JOCHAMP – Your Tray Packer Machine Provider

JOCHAMP is a leading provider of semi high-speed and high-speed tray packer machines. Our company delivers innovative design, precise product control, and cutting-edge technology to provide the most efficient and effective tray packing solution to our valued customers. Our tray packer machine can perform packing for different kinds of products such as:

- Cases of Bottle

- Cases of Cans

- Cartons of Cans

- Ringed Cans

JOCHAMP Tray Packer Machine

JOCHAMP tray packer machine can able to produce tray packaging for bottles, cans, jars, and other items. From sanitary items, beverages, and food containers – our machine can process these ranges of items with excellent performance. We can also provide a durable tray packer machine with stainless steel structures.

Our company can provide a 1-lane supply, both simple and intermittent operation, non-stop system when magazine change, very accessible, and precise piece count filling tray packer machine. We have also a tray packer machine that is very suitable for realizing the type of visual-box cases that are using stretched blanks. All of our tray packer machines are very suitable for packaging rigid products such as bags with a square on the bottom, pots, cases, vacuum bags, tins, etc.

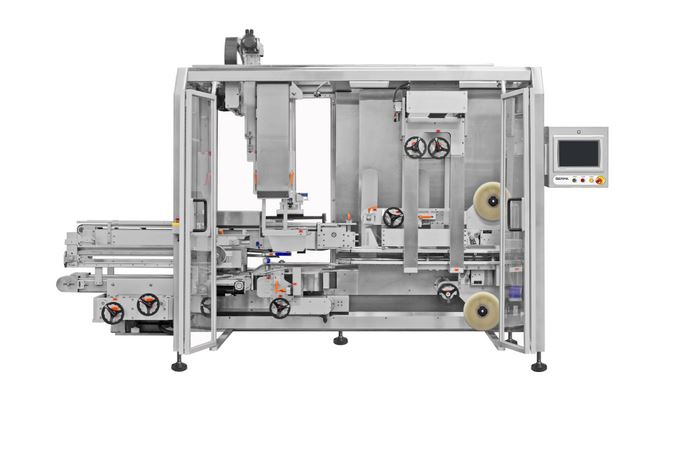

JC-501 Tray Packer Machine

This machine is suitable for packaging products with a single piece of corrugated paper. Compared with ordinary case packers, it is more compact and can accommodate a wider range of sizes.

- Use a single cardboard to wrap the box, reduce the link of box making and unpacking, and save the cost of box making and unpacking equipment

- Compared with the traditional carton, it can save about 20% of the carton area and save the cost of raw materials

- According to the customer’s packing arrangement requirements, the products are automatically arranged and combined

- Wide range of applications, can meet a variety of specifications product packing

- The use of Nordson hot melt gluer in the United States to spray glue and seal the box ensures the stability of the sealing and bonding, and reduces the downtime caused by the quality problem of the hot melt gluer.

- Control mode: PLC+touch screen+standard control button+signal switch, automatic/manual control mode

JC-501

- Technical Parameter

- Features

- Optional

| Model | JC-501 |

| Power supply | 3Phase,380V, 50/60HZ, 10KW |

| Air pressure | 0.5-0.7MP |

| Machine size | L8145*W2150*H2000mm |

| Suitable carton size | L200-500*W150-500*H100-350mm |

| Packing speed | ≤12cases/min |

| Glue solidify time | 2-3s |

| Machine weight | 2200kg |

- Use a single cardboard to wrap the box, reduce the link of box making and unpacking, and save the cost of box making and unpacking equipment

- Compared with the traditional carton, it can save about 20% of the carton area and save the cost of raw materials

- According to the customer’s packing arrangement requirements, the products are automatically arranged and combined

- Wide range of applications, can meet a variety of specifications product packing

- The use of Nordson hot melt gluer in the United States to spray glue and seal the box ensures the stability of the sealing and bonding, and reduces the downtime caused by the quality problem of the hot melt gluer.

