Mechanical Case Packer Provider in China

JOCHAMP supplies mechanical case packers that can handle various case packing operations. We specialize in case packing solutions where customization or a unique approach to product handling is required.

- Easily accessible and visible moving parts

- Simple and quick format changeover

- Compact dimensions and simple to use

- Suitable for pharmaceutical and food manufacturing

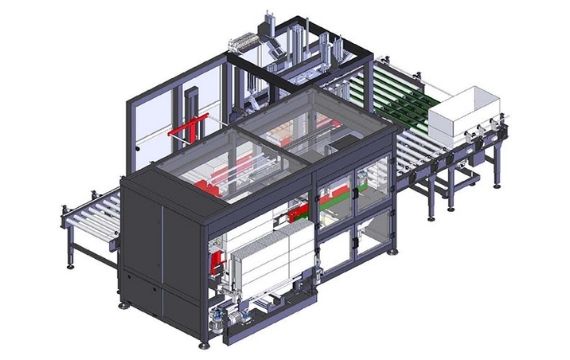

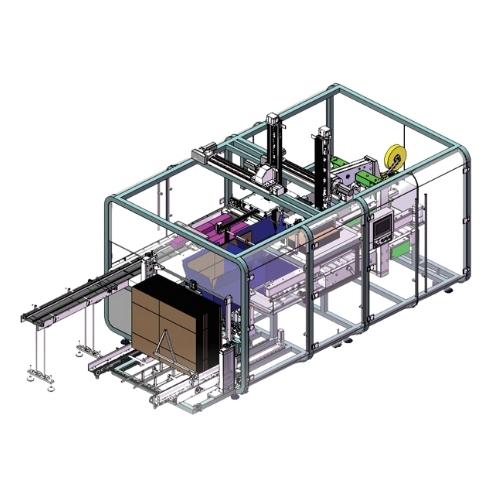

JOCHAMP Mechanical Case Packer

The mechanical case packer (MCP) is designed to pack various products into containers. They also picked up the product from the preform table and inserted it into cartons or crates using vertical movements. Other operations include machine discharges of the filled carton.

Its system comprises two mechanical axes, controlled by a cam and an interchangeable gripping head that is tailored to the product being handled. Jochamp delivers an automatic case packer featuring a high automation level, a simple and intuitive operator interface, and more.

At Jochamp, you’ll find a wide assortment of options for mechanical case packers. We’ll assist you in locating the best case packer for your requirements. Email us today!

JC-600 Mechanical Case Packer

JC-600 Mechanical Case Packer is a fully automatic packaging equipment that integrates unpacking, upstream product stacking, packing, sealing and other processes. It is the most ideal solution to solve the problem of small packaging space at the end. Thanks to the application of the full servo system and the lack of box detection, product incoming detection, stacking overload protection, carton position detection, etc. at each station, the entire production process is monitored and controlled.

- All aluminum alloy body, easy to clean and corrosion resistant

- Open design with no hidden corners

- Four-servo control system to ensure accurate action parts

- Integrated design fully automatic packing machine

- Modular design, tool-free operation, quick product changeover, easy maintenance

- PLC control system and HMI

- Safety door protection mechanism

JC-600

- Technical Parameter

- Features

- Optional

| Item/Model | JC-600 |

| production capacity | Less than 200 (boxes/hour) |

| Robotic grasping production capacity | 10 (times/min) |

| Sealing method | Tape or hot melt adhesive |

| carton size | Minimum 300x250x200mm

Maximum 550x500x400mm |

| power supply | 380V 50HZ 7.5KW |

| air pressure | 0.6mpa |

| Air consumption | Less than 1³m/h |

| Dimensions | 5000x2000x2900mm |

| weight | 2500kg |

| main material | Aluminum alloy, 304 stainless steel |

- All aluminum alloy body, easy to clean and corrosion resistant

- Open design with no hidden corners

- Four-servo control system to ensure accurate action parts

- Integrated design fully automatic packing machine

- Modular design, tool-free operation, quick product changeover, easy maintenance

- PLC control system and HMI

- Safety door protection mechanism

- Lack of case alarm, lack of tape alarm

- Stacking Palletizing System

- Modular gripping mechanism, no tool switching

- Comply with GMP standard, CE, IOS9001 certification

Secondary packaging line integration

Labeling Machine

printer

Glue sealing machine

Stainless steel

heavy duty casters

Leaflet Automatic Dispatcher

export conveyor line

JOCHAMP Mechanical Case Packer Main Advantage

On the manufacturing floor, the mechanical case packer (MCP) is simple to operate. It can bundle packs or loose items into trays, RSC cases, or crates. A mechanical arm with desmodromic-made.

Our mechanical case packer features an intuitive user interface that enables quick and simple production modifications. It provides exact orientation and makes easy switch of packing patterns.

