Weighing and Packing Machine Manufacturer in China

JOCHAMP is over ten years of supplying weighing and packing machines for food packaging solutions. These machines are perfect for packing chips, puffed food, melon, peanut, and many more.

- Can pack different bag sizes

- With powerful engines and voltage capacities

- Smart automatic and automated machines

- CE, cGMP, ISO9001, and SGS compliant

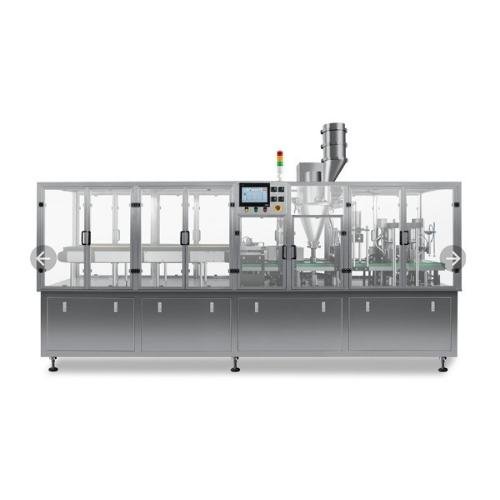

JOCHAMP Weighing and Packing Machine

For all kinds of product packaging needs, you can access automated, intelligent, and efficient weighing and packing machines at JOCHAMP. Our machines adopt intelligent options and can operate proper packaging works on a small or large scale.

JOCHAMP can provide you with not just efficient and automated but also very durable machines. Thus, it can guarantee high-quality and long-life operation. As a leading manufacturer, we use sturdy materials like aluminum and metal to improve durability.

You can choose from smart automatic or automated weighing and packing machines, varying in colors, designs, shapes, sizes, and features. These machines can pack different sizes of bags to be used in different industries. Depending on your specifications, we can custom the powerful engines and voltage capacities to improve the performance.

Send us your specifications now!

Types of Weighing and Packing Machines

Why JOCHAMP Cup Filler Pouch Packing Machine

The machines come with powerful engines and voltage capacities to increase work performance and achieve a longer lifespan.

The machines are accessible in customized designs, sizes, shapes, colors, and features. Send us the specifications you want for your machines.

The machines can guarantee energy efficiency. Also, it can reduce major costs linked to energy bills. This could also minimize manual labor costs.

Our weighing and packing machines are easy to operate and maintain. It has a faster-packing speed operated by automated, smart technologies.

Fully Automatic Weighing and Packing Machine

Nowadays, most manufacturers and companies are preferring to use automatic weighing and packing machines. It can greatly maximize output, and saves labor and costs. JOCHAMP high-speed automatic packaging lines are produced based on the technology of absorbing and digesting international packaging machines.

JOCHAMP automatic weighing and packing machines can recognize bag feeding, automatic feeding, weighing, bag loading, sealing, bag filling, and other working procedures. The operation of the entire machine acquires the automation demands and exceeds different social needs.

Weighing and Packing Machine Application

The weighing and packing machines are the most basic tools in many industries and are widely used today. These machines are constantly developing nowadays and are commonly accepted by many customers. The demand for weighing and packing machines is getting bigger, regardless of any industry:

- Beverage industries

- Pharmaceutical industries

- Chemical industries for precision packaging

Weighing and Packing Machine Feature

Do you have a small company that needs to pack different products, or do you look for a packaging solution for your wholesale business? JOCHAMP weighing and packing machine is perfect for you! Just load your product into the hopper top, set your ideal weight, and let the intelligent micro-computer fill the ingredients into your packaging. It is just a second! The following are the features of our weighing and packing machines:

- Compact tabletop size

- Works with numerous dry ingredients, 20 bags packed per minute

- Food-Grade materials

- Filling range up to 1-300g or customized

Why JOCHAMP Weighing and Packing Machine

If you have a small business looking for a reliable and cost-effective solution to speed up packing operations, JOCHAMP is the answer. We aim to provide you with high-quality weighing and packing machines that give compact packing operation.

With this machine, you can save time, reduce product wastes, minimizes food contaminants, and enhance dispensing accuracy. All of our weighing and packing machines are approved by international certifications like CE, SGS, ISO9001, cGMP, and many more.

JOCHAMP is your one-stop automated packaging solution provider in China that supports one-year quality assurance and lifetime after-sale service. You can ensure high-quality, reliable machines with us as we always perform strict quality control from material selection to machine assembly.