- Control mode: PLC+touch screen+standard control button+signal switch, automatic/manual control mode

- The fault point can be found through the touch screen for easy troubleshooting

Secondary packaging line integration

Labeling Machine

printer

heavy duty casters

Leaflet Automatic Dispatcher

export conveyor line

Why JOCHAMP Tray Packer Machine

As JOCHAMP can provide a high-speed and high-technology tray packer machine, you can surely optimize your packaging production. With our tray packer machine, you can also obtain the solution for high labor costs as you don’t need a large number of manpower to perform the task of packaging.

Aside from business matters, JOCHAMP also wants to satisfy its client by providing them with a tray packer machine with quality packaging output. Our machine cannot only optimize production output but also perform good quality packaging.

We valued our clients and customers, that’s why JOCHAMP wants to secure a safe and friendly machine. All of our tray packer machines and other types of machinery are passed on all safety standards inspection. From front to an end production line, the process with our machine is more friendly.

JOCHAMP supplies a high-technology of automatic tray packer machine. Our machine comes with a high-tech and powerful control system, easy to operate the integrated control, the fault is visually displayed, and offers more extensive expansion options.

Our Dedication to Our Clients

Many of our clients open that they get some greatest advantages on making us their tray packer machine provider. Some of them commended us for our fast service, detailed instructions, and training provided them. One of the customers points up how quickly JOCHAMP responds to the minor problems they face. They quote us:” thank you for the quick response and turnaround, because of that we didn’t experience even a little downtime to our operation”.

Not only for providing tray packer machine but also the continuous service and support make JOCHAMP long-term client partnerships. Aside from the excellent engineered tray packer machine, the quality and our dedication to our clients make our company special.

How our Tray Packer Machine provides Happier Workplace?

Some of our clients is a big company that needs to cater a lot of orders of their customers. They accept the reality that to keep their increasing demands, the packaging process of their product needs to update. In able to do this, they need a good quality tray packer machine. Today they enjoy more efficient and less crowded packaging automation by using the JOCHAMP tray packer machine.

One of our clients shares with us that the implementation of the tray packer machine is very effective. They said that before they used our tray packer machine, 4 personnel need to do the job of packaging. But after using our machine, it just needs 1 person to operate the machine. He also added that the tray packer machine gives them a 50% labor savings.

Our Design can Accommodate Diverse Industries

The tray packer machine of JOCHAMP is designed to serve and cater to diverse industries. Just as our machine for carton packaging, our tray packer machine also offers the same balcony design that offers full walk-in access. These are some features of our tray packing machinery comprehend:

- Precision in Each Application

- Innovative technology

- Balcony Design

- Semi-Automatic & Automatic Options

Choose JOCHAMP for Your Tray Packer Machine

JOCHAMP tray packer machine machinery is designed for easy use, easy to maintain, and easy to adjust. Our machine is also known for friendly-operator features and comes with a touch screen control that makes the operator experience good enhancement to the machine. Our tray packer machine also provides a tool-free standard changeover, this feature provides time-saving and effort on the part of the operators.

Some production companies deal with the problem of using manual assembling of boxes. In the times that more orders coming frequently and constantly, they are surely not able to catch up with the exact demand of orders. That’s why, in able not to experience a bottleneck in the production processes, using a tray packer machine is very ideal for every production company.

JOCHAMP Tray Packer Machine

JOCHAMP company has been serving decades in the beverage industry. We supply a non-stop automation packaging system to the beer and soda makers. If you produced your products by artisanal means, we’ll be ready to experience mass production by using our tray packer machines for brewers. Our tray packer machines will surely allow you to produce maximum output that will also surely receive by your more customers.

Our tray packer machine is designed to cater the best option for brewers’ companies that need improvement and upgrades to their packaging process. JOCHAMP, as a tray packer machine manufacturer, understands the needs of every beverage packing industry. That’s is the reason we built some affordable, reliable, and efficient packer machine-to maximize your production processes.

We do not only design our machines to become the best tray packer machines on the market, but also to provide efficiency and safety for some users and operators. All of our tray packer machines are built with high-quality, easy-to-use controls, and emergency systems.