The mechanical case packer has a scalable design making it ideal for handling multiple products simultaneously. They can execute case formation, loading, and sealing on a single machine.

Jochamp mechanical case packer has cam actuated motion, quick, and tool-free changeover. It improves your flexibility and reduces both downtime and your packaging process footprint.

JOCHAMP Mechanical Case Packer Key Features

There are numerous reasons why you should choose our products.

- Possible handling of various-sized boxes

- Quick, simple, and intuitive adjustments and use

- Cam-driven motion

- Simple to operate

- Change the format quickly

- Quick and tool-free change over

- cGMP, CE, and SGS compliant material

- Utilize renowned international brands for accessories

- One-year quality assurance, lifetime after-sales service

Primary Operations of Mechanical Case Packer

Jochamp mechanical case packer machines are retail ready packing units that deliver simple operation. It can handle high speeds and automated changeover. Though it’s a bit expensive, it provides a better return.

The packers can help maximize output per square meter in this case by optimizing layouts, speed, work, and production volumes. Providing higher rates and better results.

- It takes the lid and bottom cardboard forms from their feeders

- Organizes the products into the bundle that needs to be placed inside the cardboard

- Shapes the base and lid around the created bundle

- The finished carton is then removed from the machine.

Average productivity: max. 5-15 carton/min

Rapid Return of Investment

Savings from higher output and efficiency provide a return on investment for mechanical case packing. If case packing is your bottleneck, automation allows you to enhance production compared to historical inefficiencies. Doing so will enable you to meet production demands sooner than usual.

Labor savings, reject reduction, and wastage reduction from manual packing help you to realize your returns sooner. A mechanical case packer is your best choice with a focus on higher speed lines and improved line efficiency. Jochamp will determine the right packing solution that works best for you.

While the initial cost savings may not justify the investment, other benefits can help you take your manufacturing to the next level.

WHY YOU GET YOUR MECHANICAL CASE PACKER FROM JOCHAMP?

Jochamp owns a 3000+ square meters factory where the production of mechanical case packers is accomplished. Our 15 mechanical engineers and 20+ after-sales service team ensure each packer meets desired specifications. We are dedicated to providing a one-stop mechanical case packaging machinery solution.

All mechanical case packers are tested to meet CE, SGS, cGMP, and ISO9001 standards. Before that, meticulous quality control had been performed already. From raw materials, machine assembly, and in every step of production. We offer a free sample test of your chosen machine.

With more than 50 strategic cooperation machinery factories, we can deliver multiple machines. Jochamp also supports localized installation, after-sales, and training services.

Other company advantages include

- Provide a complete turnkey solution

- European-quality, Asian price

- Fast delivery time of 15 days

- 50+ technical patents

- One year quality assurance

JOCHAMP MECHANICAL CASE PACKER

- Thick steel frame construction

- Intelligent Control(PLC) for accurate placement

- Control panel with a color touchscreen (allow manual operation of all functions)

- Digital man-machine interface

- Modular gripping mechanism

- Transparent safety door (monitor the operation of the equipment at any time)

- Safety door protection mechanism

- Variety of container handling options

- Solid-state proximity sensors

The mechanical case packer comes with several standard features. You can, however, add options upon request:

- Case erector

- Carton sealer

- Secondary packaging line integration

- Carton sleeve inner bag

- Labeling Machine

- Printer

- Glue sealing machine

- Stainless steel

- Heavy-duty casters

- Leaflet Automatic Dispatcher

- Export conveyor line

Mechanical Case Packer Solution for Industries

Our mechanical case packer solution is ideal for high-quality home and personal care product packaging. It includes jars, plastic bottles, tubes, and cases. They optimize the tripartite need of speed, footprint, and package size range for the sector.

Duchamp’s mechanical case packer address packaging requirements in pharmaceutical industries where delicate packaging is required. The plastic bags contain liquid medical medicines, bottles, and more.

The mechanical case packer can package food goods in various shapes and sizes. Along with it are beverages in a variety of bottles. This comprises glass, boxes, PET, cans, jars, trays, and cartons in different sizes.

Jochamp mechanical case packing machines can package any form and quantity according to the configurations required. From lubricating oil cans to chemical product bottles. Our packing solutions are incredibly dependable and cost-effective.

Our mechanical case packer is also perfect for various viscosities found in cosmetics packaging. It includes scrubs, creams, nail polish, lipstick, cleansers, sunscreen, pastes, etc. Jochamp packaging machine solution is great for your beauty and cosmetic items.

Related Product

Mechanical Case Packer: The Ultimate Guide

This guide will help you choose efficient mechanical case packer machine.

It explores all fundamental aspects of mechanical case packer such as features, design, working principle, applications and benefits – just to mention a few.

Take a look:

This is the machine which is versatile in packing cases such as carton boxes, crates, trays or bottles.

