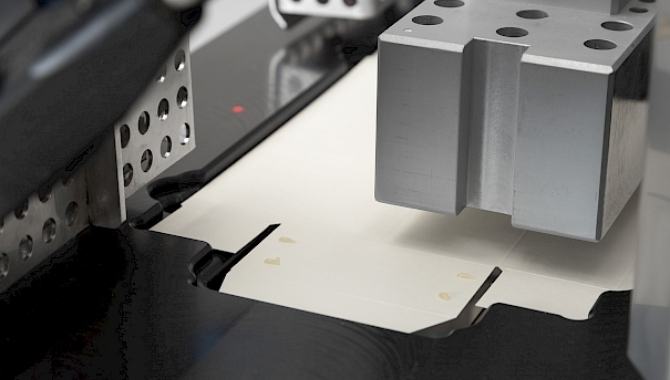

Feeding point

This is an area where the cartons are fed into the small case erector. This point acts as an inlet before the real process of erecting begins.

Holders

It is mainly for un erected cartons.

The cartons remain flap, smooth and straight. The cartons appear ready for erecting process.

Clasps

Clasps are important in lifting flattened box and place it on the metallic holders where it is folded from the bottom during the folding process.

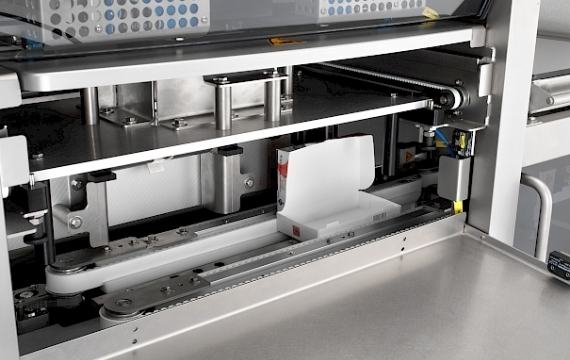

Conveyor belt or conveyor rollers

This part helps in moving the cartons from the erecting area to the sealing area or the preferred area based on the command of the operator.

Conveyors are controlled by the use of a sensor that detects the end and start of different activities.

A small case erector has holder for cartons which have not been erected.

Also, it comprises of clasps that help lift the flattened box and place it on a metallic base for folding process to commence.

However, a one sided folded box is moved forward via a conveyor belt or rollers based on the brand applicable.

Small case erectors, which work conveniently with small case sealers, the products are effectively packed with no human intervention.

Ease of operations

Due to their design manner, they can work in different size changes to offer different solutions, in a quick and accessible way.

There is less handling, hence an easy way of increasing productivity and reducing labor costs in the long run.

Faster changeover

A small case erector with fewer parts and components is key for the operators to find it easy to handle different tasks and activities.

Mass and vigorous operations

Machines offer rigourous end to end 24 hours operational environment.

Low ownership costs

A small case erector offers low maintenance costs, high productivity with less input costs.

Compact footprint

It works best in areas that have limited spaces or in areas designed not for large machineries.

Increases speed

While using the manual way, one worker can make two to three cases in a minute but an automated case erector cam make up to 30 pieces per minute, hence increasing efficiency and productivity.

Reduces backlog

An automated small case can build cases as needed, hence freeing up space on the ground for other purposes to carry on.

Food packaging industry

These include packing of fruits and cereals for exportation and local consumption.

Pharmaceutical industry

Packaging of drugs for export or preservation by use of boxes and sealing them for reference.

Perishable goods packing

Most common perishable goods comprises of flowers, vegetables and fruits.

Fast in speed and changeover

The high speed case erector ensures a quick speed and repeatable production setup of the machine by the help of a hand wheel.

It has a single pull pin adjustment that allows faster one time compression to occur.

Has a motorized adjustment that allows a single touch selection for pre-programmed products.

high speed case erector

Reliable and of quality

Despite high speed of the machine, it is designed in a way that allows for different activities to be performed at the same time.

The machine allows for both folding and sealing process to occur at the same time as gluing is done immediately despite the speed applied during the operations.

High speed case erector has a number of different features that ensures cases are remaining erected and glued continuously and in the prescribed manner despite the fast speed of the machine.

The machine offers vertical discharge which making cases emerge ready for immediate packing.

Hence, a quick production lines the edge in efficiency and facilitates further packing packaging automation.

Operator safety

High speed case erectors are built in a way that they have redundant emergency system.

Control panels are designed to offer safe and easy working environment for the operator.

Also, the machines are built in a very high quality build up system for maximum protection to the operator.

Servo-driven case manipulation

Having a high quality system that offers high speed operations provides quality cases of different sizes.

High speed maintenance

Its mechanism allows for elimination of time consuming downtime. The driveline has an automated shock absorbent hence increasing component life.

Despite both of them working on boxes, as the name suggests, a small case erector works basically on folding boxes.

small case erector

However, a small case sealer uses tape or glue to seal the bottom and/or the top of the boxes.

Small case sealers work on boxes that have already been made from the small case erectors, hence, the small case sealers perform its function based on the small case erectors.

Small case erectors have fewer competing parts than the other erector machines as the smaller case sealers have a control panel system for the management of the operations

Small case erectors have a dependable opposing-cup opening as the small case sealers have active major flap management for their efficiency and operations.

smaller case sealer

Small case erectors comprises of active-case squaring to square the cases in time as the small case sealers compose of spring board high belts that aid in movement of the flaps.

