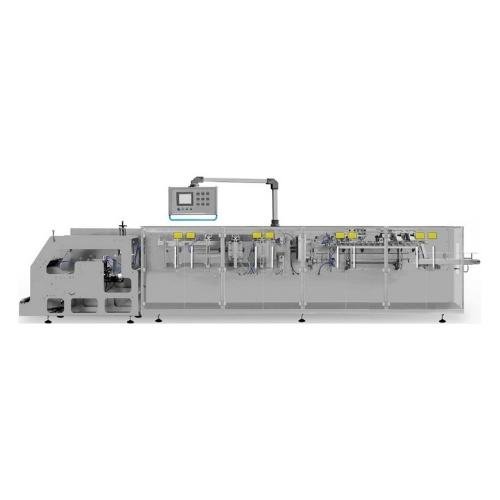

Automatic Packaging Machine Manufacturer

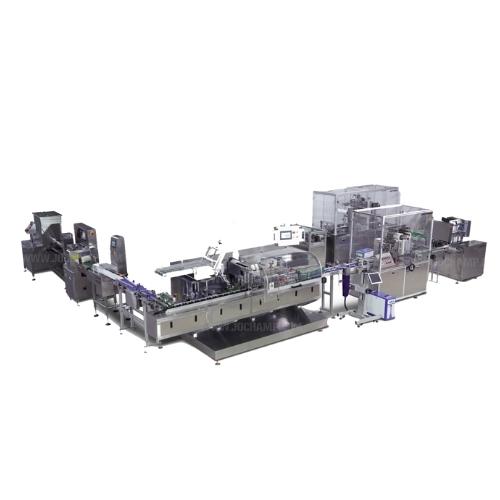

JOCHAMP has 15+ years of automatic packaging manufacturing experience. We supply all types of packaging machines widely used for packaging bottled confectionery, foodstuffs, medicine, cosmetics, or other primary packages and distribution packs.

- High-efficiency packaging machine

- Low noise operation

- CE, SGS, cGMP, ISO9001 certified

- Customized machinery design

JOCHAMP Automatic Packaging Machine

Automatic packaging machines are used to package products or components efficiently. This product area includes equipment used in fabrication, filling, cleaning, sealing, labeling, forming, overwrapping, combining, and palletizing. It also includes related machinery for counting, sorting, and accumulating. There are many types of automatic packaging machines according to the product state, function of packing, packaging industry, packaging position, and degree of automation.

Automated packaging machines from JOCHAMP are in high demand. It can be used for packing dietary supplements, hardware fittings, food, snacks, beverages, pharmaceuticals, and many more. When it comes to waste reduction, precision, sustainability, speed, throughput, and labor cost reductions, automatic packaging machines are unrivaled.

JOCHAMP has been manufacturing a wide range of automated packaging equipment for more than 15 years. We develop and custom seamless series of packaging systems. Our team guarantees to produce a machine that improved material consumption, enhance health and safety and reduces damage and unsealable. Message us today!

Types of Automatic Packaging Machine

The Carton Box Packing Machine revolutionizes the packaging process by automating the use of cases or cartons as primary packaging materials for various products. It employs advanced technology and robotic precision to load, fill, and seal products seamlessly, optimizing productivity and reducing human intervention. This versatile machine accommodates a wide range of industries, including food, beverages, pharmaceuticals, and household goods. With customizable features and adjustable settings, it adapts effortlessly to different product sizes and shapes, ensuring a tailored packaging solution. The Carton Box Packing Machine enhances packaging efficiency, ensures product integrity, and expedites the delivery of high-quality packaged goods to consumers worldwide.

The Blister Packing Machine offers exceptional product visibility, showcasing product outlines effectively. It utilizes diverse materials like aluminum-plastic, aluminum-aluminum, and paper-plastic to form combined packaging, ensuring product protection and enhancing presentation. This versatile machine caters to various industries, including pharmaceuticals, electronics, and consumer goods. Its automated operation streamlines the packaging process, reducing manual effort and increasing productivity. With its precise sealing and customizable configurations, the Blister Packing Machine ensures product integrity while providing a visually appealing packaging solution that captivates consumers and reinforces brand identity.