JOCHAMP Weighing and Packing Machine

- High automation, reasonable design, simple to operate

- Weighing preciously and efficiently, run stably, positioning accurately

- Adapts large touch screen, programmable control system

- Sensitive servo fil conveying system for film positioning

- Food-grade stainless steel, hygienic and clean

- Complete coding, filling, weighing, sealing, bag forming

- Fit to Z-type conveyor, date printer, output conveyor

- Batch coding device (hot foil/inject coding)

- Gas flushing device

- Bucket-type feeding conveyor

- Gust forming

- Outtake conveyor

- Vacuum pump and a hole puncher that is used to accommodate the pouch and produce it in the proper shape

Custom Weighing and Packing Machines Based on Your Applications

The machine has a reliable operation, is energy-efficient, and long operational life. It can also guarantee accurate, fast, and reliable weighing used for food and non-food products.

Our automatic rice packaging machine is widely utilized for packaging granular, seed, grain, block, strips, and granular-powder products. This machine is energy-efficient and reduces manual costs.

JOCHAMP coffee packaging machine has date printed functions and auto weigh fill seal. They are also equipped with intelligent controls and can work accurate packaging operations in numerous spectrums.

Related Product

Weighing And Packing Machine: The Ultimate Guide

If you are looking for any information about weighing and packing machine, all information is right here. Whether you want to learn about applications, parts, working principle, benefits or critical features – this is a perfect guide for you. So keep reading to learn more.

A weighing and packing machine is a tooling system that can weigh and fill products such as food or non-food. These products can be filled into bottles or porches or any other containers depending on the type of product. Types of products that can be filled through this machine include, powdered products, liquids, solids, semi-solids etc.

weighing and packing machine

The choice of the machine depends on the speed of the machine, type of product, cost and quality of the service. Also, the most commonly used type of weighing and packing machines is the automated option.

An automated weighing and packing machine does everything from weighing, packing to sealing.

The weighing and packing machine is made to precisely weigh and pack various products into cartons, bags, trays etc. Some of the work done by the weighing and packing machine include;

- Dispensing, feeding and weighing the product.

- Packing the product into bags, cartons or other containers.

- Packaging the filled bag into cartons or boxes.

- Sealing the package.

- Creating a print on the package.

The weighing and packing machine can be used in industries such as;

Food production industry to pack products like snacks, nuts, candy, frozen foods, vegetables, granules, fruits, spices and many other products.

Pharmaceutical industry for weighing and packing drugs, chemicals and other products.

Agriculture industry for weighing and packing agricultural products such as fertilizers, seeds, cereals and many more.

The machine can be used for a very long time since it is made of a stainless-steel frame and a tool-less changing over system.

Hopper

A hopper is the component that stores the products to be packed into the bags. This part of the machine has been designed to tapper at the bottom, this allows products stored in it to be dispensed easily.

A tapering design at the bottom makes it easier to dispense the product from the storage hopper. It also ensures that it is done uniformly.

The process of dispensing the products can be accurately controlled in quantities that are specified. Coating the walls of the hopper ensures that the products stored in there are free from contamination.

Load Cell Sensor

The load cell sensor acts to convert a force or weight or load detected on the load cell into electric signals. Again, the electric signal could be in the form of voltage or frequency or current change.

This is determined by the load cell type and circuit. The most commonly used load cells for weighing and packing machines are strain gauge load cells. They are used because they are inflexible, with good echo value and high durability.

Strain gauge load cell works when there is a stress on the load cell, the sensor also gets the exact strain and deforms. When the deformation takes place, the electrical resistance also gets changed to keep the process continuous.

Microcontroller

A microcontroller is a computerised surface with one integrated circuit. The circuit is provided with memory, processor core and programable input or output peripherals. Here, the microcontroller is very easy to learn because it uses an amplified version of C++.

Stepper Motor

A stepper motor is the component that breaks a full rotation into equal steps. Through the stepper motor, the rotation can be stopped and kept on hold at any step depending on the torque and speed. The stepping process can be controlled through a computer interface which results into precise positioning.

Stepper Motor Driver

This is an electronic device designed to drive the stepping motor. Stepper driver can transform the movement instructions to turn on or off the stepper motor.

