Pick and Place Case Packer Supplier

Jochamp offers a complete automated pick and place case packer solution for your case packaging requirements. The machine is a combination of a case erector and a pick and place mechanism. It can be customized to meet your specific needs.

- CE, SGS, and ISO9001-certified

- PLC and touch screen-controlled

- Basic and intuitive user interface

- Suitable for all types of products

JOCHAMP Pick and Place Case Packer

Jochamp pick and place case packer systems can produce a variety of pack patterns. It features tight-packed construction which boosts efficiency and output. It’s designed to consolidate three processes into a single, efficient work cell. Case erecting, hand pack stations, and tape and/or case sealing are the three options.

The ergonomically-designed pick and pack equipment’s automatic indexing system places the cases in a specific area. This can help to relieve any operator discomfort. It is also simple to use. It also features easily adjustable load stations, quick size changeover, and versatile system configurations.

Our series of pick and place case packers enables careful packaging of fragile products. JOCHAMP offers complete automated, turn-key solutions for your pick and place case packaging requirements.

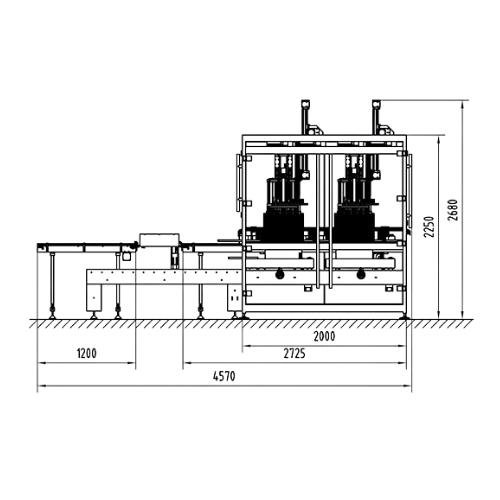

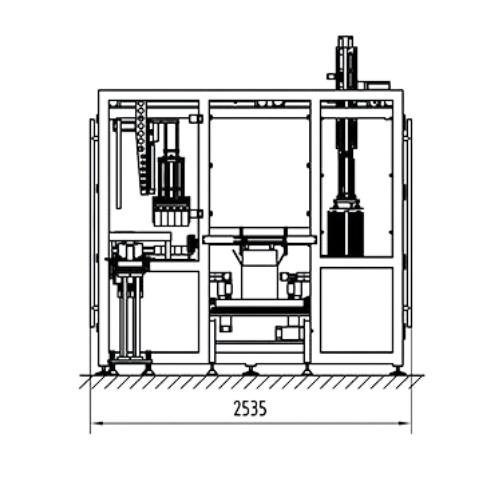

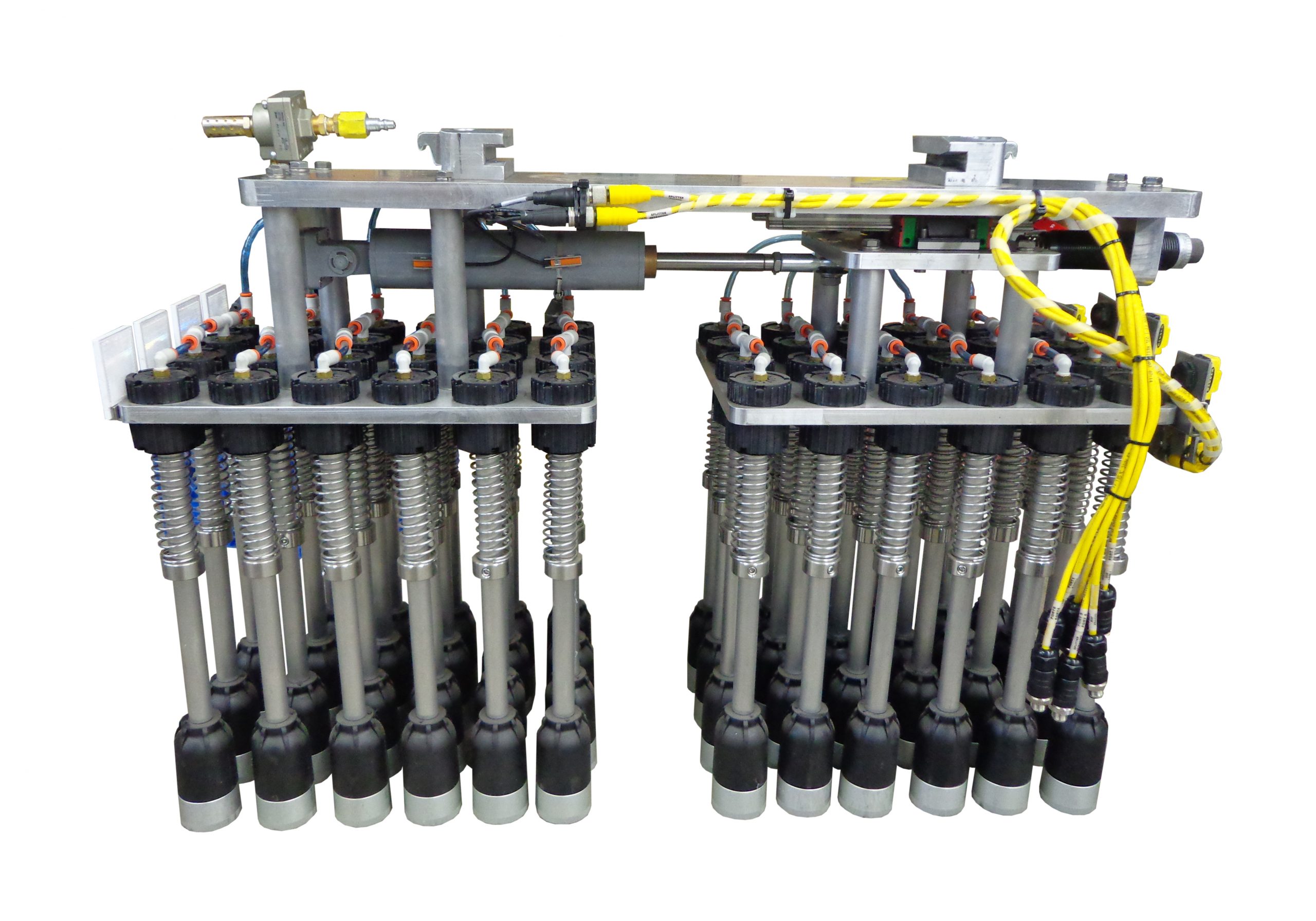

JC-502 Double Station Pick and Place Case Packer

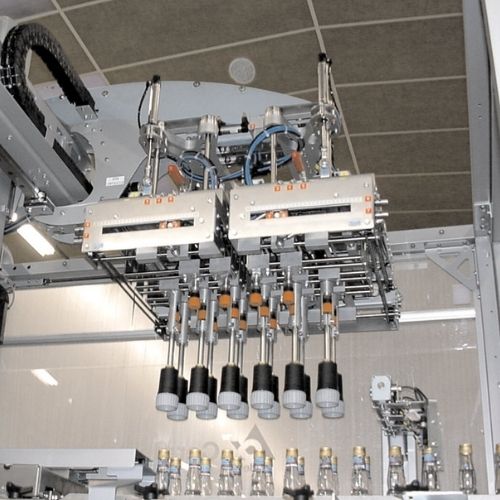

Double-station case packing machine, double-station packing and cardboard feeding, the whole machine adopts 8 servo motors to realize control, the stable speed is 10 boxes per minute, the mechanical gripper adopts suction cup and clamp, suitable for glass bottles, infusion bottles, Bare bottle, foam tray. It is suitable for grasping heavy objects or objects of the opposite sex.

