Your Robotic Case Erector Manufacturer in China

JOCHAMP is your experienced manufacturer specializing in designing packaging machinery, including robotic case erectors. If you are looking for automated packaging solutions, we offer a wide variety of machines at a reasonable cost. Our team is always ready to accommodate your inquiries anytime. Drop us a message now!

- Simultaneously erect various case sizes.

- Extreme compact footprints

- Robotically erects random cases

- Easy to set up

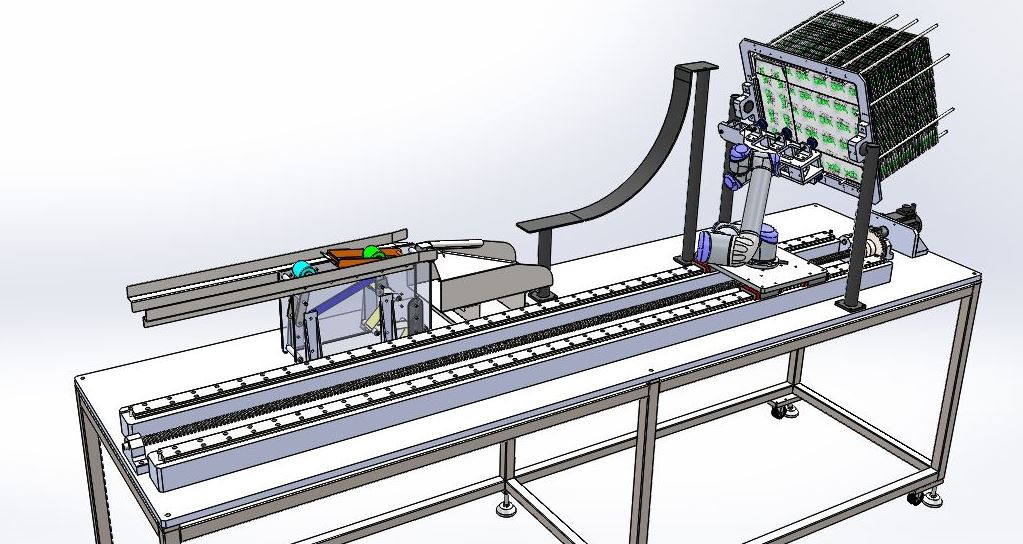

JOCHAMP Robotic Case Erector

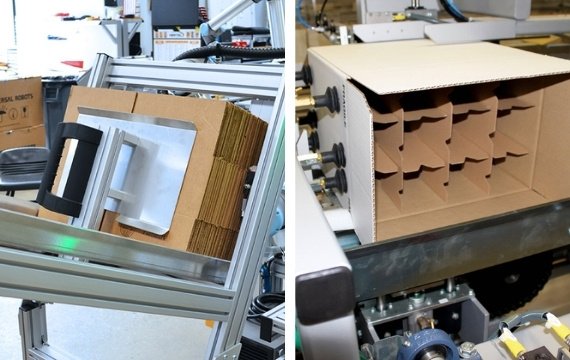

The robotic case erector machines save the case dimension recipes into the HMI. They also retrieve and choose the required case sizes for packing. These case erectors are designed with changeover expedites transitions to operate short production flow efficiently. It also helps the mix and match packaging and other configuration perform conveniently. JOCHAMP robotic case erectors provide numerous application advantages. These machines occupy minimal space as they are designed with compact structures.

Utilizing the robotic case erectors in every packaging or distribution facility lessens ergonomic issues. On the other hand, manually erecting packages results in potential mistakes. However, using the advanced case erectors increases safety, lowers labor costs, enhances outputs, and improves productivity. JOCHAMP designs them with emergency stops and safety standard assistance.

Don’t hesitate to contact JOCHAMP for more information and our services!

Robotic Case Erector Advantages

The flexibility owns by the robotic case erectors make them handle numerous random case sizes. Even though the pack products are challenging, these erectors constantly hold and support the case. They securely handle the packed products at the loading angles.

Having the robotic case erector machines in packaging factories increases uptime and productivity. These machines help erecting and packaging processes done speedily. Plus, it saves time and cost that can increase the erected number of products or cases.

The advanced case erector machines are designed with ease of operation. Using them doesn’t require robotic and programming expertise or skills. With their controlled robotic arms and flexible software, erecting processes are done efficiently without complications.

JOCHAMP provides robotic case erectors with cost-effective parts. They are typically operated by air cylinders that require frequent maintenance and replacement. However, we design them with fewer air cylinders and components for less maintenance.

Robotic Case Erector Salient Features

JOCHAMP manufactures different designs of robotic case erectors with typical characteristics. The following are some standard features the automatic case erector machines possess.