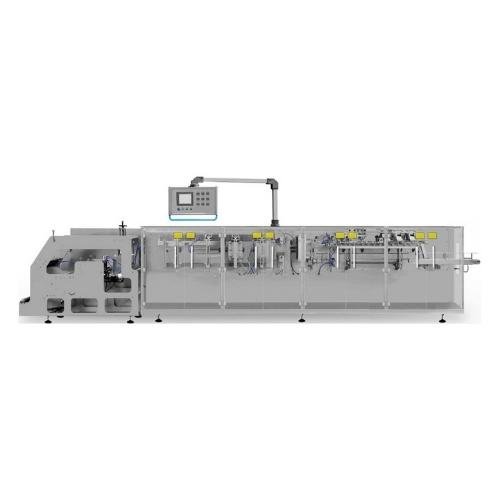

The Form Fill Seal (FFS) Machine comes in two main types: Vertical Form Fill Seal (VFFS) and Horizontal Form Fill Seal (HFFS). It primarily employs OPP or aluminized roll film as the packaging material. The machine efficiently forms the roll film into bags, fills them with the product, and then seals them, all in a seamless automated process. This versatile packaging solution is widely used across industries, including food, snacks, and pharmaceuticals, ensuring product freshness, protection, and attractive presentation for consumers. Its adaptability and high-speed operation make the Form Fill Seal Machine an essential asset for businesses seeking efficient and cost-effective packaging solutions.

The Automatic Wrapping Machine encompasses various types, such as the shrink wrapping machine, flow wrapping machine, and overwrapping machine. It efficiently utilizes OPP, aluminized film, POF, and BOPP roll films as packaging materials. These machines are adept at closely wrapping products, ensuring protection and enhancing presentation. Notably, their packaging speed stands out as one of their key strengths. With their high-speed operation, they cater to diverse industries, from food and beverages to cosmetics and pharmaceuticals, streamlining packaging processes and improving overall productivity. The Automatic Wrapping Machine offers a reliable and versatile packaging solution, empowering businesses to meet market demands effectively while maintaining product quality and visual appeal.

At Jochamp Machinery, we take pride in our ability to provide highly customized packaging production lines, perfectly aligned with our customers’ unique requirements. Our expert team collaborates closely with clients to understand their specific needs, site conditions, and desired output targets. Leveraging our extensive experience and cutting-edge technology, we design and engineer bespoke solutions that optimize efficiency and productivity. From concept to installation and beyond, our commitment to customer satisfaction ensures seamless integration and smooth operation of the tailored packaging lines. With Jochamp Machinery, businesses can achieve unparalleled packaging precision, enhance workflow, and meet market demands with utmost confidence.

Automatic Packaging Machine Feature

Designed with servo motors and intelligent systems, JOCHAMP automated packaging machines have enhanced productivity, high-accuracy and high efficiency.

Our company provide 2-year warranty and lifetime after-sales service based on confidence in the quality of the automated packaging machine.

JOCHAMP offer fully customization to meet your machine requirements and needs. You can choose the best machine based on your specifications.

All packaging machines are economical but never compromise the quality. It packages items efficiently and accurately.

Full Customization

Jochamp is a professional manufacturer that provides a range of custom automated packaging solutions in various industries. Depending on your needs, we can design machines working with cold and heat packaging. From the very basics, such as printing company colors and graphics on the equipment, to the design of equipment based on each specific product being packaged. We can also tailor the installation of bi-directional L-shaped tables, and more. Each of our machines can be customized and adapted to the individual specifications and needs of each customer

Whether you need an automated packing machine for industrial products, medical, nutraceutical, pharmaceutical, and consumer products, or package food, snacks, condiments, Jochamp has the perfect packing solution the exceed unique requirements of your business.

Advantages of Automated Packaging Machine

- Quality and performance – Automated systems have established settings and precise designed. It provides accurate and consistent operations. This machine improved the product quality, fast cycle time, and efficient overall operations.

- Productivity: Automatic packaging machines can operate at maximum efficiency for significantly longer periods of time.

- Finished product care: Automated packing machines guarantee you properly packaged, well-wrapped, and protected products. It provides long-lasting shelf life and versatility.

- Employee’s safety: Automated packaging systems can make operators safer from cuts, tears and back injuries.