It is sturdy and can easily be used during production processes.

It has the ability to run bundled or lose packs into crates, cases or trays.

mechanical case packer

The machine comes with so many benefits not only to the production industries but also to the end user.

Some of the main benefits of mechanical case packer include:

- It is easy and simple to use

- Mechanical case packer has few components making it easy to operate

- With some functions partly automated, it reduced cost of operation and labor

- These machines are easy to maintain and they are cGMP compliant

- The machine offers a very fast format when it comes to changing over and it does not need any tools for this.

- Mechanical case packer offers an intuitive and non-complex operator interface making it easy to monitor and operate.

- It also comes with sealing system put in place making the work faster and easier.

- It is made up of compact dimensions an additional advantage to the use since it aids in ease of operation.

- The machine can be able to perform almost everything from dispensing to transporting to filling to sealing and releasing.

Although the features of mechanical case packer varies broadly, some of the critical features to look for include:

Three Level Decompression Mode

It adopts a three-level decompression mode which is meant to reduce the impact created by the product.

This allows the grabbing head and product to be aligned together accurately.

The accuracy will ensure a 100% success rate when it comes to bottle grasping.

After grabbing the bottle, the system ensures that there is no built-up pressure.

Otherwise, the pressure would lead to falling of the grabbed items.

Linear Positioning System

The standard linear positioning system is adopted by the developers of this packing machine.

This is because it has high accuracy in positioning and movement.

This accuracy leads to the reduction of vibrations and impact when in operation.

It offers reliability and stability of the machine making it easy to maintain and clean.

Efficient Pneumatic System

Reliable operation is offered by the presence of specific pneumatic parts which can grasp and place the items.

It works via mechanical operation with electrical and pneumatic controls making the packing process accurate and reliable.

Variable Frequency Motor For Precise Control

Stable operation is achieved through the use of variable frequency motor which aids in the mechanical operation.

The automated action is achieved through the combination of optical, pneumatic and electric mechanisms.

These actions are coordinated and they run smoothly and accurately.

In addition to these, other critical aspects include:

- Several other functions are provided to stop operation if there happens to be any kind of failure during operation.

The machine can be switched off in situations like when the case is not filled up

It can also be switched off if the items being packed are empty and many other reasons of failure.

- Due to the automation of the machine, the output is high and the process can work with high volumes within a short time.

The mechanical case packing machine is made simple and easy to operate with a few components or parts as explained below.

Mechanical case packer technical drawing

The empty cases dispenser – this is the part that makes the cardboard available for the box erector.

The cardboard is loaded to the dispenser manually, and the rest of the processes are automated.

Box erector – the box erector functions through the use of suction cups available on the mechanical arm of the machine.

This is the part that ensures that the box is erected and folded in the required size and shape with a seal at the bottom.

After the formation of the case, it is made available to the roller conveyer.

The loading roller conveyer – this part is responsible for putting the case at the centre, closing the bottom part of the case.

It is also responsible for dragging the already filled case towards the sealing section.

It also ensures that the case maintains a perfect shape.

The bottom of the case can be sealed using an adhesive tape or/and hot melt.

Pick and place system – at this stage, the items are packed into the case through a pick and place mechanical system.

The opening of the flaps is controlled through an automated or mechanical system.

The chosen system must allow for aid in placing the case at the centre during the pick and place process.

Case closing system – when the packing process is over, the filled case is transferred to the closing and final sealing area.

This section seals the case using either a tape or hot melt.

The two sealing methods can also be used in combination to create a perfect seal.

The sealing process is automated and this makes it very accurate.

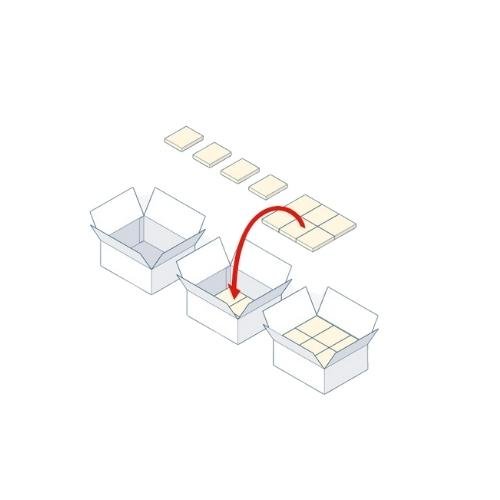

Case packing principle

Mechanical case packer machine uses a simple working principle as described below.

Dispenser makes the cardboard available to the box erector through an automated system.

The box erector forms the box in the required size and shape through the use of suction cups found on the mechanical arm.

The bottom of the box is also sealed at this stage and the finished case is transferred to the loading roller conveyer.

Then the roller conveyer centres the carton box ready for filling.

Here the filling of the box is done through a mechanical system where the items are picked and placed in to the box until it is filled.