Keypad And LCD

This part offers an interface for monitoring and control of the process of weighing and packing of various products. Through this key pad, the operator is able to key in all the requirements for a given process.

parts of weighing and packing machine

From the process station, the product moves to the hopper via a conveyer belt. The product is stored in the hopper before the weighing and the packing processes begin. Through gravitational force, the product is dropped from the hopper which is high above the weighing station.

The weighing station is made up of a U-shaped basket, load cells and stepper motor. A flap is fixed to the bottom of the basket to offer a door mechanism. When the stepper motor rotates, it opens that flap which consequently closes the basket.

At this stage, the microcontroller sends signals to the load cell once the product is detected by the system. A proportional electronic current is created through the load cell sensor. These instructions are fed in through the computer interface provided with a keypad.

Once the product has been weighed, the flap opens automatically through the functioning of the stepper motor. This action allows the product to be dropped into the bag. The bag is then sealed or stitched before being discharged.

Automatic Weighing and Packing Machine

Automatic weighing and packing machine is used to quantitatively pack large amounts of products into bags.

This type of machine can pack any kind of product from powders, solids, liquids to semi-solids. Automatic weighing and packing machine can perform functions such as feeding, weighing, packing, sealing and printing.

Automatic weighing and packing machine

All these operations are automated.

Working Principle

The product is first fed into the storage hopper until it is filled up. Once the storage hopper is full, the product, through gravity, moves into the feeder. The door to the large feeding station opens to allow entry of the product which fills it. The feeder door closes leaving a slit and through the slit, the product can again move to the small feeding station.

Once the small feeding station is full, the feeding door closes completely.

Product weighing takes place at this stage and through a bag clamping mechanism, the bags are loaded with the products.

Features

Automatic weighing and packing machine can feed, weigh, bag, seal, print and discharge packages automatically. The machine is highly precise and efficient and can handle diverse products. The weighing and packing accuracy of this machine is approximately 0.4 to 1.0 gram.

Application

Automatic weighing and packing machine is used in almost all manufacturing industries to weigh and pack various products. Some products handled by this machine include candy, beans, potato chips, almond, frozen food, pet food, hardware etc.

Semi-automatic weighing and filling machine, just like the automatic weighing and packing machine, is used for weighing and filling various products. The machine can be used mostly with ultrafine products like tonners, additives, and extinguishers.

This machine is semi-automatic because unlike automatic weighing and packing machine, it does not perform some functions.

semi automatic weighing and filling machine

Functions like feeding the storage hopper and bag forming are not performed by this machine.

Working Principle

The product to be packed is filled into the storage hopper manually. Once the hopper is filled up, the product is transferred to the weighing station through the conveyer belt.

Weighing is then done depending on the amount specified through the LCD interface. After weighing the product is moved to the loading station where the product is dropped into the already formed bags. The bag is sealed before being discharged.

Features

Semi-automatic weighing and filling machine is designed for weighing and packing various product such as nuts, powders and many others. The metering tolerance can vary depending on the product type but it remains within ±1~3%.

Components that usually get into contact with the product are made with stainless steel to avoid contamination. Working process is controlled through an HMI setting which ensures that the output is accurate and precise.

The machine is designed to self-diagnose and can stop operation if an error is detected. An alarm system will alert the operator of the said error. Through the HMI touch screen, the machine will give instructions on how to troubleshoot the error.

Another feature is the memory modules designed in the HMI control system. Memory modules are able to store memories of past instructions fed in it.

Application

The semi-automatic weighing and filling machine is capable of handling all types of free-flowing products. Some of the products handled include; rice, pulses, sugar, tea powder, wheat, green peas and white mutter.

Smart Measurements

While other weighing machines can only tell the weight of a product, the intelligent weighing machine can tell everything. It can show other aspects such as temperature, size.

Easy to Use

The intelligent weighing machine does not require any kind of effort when using it. Everything can be controlled and monitored through the LCD screen. The intelligent weighing machine has an automatic button for turning it on or off. Maintenance and cleaning can be done easily on the intelligent weighing machine.

Memory

The intelligent weighing machine comes with an inbuilt memory, meaning everything that has been fed in gets stored. Stored data is also made easier to access through the PLC interface.

Accuracy

The intelligent weighing machine gives accurate and precise results.

