Tray Forming Machine Manufacturer in China

JOCHAMP is a professional manufacturer of tray forming machines that can form a wide variety of tray-style including trays with lids, slotted trays, and other custom configurations. Our tray forming machine can work at a high speed with the use of a strong glue system.

- Available in manual, semi-automatic, and fully automatic

- Offers customized capacity, types, and tray molds

- Can erects trays consistently and quickly

- Provides lifetime durability

JOCHAMP Tray Forming Machine

As a manufacturer, JOCHAMP is always ensured to give high-quality tray forming machine that provides quick and easy fine-tuning, unlimited flexibility, reduced downtown and shorter changeover, and many more as you needed. It can enable us to react flexibly and smartly to the current market trends and needs. Our tray forming machine is designed to create a wide of products all over the world.

JOCHAMP tray forming machines can make conical trays, carton board trays, and other home foods containers. Also, our tray forming machine is widely used in the production industry that can offer easy, efficient, and provides very good price-performance ratios.

Moreover, this tray-forming machine from JOCHAMP can help to increase your production without increasing labor costs for your business. Our tray forming machines can form package trays faster and more consistently and can help you to boost efficiency for the end of line process.

Send us your inquiry!

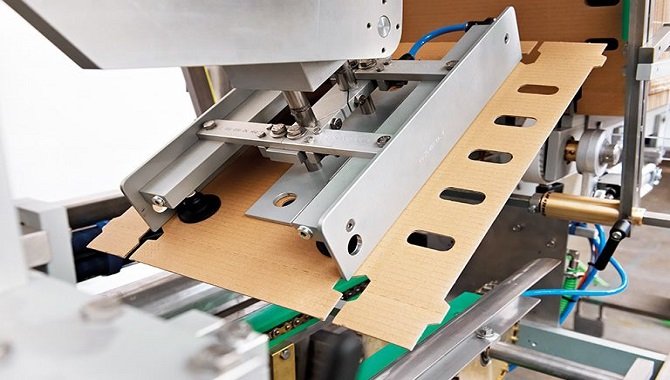

JCK-25P Tray Erecting Machine

The main function of this machine is to automatically put cardboard, and automatically fold the carton, form, spray glue, and glue the supporting equipment. By modifying the structure, it can be applied to more structured trays.

- Using servo, the operation is more stable and the speed is faster;

- This automatic box folding machine has casters and foot cups, which are easy to move and move;

- This model adopts servo reclaiming, motor lifting and lowering rack, stable and reliable operation;

- Simple operation, using PLC and man-machine interface, easy to use;

- It is suitable for folding box forming of most e-commerce product cartons;

JCK-25P

- Technical Parameter

| Machine Model | JCK-25P | Remarks |

| Folding box speed | 15-25pcs/min | according to box size |

| Applicable size | L260-300*W150-250*H40-70mm | Forming size, non-standard customization |

| Power supply | 220V 50Hz | optional 380V |

| Air supply | 700NL/min、0.6-0.8Mpa | |

| Table height | 800±50mm | can be customized upon request |

| Machine size | L2350×W1100×H1500mm | Non-standard customization is subject to actual |

JOCHAMP Tray Forming Machine Advantages

Our tray forming machine has a double folded length to add stability and sealing surface. It is operated by a drying system, and forming process, to give you a unique result with high performance.

As a provider of tray forming machines, we give you the best result to increase productivity. Our tray forming machines can make 30 to 50 trays per minute and 1000 every hour.

We provide high accuracy in designing our tray forming machines along with great productivity. JOCHAMP has a lot of professional staff and engineers to machines for your business.

Our tray forming machine can help you with the large production of trays and offers you very affordable price features. This machine also provides low maintenance and is very easy to use for your needs.

What is Tray Forming Machines?

Tray forming machines are a form of a wide variety of tray styles. It can help with a wide variety of productions process. It ensures to make stable loads with straight sides and is applied with glue for a consistent product. It can ensure reliable results and increased productivity.

Our tray forming machines is perfect solutions for forming and gluing dye-cut trays. These tray-forming machines are built with pride, care, and in-depth details. These tray forming machines are applicable to various tray styles including 5-stuck display trays, 2-struct trays, tray with lid 2-stuck, swing-lock 2-stuck, octagon 4-stuck, and tapered 2-stuck.