Applications

Due to its high efficiency and high performance, Jochamp automatic packaging machines are used in wide industries. This machine may include bag forming, sealing temperature control, material filling, status display, or custom designs.

Some are the following applications automated packing machines used:

- cosmetics and perfumery

- automotive, electronics, and semiconductor

- food and foodservice

- garment, household product

- military and hardware

- music, video and software

- tobacco

- stationary

- medical and pharmaceutical

- chemical and petrochemical

Why Choose JOCHAMP Automatic Packaging Machine

Started in 2005, Jochamp is a leading automatic packaging machine supplier and manufacturer in China. We provide one-stop packaging machine solution for clients worldwide. These machines include flow wrapping machine, heat shrink wrapping machine, cartoning machine, capping machinery, bundling machinery, and more.

Our packaging machines help you to increase the efficiency of your workforce. This will allow you to cope smoothly with possible demand spikes. You will greatly increase your production capacity by being able to work more, in less time, and in a safer and more profitable manner, quickly recouping your packaging equipment investment.

With our expertise and knowledge, we have the ability to manufacture complete turnkey automated packaging lines for your project. All packaging machines are compliant to ISO9001, cGMP, CE, SGS certification. It has a 1-year quality assurance and lifetime after-sales service.

Choose an appropriate automatic packaging line based on your current and future production requirements. On the basis of the basic equipment, you may additionally add an automatic packing line. Custom your automatic packaging machine with Jochamp!

Our range of automated packaging machines guarantees a safe, economical, and appealing finished product. Select automated packaging equipment that is appropriate for your products. These automated machines enable you to grow your business, while at the same time, maintaining employee safety and profitability. Some are the different package types our packaging machine use:

- cartons and boxes

- aerosol containers

- bags and pouches

- bottles, cans and jars

- capsules, cartridges, cases

- kegs and pails

- tubes, and vials, etc.

Automated packaging machines are available in various shapes, designs, sizes, and applications. Jochamp’s integration services can assist the customer to design new equipment from current production lines, as well as setting up equipment and educating staff. Below is the common packaging machine we offer:

- box making packaging machine

- banding machinery or sleeving machinery

- cartoning machinery

- closing machinery

- capping machinery

- bundling machinery

- bagging machinery, etc.

Custom Automatic Packaging Machine Based on Your Applications

Jochamp designed a variety of automated packaging machines that can efficiently pack foods such as flour, dry fruit, biscuit, bread, coffee, snacks, popcorns, corn, chocolates, candy, etc.

You can trust Jochamp for pharmaceutical packaging machines production. It is made rigorously with strict quality control. We made machines for packing syringes, pills, swabs, gloves, face masks, and more.

When it comes to hardware products, you can request a custom hardware packing machine at Jochamp. We manufacture machines suitable for packing fasteners, bearings, screws, rubber, nail, PVC tape, led bulb, and more.

For household industry, Jochamp specifically designed packaging machines with high performance and durability. It can cater to household products such as soap packaging, spoon, washing powder, plate, candles, straws, toothpaste, incense stick, and many others.

Jochamp has a wide range of tobacco packing machines for your projects. It includes a tobacco pouch packing machine, shisha tobacco packing machine, molasses tobacco machine, shisha tobacco cartoning machine, cannabis packaging machine, and many more.

Related Product

Automatic Packaging Machine: The Ultimate Guide

There are quite a number of automatic packaging machines in the market.

You will choose the machine depending on features, working principle, application or design.

The best part – this guide explores everything you need to know about automatic packaging machines.

Let’s dive right in.

It is a piece of equipment used throughout a wide range of packaging operations that involves primary packages to distribution packs.

automatic cartoning machine

This type of machine is available in different types, each designed to perform a specific packaging function in a manufacturing setting.

Thus, it is always fundamental to know the exact automatic operation your application requires when choosing this machine.

You can find them in different sizes, designs and specifications depending on a broad range of factors.

In a modern manufacturing setting, several operations can only be accomplished with the assistance of automatic packaging equipment.

Hence, the effectiveness of different auto-packaging machines is critical to product safety, aesthetics and labeling among others.

This article explores various aspects surrounding automatic packaging machines.

Its advantages, variants, main parts, features, applications and comparison to other machines are among the notable areas discussed in this article.

