Glue Case Erector Manufacturer in China

JOCHAMP is a glue case erector manufacturer with an efficient and professional staff. All of our glue case erectors have been certified by CE, ISO9001, and SGS. Every stage of the quality control process, from raw materials to machine assembly and testing, is controlled by specialists.

- Suitable for small and big carton boxes

- Automatic alarm function

- Operation is quick and simple

- The machine is easy to maintain

JOCHAMP Glue Case Erector

The glue case erector is equipped with a dependable and industry-leading system configuration that enables accelerated and high-powered performance. It consists of heavy-duty mechanical motors and controls, which are highly beneficial for high-speed packaging of products such as beverages, distilled spirits, chemicals, food production, and other industries.

JOCHAMP glue case erector always runs in good condition, making it the best to use for massive production needs. Besides, the entire machine comes with the correct parts, which can be customized, tooled, or upgraded. JOCHAMP manufactures the best-quality glue case erector that suits the industrial application, requirements, and budget.

If you are looking for a sustainable glue case erector for your business and projects, JOCHAMP has an extensive selection. Whether you like pneumatic, automatic or semi-automatic glue case erectors, JOCHAMP always provides.

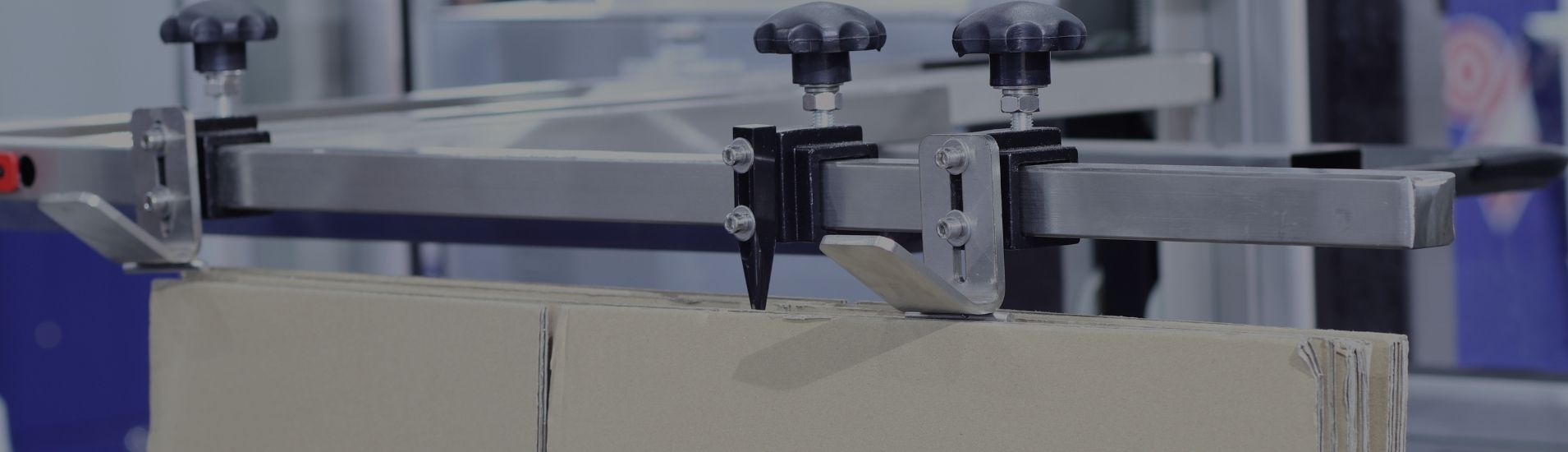

JCK-50H Glue Case Erector

For optimal durability, reliability and value, JCK-50H case erectors erect corrugated cases and close the bottom flaps with hot melt glue. Equipped with the dependable, industry leading Hot Melt System, glue applied directly to case flaps creates a strong, rigid bond which helps ensure boxes remain intact and the contents secure at all times.