- Ethernet connected for direct case sizes options

- Extended case magazines

- Utilizes hot melt glue, tape, and glue closure

- Designed with adjustable side belts for speed efficiency

- Various case sizes capacity, depending on requests

- Automatic changeovers

- With safety labeling, guarding, and emergency stop

- Designed with end-of-arm tools

You can tell us your desired feature and case erector with robotic arm specifications, and we will do the rest of the customization process.

Robotic Arm Utilization Edges

JOCHAMP designs robotic case erectors with various suitable sizes and functional arms. The following defines some edges of robotic arms in a case erectors.

- Accommodates Improved SKU: The robotic arms accommodate different graphics and shapes of packaging. It achieves the best outcomes with greater production efficiencies.

- Satisfies Retailer Needs: The flexible robotic case erectors fulfill the retailer’s needed product packaging. The robotic arms help to package processes more precisely without struggling with changeovers.

- Achieve Labor Requirements: The presence of robotic arms prevents repetitive strain injuries. They smoothly set up various case sizes, resulting in efficient production and gratifying labor jobs.

- Ease of Utilization: Operating robotic case erectors is effortless. They come with robotic arms that functions according to the program. Operating expertise is not required to utilize such high-tech erector machines.

Custom Robotic Case Erector Designs

JOCHAMP customizes required robotic type case erector specifications. Manufacturing according to applications is crucial as various products are typically handled differently. That’s how a bespoke system provides erector and packaging solutions. You don’t have to worry, as JOCHAMP has a skilled design team providing bespoke projects.

We professionally manufacture and create innovative designs that increase your factory floor space and value. Our designing team customizes practical and precise robotic case erectors depending on requirements and necessities. We always tend to satisfy our customers’ desire with the machine qualities and services. Let’s talk about your preferred design!

Why Choose JOCHAMP Services

JOCHAMP is an expert machine manufacturer based in China. We specialize in developing, manufacturing, and distributing different packaging machines, including robotic case erectors. Additionally, we provide various machines, like flow wrappers, high-speed shrink machines, liquid filling lines, and many other packaging solutions. Choosing our services guarantees CE & IOS9001 certified approved products.

For more than 15 years of manufacturing various packing machines, we have supplied about 40 countries worldwide. We possess advanced production equipment, 100 skillful workers, and ten technical sales team that can produce more than 50 sets of packaging machines per month. That means you can have continuous supplies and be provided with your urgent requests.

When choosing the most suitable robotic case erector designs, you can ask for assistance. Our friendly sales staff will provide quick response and satisfying information. Feel free to talk with us right now, right here!

JOCHAMP - Your Reliable Manufacturer in China

Choosing the suitable case erector machines with the best efficiency and performance affects overall production. You can consider the following differences between robotic and traditional case erectors to make an ideal decision.

- Mechanical Parts: The robotic erectors have fewer components than the traditional ones. They are typically controlled by programming, more secure, and have less noise than traditional erectors.

- Footprints: The traditional case erectors designed with multiple parts consume more giant footprints than the robotic ones.

- Lower Decibels: The robotic erector types operate quieter than traditional case erectors’ components. Also, the robotics’ free parts have a more flawless movement that lowers decibel levels.

- Changeovers: The traditional case erectors need more adjustments and tuning while changing over. Robotic ones use high repeatability that reduces adjusting and tuning requirements.

Evaluating the information above may help you decide what case erector machine you need. You can also contact us for further questions.

The advanced robotic case erectors smoothly operate with the support of functional components. However, some details are customizable to suit your applications and needs. The following are some common parts of a robotic-type case erector.

- Smart Touch Screen: They are designed for ease of operation. This control is safe and convenient. It comes with an emergency stop switch.

- Electrical & Program Control: This imported rigid electrical system enhances automation system levels. It also has optional configurations.

- Adjustable Handles: It functions and adjusts according to the case sizes.

- Sucker: This component has a suction cup with extreme suction and can grasp the case successfully. It is designed with extended service life and smooth operation.

- Air-Source: It drains the water using the filter and adjustable pressure.

JOCHAMP assures well-established robotic-type case erectors machines with functional components. Feel free to negotiate with us!

Custom Robotic Case Erector for Various Industry

Robotic case erectors are in-demand in the food and beverages industry. They increase food packaging productivity and efficiency. Forming the correct case sizes and stability prevents the risk of food contamination. These machines precisely assemble various case types that fit packaging foods or beverage products.

Electronic products are essential to be packed with appropriate cases. They come in different sizes that need suitable packaging dimensions. That is why the electronic industry utilizes advanced robotic erector systems. It saves more time and effort. Using the mentioned machines minimize electronic component damages.

Cartoning is in-demand when it comes to the packaging of consumer goods. The robotic case erectors accurately assemble the suitable boxes. These machines provide fewer labor injuries and work. They maximize packaging efficiency without mistakes. Most consumer goods do not have the same packaging sizes, but robotic erectors can make it faster.

