Ampoule Packaging Line Manufacturer

Jochamp has built a solid reputation as a professional and trusted manufacturer of packaging lines for ampoules. All our packaging lines are exclusively distributed to all prestigious companies and businesses worldwide.

- Provide complete turnkey packaging line solutions for ampoules

- Easy-to-operate and user-friendly machine

- Guaranteed consistent, safe, reliable and robust performance

- All packaging machine models can be ordered

JOCHAMP Ampoule Packaging Line

Ampoule packaging lines are used to fill each ampoule with a range of liquid or solid items. Includes cosmetics, food supplements, drugs and other substances. In addition, the ampoule packaging line also has ampoule cleaning machines, sterilization channels, ampoule filling, sealing machines, and ampoule self-adhesive labeling equipment.

In addition, the Jochamp ampoules have an adjustable structure to accommodate the internal control system of various items to ensure error-free production. With well-equipped testing equipment and a strong technical team, Jochamp is a manufacturer of various types of ampoule packaging lines and other packaging machinery.

With plenty of options, high quality, affordable prices and stylish designs. Send us a message now!

Ampoule Packaging Line Feature

Jochamp electronic control PLC touch screen. Color human-machine interface, easy to use for packaging line.

Our ampoule packaging line uses high-quality construction and materials to work for long periods of time.

The ampoule packaging line is highly automated. Multiple inspection points ensure excellent accuracy.

The main motor of this machine is an equipment overload protection device to ensure safety. All spare parts are engraved with codes.

Varying Constructional Design

Jochamp ampoule packaging line comprises a high-programmed machine primarily used in an array of packaging industries and sectors. The whole machine is designed that reaches the advanced packaging level and standard. Its mechanical structure will constantly give high automation, high production efficiency, stable, accelerated, and continuous operation.

Our ampoule packaging line is available in different models. It is produced according to shapes, dimensions, types, and capacities that are suitable for certain use. However, JOCHAMP can also produce other machines that are related to the ampoule packaging lines.

Structural Features

Jochamp ‘s line of ampoule packaging exceeds major packaging requirements. Due to its unparalleled features, it has received huge demand from all well-known packaging companies and businesses, such as:

- Equipped with high quality stainless steel construction.

- All structural designs comply with cGMP, CE, ISO9001 and SGS requirements.

- The entire agency is designed and components work in harmony.

- Equipped with safety devices.

- User friendly and eco-friendly.

- Easy to operate.

- Time consuming and low cost.

- energy economy.

Excellent Quality Control

Our ampoule packaging line is highly efficient, effective, and reliable to use. The necessary prerequisites for high-performance machines are automation and accurate processes that acquire strict quality control. We regularly performed a random inspection and testing for all components taken to the ampoule packaging line to ensure their quality and functionality.

Adopting the advanced manufacturing strategy is beneficial to producing more powerful and improved machines. As your leading manufacturer, we can offer both automated and semi-automated ampoule packaging lines to support your business and projects. We are certain to focus on producing thousands of machines without wasting time, energy, and materials.

Why Choose JOCHAMP Ampoule Packaging Line

Jochamp is an experienced international commerce team that handles everything from payment to document certification to freight and customs clearance. Ampoule packaging line has a simple and powerful industrial control system; easier to use, faults are graphically displayed, and maintenance is simple.

Users recognize and trust the Jochamp ampoule packaging line, which can adapt to changing economic and social needs. We welcome new and returning clients from all walks of life to get in touch with us in the hopes of forming long-term business connections and mutual success.

To secure the safety of equipment during shipment, Jochamp uses sturdy transport packaging. Contact us now for your orders.

Using the JOCHAMP ampoule packaging line offers bountiful advantages to your market sales. Due to its powerful settings, it can perform multiple packaging tasks without troubles and difficulties. Moreover, our ampoule packaging line requires less maintenance.

For fast, simple, and optimize packaging process, we highly recommend taking the advantage of using our ampoule packaging line. It guarantees:

- Compact durability

- Stability

- Sustainability

- And endurance

The ampoule packaging line hugely applies to the medical, pharmaceutical, and cosmetics industries. This is a good choice for elevating market profit. It is flexible to use in packaging products in different sizes and volumes.

This ampoule packaging line is suitable for both solid and liquid products, such as:

- Injectable medicines

- Antibiotics, biotech

- Diagnostics

- Other medical, cosmetic

- And chemical-related products

Custom Ampoule Packaging Line Based on Your Applications

The automated packaging line contains high automated packaging machines for both liquid and solid products. It leads to ameliorating product packaging speed. This enables the prestigious companies in all industries to pack immense product quantities.

The pharmaceutical packaging line is produced intended for the pharmaceutical industry. It incorporates several machines that are capable of packaging pharmaceutical products such as medicines, syrup, capsules, and various medications.

