Random Case Sealer Manufacturer in China

JOCHAMP has rich experience in supplying random case sealers with bottom and top sealing capabilities. Every case associated with the machine is measured in width and height to position the sealing and folding mechanism automatically. We can manufacture random case sealers for meeting customers’ requirements.

- Great for heavy and wider cartons

- Height and weight are adjusted manually

- Sturdy and precise tape applicator

- Easy to operate

JOCHAMP Random Case Sealer

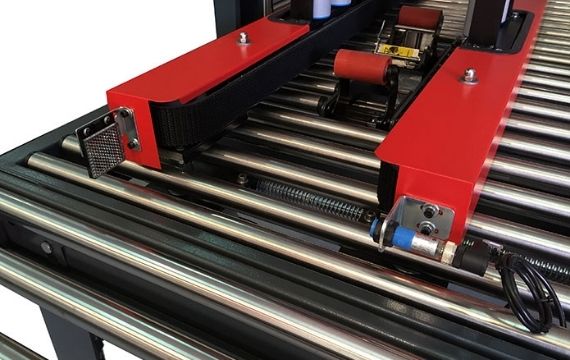

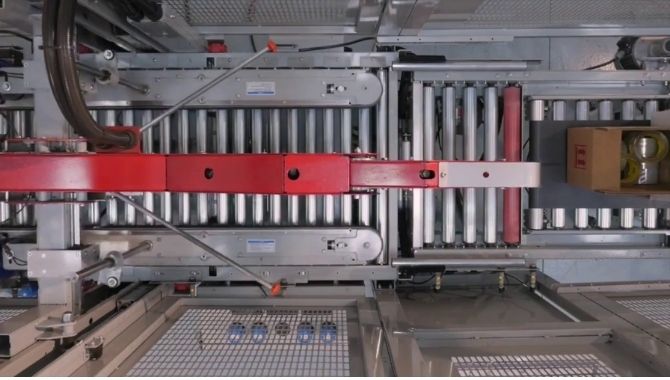

JOCHAMP random case sealers enable the tape head height to be adjusted to different sizes of the case. The tape head can be lowered or raised using sensory equipment to find the right height. By means of the powered roller system, the case will move and then seal the flaps.

JOCHAMP manufactured a random case sealer to meet different packaging equipment solution that uses numerous box sizes at a time. We can provide you random case sealer available in automated running formats or semi-automated running formats. Additionally, JOCHAMP random case sealers are built with a rugged structure to support 24/7 operations.

Message us now!

JCE-50A Random Case Sealer

Using the combination of sensors and sensing systems, the machine can automatically and adaptively seal cartons of random sizes.

- Random size adaptive size

- One-click fix size

- security door system

- Blade guard, anti-stab

- Thick frame design, less vibration and longer life

- Multi-channel spraying process, corrosion resistance, easy to clean

- High wear-resistant belt drive

- Siemens, Panasonic, Omron, SICK, SMC and other internationally renowned brands of motors and accessories

- It can work on a stand-alone machine or online.

JCE-50A

- Technical Parameter

- Features

- Optional

| Model | JCE-50A |

| power | 420W |

| power supply | 220V 50HZ |

| Tape width | 48-60mm |

| speed | 18m / min |

| air pressure | 2/3L 5Kgf/cm |

| Maximum carton size | 700*500*500(mm) |

| Minimum carton size | 260*200*160(mm) |

| work surface height | 600-800(mm) |

| Machine size | 2889*1056*1815(mm) |

- Random size adaptive size

- One-click fix size

- security door system

- Blade guard, anti-stab

- Thick frame design, less vibration and longer life

- Multi-channel spraying process, corrosion resistance, easy to clean

- High wear-resistant belt drive

- Siemens, Panasonic, Omron, SICK, SMC and other internationally renowned brands of motors and accessories

- It can work on a stand-alone machine or online.