Ordinarily, this type of machine plays an integral role in accomplishing the manufacturing process depending on the specific role it is designed for.

Automatic packaging equipment and related systems are beneficial in typical industrial production.

Here are the main ways this packaging machine can add value to your business;

Provides Safe Working Conditions

Heavy, cumbersome and bulky products threaten health and safety during packaging.

But using this machine for such products eliminates the possibility of injuries among your personnel since it enhances a safer working environment.

Increases Product Quality

This packaging equipment guarantees well-packaged and protected products through a standardized working process.

It provides tailored packaging design and shapes for each product to ensure protection uniformity, which enhances overall quality.

Increases Production Throughput

Typically, this machine is fast and can process thousands of products within shortest time possible, depending on its features.

Of course, improved production volume is quintessential since it ensures you easily meet the rising demand.

It also ensures your customers never run out of stock, thus improving reliability in the long run.

Reduce Product Waste And Rejection

Manual product packaging is synonymous with a lot of waste arising from human error.

Using this machine, however, prevents such occurrences since it is set accordingly to ensure high accuracy levels.

Reduces Labor Cost

Most aspects of automatic packaging machines hardly require human intervention.

It has different features that coordinate a wide range of functions, making it possible to eliminate or reduce labor needs.

In essence, it saves your running costs since you will have a few machine operators to pay, ultimately.

Eliminates Downtime

Manual packaging process entails a lot of downtimes since the workers are entitled to breaks from time to time.

Such breaks reduce efficiency and production speed resulting in a loss of revenue in the long run.

However, automated packaging machines eliminate such breaks since they can operate 24/7, depending on the settings.

Enhances Specialized Packaging

Different automatic packaging machines are designed to package different products.

Moreover, if your package needs different products, you can also go for an on-demand solution, which tailors each package to fit shape of the item.

Industrial packaging is a comprehensive process that comprises several operations to accomplish successfully.

Thus, different types of machines are often used in this process based on the specific types of products.

They are quite several in the market, but the notable ones used in different industries for various products include the following;

automatic packing and filling machine

- Automatic Packing And Filling Machine

- Automatic Wrapping Machine

- Automatic Cartoning Machine

- Automatic Vacuum Packaging Machine

automatic labelling machine

- Automatic Labeling Machine

- Automatic Flow Wrapping Machine

- Automatic Filling And Closing Machine

- Automatic Metal Detecting Machine

- Automatic Sealing Machine

- Automatic Accumulating And Collating Equipment

- Automatic Label Dispensing Machine

- Automatic Strapping Machine

automatic flow wrapping machine

automatic pouch filling machine

- Automatic Shrink-Wrap Packing Machine

- Automatic Skin Packaging Machine

- Automatic Pouch Filling Machine

- Automatic Weighing Machine

- Automatic Palletizing And Load Unit Assembly Machine

- Automatic Orienting Machine

- Automatic Overwrapping Machine

- Automatic Tube Filling Machine

- Automatic Chewing Gum Packaging Machine

- Automatic Double-Side Sticker Labeling Machine

- Automatic Seaming And Sealing Machine

- Automatic Forming Machine

- Automatic Feeding And Orienting Machine

- Automatic Stretch-Wrapping Machine

- Automatic Water Pouch Packaging Machine

Ideally, packaging machines are available in different varieties depending on the specific packaging function it performs.

Some have simple parts, whereas others have relatively complex parts also depending on the design-construction of the equipment.

However, some primary parts and components available in a wide range of typical packaging machines include the following;

Hopper

It is a funnel-shaped component designed to specifically let the products into the machine for respective packaging processes.

You can find it in different sizes and designs depending on your preference and production volume.

Feeding Tray

In some automatic packaging machines, these components come in handy by allowing the products to settle, awaiting subsequent packaging operations.

Inspection Port

It consists of a system that monitors different set elements of the product to ensure it meets the required conditions before packaging.

Conveyor Unit

This component is responsible for moving the products or items through different stations in the machine for respective packaging operations.

For instance, it moves the items from the hopper to inspection port, labeling unit, sealing etc.

Electric System

It consists of various electrical components designed to carry, distribute and convert electrical power from a delivery point around the equipment.

