Robot Case Packer Manufacturer in China

At Jochamp, we offer many different models of vision-guided and high-speed robot case packers that are great for facilities that have a wide range of products. Our robot case packers can accommodate various pack patterns, speeds, case styles, case sizes, etc.

- Customizes to your specifications

- Certified by the SGS, CE, cGMP, & ISO9001

- One-year quality assurance

- Offers free sample packing test

Jochamp Robot Case Packer

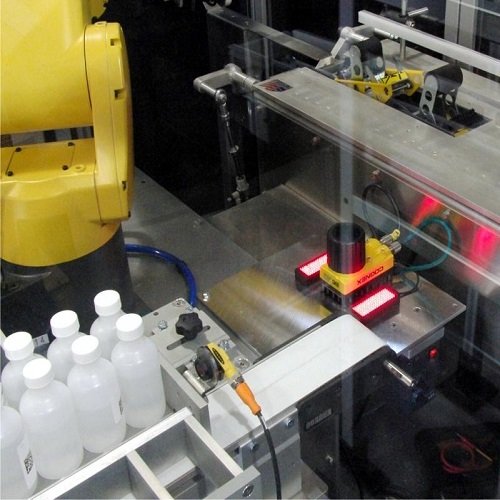

Jochamp robot case packers are integrated with a visual inspection system that can detect disordered products and neatly arrange and place them into the cartons. They can handle a variety of case styles such as regular slotted cases, trays, half-opened cartons, wrap-around cartons, and more. Also, they have easy changeovers and a range of speed capabilities.

To fit your needs, we also engineer various optional parts that can be integrated with the robot case packers such as case erectors, printers, and more. Our robotic case packers can increase your production and you will also save labor costs since they can erect boxes consistently, accurately, and efficiently. They can be easily integrated into your existing production lines and assist you in automating your manual processes.

Our robot case packers have improved packaging reliability, efficiencies, and throughput, and have been cost-effectively designed to support various product packaging needs.

If you have questions about Jochamp robot case packers, please contact us now!

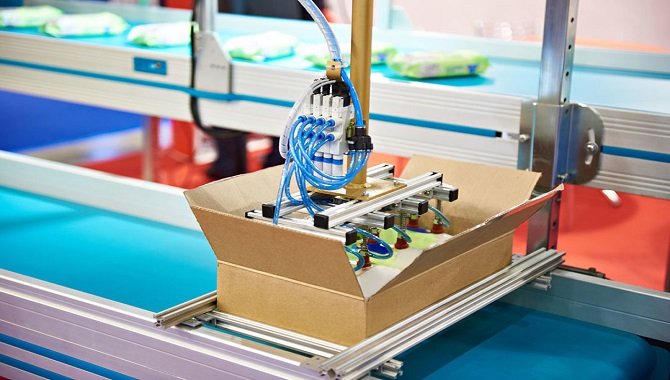

JC-503 Robot Case Packer

The machine integrates the visual inspection system and the manipulator picking system into a set of box systems. The disordered products can be neatly put into the carton by visual correction. Suitable for integration into production lines.

- Extensive product adaptation

- Maximum compatibility 7kg product

- Arrangement for disordered products

- Compact design, rational use of space

- Easy integration into production or packaging lines

JC-503

- Technical Parameter

- Optional

| machine type | JC-503 |

| power supply | 220V/380V 50/60HZ 5KW |

| Crawl rate | Single: 80-120 pieces/min; Double: 160-240 pieces/min |

| Packing method | Single case/Multiple cases |

| Use air source | 6-7kg |

| Machine size | 3000mm*2200mm*2550mm (L*W*H) |

| machine type | JC-503 |

case erector

carton sealer

Secondary packaging line integration

carton sleeve inner bag

Labeling Machine

printer

Glue sealing machine

Stainless steel

heavy duty casters

Leaflet Automatic Dispatcher

export conveyor line

Jochamp Robot Case Packer Advantages

The surface of the robot case packers is made from high-quality and corrosion-resistant stainless steel. Due to that, they are very easy to sanitize and safe for contact with food products.

The robot case packers are integrated with the manipulator picking system and visual inspection system. For that reason, the disordered products will be placed into the cartons neatly and accurately.

Jochamp robot case packers are designed with a friendly HMI or human-machine industrial control system which makes them easier to operate. You do not need skilled workers to operate them.

Jochamp has the ability to design custom robot case packers to meet your exact needs. We have customized solutions for automatic arranging, picking, and placing of various products.

Leading Robot Case Packer Manufacturer

Jochamp has more than 15 years of experience in the production of robot case packers. Our experience makes us one of the leading and trusted manufacturers. Also, our experience means that we are capable of handling a higher level of robot case packer projects.