- Automatic forming for corrugated cardboard

- Automatic folding flaps and bottom sealing

- Automatic alarm function

- Simple replace carton and tape roll

- Edit PLC program available if you need;

- Suitable for small and big carton boxes;

- The maintenance of the machine is simple;

JCK-50H

- Technical Parameter

- Features

- Optional

| Model | 50H |

| Max.Packager Size | L510mm*W340mm*H400mm |

| Min.Packager Size | L240mm*W120mm*H160mm |

| Width of Tape | 36mm-68mm |

| Power Consumption | 0.7KW |

| Machine Size | 2180mm*1228mm*1870mm |

- Automatic forming for corrugated cardboard;

- Automatic folding flaps and bottom sealing;

- Automatic alarm function;

- Simple replace carton and tape roll;

- Edit PLC program available if you need;

- Suitable for small and big carton boxes;

- The maintenance of the machine is simple;

stainless steel frame

Heavy Duty Locking Casters

Alarm for too few case

Glue Case Erector Advantages

The wiring and layout not only satisfy the design specifications, but the workmanship is also straightforward and attractive. High transmission quality, quick speed, and stable operation are all possible thanks to the use of PLC control.

A glue case erector has a man-machine interface that is both unique and attractive. An internal function is completed, and the operation is simple and straightforward. It is useful and safer to use with an emergency stop switch.

Our company, JOCHAMP, invented and built the glue case erector. This results in a compact design, a pleasing appearance, low energy usage, dependable operation, and ease of use. For the greatest results, go with Jochamp.

Customers can customize their own glue case erector sizes and types. This can accommodate all consumer requirements. We are able to offer competitive pricing while maintaining a high level of quality that is really useful to your business.

What are the Used of Glue Case Erector?

The glue case erector is used to fold the two bottom flaps of the empty case, then directly applied by glue, creating a robust and rigid bond. The formed cases will hold onto for a while, ensuring that glue hardens and dries. This machine ensures that cases remain intact and keep all contents secured.

The glue case erector is applicable for manual or fully automatic packaging lines. All machine movement is cautiously controlled, preventing technical issues and troubles. This gives more increased production rate in every operation it undertakes.

High Progressive Glue Case Erector

JOCHAMP glue case erector is easy to maneuver. It is made with high-functional components that are operated in unison. Moreover, the configuration of the entire machine gives good stability and high-speed production that accomplishes thousands of outputs in continuous operations. Furthermore, the JOCHAMP glue case erector is highlighted because:

- Advanced device layout.

- Has a unit that automatically stops the process when any faults happen.

- Self-vacuum system.

- Working speed depends on carton dimensions.

- It is easily adjusted to fit cartons of different sizes.

Glue Case Erector Components Configurations

JOCHAMP glue case erector is manufactured using advanced international technology that grants stable and long-life operating performance. It is also equipped with security protections such as overloading and malfunctionality.

- Good quality bearings

- Imported parts and electrical components

- Belt

- Sharp sensors

- Hotmelt glue machine

- Low failure rate motors

Why Choose JOCHAMP Glue Case Erector

For over 15 years, JOCHAMP has supported the automatization progress in manufacturing glue case erectors. It is concretely designed for high-volume industries that require robust and innovative packaging solutions. JOCHAMP entirely complies with the international certifications, including the CE, SGS, ISO9001, and cGMP.

Moreover, the glue case erector from JOCHAMP has access to capability, reliable benefits, and convenience features. Using this will reduce pending work and deliver fast-moving and consistent performance. The glue case erector will eventually erect all cases, cartons, containers, or boxes in just a few moments.

Investing in our glue case erector will benefit the progression of your entire packaging business and save your long-term costs. For more information about our glue case erector and our services, request a quick quote for assistance.

JOCHAMP focuses on research and development design for glue case erectors. It is constructed by using the finest industrial-grade materials that guarantee durability and endurance:

- Heavy-duty, compact, and welded steel construction

- High-speed operation

- Less space location

- Easy for adjustment and less maintenance

- Used as an individual or combined with the packaging line

- Rapid replacement

- User-friendly interface

- Easy to solve the cartons, boxes, or cases malposition problem

JOCHAMP has the best production line for glue case erectors. It comes with a compact construction that delivers outstanding operation benefits, such as:

- Lower waste

- Increased production rate for a wide range of applications

- Secure cases every time

- Prevents corrugated dust

- Industry-standard for integrated control

- intelligent motor control

- Instant labor savings and increased production for a wide range of medium-speed applications

Custom Glue Case Erector to Syrocket Your Business/Project

The carton box gluing erecting machine is easy to operate and incorporates an emergency stop switch, making it convenient and safe. The Siemens PLC control is long-lasting and reliable, with a high-efficiency rating. This machine seals tightly without slipping tape. Optionally, you can use a hot melt glue system. JOCHAMP has a capable R & D team as well as skilled engineers.