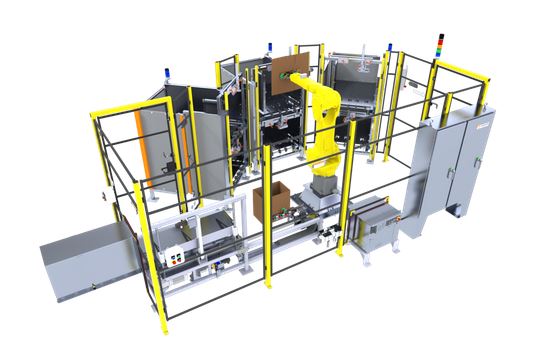

- Small Robotic Case Erector

Small robotic case erectors are flexible in packaging which accommodate different product sizes and varying configurations.

In a single system, the small robotic case erector runs variable case dimensions.

Data can be saved and be retrieved when in need.

There is an easy way of changeover transitions for an easy access of operators to perform short term tasks, mix and match packaging works.

The system is compact and safer way ahead of the manual system.

robotic case erector

Small robotic system has an emergency stop in cases of abrupt deformity.

It helps in elimination of ergonomic issues during the operational process.

It also reduces case cycle time.

- Semi-automatic Small Case Erecting Machine

A semi-automatic small case erector works by folding the lower flaps and retaining open part steady, hence allowing packing using both hands.

With it’s mode of working, it offers a higher productivity as well as reducing production costs.

It also reduces time used to manually erect the case using low costs.

Based on its working principle, the machine can be used either alone or can as well work closely with a case sealer adjuscent to it.

Ideally,the machine can well be erected in a certain angle that allows packing of materials which appear unstable,for instance bag packing or bottles packaging.

This allows a systematic way of forming a horizontal belt drive that allows the belt to feed into the case sealer.

There is no need of a changeover to the former case for complete flexibility. It can be close coupled hence offering the erecting and sealing solutions.

- Fully Automatic Small Case Erecting Machine

Fully automatic small case erectors do not always need the assistance from the operator as it works independently or based on the demand or command given.

Models use a dual opposing vacuum feature to erect flat cases and seal on the base with self-adhesive tape or hot melt glue in the process.

Each of the small fully automatic erector machines are designed to meet the customers’ expectations.

automatic small case erecting machine

Include a sensing kit that informs the operator suppose there is less glue. They also provide a footprint for tight production halls.

Comprise of servo drives for speed and flexibility of the machine.

Simple to operate and maintain hence better return and low ownership costs.

- Small Case Erector With Bottom Taper

Small case erector with bottom taper comprises of tape head that slides out of the machine for easy tape roll changes and maintenance of the machine.

All the machine adjustments are based on the width and height dimensions of the case.

It utilizes the solid state sensors and the photo eyes for dependable operation during the erecting process.

It has a small footprint design that minimizes floor space during the operation.

Small case erectors with bottom taper have low case and low tape alarms with stack light which assures continuous operations.

It comprises of a very fast changeovers for speed increase.

- Small Case Erector With Bottom Sealer

Has a compact design that helps for easy adjustable movements while in use, hence different cartons of different sizes are served.

When the volume of cases is increased, it is advisable not to erect or tape the material in use.

Can erect and seal 12 cases within a minute if service.

System has a tough panel as a control system.

small case erector with bottom sealer

Machine is fixed with a mechanism of no tapping, a taping sealing failure and a tape cutting failure.

- Small Case Erector With Servo Sealing

Works by opening the carton blanks by a servo motor then the bottom of the carton blank folded based on the procedure and sealed with tape and then moved to downstream packing place by a conveyor.

Since the machine has a simple structure, it is easy to operate and maintain.

Belts are driven by two servo motors from the sides of the box, hence ensures the cartons are squared.

small case erector with servo sealing

Since the machine is highly automated with robots, there is reduced labor size.

Low noise is emitted from the machine as it has a smooth operation and almost no damage to the carton.

Small case erectors work on given products while small tray erectors work on almost any production.

Small case erectors involve the use of a conveyor belt as the small tray erectors do not need the use of a conveyor.

small tray erector

Both of the small case erector and the small tray erector work under one common product, to erect boxes or to fold cartons into boxes.

Essentials needed for operation are mainly considered based on;

Type of case needed

One considers the brand of the case machine, the dimensions it works on and the quality of the material to work on and produce.

The quality of the material will aid in choosing the kind of small case erector to purchase.

The extent of the compliance of the manufacturer to the spec is mainly put into consideration.

Hence, it is important to get a small case erector that will serve your interest in the long run.

Case speed

Speed is an essential factor in any working environment. Machines with high speed increases productivity as they reduce costs, for instance human labour use.

It is always possible to make a slower small erector machine run faster but impossible to make a small erector machine run faster.

Seal type

Small case erectors use glue sealers or tape sealers machines. Glue sealers are always more expensive than tape sealers.

The choice of the type of sealers to use will dictate the decision to make while purchasing the small case erector.

Duration

The asset life of the machine is important. The longer the machine life, the better for the production rate and duration.

Machines that run the entire day are more productive in the long run.

You may also like:

For all your small scale case erector needs, contact us now.