This unit entails different elements such as conductors that generate various loads within the various units utilizing electrical energy in the machine.

Motors

These are devices which convert electrical energy into mechanical energy.

A typical automatic packing machine consists of various electrical motors designated to power different components.

PLC Screen

It is a display interface used for regulating different machines’ parameters and functions.

Ordinarily, this screen allows you to monitor progress and other functions surrounding this particular machine.

Sensors

These are devices designed for converting signals from one energy domain to electrical domain.

Ordinarily, they detect and respond to different inputs from the machine.

Ejecting Chute

Also known as a dispatch chute in some machines, it is located at the furthest end of the equipment designed to enable release of packaged products.

Use of automated equipment in packaging industry is integral since it facilitates efficiency of the processes and increases production volume.

However, machine automation levels usually vary in different product packaging applications depending on the demands or preferences.

fully automatic packaging machine

As such, you’re likely to find fully automatic or semi-automatic packing machines used in such applications.

Both have their strengths and limitations, and this is how they primarily compare on the following grounds;

Operation

Working process of semi-automatic unit consists of the machinery and labor force.

Thus, some of its operation and input aspects require human involvement.

On the other hand, fully-automatic unit, as the name suggests, has all its functions automated with no human labor required.

Speed

In high-speed and large scale packaging needs, fully automatic unit is more efficient since it depends on the set parameters to deliver required results.

Semi-automatic units, on the other hand, can deliver moderate speeds but still not at faster rates as the fully automatic option.

Convenience

Ideally, a fully systemized machinery offers immense convenience in packaging industry since it is programmed to do all the functions accordingly.

With semi-automatic machine, you will only attain convenience up to a limited level depending on the specific type you are using.

Cost-efficiency

Ordinarily, the running costs in this setting usually increase with labor needs and vice versa.

Hence, when using fully automated packing equipment, you are likely to eliminate overhead costs arising from labor, unlike using a semi-automatic unit.

Besides, the former allows you to save material since it prevents wastage, unlike the latter, which in some instances, can be difficult to reduce wastage.

Precision

Of course, fully-automated machinery is programmed according to required settings, thus guaranteeing higher accuracy.

Semi-auto packing machine, on the other hand, leaves room for inaccuracies, especially in operations conducted manually.

Maintenance

It is easier to maintain semi-automatic packing machinery since it features relatively simple design construction.

Fully automatic unit, however, tends to be more complex and requires a specialized technician to handle some of its critical maintenance needs.

semi automatic packaging machine

Ordinarily, different packaging demands require different types of packing machines.

Manual packing machine is mostly used in small and medium scale production where speed is not necessarily a primary concern.

horizontal form fill seal machine

However, it compares differently with automatic packaging machine in various ways, such as follows;

Uniformity

When using automatic packing equipment, you are guaranteed uniformity across all the packaged products.

This equipment applies same amount in a similar manner to each package.

Of course, this is fundamental since it controls quality, especially where customer expectations are high.

Manual packaging equipment, on the other hand, does not guarantee uniformity since the entire process is carried out by human labor.

Production Speed

If you are concerned with faster packaging speed, automatic unit is the best choice since it is programmed depending on preferred rates.

On the other hand, manual unit is quite slow thus suitable for small volume production.

Efficiency

Automatic packaging machine is highly efficient and reduces material wastage significantly.

You can program it to fit the required specifications, and the waste reduction efficiency makes it more cost-effective.

In manual packing equipment, it is relatively difficult to control wastage since all operations are done by human labor.

Precision

The settings on automatic packing machine make it easy to attain high accuracy in different packaging operations throughout the process.

On the other hand, manual packing equipment is prone to several errors since the operations are done manually.

Working Conditions

Using auto-packing machine eliminates unnecessary repetitive tasks, which in some instances are usually quite strenuous.

As such, the employees are unlikely to suffer burnout or injuries. Moreover, it fundamentally impacts employee retention and health insurance cost.

But using manual packaging equipment can be pretty hectic and difficult to avert repetitive tasks.

Besides, it subjects the workers to possible machine-related injuries and excessive burnout, which ultimately reduces productivity.

Maintenance Needs

Ordinarily, it is cheaper to maintain a manual packing machine than its automatic option.

In essence, the former has simple design construction and basic features that are easy to handle often.