We have an in-house team of mechanical and electrical engineers that are developing software and processes that are beneficial in the packaging industry. They develop various systems to make the robot case packers easier to operate and suit random packaging needs.

Benefits of the Robot Case Packer

Many companies want automated packaging solutions that will enable them to be more competitive and faster. Some of the benefits of the robot case packers include:

- Can handle a variety of products

- Has a high level of accuracy and precision in packaging

- Lessens repetitive stress injuries in your workplace

- Capable of fulfilling increased product demand

Reduced labor costs, less downtime, and increased production make robot case packers an excellent choice for many businesses.

Options for the Robot Case Packer

The robot case packers can be added with a variety of optional parts and devices depending on your needs. Below are some of the options that can be added:

- Carton sleeve inner bag

- Heavy-duty casters

- Carton sealer

- Case erector

- Printer

- Glue sealing machine

- Labeling machine

- Secondary packaging line integration

- Export conveyor line

- Leaflet automatic dispatcher

- Stainless steel for wash-down applications

Jochamp | Your Trusted Robot Case Packer Supplier

Jochamp has been specializing in the production of various kinds of high-performance robot case packers for more than 15 years. We are also capable of customizing the robot case packers in accordance with your exact specifications to fit your specific needs. Our research and development facilities are designed for the production of custom robot case packers. We have over 3000 square meters factory that is enough for the testing of products.

All of the robot case packers we offer comply with the requirements from ISO, CE, SGS, cGMP, and other international quality management standards. They are made from high-quality and strictly inspected raw materials. We are following strict quality control in every process of the production of robotic case packers to ensure their quality and reliability.

If you are interested in our robot case packers and our customization services, Jochamp is willing to work with you. Send your inquiry now!

Jochamp Robot Case Packer

The robot case packers are designed with a lot of features such as:

- Easy integration into production or existing packing lines

- Precise positioning & arrangement of disordered products

- Extensive product adaptation

- Robust structure

- High precision movements

- Shorter cycle times

- Low power consumption

- High output from a smaller footprint

- Open and ergonomic design

- Low noise operation

- High corrosion resistance

- Food-grade and drug-grade surface

The robot case packers are great for loading, picking, neatly placing, and packing a wide variety of products into a set of box systems such as cartons. Some of the packaging containers or products that the robot case packers can handle include:

- Cans

- Bricks

- Various types of pouches such as stand-up pouches

- Various types of bags

- Jars

- Bottles

- Doy packs

- Flowpacks

- Other products

Jochamp Robot Case Packer for Various Industries

The robot case packers are widely used in the food and beverage industry for packing ready meals, poultry, fish, drinks, and many more. Their robot arm can be finetuned to optimize the speed and positioning within cartons and other secondary packaging. For the product changeover, they can be automatically and quickly fixed using the user-friendly HMI control system.

At Jochamp, we also offer high-performance robot case packers for packing bathroom tissues, diapers, converted papers, table napkins, and other paper products. Our robot case packers can be easily into your existing packaging lines. They have high speed, gentle packing ability, and accurate positioning.

The robot case packers can also be used in the pharmaceutical industry for packing various pharmaceutical products that are packed in a bottle, blister pack, pouch, bag, etc. They can be configured into single or multiple pick up of products.

Jochamp robot case packers are used in many facilities that packs various types of chemicals such as household chemicals. They can gently pack a variety of chemical products that are in rigid containers such as plastic bottles and other packaging containers.

Related Products

Robot Case Packer: The Ultimate Guide

With technological advancements, you may consider robot case packers for accuracy, consistentcy and reliability. This guide explores all fundamental aspects you need about robot case packer machines. Take a look.

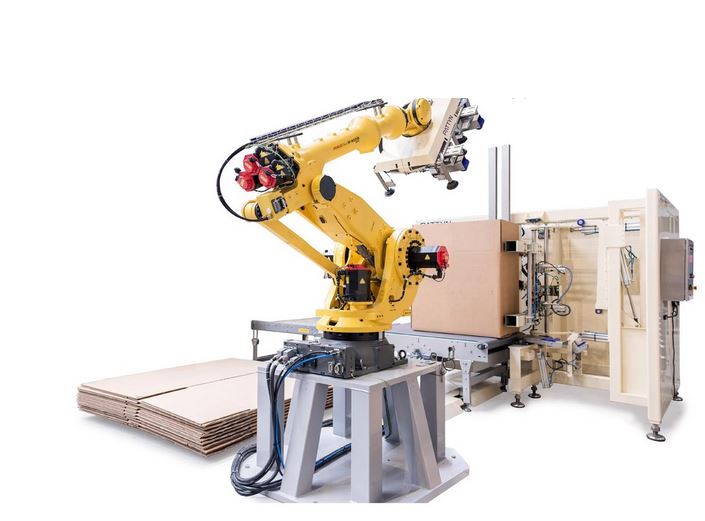

Simply put, a robot case packer is a robot-assisted end-of-line packaging device.