Stainless steel rack

Docking case packer

Electric regulator

Up and down drive structure

Automatic folding mechanism

side sealing

strapping

Random Case Sealer Advantage

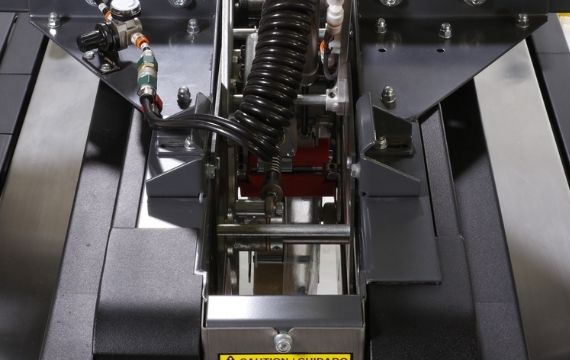

The machine has a built-in indexing gate, flight bar drive, linear self-centering rails, and powered top squeezers. These features can assure high-quality sealing.

Random case sealer comes with flip chart operation information. Featuring pneumatic, high-speed, and interchangeable tape cartridges. No set-up is required.

Available in manual or automatic tape selectivity for the bottom and top closure omission. Customers opt for unique paints or special colors of machines.

Our random case sealer is manufactured with safety in mind. It has a safety monitoring relay and safety door that will shut down automatically when opened.

Provides Flexibility and Fast Productivity

The machine can automatically adjust different sizes of boxes. Our random case sealer uses tape to seal small or large quantities of different box sizes per minute. Depending on your application, we can provide different dimensions and speeds of a random case sealer that efficiently increases productivity.

JOCHAMP case sealer is built with many features that help fast production. For example, the machine has photo eye detection for fast response to any size of the case and the electro-pneumatic height adjustment provides accurate performance. The machine also provides flexibility for smaller boxes by means of offset taping head position.

Recommended Applications of Random Case Sealer

There are a lot of industries that can get an advantage of the feature of our random case sealer, including:

- Medical Devices

- Food and Beverage

- E-Commerce Fulfillment

- Electronics

- Pharmaceutical

- Distribution Center and Manufacturing

- Logistic Industry

Random Case Sealer – Great for Logistic and Distribution Industries

Our high-speed random case sealer is built to meet the requirements in high-volume lines that require quick processing. Designed for speed and flexibility, JOCHAMP random case sealer is suitable for distribution and manufacturing centers with various numerous packaging lines that integrate sealing.

- Automatically adjust to the incoming box

- The infeed guide is automatically adjusted to ensure proper infeed with accurate distance to avoid jams

- Keeps cases square to provide stacking strength and product protection

JOCHAMP – Trusted Random Case Sealer Manufacturer

At JOCHAMP, you can expect a rugged random case sealer design that optimizes long life and durability equipment in a 24/7 environment. You can get benefit from our constant user interface to meet your sealing, packing, erecting, and palletizing equipment needs.

In China, we are a well-known packaging solution provider that counts on the aftermarket, comprehensive sales, and service support. Being an experienced random case sealer manufacturer, we provide shorter down-payment cycles and quicker delivery.

For your case sealer needs, you can rely on our packaging specialists who have a great understanding of case sealing equipment. We can help you find the best ways to minimize costs.

JOCHAMP Random Case Sealer

JOCHAMP random case sealer features detection of the non-contact box for centering by means of photo-eye detection. It can quickly respond to different carton sizes to quickly continue production.

The case sealer also has a bottom and top belt drive that provides positive box conveying. In addition to its unique features, the case sealer has an infeed conveyor, double masts, and an emergency stop. If required, you can also build on a supplemental part like locking casters, exit conveyor, light indicator, and low tape indicator.

- 25m/min belts speed

- Top and bottom carton sealing

- Independent side belt motor for carton dragging

- Tape tension adjustment

- Metal rollers to move the cartons

- Adjustable top guides

- Carton height and width adjustment

- 570mm to 800mm working height adjustment

What Makes JOCHAMP Random Case Sealer Different From Other

Our random case sealer can guarantee smooth case movement by means of the sealing cycle. It has a metal roller that supports cases and boxes to transit through the sealer.

The machines adopt front flap pre-folding to ensure productive closure. The random case sealer ensures accurate rear flap folding, an easy-to-stack case, and ease of handling numerous case qualities.

JOCHAMP random case sealer featuring standard tape head that ensures easy to changeover tape. Also, it can handle different brands of tape.

Our random case sealer comes with a high-efficiency glue nozzle that can guarantee excellent glue bead control.