Our tray packer machines are designed with JOCHAMP that provide easy access control systems. Some of the doors of our tray packers are guarded by anti-intrusion switches, which when opened unwantedly – the machines stop automatically. There are also some emergency stop stations on every side of our machine to secure quick access when an accident happens.

Custom Tray Packer Machine for Your Business

For JOCHAMP, tray packers simplify everything. Our tray packers have now developed on a high and new level of technology. in 15 years of material, product, and machine experience, we are now evolving into simple next-level performance, simple operation, and simple maintenance. This horizontal load tray packers’ machine of JOCHAMP can perform a maximum of 40 cases per minute.

We all know that maximum production comes with machine capacity to provide leading speed on production. JOCHAMP tray packers can extremely meet the most demanding speed of production with quality results. With our tray packer machine, you can blend a perfect combination of design and technology to obtain excellent performance for every tray packing application.

JOCHAMP top loading and product collation technologies will ensure great optimal product, packaging, and machinery interaction that will surely provide the most effective tray packers on every client and user application. Our top-load tray packer machine can cater up to 25 trays per minute.

We can guarantee you to experience a great production line process with our top-load tray packers known as the most flexible and adaptable load tray packer system machine on JOCHAMP. Be ready to maximize your packaging by choosing JOCHAMP as your top load tray packer machine provider.

If top loading is not your suitable option for tray packaging production, maybe the smooth tray loading, pre-load product collation, and the use of bottom load tray packers is the great option for your alternative automation tray production process.

This type of tray packer machine can finish 15-20 trays per minute and very ideal for some heavy products such as bottles, jugs, tubs, and others. This JOCHAMP machine can provide gentle handling and alternatives to drop packers.

Related Product

Tray Packer Machine: The Ultimate Guide

Choosing tray packer machine can be overwhelming task without the right information. A reason this guide explores all vital information including features, working principle, and design among other critical elements. If you want to be an expert in tray packing machines, read this guide.

A Tray Packer is a device that assists in packaging products into trays. It erects trays by utilizing an interchanging feeder and a series of tugs.

The product is then gathered into the desired arrangement and loaded into the erected tray through the sides.

tray packer machine

After the tray is fully loaded, the flaps are closed, and the tray is sealed. Sealing can either be done using the glue method or the tuck method.

There are numerous configurations of the tray packer machine. The tray packing machine varies with the type of machine as well as the size or capacity of the devices.

Different configurations determine the speed of the tray packer machine.

Some configurations for the Tray packer machine include; 2×2, 3×2, 4×3, and 6×4, which are some of the most commonly used arrangements.

However, the tray packer machine can be customized to suit your unique needs.

The tray packer machine has varying specifications from one manufacturer to another.

They could also be different depending on the type and capacity of the tray packer machine.

Some of the general specifications of the Tray packer machine include;

- The device is made of stainless steel.

- Configuration can be done to meet different speeds.

- It has an open tray capacity to allow for different tray sizes.

- The tray packer machine has a variety of control options.

- Customization can be done to address any specific requirements.

- Pneumatic control system

- Varying speeds of as low as 5 to as high as 100 trays per minute.

These features vary according to the type and capacity of the Tray Packer Machine.

Some of the components may be included by other manufacturers, while others may be omitted.

These features can also be customized according to the user’s specifications. They include.

- The tray packing machine has a small footprint.

- It is user-friendly and, therefore, easy to use.

- Changeover is simplified as it is tool-free.

- It only requires simple set-up adjustments.

- The tray packer machine typically has a steel frame.

- Hot glue system

- Empty tray alarm system

A Tray Packer is a device that assists in packaging products into trays. It erects trays by utilizing an interchanging feeder and a series of tugs.

The product is then gathered into the desired arrangement and loaded into the erected tray through the sides.

case packer

After the tray is fully loaded, the flaps are closed, and the tray is sealed. Sealing can either be done using the glue method or the tuck method.

The case packer is an automated packaging machine that utilizes both trays and cases.

The products can either be loaded from the side, from the top or the bottom. After loading the products, the machine closes the flaps and seals the cases.

tray packer

Some top advantages of the tray packer machine include:

- Low labour cost; the Tray Packer Machine reduces the personnel required during the packaging process.