The robots, in this case, are extended arms whose chief role is to aid in packing various products into cases.

The robotic arms of the robot case packers are programmed to achieve various packaging patterns and speeds.

Robot case packer

Depending on the customization, the robot case packer can have multiple arms to boost the production of the case packer.

Notably, productivity is in terms of speed and products packaged per minute.

The essence of any machine in an industry is to impact productivity positively. The robot case packer is no exception and comes with the below advantages:

- Speed – Robot case packers guarantee fast and constant packaging compared to human labor. Humans are susceptible to fatigue, unlike robots.

- Accuracy – With human labor, the accuracy of packaging decreases over the working period due to boredom caused by repetition.

However, the robot case packers ensure that packaging accuracy is maintained throughout the packaging period.

- Flexibility – Robot case packers are highly flexible.

First, they can package a range of products since it is easy to adjust the robot case packer to fit the packaging requirements of a particular product.

Second, they are capable of supporting high-case packing with ease.

- Reduced labor costs – Robot case packers significantly reduce the labor cost requirement for case packing.

- Ergonomic Design –Most robot case packers have an ergonomic design implying user’s ease of operation.

- Gentle product handling – The robotic arm carefully packages the products without damaging them.

- Diverse configuration options – There are various types of robotic arms you can opt to use for your robot case packers.

- Low maintenance – Typically, the structure of the robot case packers makes them require minimum maintenance.

- High Uptime – Despite low maintenance requirements, the robot case packers can operate efficiently for extended hours.

- Versatile – You can install the robot case packers as a stand-alone system.

Alternatively, you can seamlessly integrate it with other end-of-line automation machines such as conveyor systems, case sealers, case erectors, etc.

- Reduced Safety Cost – Lastly, robot case packers cannot get injured like most human labor.

Also, semi-automated robot case packers are manufactured with a high priority on user safety.

Consequently, the robot case packer is associated with the minimum work-environment hazard.

This translates to reduced safety costs for the human labor within the production premise.

There are various types of robot case packers with different features. However, all the available robot case packers use the below-working principle.

First, the products are transported to the robotic cell via sorters or conveyors. The products are then queued up, ready for packing.

Next, the cartons are erected and positioned before the system, automatically initiating the packing process.

Upon initiation of the packing process, a custom end-of-arm tooling (EoAT) rapidly picks the products and places them into the desired package.

Once a carton is filled, it is automatically sealed and exits the system.

The robot case packer will repeat the above process until all products have been successfully packed.

robot case packer

Features are an essential aspect when selecting a robot case packer. However, these features vary depending on the type and the manufacturer of the robot case packer.

Nonetheless, there are some standard features that most robot case packers have. These features include:

- All in one station; meaning the machine does all the necessary packing nitty-gritty.

- A high operating time; averaging about 80,000 hours before failure.

- A modular design that allows for easy integration of complementary parts. Also, the modular design allows you to easily move the machine.

- Scalable – This feature allows you to easily upgrade your robot case packer for improved efficiency.

- User friendly Interface – Most interfaces have memory that allows them to store previous packing patterns. As such, you can easily switch between the packing patterns.

- Gentle product handling

- Low maintenance cost

- Multiple configuration options.

- Open and ergonomic design

- Accurate product positioning

- Small footprint

Before purchasing a robot case packer, you should make considerations to ensure your investment is worthwhile.

Some key considerations include:

- Facility layout

- Number of robots required and throughput rate

- Factory acceptance testing for the machines.

- Identification and orientation of individual products

- Size, shape, and weight of the products you handle.

- Physical characteristics of the products.

The above considerations will dictate whether your ideal robot case packer should have either of the below:

- Multiple EoATs

- Quick-change functionality

- Custom size

- Multiple robots

The technological advancements of robot case packers have been inclined to the below aspects:

- Speed – There is an increasing need for faster packaging in various industries.

Consequently, industries are looking for a hands-on machine that carries out faster packing.

Machine manufacturers have proven to be up to the task by developing high-speed machines that utilize sophisticated technology.

An important advancement in robot case packers’ speed is advanced servo-technology.

- Flexibility – For the efficiency of any machine, flexibility is key.

Flexibility can be in terms of packing of various products, easy mobility of the machine or quick integration of complementary machines to the robot case packers.

Modern robot case packers have modular designs for easy integration.

Additionally, the current case packers feature technology that incorporates various pack patterns, making the machine more efficient.

- User-friendliness – Manufacturers are gradually migrating to creating HMIs that are more intuitive.

Modern HMIs are more or less similar to tablet or smartphone applications.