Related Product

Random Case Sealer: The Ultimate Guide

In this guide, you will find all information about random case sealer machine. With random case sealing machine, you can achieve high level of efficiency and reliability. This only possible when you choose the right machine. Let’s look at some fundamental aspects of random case sealer.

It refers to a case sealing system that can adjust its tape head height in different case sizes on the fly.

The design construction of this equipment allows it to offer top and bottom sealing capabilities at relatively high speeds.

Typically, each case getting into this machine is measured in height and width to allow it to position the folding and sealing mechanism automatically.

This article looks into various elements surrounding the random case sealer.

Therefore, you’ll be able to know the general and specific information about this equipment to guide you when purchasing it.

random case sealer

In the present fast-paced world, using random case sealers is seemingly a smart choice for your packing and shipping solutions.

It offers several advantages, which is imperative in enhancing the efficiency and performance in a typical manufacturing setting.

Some notable advantages of using this equipment include the following;

Easy To Operate

The design of this machine features clear access with simple controls that are easy to adjust to specific size changes.

Hence, it makes this equipment quite user-friendly to the operator and allows for a faster and easy change, cleaning, and maintenance.

Affordability

The cost of owning this equipment is quite affordable since it is designed to give you the best value for your investment.

It guarantees maximum productivity with minimum delays during packaging process.

Easily Adjustable

Since it seals cases randomly, it means it can adjust its settings automatically to close different cases in any sequence.

Hence, it gives you the necessary flexibility and reduces time-wastage when sealing your cases.

Highly Durable

The design construction of this machine is quite robust, with various parts and components housed in a strong chassis material.

This is advantageous because it ensures 24-hour operation if need be and minimal servicing.

Increases Production Volume

Since this machine’s operation is automated, it implies you

This equipment is used in different industries where product packaging in different cases is a concern.

Since it is available in different designs and sizes, it makes it easy to use it in packaging different products in various sectors.

The common uses of this equipment thus include the following;

Pharmaceutical Packaging

A wide range of pharmaceutical products are packaged and sealed using a random case sealer.

Often, this machine gives a better alternative, especially when packing pharmaceutical case sealers of different dimensions.

FMCG Packaging

This equipment is quite dominant in fast-moving consumer goods (FMCG) industries, where it is used in packing numerous products.

The speedy and random packaging ability of this machine makes it ideal in this sector since they are vital concerns in ensuring products get to the market faster.

Confectionery Packaging

It is used in packing various confectionery products like biscuits, chocolates, chewing gums, lollipops, etc.

Ideally, this machine offers immense convenience in packing such items, especially due to its ability to pack different case sizes.

Food And Beverage Packaging

The common food and beverage products usually packaged using this machine include poultry products, dairy products, coffee, ice cream, water rolls, soft drinks, etc.

Personal Care And Hygiene Products Packaging

Random case sealer is commonly used in industries that manufacture a wide range of personal care and hygiene products.

For instance, facial masks, toiletries, toothpaste, diapers, cotton pads, perfumes, body lotions, and skin jelly among others.

Automotive Parts Packaging

A wide range of auto parts and components are also packaged using random case sealers due to their different sizes and shapes.

Typically, a uniform case sealer is a packaging machine which uses a fixed tape head for a specific case size on the fly.

In essence, it means that the tape head of this case sealer variant requires manual adjustment for every box with a different height.

uniform case sealing machine

Thus, it is most suitable for large-scale packaging runs using similar size cases.

You can find it in different sizes, and speeds hence guarantees a specific system that fits your particular packaging needs.

On the other hand, random case sealer has adjustable tape heads, making it suitable for packaging cases of different heights.

Essentially, it features a sensory device that allows tape head to raise or lower until it gets the ideal height.

As such, it offers great packaging solutions when packing different box sizes simultaneously.

Nonetheless, you can find uniform case sealers and random case sealing machines in both automatic and semi-automatic running formats.

random case sealer

Besides, both offer great packaging speeds hence ideal for industrial packaging where volume is a great concern.

Adjustable case sealing machine allows for a rapid manual change by setting up rugged units into same-size carton seal runs.

Ideally, it means that the design of this equipment enables it to seal various cases but of identical size at different runs.

Hence, once the seal for a particular case-size is over, you quickly adjust the machine manually for a new run.