- Double station, double speed

- Paper partition delivery mechanism

- 8 servo motors, PLC control system, HMI

- Stainless steel body, easy to clean and corrosion resistant

- Open design with no hidden corners

- Modular gripper design for easy exchange

- Tool-less adjustment, quick product changeover, and easy maintenance

- stand-alone console

JC-502

- Technical Parameter

- Features

- Optional

| production capacity | Less than 600 (boxes/hour) | |

| Robotic grasping production capacity | 12 for each manipulator (times/min) | |

| Sealing method | Tape sealing or hot melt sealing | |

| carton size | minimum | 300*250*200mm |

| maximum value | 600*500*500mm | |

| power supply | Power supply: AC380/50Hz Power consumption: 7.5kw | |

| Gas source | Pressure: 0.6MPa Air consumption: less than 1 cubic meter/hour | |

| Dimensions (L*W*H) | 4000*2200*2900mm | |

| weight | 3000 (kg) | |

| main material | Aluminum alloy, 304 stainless steel | |

- Double station, double speed

- Paper partition delivery mechanism

- 8 servo motors, PLC control system, HMI

- Stainless steel body, easy to clean and corrosion resistant

- Open design with no hidden corners

- Modular gripper design for easy exchange

- Tool-less adjustment, quick product changeover, and easy maintenance

- stand-alone console

- Easy integration in packaging lines

- Comply with GMP requirements, passed CE, IOS9001 certification

case erector

carton sealer

Secondary packaging line integration

carton sleeve inner bag

Labeling Machine

printer

Glue sealing machine

Stainless steel

heavy duty casters

Leaflet Automatic Dispatcher

export conveyor line

Jochamp Pick and Place Case Packer Advantage

The pick and place case packer has user-friendly Operator Interface capability. The stored recipes allow easy to use interface and easy switching of packing patterns. Increases productivity and efficiency.

Jochamp’s pick and place case packer adjusts or replace the container gripper assembly. It slide the product guide rails to accept the new containers and select new one on control panel.

Jochamp pick and place case packer offers a lot of versatility. It is due to its variable speed product in feed and on-demand case presentation. Can be integrated with 1-4 operator stations.

The containers are gently lowered to the case’s bottom, rather than being dropped. For exact container placement without label damage or scuffing, the pick and place process is servo-driven.

Pick and Place Case Packer Handling Capacities

JOCHAMP is capable of handling a wide range of items, including semi-solid products, flexible bags, shrink-wrapped packages, chipboard cartons, and more. It can handle any other package that requires unique handling, exact layer placement, and orientation.

These compact case packer are great for top loading numerous layers of product into corrugated cases. They can handle a variety of case sizes and pack patterns. This packaging technology will boost your output. At the same time, it cuts labor expenditures when compared to manual case packing.

Pick and Place Case Packer System Highlights

JOCHAMP pick and place case packer is highly recognized in the market for its unparalleled attributes. These includes:

- Capability of each pick of packing two cases

- Compact design (requires the least amount of floor area)

- Product collation and case packing in one step

- Fast product changeovers (capable of handling various product sizes)

- Easy setup and troubleshooting (use PLC and a touch screen HMI)

- Complete security with safety interlocks and hinged doors

- Guarded case packing room for safety

- Use SS304 or a food-grade vacuum sucker for product contact

- Accommodating various packing patterns

Pick and Place Case Packer to Start Your Project

JOCHAMP pick and place case packer is the ideal solution for both partitioned and partition-less case packing. It has field-proven reliability.

Our experienced, innovation, and technology allow us to provide a bespoke solution for your next project. We can satisfy your layout, speed or performance, and king of packaging requirements. Whether your owner of food business, beverage, cosmetics, plastic, or electronics, we can provide solutions for you.

- The unit has included a number of useful features:

- Stainless steel tubular frame ensures durability

- Walk-by maintenance is simple with see-through safety guarding.

- Excellent Fit and Finish

- Versatile handling ability

- Intelligent Control for precise positioning

- High Reliability – Designed to work around the clock.

- Simple Operation — Simple to operate.

Why JOCHAMP Pick and Place Case Packer is Trusted by Thousand Customers

Jochamp specializes in research, development, and manufacturing pick and place case packer. For over 15 years in the field, we supplies automated packaging solutions. Among our customers are part of pharmaceutical, food and beverage, personal care, dairy, paper, and plastics.