This way, the robot case packers are more user-friendly and require reduced training of the operating personnel.

- Simplicity – Modern case packers have also taken the route of simplicity.

The technology currently employed reduces the machine’s complexity while retaining the package-format flexibility and the machine reliability.

- Use of different style robots – Lastly, advanced robot case packers have different robots that work harmoniously to improve the general efficiency of the machine.

- Tracking and picking technology – Most robot case packers have adopted improved tracking and picking technology.

Notably, the different robots are specialized and have a designated function.

Common robot types include delta robots, traditional mounted and inverted robotic arms.

Below, we have highlighted some key advantages of the above advancements:

- More uptime

- Less operator invention

- Easy machine integration into existing plants

- Being able to achieve more with one machine.

- Improved placement.

- Increased throughput.

It is essential to mention that you have yet to see the end of these advancements.

Most manufacturers continue to pride themselves on receiving feedback from their customers on ways to improve their robot case packers better.

Below are some important standards that robot case packers should adhere to:

- Adherence with all robotic safety standards including the most current version of RIA R15.06 specifications.

- Programming standards for robots.

- Main body material should be stainless steel.

- Internationally accepted electrical standards – mostly CE compliance

The robot case packer is ideal for top load pick and place products. The products can be in containers such as:

- Regular bottles

- Viz bottles

- Pouch

- Bags

- Bottles

- Cans

- Jars

All these products are carefully packaged into cartons or crates. Notably, the robot case packers can be used as an end line packaging equipment in almost all industries.

The efficiency of a machine can be measured by calculating the difference between the actual and intended production.

The lower the difference, the more significant the efficiency.

Some typical ways of boosting the efficiency of our robot case packers include:

- Stabilizing the speed of your robot case packers

- Upgrading your machine’s software and hardware.

- Employing different style robots on your robot case packer.

- Regularly maintain your robot case packer.

Modern robot case packers feature smart controls, improved robotics and vision systems which has exponentially increased their flexibility.

Our modern robot case packers will:

- Automatically correct any operational problems

- Allow for streamlined changeover

- Allow for a flexible change of pack patterns without interfering with the packing speed.

The above capabilities clearly show how flexible our new-age robot case packers are. These machines can efficiently cope with the increasing variability of SKUs.

The robotic case erector can be considered as a complementary machine to the robot case packer. This machine is also key in an end-of-line packaging system.

robotic case erector

Below is a simple highlight of how a robotic case erector works:

- Once a signal is sent, the robot picks the desired case off the magazine.

- The case is then opened and squared into position by the end of the arm tool (EOAT).

- Next, the robot guides the squared case over a set of rails that close the minor flaps.

- Finally, the case is transitioned into the final section, where the major flaps are folded and taped.

- Once the case is wholly erected, it is placed on the conveyor- ready for filling by the robot case packer.

case packaging machine

Although the robots in a robotic case packer may vary, the typical standard robots include:

- Delta robots

- Traditionally mounted robots

- Inverted robotic arms.

- Vision robots

Knowing how to troubleshoot a robot case packer is an essential skill you need to grasp. Not everyone can troubleshoot a robot case packer.

For this reason, there are short courses/training and guides for the same.

Troubleshooting is critical when:

- The robot case packer becomes faulty.

- You are reprogramming the robot to pack new products.

Some fundamental troubleshooting techniques employed in the case of robot case packers include:

- Use of a teach pendant to jog the robot manually.

- Troubleshooting faults using the input/output screens on the Human Machine Interface (HMI)

- Instantly diagnosing faults through the alarm menu

Notably, about 90% of problems encountered by the robotic machines can be tracked back to the input/output systems.

Considering the frequent vibrations, the devices on these systems are prone to wear and tear.

Robot case packers require minimum maintenance owing to their exceptional design. Notably, they do not require regular greasing or change of batteries.

However, this does not imply that you shouldn’t carry maintenance on your robot case packer over an extended time frame.

You or your maintenance team should carry out periodic preventive maintenance. This way, you can ensure your robot case packer has an extended uptime.

Periodic preventive maintenance will also assist in minimizing errors.

When the maintenance team (or yourself) go for an extended period without maintenance, you may forget specific crucial steps.

Typically, preventive maintenance of robot case packers involves:

- Greasing the robotic arm

- Replacing the batteries

- Other practices deemed fit by the manufacturer.

Lastly, you can outsource the maintenance internally (employ staff) or outsource the technician.

The upward side of outsourcing is that the external technicians are better experienced.

As such, they will not only carry out maintenance but also do upgrades or modify your robot case packer for improved performance.

The conveyor system is another important part that needs to be regularly maintained.

Ensuring the conveyor system remains efficient will enable timely delivery of both the cases and the products.

Realated Resources:

For all your robot case packer machines, contact us now.