The machine handles the majority of the packaging work. Therefore, fewer workers are needed.

- Reduced packaging materials. Since the machine carries out the packaging, there is a lesser error probability.

There will be a significant reduction in the number of damaged trays during the packaging process compared to manual packaging.

- Decrease in the cost of production; using the tray packer saves on time and resources. This, in turn, reduces production costs that would have otherwise been incurred.

- Customization; the tray packer machine can be easily customized to suit your unique needs and designs.

- Versatility; The tray packer machine can handle various products and packages in different tray designs.

The device can also be configured to increase packaging speeds. This provides for room to grow your operations without needing to make a new purchase.

- Increases the efficiency of the production process; the tray packer helps streamline the production process by bearing the bulk of the packaging process.

Incorporating a tray packer machine in your production line will be held increase the efficiency of your production.

- Increase in output. Using the tray packer machines helps increase your overall packaging output.

There are various tray packer machines to address the diverse packaging needs.

These machines mainly vary depending on the type of product you want, and the packaging speed required.

The different kinds of tray packers include;

Wrap Around Tray Packer

The wrap-around tray packer machine is a versatile machine that can be used to package various products, including cans, bottles, trays, e.t.c, onto cases that wrap around the product.

wrap around tray packer

The machines are user-friendly and are also easy to maintain. The operation cost of the wrap-around is also limited, making it a cost-effective method.

Horizontal Tray Packers.

These are end-of-the-line packaging machines. They are automated tray packing machines that load the products through the sides.

horizontal tray packer

As they are mainly automated, it offers a simple and low maintenance cost.

There are different types of horizontal tray packers. They are;

Intermittent Motion Packers

Intermittent motion packers are utilized in products that require a multi-step packaging process or when different speeds or designs are required for other products.

intermittent motion packer

Continuous Motion Packers

Continuous motion packers are incredibly efficient with varying packaging speeds. The products are packaged by machine with minimal alterations to the packaging process.

continouous motion packer

Vertical Tray Packer

Vertical tray packers can be used to pack various products, including flexible and rigid products.

This type of configuration allows for customization to meet your packaging needs effectively.

verticle tray packer

The vertical packers come in different layouts to better address other needs.

Bottom Load Tray Packers

This machine is used as an alternative to products that the top load packers cannot pack.

Fragile and heavy products mainly utilize this method as they are likely to sustain damage when packed using the drop method employed in the top load packer.

bottom load tray packer

The tray packer machine has built-in features that make it more sustainable. These features include;

- Fewer wear parts. The tray packer machine is incorporated with fewer parts that are high wear. This helps reduce the cost of purchasing spare parts as fewer parts will need replacing.

- Cutting-edge technology. The use of high-grade servo technology reduces interference during the packaging process.

Minimal interference ensures reliable operations for a longer time.

- Reduced material consumption. The high-precision systems minimize the use of materials such as glue and packaging materials. The system ensures that any misuse is minimized.

The tray packer machine is cost-effective as it efficiently utilizes the raw packaging materials. It helps save not only on the cost of production but also on maintenance.

It has fewer worn parts, requires fewer spare parts and a more straightforward maintenance routine.

The tray packer machines have varying adjustable speeds, which takes into consideration future expansion.

It also saves time by packaging a high number of the tray, for example, one hundred trays per minute.

Several factors should be taken when choosing a Tray Packer Machine.

- Purchasing cost of the machine; different types of Tray Packer machines have additional purchasing costs.

The lower the output, the lower the purchasing price. Customizing the tray packer might also impact the pricing depending on the manufacturer.

- Safety of the Tray packer machine; it is essential to consider the machine’s safety features.

The security of the operators should also be taken into consideration. User-friendly surfaces are preferable as they boost the safety of the machine.

- Size of the items that are to be packaged; The size of the items should be taken into consideration as they determine the size of the tray.

- Production capacity of the Tray packer machine; The Tray packer machine should be able to keep up with your scale of production.

Larger scales of production require cartooning devices with faster speeds.