The glue case erector erects corrugated cases and glues the bottom flaps shut for maximum durability, reliability, and value. Glue applied directly to case flaps, which are equipped with the trustworthy, industry-leading hot melt system, generates a strong, firm connection that helps ensure boxes remain intact, and their contents secure at all times. Contact JOCHAMP now for your customized glue case erector.

The adhesive case carton erector has been created specifically for small cartons. It is possible to pack up to 20 cases every minute. During peak e-commerce season, it can solve the problem of high quantities and delayed packaging. It can be utilized with weighing, labeling, code scanning, sorting, or as a stand-alone system. JOCHAMP provides high-quality glue case erectors while also enhancing after-sales service.

Cartons can be loaded at any moment without halting the machine in vertical storage. It can build and seal identical-sized containers—an advanced photoelectric induction control system with manual adjustment to modify carton sizes. JOCHAMP has a competent team that takes pride in providing effective services to all customers.

The bottom of the carton box will be sealed with hot melt glue by the vertical automatic hot melt glue carton case erector. The machine’s control systems include Siemens touch and Siemens PLC, allowing the operator to operate and adjust the program. Small and large cartons are ideal. Inquire at JOCHAMP now.

Related Product

Glue Case Erector: The Ultimate Guide

Glue case erector plays an integral role in modern packaging solutions. This guide will help you choose reliable and efficient glue case erector machine. Whether you want to learn about features, specifications, parts, working principle or applications – you will find all information right here.

This machine automatically fabricates, folds, and seals corrugated cartons from their raw materials. These raw materials are usually flat boxes.

glue case erector

Key advantages of using a hot melt glue case erector are:

Facilitates Production Of Your Corrugated Cartons

This machine produces several units of your corrugated cartons per unit time.

Utilizing it enhances the production of your cartons which is essential when you have a high demand for them.

Reduces Operational Cost

A hot melt glue case erector fabricates folds and seals your corrugated cartons.

Managing all these stages of producing your carton implies that you don’t have to hire human resources or purchase other machines.

You, therefore, minimize your organization’s overall production and operating cost.

Enhances Quality Production Of Your Corrugated Cartons

You are sure of getting quality corrugated cartons when using this machine.

This is because the machine uses quality raw materials and monitors each step of the production process.

You also set the parameters you want your machine to operate, guaranteeing you quality production.

The primary function of hot melt glue is to form cartons for use in different applications.

Besides, the machines work by forming, folding and sealing various carton designs.

You can integrate other machines with your hot melt glue case erector to enhance its functions.

For instance, you can use a labelling machine to mark the content your carton will carry.

A glue case erector has the following parts:

Control Unit

The control unit allows you to control the functioning of your glue case erector. This is by setting the correct parameters before operating your machine.

For instance, you have to power on your machine, which is possible by switching the power button. You also have to set the speed and the dimensions of the folding unit for the machine to fabricate your cartons correctly.

Feeding Hopper

You need to introduce your raw material for fabricating your carton boxes by the case erector.

This is possible through the feeding hopper, usually on top or at the sides of your glue case erector.

The feeding hopper can vary in design depending on the case erector you are using.

Conveyor Belts

Conveyor belts are the transportation channels of your glue case erector.

They facilitate the movement of your raw materials and carton boxes from one section to another along the machine.

Cutting Section

Your cardboard needs to have a design that makes it easy to fold in the folding unit of your machine. The cutting section cuts your cardboard as per the design of the carton you want to manufacture.

Before operating your machine, you must set the design on the control panel to facilitate the cutting process.

Folding Unit

The folding unit is what transforms your cardboards into carton boxes. This is done by folding the various sections of your cardboard into boxes.

There are different designs of your carton box that your folding unit can accommodate. However, you must set the right design before the production process starts.

Glue Section

Once you have your carton box, it moves to the glue section, where bonding occurs.

Bonding involves an adhesive to attach the different sections forming a tight and durable carton box.

Rollers apply an adhesive which can either be glued or taped over the side of your carton. Applying pressure on the sides of the cartons ensures you have a strong bond.

Your hot melt glue erector starts operation by feeding the raw material of cardboards into it. This is through the feeding hopper.

The size and dimension of the final carton dictate the type of cardboard to use. You can moderate the feeding speed by using the control panel.

A conveyor belt moves the cardboard to the folding unit. It is here that the actual formation of your carton takes place.

Folding depends on the design of your carton. Different designs require adjustment of your machine, which is possible in the control system.

After folding, the carton box moves to the adhesive section via the conveyor belt. Joining the different sections of your carton takes place here.

A roller spreads the hot melt glue on the open sides of your cartons before attaching the parts.