The automobile industry mostly prefers to use robotic case erectors, which precisely perform the case folding instructions. These machines also have extended parts utilized to box the auto parts items, unfold, print, and seal their cases. The robotic machines for erecting cases are designed with automatic stop switches when processing abnormalities occur.

Related Products

Robotic Case Erector: The Ultimate Guide

At times, choosing a reliable robotic case erector can be an overwhelming task without the right information. A reason this guide explores all information about robotic case erector machine such as features, parts, working principle, and classification, just to mention a few. Let’s dive right in.

A robotic case erector is an end-of-the-line automated machine. It helps with putting together cases used for packaging products.

The Robotic case erector eliminates the repetitive task of erecting cases that is time-consuming. This, in turn, cuts down on both the cost of production and is time-saving.

robotic case erector

The robotic case erector’s speed ranges from six to fifty cases per minute. The speed of the Robotic Case Erector is dependent on several factors.

These factors include;

- Type of Robotic case erector – There are different types of Robotic case erectors, each best suited for varying purposes, and therefore have different speeds.

- Size and capacity of the Robotic Case Erector

Large-scale productions require Robotic Case Erectors with higher speeds than Robotic Case Erectors used by small-scale productions.

You should select a Robotic case erector that best suits your production capacity while allowing for room to grow.

There are several advantages to automating your end-of-the-line processing by integrating the Robotic case erector. These advantages include

- Flexibility; The Robotic case erector can handle cases of varying sizes.

This eliminates the need for a changeover that would be needed when shifting from one case size to another.

- Eliminates ergonomic issues; Replacing human workers using the robotic case erector helps to do away with ergonomic issues with the cases, that would have otherwise arisen.

- Saves on space; the Robotic case erector’s compact design makes it ideal even for small spaces.

It does not occupy much space; thus, you need not redesign your space to accommodate it.

- Higher productivity; integrating a Robotic case erector boosts productivity as it simplifies part of the packaging process.

- Reduced labor costs; there will be a reduction in the labor cost as the machine replaces the need for human labor for case erection.

It also reduces the downtime experienced if the laborers get sick or exhausted.

- Safe working environment; the Robotic case erectors are fitted with safety guarding to ensure that no that could harm the worker’s accidents occur.

We have compared the two with the below sub-headings for better comprehension.

Changeover

The manual box erectors require a changeover.

These involve tuning and adjusting the settings to accommodate boxes of different sizes.

Often involves halting the machine, which in turn lengthens the production time.

The Robotic Case erector utilizes a Robotic arm capable of handling cases of different sizes without requiring a changeover.

Structural Features

The Manual box erector has numerous parts to cater to different needs.

For any case erecting machine requiring a changeover, there are likely to be more mechanical parts to handle cases of different sizes.

manual box erector

The Robotic Case Erector has fewer parts as its Robotic arm is capable of handling varying case sizes.

Fewer parts in a machine are advantageous as there will be fewer breakdowns and fewer high-wear parts, making it easier to maintain.

It also allows for a compact design that can fit anywhere.

Footprint

The Manual Box erector has a larger footprint than Robotic Case erectors of similar capacity.

This makes the Robotic Case Erector preferable in a small-scale setup.

robotic case erector

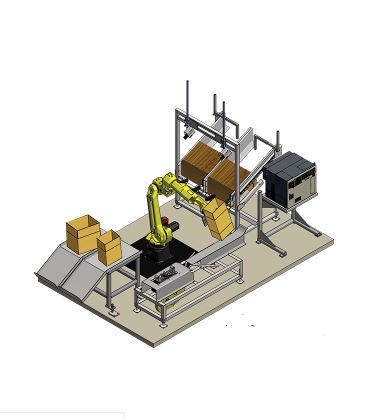

The various types of Robotic case erecting machines differ in their mode of operation.

It is essential to select a Robotic Case Erector machine that will adequately address all of your needs.

The different types of Robotic Case Erecting machines also come in various capacities to better handle different scales of production.

Random Robotic Case Erector

The Random Robotic case erector is a type of Robotic case erector. It combines a robotic arm with a case magazine containing different sizes.

The random robotic case erector can handle cases of different sizes without requiring a changeover.

Standard Random Robotic Case Erectors feature three case magazines.

random case erector

It is, however, possible to customize your Random Robotic Case Erector to accommodate more case magazines.

Robotic Case Erector With Bottom Taper

Simply put, it is a Robotic Case Erector containing a bottom sealer.

A PLC is the primary controlling mechanism for the machine. However, you can also operate it from an HMI system.

robotic case erector with bottom taper

The Robotic case erector with bottom taper consists of a self-centering and uneven bottom belt and a heavy-duty mast capable of handling cases of varying sizes.