- Types of products being packaged; Different products have different needs and, as such, may require additional equipment in order to properly preserve the products.

- Machine spare parts; You should take into consideration the machine’s change parts.

You should pick a Tray packer machine that requires changing a few elements in order to adjust tray sizes.

- Setting up area; It is vital to consider the space you have available for installing your machine.

- Selecting Mechanism; the equipment used to pick up the product should be compatible with that type of product.

- Speed; the Tray Packer machine you select should be able to handle your current desired product output and allow room for future expansion as well.

- Personnel training; The type of machine you select will determine the extent of training and teaching required.

The more advance the device, the more intensive the training will be.

The Tray packer machine is a versatile machine that can be used to package different types of products. These products can be classified under the following categories;

- grain and Spice.

- Fruits and vegetables.

- Clothing and textiles.

- Electronics.

- Food and beverages.

- Pharmaceuticals and cosmetics.

- Chemical.

- Tobacco.

- Sports equipment.

- Toys.

There are several safety standards in place to ensure the safety of the users of the packaging machine. Some measures are general, while others target specific sectors.

Some of the safety standards for the Tray packer machine include;

BS EN 415-10:2014; this safety standard covers safety specifications and verification commissioning, operation, cleaning, design, construction, installation, adjustment and maintenance of the tray packaging machines.

EN ISO 12100:2010; this safety standard covers the general requirements for the design. This includes the terminology, the principles and the methodology utilized.

ANSI/PMMI B155.1-2016 this safety standard covers rebuilt, altered or entirely new systems.

ISO/TC 313; this safety standard covers in-depth the standardization of the packaging machines.

There are several systems that can be integrated with the tray packer machine in order to achieve better results and to further automate your production process.

These systems include;

- Inspection systems; it is essential to incorporate a secondary inspection system in addition to the inbuilt system.

This helps eradicate any errors that might have bypassed the original inspection system of the tray packing machine.

- Lane diverters; lane diverters are helpful when handling large quantities of products. It could also assist when packaging different types of products.

It helps with organizing and diverting products to their required lanes.

- Weighing system. It is essential to incorporate a weigh scale into your tray packing machine. The weighing system ensures that the products are all similar, thereby reducing or spotting errors that may have occurred during the packaging process.

- Infeed conveyor system; the infeed conveyor system helps to automatically load the products into the trays for packaging.

This removes the need for human labour, saving on labour costs and minimizing human error.

- Product orientation system; the product orientation system is especially useful in fragile and perishable goods that require proper handling.

This system ensures that the products are correctly positioned in order to avoid damaging the product.

- Stretch wrapping system; the wrapping system helps with securing the products to the tray while adding an additional layer of protection.

- Palletizing system; Adding a palletizing system helps with fully automating the packaging process.

Which helps in cutting production costs and money.

- Pallet Conveying system; Pallet conveyor assists with transporting the sealed pallets to the next stage in the production system.

It is essential to properly maintain your Tray Packer Processing machine.

It lengthens the lifespan of your cartooning device and ensures that all the operations run smoothly without interference from constant breakdowns.

The most crucial step is to set a routine maintenance schedule. The maintenance routine’s depends on the machine’s scale and frequency of use.

Machines that are constantly being utilized should be checked on more regularly than machines that are used once in a while.

During the routine maintenance schedule, you should conduct the following activities;

- You ought to inspect parts that are most likely to wear and the level of the lubricant.

- Thoroughly clean the machine to ensure that every part of the machine has no waste or debris that might lead to the malfunction of your tray packer machine.

- Maintenance of the tray packer involves installing software updates.

The machine is partially automated and, as such, requires regular updates to ensure operations run smoothly.

- You should change the highly wearable parts before they get too damaged.

- It is essential to keep track of the machine’s energy consumption levels. A spike or a drop in the tray packer could signal a potential problem.

- Conducting visual inspection to affirm that the machine is visibly in good physical condition

- You should do basic cleaning of the machine to prevent the build-up of dust and other dirt particles, which may slow down the productivity of the device.

You May Be Interested In:

For all your tray packer machines, contact us now.