Our food packaging line is equipped with a complete unit of machines used to pack a variety of food products in different packaging types. Build from industrial-grade materials that provide powerful and efficient performances.

The liquid packaging line is called to be an easy and effective way of packaging different liquid substances into various container types. It comprises several machines that can handle multiple liquid packaging ranging from light to heavy-duty packaging.

The packaging production line is Jochamp’s best-selling packaging line products. It is the basic packaging equipment used to pack an extensive range of finished products. It employs different machines, including automatic and semi-automatic configurations.

Related Product

Ampoule Packaging Line: The Ultimate Guide

An ampoule packaging machine plays an integral role in today’s industry.

So, whether you want to learn more about ampoule packaging line, or invest in a new equipment – you will find all the vital information you need right here.

Let’s dive right in.

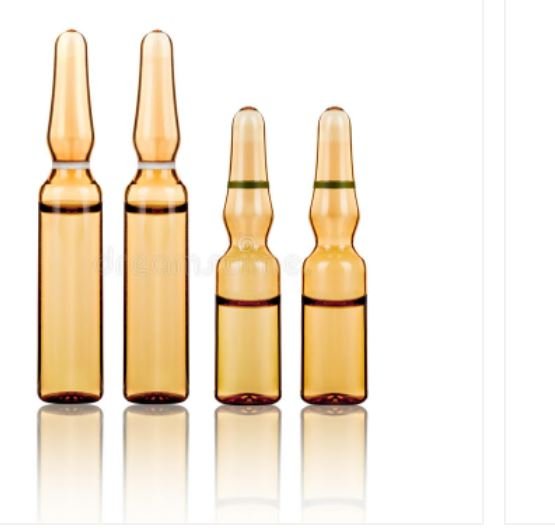

It refers to a small sealed plastic or glass bottle designed to preserve and contain different samples, preferably for pharmaceutical, cosmetic and personal care items.

ampoule packaging

Ampoule packaging involves sealing the shut such that the chemical inside is safeguarded from exterior elements such as oxygen.

This type of packaging is hardly reusable thus suitable for transporting single doses of medicine or samples.

You can use ampoule packaging for liquid, powder, and pastes, which are hermetically sealed.

Besides, this packaging contains pressure points often squeezed to release the seal and allow product out of the container for use.

It is a compact sealed container with solid or liquid materials often used in pharmaceutical and chemical sectors.

ampoule

The essence of ampoule is to store and preserve the contents and mainly protect them from air and contaminants.

Ampoules are primarily made of glass materials, but nowadays, you can find them in a wide range of thermoplastic materials.

Hermetical ampoule sealing by melting the thin top using an open flame makes it stronger and defiant of any air or contaminant.

Before sealing, the space above the chemical may be filled using inert gas.

Moreover, ampoules have strong walls making them easy to bring them into glovebox.

You can pressurize this sealed container and have air evacuated from it and replace the air with other gases, typically inert ones.

It refers to a cGMP injectable line with washing, filling, sealing, inspection and labeling operations all integrated into the machine.

The machines offering the various operations are integrated into the equipment to provide a single complete unit.

This packaging line is designed to ensure it offers increased production rates in different applications where it is used.

Primarily, the ampoule packaging line machine is used for filling and sealing different liquid and semi-liquid drugs in small containers.

However, you can also find them in different industries where packaging and sealing substances and such products.

Ampoule Filling Line

Usually, you will find ampoule filling lines in two main categories, which include the following;

Fully Automatic Ampoule Filling Line

In a fully automatic unit, all the equipment are wholly-integrated to function together as a single complete unit.

fully automatic filling line

It consists of washing, sterilization, filling, sealing and labeling machines, all programmed to function accordingly.

Thus, this type of ampoule filling line does not require human intervention since all the operations are controlled and monitored from the control panel.

In other instances, this type of line is known as a high-speed ampoule filling line.

Essentially, it can package as many ampoules as possible within shortest time depending on the settings, product and size of the container.

It is also highly efficient and rarely breakdown easily since the system easily monitors all the functions and detects possible malfunctions.

Semi-Automatic Ampoule Filling Line

This ampoule filling line variant is more or less similar to the fully-automatic type, albeit in key aspects.

Ideally, it has several automated functions, but a few are operated manually.

In other words, it means that human involvement during production process is often required when using this machine.

semiautomatic filling line

As such, it is a bit slower than fully automatic unit, but it still serves the purpose efficiently in ampoule filling and packaging process.

Besides, it comes out as a cheaper option for fully automatic units; hence you may consider it when operating within a tight budget.

Nevertheless, some notable machines integrated into ampoule packaging line include the following;

Ampoule Washing Machine

Also referred to as ampoule washers, it is particularly designed for washing ampoules.

ampoule washing machine

While at it, this machine ensures there is minimum contact of machine parts with the ampoules hence complying with the required cGMP standards.