In addition, tray forming machines have a latter designed to handle two parallel trays and more. These machines are very helpful for production facilities and businesses. It can help to make you the different sizes of trays, colors, design, quality, and more.

Send us your inquiry

How JOCHAMP Tray Forming Machines Works

The tray forming machine from JOCHAMP can work in a step-by-step process to meet the durable and standard trays that are used for different industries. It always begins with the magazine that is full of die-cut tray blanks. After that, the tray blanks are pulled or pushed through the tray forming machine individually by using vacuum cups and are formed with a mandrel.

All side of our tray forming machines helps to keep the tray’s edge in place and the hot melt glue is applied to the flaps while the blacks move through the tray creating machines. Our tray forming machine the glue sets, molds the tray, and the newly formed tray is moved along to the conveyors to the next step of production lines.

Furthermore, our tray forming machines has horizontal and vertical tray formers that can handle different sizes and lock or sealing mechanisms. In addition to hot melt glue, you can choose self-locking or automatic trays in which tabs are folded and inserted into slots to holds the size of the trays in place. Overall results from tray forming machines can make the same effects the perfect form and the sealed trays.

The Benefits of Tray Forming Machines

We manufactured tray forming machines that can easily integrate into existing production lines. It combines case erectors, case labelers, case packers, and other end-of-line equipment to create custom packaging lines for different products. With the help of our tray forming machines, you can easy to change over when it’s time to switch. The changeover process in our tray forming machines can quickly tray size and blanks for productions in just seconds with some models. JOCHAMP tray forming machines has heavy-duty features and are designed to work around the clock to help you with your business.

Our tray forming machine can perform for up to 40 trays per minute depending on the model. It compelling way to improve efficiency without sacrificing floor space. The tray forming machine can help to reduce labor costs, free up your team from forming trays by hands, is designed to consume less power, and is operator friendly. This tray forming machines are built using high-quality materials and construction to ensure their durability will last. It uses precise servo motion controls for accurate, steady formation and placements in creating packaging solutions.

JOCHAMP – As Your Trusted Tray Forming Machine Supplier in China

JOCHAMP is a trusted supplier of tray forming machines which is the ideal equipment to produce boxes including hamburger boxes, cheese boxes, fried chicken boxes, food pail boxes, and much more containers that are made of corrugated, cardboards, etc that are suitable for food industry needs. Our tray forming machines can easily make trays and can save costs for your business.

Our tray forming machines can give you different features from firm structures, low noise, high quality, durability, and high efficiency. It has a paper feeding unit, glue unit, adjustable unit, forming unit, counting unit, and finished products collecting units.

However, if you want your business to run smoother and you want to create a tray quickly, our tray forming machines is your ideal choice and can offer you an affordable price. It very good investment for different industry applications.

Don’t hesitate to contact us now!

JOCHAMP Tray Forming Machine

We manufactured tray forming that has widely used for different industrial applications. It helps to work with chipboards, corrugated and other materials to create a tray for variety of industries consider the following below:

- Foods

- Beverages

- Home goods

- Electronics

- Agriculture and more.

Our tray forming machines are automatic that can eliminate the need to develop trays by hand and they can create retail-ready results in no time. With the help of our tray forming machines, you can create standard industry corrugated trays for display and shipping, and also you can change up your tray size, restart the line and switch out blanks. Tray forming machines can use hot-melt glue to seal the caps and automatically erect and lock the sides using tab and slot constructions.

We manufacture tray-forming machines that offer you different features for different applications. Including the following bellows

- Can achieve high efficiency and high accuracy

- Offers long life service and good stability

- Ensure high security and high-quality clutch can reflect rapidly

- Have high quality sealed bearings to avoid dust and liquid quality service

- Made from heavy-duty welded steel that is suitable for high volumes tray productions.

- Provides solid output

- It offers you a quick and easy set-up using a single blank

- Can reduce waste

- Can set up date storage

- Unlimited flexibility

- Less maintenance

- Easy to use and more.

What JOCHAMP Can Offer for Your Business

Our tray forming machines uses internationally renowned brands. We also have our own processing center to meet the quality of materials made for our machines. The mechanical structures are molded using CNC machining principles to ensure the accuracy of the whole machine and improve mechanical quality.