Fully Automatic Robotic Case Erector

A fully automatic Robotic case Erector is a type of Robotic Case Erector that seals all the top four sides and bottom flaps.

It consists of an adjustable flab closer system which gives it access to all the sides of the case. It is also capable of handling cases of different sizes and designs.

automatic robotic case erector

This type of Robotic Case Erector is fully automated and fitted with sensors that ensure that all the processes are executed adequately before moving on to the next case.

Robotic Case Erector With Hot Melt Glue Closure.

The Robotic case erector with Hot melt glue closer utilizes hot glue instead of the more traditional tuck-in closer.

Its application is mainly in the pharmaceuticals and food industries.

The Robotic case erector with hot melt glue closure produces cases with an even more appealing visual.

Additionally, it is cost-effective and can handle cases of different sizes properly.

The Robotic Case Erector consists of three main parts.

- Flexible end arm tool; is responsible for picking up and erecting the cases.

The arm can handle cases of different sizes, which reduces the costly downtime required during a changeover.

- Case magazines: The standard Robotic case erector consists of three case magazines, but you can get up to six case magazines or more, depending on your production needs.

- A flap folder: The method and type of flap folder vary according to the kind of Robotic Case Erector.

- Remote operating system: The Robotic Case Erector has a remote operating station.

This allows the operator to handle the machine and make any adjustments easily.

- Opposing Vacuum: The opposing vacuum is effective in picking up the knockdowns.

The raised blank is grasped on both sides in preparation for folding.

The Robotic case erector can also be integrated with other devices to provide a more seamless operation.

A few of these additional parts include

- Different case magazines; vary in size and, therefore, capacity.

- An Ethernet; can be done manually for a more fully automated experience as both setting up and controlling the case erector.

The Robotics Case Erector mainly comprises three essential parts. A robotic rotation system with an attached arm tool.

A case magazine is usually three but could be more depending on your needs and a flap folder.

The rotating robotic system allows the arm to pick up cases from different magazines through an easily programmable selection sequence.

The system is set on an axis.

Additionally the Robotic Case Erector has a calibrated system that uses an articulated motion to ensure that there are no errors such as missing blanks during pick-up.

A three-axis robot can only utilize three case magazines; likewise, a six-axis robot can be fitted with up to six case magazines of various sizes.

The machine has an opposing dual vacuum that effectively picks up the knockdowns. The raised blank is grasped on both sides in preparation for folding.

After the erection of the case and subsequent product packaging, the case is closed by the flap folder and sealed.

The sealing method varies with the type of the Robotics Case Erector. Examples include using hot glue or tape to seal the case.

It is possible to modify features of a Robotic case Erector to address different needs better. Therefore, features may vary from one Robotic Case Erector to another. The general features of the Robotic Case Erector include:

- Simple case selection: The Robotic Case Erector should have a simple and easily programmable selection sequence.

This sequence can easily be adjusted and set according to the sizes and quantities needed.

- Pick-up error prevention: The Robotic Case Erector ought to have a calibrated system that uses an articulated motion to ensure no errors such as missing blanks during pick-up.

- Dependable opening of knocked-down blanks: The machine should have an opposing dual vacuum that effectively picks up the knockdowns.

The raised blank grasps on both sides in preparation for folding.

- Uniformly erected cases: The Robotic Case Erector should have a dual chain drive that assists in transporting formed cases.

The cases are taken through closing and sealing. It ensures that the erected cases are uniform in shape.

- Adjustable case magazines; The Robotic Case Erector ought to have multiple case magazines.

The magazine cases are powered and allow for the restocking of the blanks without causing any disruption to the production process.

- No changeover; The Robotic Case Erector with multiple magazines that can accommodate cases of different sizes.

It also has a random selection sequence. This eliminates the need for a changeover.

- Remote operating system: A remote operating station allows the operator to handle the machine and make any adjustments easily.

The Delta Robot is mainly utilized in processes that require repeated actions.

In this case, the Delta Robot is used to pick up and put cases together. The Delta Robot has many benefits, including:

- Delta Robots have visual technology. This allows it to sort cases I’m terms of sizes, shapes, colors, and design.

Next, the cases are then placed according to the program input.

- These Delta Robots are programmed to handle tasks at high speeds. This reduced the time taken during the packaging of the products.

- Delta Robots execute tasks uniformly. This ensures that all the cases appear uniform.

- The Delta Robot has a compact design and a small footprint. This allows it to fit in areas where space is limited.

- Delta Robots are typically fitted with a lightweight arm, making them more efficient and faster than other industrial robots.

The Robotic Case Erector has disadvantages just as any other equipment. These limitations include:

- Used for light-load: The robotic Case Erector has a lightweight arm that can only handle a light load.

- The Robotic Case Erector has limited flexibility. The Increased speed of the Robotic Case Erector limits its flexibility.

You May Like:

For all your robotic case erector, contact us now.