Owning over 3,000 square meter workshops, we produce state-of-the-art packaging machinery. We have 15+ mechanical engineers and 20+ after-sales service teams. With a strong workforce, we can provide a one-stop automated pick and place case packer solution.

Other advantage include:

- More than 50 technical patents

- Free sample test on every machine

- One-year quality assurance

- After-sales and training support

JOCHAMP Pick and Place Case Packer

Our pick and place case packer machinery is designed and built for the following uses:

- Boxes

- Cans

- Jugs

- Pails

- Bottles

- Jars

- Cartons (including gable-top)

It is also ideal for different types of containers, including plastic containers, spray containers, containers with bails and handles, pump-top containers, rigid containers, glass containers, and more.

If your pick and place case packer requires particular handling or orientation, JOCHAMP can customize or upgrades the system for you. The optional equipment involves:

- Stainless steel structure machine

- No-Tool quick changeover

- Multi-lance product diverter

- Line tracking and iRVision

- More robot stations for higher rates

- Below bottle detection

- Flexible conveyor system

- Case sealers that automatically seal the cases

- Non-round containers are classified as “D” series

OEM Pick and Place Case Packer for Your Industrial Project

JOCHAMP’s pick and place case packaging machines are ideal for the paper industry. It can pack and unpack up to 30 cases per minute depending on the application. Gripper, vacuum tooling, and optional bladder are some of its features.

JOCHAMP pick and place case packer is a good technology for packaging plastic goods. It may be for personal care, household goods, and more. We specialize in providing packaging that requires unique orientation and/or precise positioning.

The pick and place case packer allows for high-speed, sanitary packing of dairy products. Through reduction and elimination places where germs can grow. We are serving largest egg and dairy processors.

JOCHAMP has worked on various pharmaceutical packaging projects. It includes single-dose and blister packs, tablet bottles, and many more. We also create specialized case packaging solutions that adhere to tight norms and specifications.

Jochamp offers pick and place case packer system are ideal for low- and medium-speed beverage packaging. Our case packaging solution has container handling expertise in any size or shape. Also feature modular packing heads allow for quick changeovers.

Related Product

Pick And Place Case Packer: The Ultimate Guide

In this guide, you will find all information you are looking for about pick and place case packer.

From features, parts, benefits, applications to working principle; you will find everything you need about pick and place case packer here.

Keep reading.

Pick and place case packer

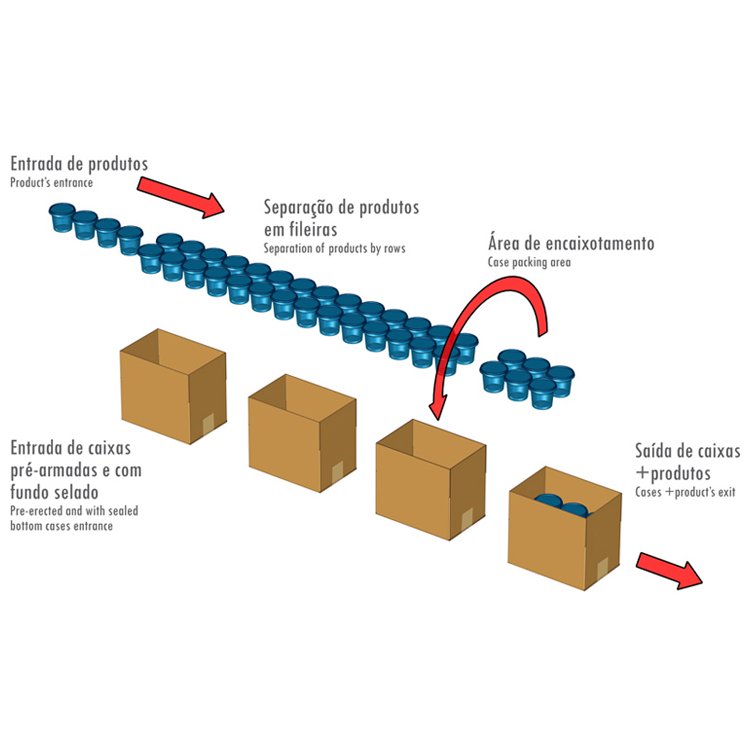

This is an automatic machine that aids in setting up a case or tray and picks and loads different kinds of products.