As a manufacturer, our team has many professional engineers who have many experiences in mechanical design and debugging. We provide guaranteed machines and after-sale technical service. Our sales team can provide professional services during and after sales to give perfect delivery of the machines to your hand.

JOCHAMP established a perfect after-sales service system. Every problem encountered by our customers will be recorded in our customer management system to ensure that every problem raised by our customers can be seen in the production, technical levels, and sales. We assure to respond and provide you with a perfect solution promptly.

Related Product

Tray Forming Machine: The Ultimate Guide

There are many tray forming machines in the market. As a result, without the right information, choosing reliable and efficient machine can be overwhelming task. In this guide, you will find all information about tray forming machine.

A tray forming machine is a machine that creates trays at high speeds utilizing a solid adhesive system.

The device forms uniform trays at increased rates. The tray forming machines can form various trays, including slotted trays and covers.

tray forming machine

Moreover, the tray forming machine allows for customization of trays as well to better suit your needs.

The tray forming apparatus is quick and precise, which, in turn, helps in increasing productivity.

The Tray former machine is a versatile machine used to form trays in various industries.

Mostly, these products can be classified under the following categories;

- Electronics.

- Food and beverages.

- Grain and Spice.

- Fruits and vegetables.

- Clothing and textiles.

- Sports equipment.

- Toys.

- Pharmaceuticals and cosmetics.

- Chemical.

- Tobacco.

There are various types of tray forming machines. They include;

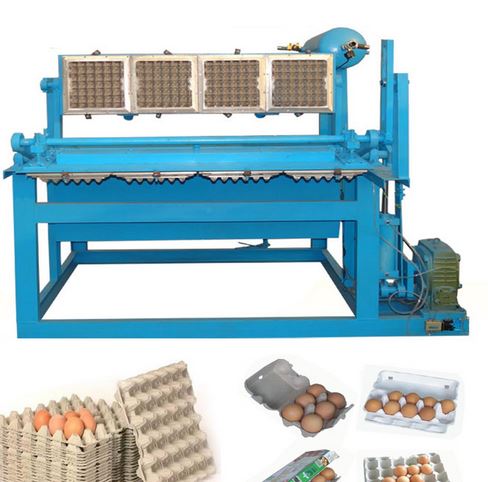

Paper Tray Forming Machine

The paper tray forming machine is a type of Tray Forming Machine from paper trays. The paper trays are primarily made out of corrugated paper or cardboard paper.

Paper Tray machine can produce customized paper trays that suit the user’s needs.

paper tray forming machine

Paper trays are commonly used in the food industry to make trays such as chips trays, fried chicken trays, hamburger trays, etc.

Plastic Tray Forming Machine

The plastic tray forming machine is a type of Tray Forming Machine from plastic trays. The paper trays are primarily made out of plastic.

Again, the plastic Tray machine can produce customized plastic trays in various shapes that best suit the user’s needs.

Plastic trays come in multiple shapes and sizes.

plastic tray forming machine

They are used in various industries such as pharmaceutical companies, food and beverage industries, and cosmetics.

Cardboard Tray Forming Machine

The cardboard tray forming machine is a type of Tray Forming Machine from cardboard trays.

Here, the cardboard trays are mainly made out of cardboard boxes.

The cardboard tray machine can produce customized cardboard trays that suit the user’s needs. Cardboard trays are used in various industries, including; food and beverage, pharmaceuticals, toys, sports, etc.

cardboard tray forming machine

High Speed Tray Forming Machine

High-speed tray forming machines are tray forming machines that have been designed to produce a large number of trays per minute.

High-speed tray forming machines utilize a range of accurate servo motion controls for uniform and precise formation and placement of the tray.

high speed tray forming machine

This type of tray forming machine is mainly used in industrial settings.

It can produce up to a hundred trays per minute, depending on the make and model.

Semi-automatic Tray Forming Machine

A semi-automatic tray forming machine is a type of Tray forming machine that require human interventions with some steps such as loading blanks.

semi automatic tray making machine

The semi-automatic tray forming requires a changeover.

Fully Automatic Tray Forming Machine

The Fully Automatic tray forming machine is a tray forming apparatus independent from any human intervention.

All its system is automated and can be operated from a remote server.

automatic tray forming machine

A fully automated tray forming machine can be integrated with tray erectors, labelers, and other end-of-the-line machinery, eradicating the need for a changeover.