Random case sealer, on the other hand, adjusts automatically to ensure it accurately and reliably seals different carton sizes simultaneously.

adjustable case sealer

Thus, you will hardly need to adjust the equipment for different runs since it has sensors enabling it to re-adjust accordingly based on height of the case.

A typical random case sealer features a wide range of integrated parts to deliver a fully functional unit.

However, the notable parts you should be familiar with in this machine include the following;

Belts – For transporting cases within the equipment and through the changes in direction or elevation.

Tape head – It is a transducer device that converts electrical signals into magnetic oscillations, thus help in adjusting to case height accordingly.

Metal rollers – Designed to assist in efficient movement of cases from one station to another within the equipment during sealing process.

Electric panel – It is a box holding different types of electrical components used in running the machine.

Control switches – They are used for closing and opening different control circuits in automatic and semi-automatic control systems.

Adjustable top guides – Are used for keeping the flaps squared during case sealing process.

PLC touchscreen – It displays various operating parameters of the machine during sealing for easy control and monitoring.

Tape roller – Applies the sealing tape on the case surface for secure packaging.

Photoelectric detector – This device has an inbuilt light-emitting component, which activates a light beam and detects presence or absence of cases during sealing.

Safety guard – Protects or reduces imminent injuries or damage to the operator or machine respectively.

The working principle of this machine is quite straightforward and starts with feeding random size cases with opened flaps into the equipment.

Automated arms in the machine detect the presence of the case and get the right height.

The system is activated to fold down the top flaps of the package.

Once the flaps are folded, the case moves through the tape head to allow for sealing of the flaps.

Immediately the flaps are closed, flaps are sealed, the case packages are ejected from the machine’s back end for subsequent handling operations.

The process repeats for all the cases at relatively high speeds.

Essentially, the most outstanding feature of this case sealer is its ability to seal different case sizes randomly and accurately without adjusting any settings.

However, it also exhibits a number of excellent features making it among the best considerations in the market, which include the following;

- Photo-eye sensor for case centering, which responds to cases of different heights and widths.

- Dual-extruded columns for smooth and automatic case heights adjustments

- Electromechanical height adjustment to produce application precision

- Offset taping head position for effective flexibility when sealing shorter cases

- Interchangeable taping heads to optimize production flexibility

- Electronic PLC touchscreen control panel with primary disconnect switch for easy monitoring and fast access, and convenient setting.

- Compression rollers for closing flaps before taping.

- Sliding access doors featuring electrical interlocks for disconnecting power and air to enhance operator safety.

- Servo controls for consistent power to guarantee accurate positioning and greater response time.

- Faster sealing speed of up to 30 cases per minute, depending on the design and features.

- Mild-steel powder-coated framing material

- Fully-automatic and semi-automatic running formats

Primarily, random case sealer is available in two main running formats, which include automatic and semi-automatic units.

Technically, a semi-automatic unit offers an easier and simpler way to seal cases of different sizes simultaneously.

Hence, it requires an operator to be involved in some aspects of sealing process, such as folding the top flaps of the carton.

semi-automatic random case sealer

The operator in this type of machine running format also needs to feed the case into the case sealer for the sealing process to begin.

In other words, a semi-automatic random case sealer involves assistance of human labor in some operating parameters.

Automatic random case sealer, on the other hand, hardly requires any form of human intervention in all of its operating parameters.

Automatic random case sealer

All the functions from the case feeding, rolling, sealing, and ejecting are performed automatically.

It has a PLC screen for monitoring and displaying various operational parameters and enhancing the overall efficiency.

It contains the following features

- Rugged construction featuring a welded steel frame and powder coated finish

- Randomly adjusts to handle various box sizes

- Servo controls for reliable power for positioning and immense response time

- Top flap compression rollers

- High speed of up to 15 cases per minute depending on case size

- Carriages retract for simple carton removal

- Fault detection and alarming lights

They include the following;

Hot melt closure – It involves using adhesive systems with a broad range of adhesion. Essentially, it involves applying sealable lines of adhesive to the case directly during manufacturing.

Tape closure – This closure option involves applying pressure-sensitive adhesive tape on the case surface directly from the tape roller.

More Resources:

For all your random case sealer machines, contact us now.