The products can be packed from the side or the bottom or the top.

After packing the product, the machine seals the case or tray through a tape or glue.

Case packing

There are various applications for the pick and place case packer and some of them are described below.

Beverage industry – In this industry, the pick and place mechanical case packer is a requirement.

The beverages include coffee, tea, and many others.

It is used for packing the beverages into trays or carton boxes or any other containers as desired.

Food industry – various food products in the food industry require the services of a pick and place case packer.

Food products like pizza and other processed foods are packed into carton boxes or trays before being distributed into the market.

Another set of food products that are packed through this machine include rice, snacks like biscuits, dried foods among others.

Chemical industry – chemicals and other products within this industry need packing through the pick and placed packer before shipment.

The process of packing these products ensure their integrity to avoid things like spillage and other damages.

Pharmaceutical industry – the various pharmaceutical products must be packed into cartons or other containers for ease in distribution.

Some of these products maybe in the form of liquid, tablets or capsules.

Some equipment or apparatus are also packed into boxes before shipment.

Cosmetics industry – some of the products here may include but not limited to hair, facial and body products.

Packing these products into the appropriate containers in the right quantities require the services of a pick and place case packer.

Consumer products industry – in this industry, the pick and place case packer can be used to pack items into boxes or trays or any other containers.

Such items may include candy and confectionary among others.

Cereals and seeds – there are several and seeds types that can be packed through the pick and place packer.

Some of these products include Cereals, Alfalfa, Silage, Sorghum seeds, Sunflower seeds, Maize seeds and Soybeans.

Forestry – some of the products in this industry include Wood chips, Sawdust, Wood shavings, Bark, Compost, Mulch, Peat moss and Soil

There is need for the use of a pick and place packer.

Minerals and aggregates – products like Cement, Clay, Sandstone, Gravel, Sand, Talc can be packed into boxes or trays.

This is done through the pick and place case packer machine.

Animal feed – some of the products here include Ingredients, additives and supplements for Bird seed, Animal feed and Fish food

They can also be packed into boxes or other containers through pick and place case packer.

The pick and place case packer is made up of simple and easy to operate components as described below.

Picking system for case packer

The empty cases dispenser – just as the name suggests, it avails the empty cases to the section that erects the cartons.

The machine is equipped with the system that picks the cases and dispenses them to the box erector automatically.

Box erector – the box erector is capable of making boxes or cartons into the right shapes and sizes through an automated system.

The box erector also ensures that the bottom of the box is sealed before being conveyed to the packing station.

The loading roller conveyer – the conveyer rolls the already formed case to the loading station and ensure it placed at the center.

The roller conveyer also transfers the already loaded or packed case to the sealing section.

It is important that the conveyer keeps the case safe and undamaged during the transfer from one station to another.

Pick and place system – the product is picked and placed into the case properly leaving no spaces until it is full.

Processes of picking, placing and flapping of the case wings are automatically controlled.

The case closing system – once the pick and place process is over, the roller conveyer again transfers the packed case to the sealing station.

The sealing is done through the use of a tape or a hot melt or a combination of the two.

Pick and place case packer system

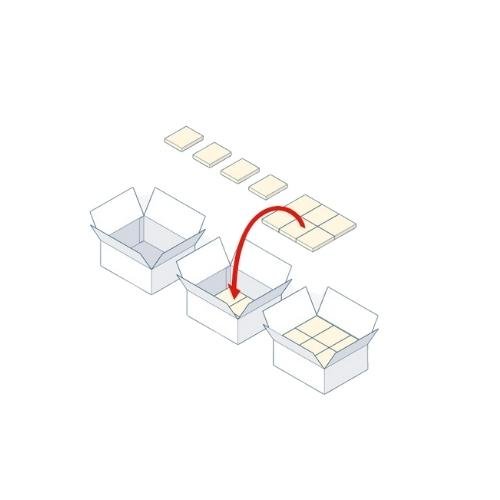

The pick and place case packer has a simple working principle as described below.