There are several parts of the Tray machine. These parts differ from one Tray Former to another depending on the type of machine and its manufacturer.

Some of the main features include;

- Tray magazine; The magazine holds the die-cut tray blanks used to form the trays.

- Vacuum cups; the Vacuum cups could differ from one Tray Forming machine to another. They are used to pull and push the blanks from the magazine.

- Mandrel; the mandrel in the Tray Forming Machine assists in the tray formation process.

- Safety rails; the safety rails usually located at the sides of the tray forming machine are used to keep the tray in place.

- Hot glue; the hot glue is used to seal the flaps of the tray once the tray has been created.

- PLC system; It has a PLC system used to set and change parameters and control the Tray Forming Machine.

Tray forming process executed by the tray forming machines begins with a magazine holding die-cut tray blanks.

Next, the blanks are then pulled from the magazine using vacuum cups and then transported to the mandrel, which helps in the tray formation process.

The trays formed are kept in place by the machine’s sides. The glue is then applied to the flaps of the tray blanks as it is carried through the machine.

Additionally, tray forming apparatus then shapes the tray. The adhesive used for the flaps set and the formed tray is transported to the following production process.

Tray Forming Machine

Tray forming machine is an equipment that creates trays at high speeds utilizing a solid adhesive system.

Normally, the device forms uniform trays at increased rates.

The tray forming machines can develop various trays, including slotted trays and covers used in multiple industries.

tray forming machine

Also, the tray forming machine allows for customization of trays as well to better suit your needs.

Besides, tray forming apparatus is quick and precise, which, in turn, helps in increasing productivity.

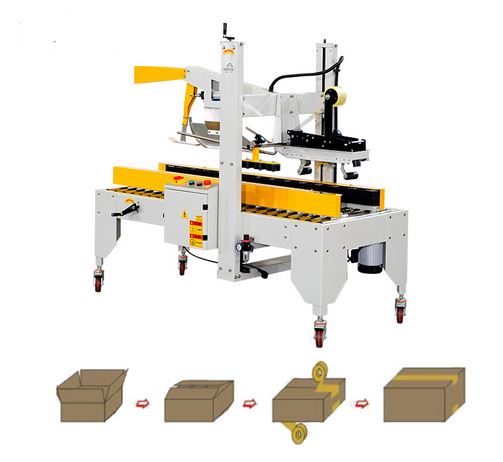

Carton Folding Machine

A folding carton machine is a machine that folds, closes, and seals the package.

The device is fed with blank carton magazines. The machine then creates carton boxes that are used to store products.

Once the products have been packed manually into the folded cartons, the machine seals the carton. The device can be used for packaging a broad selection of products.

carton folding machine

It can accommodate cartons of varying designs. The cartons used are made with different raw materials.

Box Forming Machine

A Box Forming Machine is the equipment used to produce corrugated boxes.

The machines feature cartoon magazines that feed the Box forming machine, erecting blanks into boxes.

box forming machine

Here, the sides are then glued using a hot glue system which may differ depending on the device’s make. Additionally, the erected boxes are loaded automatically or manually before the machine seals the package.

Tray Forming Machine

Tray forming machine forms a tray made of various materials, including cardboard and paper trays.

Also, the device utilizes different raw materials to create resilient and long-lasting trays.

The tray forming machine allows you to customize trays to suit your needs without a long changeover, which will lengthen the production time.

Tray Erector

Tray erectors are tray-creating machines.

These tray formers are used to erect trays from flat blanks. They utilize flap folding and sealing systems for the various packages.

tray erector

The tray formers are fed blanks by a tray magazine which is then folded. Hot glue is applied to the flaps to close the tray.

Tray Formers

The tray forming machine forms a tray made of various materials, including cardboard and paper trays.

It utilizes different raw materials to create resilient and long-lasting trays.

Moreover, the tray forming machine allows you to customize trays to suit your needs without a long changeover, which will lengthen the production time.

- Integrating machines; The High-speed tray forming machines are automated and typically have a small footprint.

This allows it to be easily integrated with other end-of-the-line machineries, such as case labelers, case loaders, and case erectors.

- Reducing production time; high-speed tray forming are particular devices utilize servo motion operations to ensure that trays are created at increased speeds.