Now, the pick and place process ensures that the items are properly arranged in the box leaving no spaces.

After the filling of the box, the roller conveyer is again responsible for transporting the filled box to the sealing station.

At the sealing section, the carton box is sealed using either a tape or hot melt.

The two sealing methods can also be used in combination to create a perfect seal.

Remember, the sealing process is automated and this makes it very accurate.

After sealing the completed packed carton box is moved out of the machine and this is also automatic.

The main functions of the mechanical case packer machine are explained below.

- It makes the carton boxes from the cardboards available at the dispenser.

It ensures the right shapes and sizes of the carton boxes as required for any given product packing.

- It is also used to collect and prepare the right quantities of the product to packed into the carton box.

This is possible through the automated system.

- The mechanical case packing machine is also responsible for transporting the already made carton box to the filling station.

It ensures that the carton box remains in shape and is not destroyed in any way.

- The mechanical case packing machine helps to automatically pick products form their dispenser.

After picking the product, it places it into the carton box with accurate arrangement.

- It also ensures that the right quantity on the product is properly fitted into the carton box.

- This machine also aids with conveying the already filled carton box to the sealing station making sure it is not destroyed.

- The machine is equipped with sealing mechanisms such as a tape or hot melt to ensure a perfect seal on the box.

- The mechanical case packer also ensures that the already filled and sealed carton box is discharged from the machine.

- The machine also offers an interface screen where the operator can control all the operations from.

- The machine controls the quality of the packed carton boxes and quantity of the products therein.

- The machine offers a self-cleaning mechanism and it is easy to maintain and with minimized or no risks to accidents.

- The machine is operated at high speed and can give high quantity output in a short period of time.

There are several applications for the pick and place mechanical case packer and a few of them are discussed below.

- Beverage industry – in the beverage production industry, the pick and place mechanical case packer is used.

Such beverages include coffee, tea, and many others.

It is used to pack the beverage into carton boxes or any other containers as required.

- Food industry – there are several food options in the food industry that will require the services of a case packer.

Food like pizza and many others must be packed into carton boxes before being shipped to the consumer.

Other food items that need these services are frozen foods, rice, dry foods, liquids like juice, and snacks like biscuits

- Chemical industry – after the production of chemicals, the production company will need to ship them too various consumers.

For them to be shipped, there is need for packing them into containers and in the right quantities.

This is where the pick and place mechanical case packer comes in.

- Pharmaceutical industry – there are several products in the pharmaceutical industry that require being packed after the production.

Products like drugs be it tablets or syrup or capsules need the services offered by the pick and place mechanical case packer.

- Cosmetics industry – the products in this industry include hair, facial and body products and make up and perfumes.

Pick and place mechanical case packer can also be used in this industry.

- Consumer products industry – in this industry, the pick and place mechanical case packer can be used to pack items into boxes.

Such items may include candy and confectionary into cartons and pillow bags.

- Cereals and seeds – Cereals, Alfalfa, Silage, Sorghum seeds, Sunflower seeds, Maize seeds and Soybeans.

These can also be packed into boxes or other containers through the use of a mechanical case packer.

- Forestry – Wood chips, Sawdust, Wood shavings, Bark, Compost, Mulch, Peat moss and Soil can be packed into boxes or other containers.

- Minerals and aggregates – Cement, Clay, Sandstone, Gravel, Sand, Talc can be packed through mechanical case packer machine.

- Animal feed – Ingredients, additives and supplements for animal feed, Bird seed, Animal feed and Fish food also need the machine to be packed.

It can be used for packing contents into cases like cartons, bottles, bags, cups, cans, crates and many more.

There are several mechanical case packer machines available in the market today.

The choice of the machine will depend on the intended item to be packed.

- Product bench mechanical case packer – this is normally used on the bent for small companies producing their products in smaller quantities.

This type can be used with crates, carton boxes, cans, tanks, trays and many more.

bench mechanical case packer

- Racetrack bench mechanical case packer – this is meant for companies that work with medium quantity production volumes.

- Top loader mechanical case packer – for industries that do their productions in high volumes, this is the right type packing machine required.

- Mechanical case packers for the glass containers – the glass containers can be filled through the mechanical case packer and be sealed thereafter.

- Mechanical case packer for carton boxes – this has the functions of erecting the carton, filling and sealing it.

- Mechanical case packers for trays – in this case, the trays are ready, the machine does the filling and the sealing.

It is mostly used in the agriculture and food and beverage industries.

- Mechanical case packers for cans – this machine is designed for filling up cans with already packaged products.

It is mostly used in the food and beverage industry.

- Mechanical case packers for storage tanks – this type of machine is recommended for companies dealing with products such as chemicals and oils.

It is used for filling the storage tanks awaiting shipments or distribution.

mechanical case packers

More Resources:

For all your mechanical case packer machines, contact us now.