· In-motion Check Weigher

An in-motion checkweigher is the machine that has been designed to weigh items passing through the production line. The machine can also classify the products by using the pre-set weight zones, and also eject or sort the products. The products can be ejected or sorted depending on the classification of each type.

in motion checkweigher

In-motion Checkweighers can weigh up to 100% of products on the production line. The in-motion checkweigher is made up of infeed part, weighing section, discharge section, rejector, loading station and LCD interface.

Functions Of An In-motion Checkweigher

Checking for packages that are underweight or overweight. Making sure that the packed products comply with the standards. Identifying any missing components of a package such as lids, labels, instructions etc.

Making sure that all the components of a particular case are available. Reducing the product giveaway through the use of checkweigher totals for determination of filler adjustments.

Classifying items into weighing grades. Weighing before and after every process to ensure the accuracy of the process. The in-motion checkweigher machine can also open flaps on a carton, check missing caps, bar code labels and metal contaminants.

Application

Every manufacturing industry needs the services of an in-motion checkweigher for weighing before and after packing their products. Industries can use these machines to weigh and pack products in solid, semi-solid, powder and liquid forms.

Linear Multi Head Weigher

A linear multi head weigher machine is a combination of accuracy, speed and reliability. The machine can be used for packing both food and non-food products.

linear multi head weigher

Linear multi head weigher is designed within packing machines to enhance efficiency and cut on labour costs.

Working Principle

Once the product is fed into the first multi head weigher, it is dispersed to the hoppers. The products are then dropped to the weigh hopper. Through the computerised interface, the operator is able to control the amount of weight that will be allowed to be loaded.

The multi head weigher can open all the hoppers that will drop the given weight requirements for combination. The specified weight is dropped into bags or trays or other containers.

The products are dropped from the hoppers through the gravitational forces, or vibration or other forces.

Functions Of The Linear Multi Head Weigher

Feeding the products into the storage hoppers. Weighing the products through mix weighing.

Loading the products into bags or trays. Sealing the bags and printing them.

Applications

Industries all over the world use the services of a linear multi head weigher for the following products.

- Sticky products like fresh meat, fish, cheese, poultry.

- Granules and powders like coffee granules and loose tea.

- Fragile products like chocolates, gourmet biscuits, baggers, pizza etc

- Complex products like a mixture of rice, meat and vegetables.

Less Space

The table top weighing and filling machine occupies a smaller space on the working table. It can be placed in one conner or the building creating space for other applications.

Speed And Efficiency

The table top weighing and filling machine can combine both weighing and packing in one place. This ensures efficiency and speed of the process.

Accuracy

Weighing is very accurate since the machine can confirm weights of products before and after packing.

top table weigh and filling machine

Weights that do not conform to standards are ejected from the machine.

Reliability And Consistency

Table top weigh and fill machine will always measure and pack the exact amount of product as specified through the HMI.

Versatility

Table top weigh and fill machine can work with diverse packing materials with various shapes and sizes. The machine can also weigh and pack variety of products.

Simplicity In Control

A computerised controlled interface is part of the table top weigh and fill machine. Through this interface the operator can feed in instructions easily.

Less Labour Costs

Since the table top weigh and fill machine is automated, the labour needed is just for monitoring and control of the whole process.

Easy To Upgrade Machinery

The table top weigh and fill machine is flexible enough to allow for upgrades depending on the needs of a company. For instance, it is possible to add filler heads.

Hygiene

Machine parts that get into contact with the product being packed, are made up of stainless steel or coated with safe products.

Portability

Table top weigh and fill machine is not very huge and can be transported easily from one station to the next. The size cuts on the shipping costs.

Before choosing any weighing and packing machine you need to define the following;

Product Variety

You need to know the product variety you will be weighing and packing through the machine. This will help you decide on the right machine type.

Quantity Of Production

Deciding on which weighing and filling machine to go for will highly depend on the quantity of your products.

Quality Required

Every manufacturer builds their machine with a given level of quality; therefore, the type of product will determine quality. The quality of the product will consequently determine the type of machine to go for.

Packaging Material

There are machines that can handle plastics, others cartons, others glass and many more. You should be able to tell the packaging material and choose the machine that will work with it.

Look And Style

This will depend again on the product type and also what your competitors have in the market. If you want the packaging print to be professional, go for the right machine.

Check With A Specialist

After you have defined all the above factors, now ensure to consult an expert who can help you choose the best machine. The best choice also includes the supplier, find out from the competition, the reliability of a given supplier.

For all your weighing and packaging machines, contact us now.