Dispenser delivers the cardboard to box erector station through an automatic system.

The box erector creates the case into the specified size and shape through an automated process.

After carton creation, it is sealed at the bottom and moved by the automated conveyer to the next station.

At the pick and place station, the roller conveyer places the case at the center for the packing process to take place.

The filling of the box is done through an automated system and the products are picked and placed in to the case.

This process ensures that each product is placed properly into the case with no spaces left.

At this stage, the case is packed and needs to be sealed; the roller conveyer again transfers the case to the sealing section.

Sealing of the case is again an automated process and is done using either a tape or a hot melt.

For a perfect seal for delicate or heavy weight products, the two sealing methods can be used together.

The process of ejecting the packed case from the machine is also automatic once the packing process is complete.

Pick and place case packaging system

Some of the main features include

· Accurate Picking And Placing Mechanism

It employs a system that can minimize the impact produced by the product to be packed into the cases.

It means the grabbing head and the product to be picked are aligned accurately to avoid mistakes.

Due to the accuracy of the machine, the products have a 100% picking rate and this contributes to its efficiency.

Once items have been picked, the system eliminates any pressure built up to avoid falling of the already picked up products.

· Standards Linear Positioning System

The manufacturers of this pick and place case packer employs a standard linear positioning system.

This is basically preferred because it offers high accuracy during movement and positioning.

The system is able to produce accurate results and therefore can reduce vibrations and any kind of impact when in use.

Reliability and stability offered through the system offers easier cleaning and maintenance procedures.

· Pneumatic System For Accuracy

The pick and place processes are made automatic and accurate through the use of specific pneumatic parts.

The whole process employs an automated system coupled with pneumatic and electrical controls that results into reliability and accuracy.

· Variable Frequency Motor

Stable operation is made possible by the presence of a variable frequency motor making the operation automatic.

Automation of the machine is attained through combining electric, optical and pneumatic techniques.

The three techniques employed in this system are well coordinated and they can run accurately and smoothly.

In addition to these:

Several other functions like control panel system through a monitor interface.

It is possible to switch off the machine in situations of failure like when the case is not filled up.

Another situation is when the items needed to be packed are not filled up with required products plus many other reasons.

Pick and place system

Below are some of the factors to consider when choosing pick and place case packer machine for your operations.

Type Of Case To Be Used

Some of the case types that can be used include; top load regular slotted container, side load or wrap round.

It is important to go for the kind of case packer that supports the kind of case chosen for your product.

Primary Product

There are products that are packaged into delicate container like glasses in the case of wines or spirits.

The choice of case packer machine should be able to handle this product with high accuracy to ensure there is not damage.

Line Speeds

The speed of the upstream filling process is very important because it will determine the system output.

Speed that is too high is not recommended because it can lead to unnecessarily high costs.

Machine Loads

When selecting a pick and place case packer machine, make sure to see a similar one in operation and be keen on the product weight.

Check on the production rate of the machine under the specific load weight of the product.

Floor Space Available

The layout of the machine in question should be able to fit in withing the operation area within the floor.

Some case packer machines are very large and may occupy large spaces interfering with other operations.

Changing Over And Flexibility

Choose a machine that offers high flexibility when it comes to changing over also putting into consideration the cost involved.

There are various benefits that can be gained through the use of an automated pick and place packing machine.

Some of the benefits are described below.

- The pick and place case packer machine has the advantage of simplicity and ease of use to the operator.

- The machine is very simple and is made up of a few components hence ease of learning and operation.

- Since the whole process is automatic, the company does not incur labor cost cutting on the overall cost.

- The pick and place case packer machine is also built in a manner that enables easy cleaning and maintenance processes.

- Changing over process is very fast and smooth and does not need the use of any tools.

- Normally, the whole process is easy to monitor and operate since it comes with an intuitive and very simple operator interface.

- Sealing process is incorporated into the system making the product ready when it gets out of the machine.

- The compact dimension of the system enables ease of operation to the user, not requiring a lot of training.

Depending on your unique requirements and specifications, we have a range of pick and place packers for unique requirements of your applications – contact us now.