This helps reduce the overall time that would have been taken using manual labor.

- Maximizing productivity; the high-speed tray forming machine is an industrial end-of-the-line machine.

The high-speed tray forming machine maximizes productivity by cutting production costs and time while producing increased output.

- Reducing labor cost; the tray forming process can be tedious and repetitive when human labor is utilized.

Human error is most likely to occur, which leads to additional charges.

A tray forming machine can form up to fifty uniform cases per minute, which cannot be managed by a human worker.

For marketing purposes, the tray forming machine produces uniform cases whose design depends on your needs.

The tray forming apparatus allows you to customize the tray to best market your products.

Besides, the device can also be integrated with labelers to create a unique package that can easily be identified by your end-users.

Small footprint; the tray forming machine comes in various shapes and sizes. It is best to choose a device that is compact in design.

The machine’s small footprint will allow it to fit even in areas where space is limited.

Reduced changeover period; most tray forming machines have a reduced changeover period, with some models featuring changeover carried out in seconds.

There are types of tray forming machines that are fully automated and therefore have zero changeovers.

Heavy-duty tray forming machine; There are tray forming machines that are heavy-duty.

The heavy-duty tray forming machines are capable of working around the clock. This helps in maximizing productivity.

Operator friendly; the tray forming utilizes a remote control panel that allows the operator to set and change the containers’ parameters.

Additionally, the control panel is user-friendly and does not require skilled labor.

Size of the trays to be formed; the items’ size should be considered as they determine the size of the tray.

Most tray forming machines offer a range of sizes. You should select the tray former best suited for your needs.

Production capacity of the Tray forming machine; The Tray forming machine should be able to keep up with your scale of production.

The Larger scale of production, the faster the tray forming machine should be.

Similarly, small-scale operations do not require industrial-grade tray forming machines.

Types of products being packaged; Different products have different needs and, as such, may require additional equipment to properly preserve the products.

Various types of tray forming machines utilize a wide range of raw materials.

You should select a tray-forming apparatus that uses packaging materials that best preserve and protects your product.

Machine spare parts; you should consider the machine’s change parts.

You should pick a Tray forming machine that requires changing a few elements to adjust tray sizes.

Personnel training; the type of machine you select will determine the required training and teaching.

The more advance the device, the more intensive the training will be.

Tray loading machines are used to load products on erected trays.

The tray loading machine can be easily integrated with the tray forming apparatus to fully automate the packaging process.

At the same time tray-loading machine is quick and precise, with built-in sensors to ensure that each tray is loaded before moving on to the next stage.

tray loading machine

The tray forming machine is responsible for forming trays. The device uses die-cut blanks, folds, and closes in the desired design to create trays.

Trays are then loaded before being sealed.

It is essential to properly maintain your Tray forming machine. It prolongs the shelf life of your tray-forming device.

Also, it ascertains that all your tray forming operations run smoothly without errors during the formation process.

It reduces the number of breakdowns, saving on extra costs that would have otherwise been incurred.

The essential move is to create a routine maintenance schedule.

The regularity with which maintenance should be conducted id dependant on how frequently the tray forming machine is used.

Maintenance should be done more often if the device is constantly operational. Similarly, dormant machines do not require frequent maintenance.

Tray forming machine maintenance involves various activities, some of which are unique to the type of tray forming machine.

Some of the general routine procedures include;

- You should inspect high-wear parts and the level of the lubricant.

- The tray forming machine should be thoroughly cleaned. This ensures that there is no debris or waste in the device, which could lead to the appliance breaking down.

- Maintenance of the tray forming machine may involve updating the software system to ensure that the appliance operates smoothly. It also allows for calibrations and other adjustments to be made with ease.

- Depending on the type of tray forming machine, you might need to regularly change high-wear parts before they become too damaged.

- It is vital to track the tray forming machine’s energy consumption levels. An increase or a decrease in the tray former could be a potential problem.

- Performing a visual inspection on the tray forming machine to ascertain that the device is in the proper conditions for maximum output.

- Basic cleaning of the tray forming machine should be conducted to stop the pilling of dirt and debris, which might cause the device to slow down.

Other machine you may like include automatic cartoning machine, case packer, case sealer and case erector.

For all your tray forming machines, contact us now.