The compactness of the parts ensures you have a durable carton box for your usage.

Both of these machines work on the production of durable cartons for various uses.

However, a glue case erector combines the formation and sealing of your cardboards into strong and durable cartons.

adhesive sealing case erector

Adhesive sealing case erectors have a single function of biding the different parts of your cartons. The binding process results in a durable carton box.

Glue case erectors are pricier than adhesive sealing case erectors due to their function. Integrating an adhesive sealing case erector with your case erector is possible.

glue case erector

Essential considerations in your selection of a case erector are:

Case Type

You have to consider the case type that you want to fabricate.

Case type includes checking on the dimensions and material you want to use in fabricating your corrugated carton.

Another aspect of your case type to consider is the corrugated quality. The quality affects the performance of your case erector.

Speed Of A Case Erector

Speed determines the output of your case erector. The ideal speed you select should consider your cartons’ current and future demand requirements.

Checking on the speed reduces the purchasing cost in case of a rise in the demand for your case erectors.

Seal Type

Case erectors are available in different seal mechanisms. For instance, you have hot glue case erectors that use glues and tape sealing case erectors.

Tape sealing case erectors are cheaper compared to hot glue case erectors. However, they don’t produce durable seals on your cartons.

Hot glue case erectors utilize hot glue to manufacture your cartons.

This results in strong and durable seals for your cartons, giving them a wide range of usage.

However, you have to pay more to purchase a hit glue case erector than a tape sealing case erector.

Durability Of Your Case Erector

A durable case erector reduces your purchasing expenditure and helps you save in the long term. Durability involves checking on the lifespan of your case erector and the availability of spare parts.

You can guarantee this by purchasing your case erector from a reputable manufacturer.

Such a manufacturer should guide you on where to purchase the spare parts.

The significant difference between a large and small case erector with hot melt glue is the size of the carton they can manufacture.

A large case erector manufactures large boxes due to the dimensions it can handle.

A large case erector has a higher price than a small-scale erector with hot melt glue.

Proper budgeting is essential if you are planning to purchase a large-scale case rector.

If you have large order demand, a large case erector is ideal for your usage.

This is due to the size of carton boxes a machine can produce and its speed during production.

A glue case erector is a machine that forms, folds and seals various designs of carton boxes. The sealing process uses glue as the sealant.

case sealer machine

A case sealer is a machine that seals your carton to form durable cartons for different applications. You can use sealants like sealing tapes or glue to seal your cartons.

The price of a glue case erector is higher than that of a case sealer machine.

Usage of high-speed case erectors is common in areas with high demand for cartons. For instance, you can use this machine to produce cartons for the shipping industry.

Cartons produce here are strong and highly durable. You can also use this machine to produce carton boxes for packaging cosmetic products.

The medical industry is another area where these machines are highly usable.

In this industry, you can use the machine to produce cartons for packaging medical equipment and medicines for proper storage and shipping.

Before using a particular high-speed case erector, always ensure you can adjust it to the specifications of the cartons you want to manufacture.

Maintaining your adhesive sealing case erector involves the following considerations:

Replacing Worn-out Parts

Worn-out parts have the effect of reducing the productivity of your machine.

This can significantly affect your output and profitability levels, especially when you have a high demand for your carton boxes.

However, you can prevent this by checking on your machine regularly and replacing these worn-out parts.

Always ensure you purchase the replacement parts from a reputable manufacturer or an authorized dealer.

This is to prevent the malfunctioning of your machine while enhancing its durability.

Frequent Lubrication Of Your Machine

Friction causes wear and tear to the different parts of your glue case erector. Constant wear and tear reduce the durability of your machine while limiting its operation.

This can increase the operating cost of your machine since you may have to purchase another one if you don’t prevent the friction.

Lubrication offers the best way of preventing friction on your glue case erector.

You achieve this by applying an appropriate lubricant to the surface of your moving parts. For instance, you can apply it on the rollers and the conveyor belts.

The type of lubricant you use should, however, be what your manufacturer recommends. This is to minimize the breakdown of your glue case erector machine.

Using Suitable Materials For Carton Fabrication

The suitable raw materials form the basis of having quality production of your carton boxes.

You also allow your machine to operate at an optimum level when you use suitable materials.

However, poor quality material can cause malfunctioning of your machine. This is by the material getting stuck along the production line.

Always check if the materials pass the recommended quality standards before using them.

More Resources:

Packaging And Labelling Machine

For all your glue case erector, contact us.