The latter, on the other hand, features a relatively complex design construction and has delicate specifications that require a competent technician.

Different auto-packaging machines use various technologies to fill, seal and pack the respective products.

In many instances, the following are the common techniques that this machine often uses;

Gravimetric Filling

This filling and packaging technology entails measuring the accurate weight of fill material by using a balance.

Ordinarily, this technique is controlled electronically and often programmed to ensure a precise amount of product is placed in ideal container as desired.

Volumetric Filling

It is technology used for filling and packaging liquid products into a wide range of containers.

This filling method is also accurate, but the speed is dependent on the type and properties of liquid you are filling.

Moreover, the container size you are filling also influences the efficiency of this filling technique.

Weight Filling

It involves filling the container based on the weight.

Ordinarily, the machine, in this case, dispenses a specific measured weight of a particular product.

Piece Filling

This filling technique entails the machine dispensing the specific count of product.

It is most common in packaging products such as candy mints, chewing gum, tablets, capsules and lollipops among others.

However, in some instances, the package label claim determines the ideal technology to use.

Additionally, product sealing technologies that different automatic packaging machines offer include the following;

Heat-Sealing

Quite common in packaging industry, and it uses heat to weld the packaging together at a set pressure and temperature.

Cold Sealing

This system uses pressure and special sealing adhesives but hardly uses heat since it can destroy the products.

It is suitable for a wide range of cold products such as food items, chocolates, and ice cream among others.

Vacuum Packing

It entails removing air from the packaging material before sealing to enhance the product’s shelf-life.

Ideally, the essence of this packing technique is to enable the packaging material to get into intimate contact with the item.

Different automatic packaging machines have varied features depending on design construction and intended product.

The design of some of these machines enables them to provide more than one operation in the packaging process.

For instance, you can find an automatic packaging machine that offers filling, counting, packaging and sealing operations.

Nonetheless, the general specifications of this machine is divided into different categories based on the following elements;

Control

The control features of an automatic packaging machine entail the following elements;

- Full PLC control

Peripheral control panel, which incorporates the following;

- Multi-lingua touch screen

- Longitudinal and traversal seal temperature controller

- Production volume internal counters

- Error messages, explanation and remedy

- Power and emergency main control switches

Electric panel

It contains the following features;

- CE-approved electric wiring

- Motors with protection switches against overload

- Complete isolation unit for power supply

- Well-marked electric wiring cables in a single housing

Technical Specifications

- Stainless steel framing component

- Feeding tray

- Motor with invertor

- Mechanical adjusting system

- Electronic control based on package length

Technically, this type of packaging machine is highly efficient and does not necessarily require routine in-depth maintenance.

But it is always important to know that an enhanced performance always relies on how well the machine is maintained.

One major maintenance method of this equipment is ensuring you update the software accordingly.

Since most aspects of this machine are automated, it means you need to get and install the latest software for high performance.

You also need to conduct diagnostic analysis using relevant tools often.

It helps determine the issues likely to arise that may affect machine’s performance.

Another practice involves replacing damaged or worn out parts using recommended OEM parts.

Most of these parts have unique numbers that you can easily use to order some from the manufacturer or dealer.

Also, always ensure that you clean the machine properly and thoroughly after using it.

Remove the dust from the sensitive components to prevent unnecessary breakdowns.

Importantly, lubricate all the moving parts to reduce friction, which is always likely to lead to a faster wear out of such parts.

Always use the machine’s manual when unsure of carrying out any maintenance procedure.

Moreover, ensure you engage a qualified technician to look into the various malfunctions of the machine.

This packaging equipment is used in different production and industrial settings to enhance efficiency, safety and productivity.

The common areas where this machine is often used include the following;

- Pharmaceutical manufacturing, including tablets, capsules, syrups etc.

- Food, water and beverage processing

- Automotive parts industry

- Tobacco manufacturing

- Cosmetics and perfumery

- Stationary manufacturing

- Confectionery manufacturing including a lollipop, chewing gum, candy, chocolate, ice cream etc.

- Garment making

- Chemical processing

- Milk processing

- Nutraceutical industry

Related Resources:

Automatic Shrink Wrapping Machine

For all your automatic packaging machines, contact us now.