Ideally, the ampoule washer features a gripper system that holds the ampoule from the neck and inverts it until the washing operation is complete.

Once the ampoule is washed, it is released into outfeed feedworm system in a vertical posture to ensure a positive wash.

It is ideal for washing 1ml to 20ml ampoules with assistance of changing parts.

Sterilization Tunnel

This equipment is designed for sterilizing and depyrogenation of cleaned ampoules.

Transportation of glass ampoules in the tunnel through a stainless steel wire conveyor from the ampoule washer to the sterile area.

ampoule sterilization machine

Ampoule Filling And Sealing Equipment

The role of ampoule filler is to fill different packages of pharmaceutical glass ampoules accordingly.

Ordinarily, the ampoules are filled with liquid and purged with nitrogen gas before sealing using combustible gases.

It has a specially designed filling pump for accurate liquid filling with neck centering during filling.

Immediately after filling the liquid, ampoules are sealed to avoid possible contamination of the product.

Ampoule Inspection Machine

It is designed to examine and ascertain the ideal injectable glass ampoules that meet the required conditions.

A typical ampoule inspection unit has four tracks fabricated using nylon.

It also has 6-roller chains with a spinning assembly made of A.C drive rejection units.

All the contact parts of this machine are made from approved stainless steel material.

Ampoule Labelling Machine

This high-end equipment is designed to perform a wide range of labeling operations on different glass ampoules.

ampoule labelling machine

You can install a printer onto the machine for printing different elements such as batch number, manufacturing date and other relevant details on the label.

Besides, you can install a camera for checking barcodes and system print.

It uses a wide range of materials such as transparent labels, paper labels, self-adhesive stickers and BOPP labels.

Ampoule Counter Machine

This specific machine counts ampoules accurately to ensure full responsibility before moving to secondary packaging.

ampoule counter machine

Ordinarily, human error during counting is likely to cause product recall; thus, automation machinery suffices in such instances.

Moreover, this machine can detect fallen or misplaced ampoules and identify those with wrong shaped caps and color6s etc.

There is a thin line between ampoule packaging line and vial packaging line.

In essence, it means you can use the machines interchangeably to pack products in these two types of small containers.

Ordinarily, the working principle of both ampoule and vial packaging lines is more or less similar.

The fundamentals features in these two lines include the following;

- Cleaning-in-Place (CIP) and Sterilizing-in-Place (SIP)

- U-Shape with wall installation

- Restricted Access Barrier System (RABS)

Hence, attaining optimum production efficiency requires setting up vial and ampoule packaging lines in a U-shape with wall installation.

It greatly reduces space needed in highest cleanroom class.

Besides, vials and ampoules packaging lines increase tend to increase employee productivity.

Essentially, it creates less movement that the operators need, especially between different cleanroom zones and this increases productivity.

RABS, in these packaging lines, reduce contamination risks in a cleanroom since they allow most processes to be undertaken with doors closed.

And the CIP/SIP systems in these machines also reduce contamination risks.

In essence, ampoule packaging line consists of several parts and components assembled and integrated to offer a single functional unit.

The notable parts and components include the following;

a) Conveyor belt; for conveying ampoule containers from the filling station to the receiving station.

b) Filling tank; which feeds the liquid and acts as a reservoir tank for the entire filling operation.

It is always refilled, in case, the liquid is depleted.

c) Stainless steel belt; designed for loading ampoules and receiving vacuum-packed ampoules.

d) Adjustable volume wheel; used for regulating liquid volume fed in inside the ampoule bottles.

e) Plunger; ideal for pushing or squeezing liquid into ampoule container.

f) Exhaust fume excavator; designed to channel out any fumes produced in ampoule sealing process.

g) Rotary pump; designed to ensure the right amount of pressure is exerted within ampoule bottle.

h) Volume sensor; produces signal as a response to volume changes adjusted by the adjustable volume wheel.

i) Needle bevel; allows liquid passage into ampoule bottle.

The working principle of ampoule packaging machine is quite straightforward.

Ideally, it starts with the infeed conveyor receiving ampoules from the sterilizing tunnel.

Ampoules are then loaded into the conveyor unit into a screw conveyor placed in upright position.

The screw conveyor then moves the ampoules to the segment wheel to be transported to a conveyor cradle.

Ordinarily, the conveyor cradle can handle 4, 6 or 8 ampoules in a group through the different stations.

Pre-gassing, pre-filling, filling, post-gassing, post-filling, pre-heating and heating are all carried out when the ampoules are vertical.

Essentially, the ampoule packaging equipment performs filling and sealing operations.

In liquid filling function, the manifold is filled while dosing syringes and other stainless steel elements discharge needles.

It also entails micro-fine dosing adjustment volume for filling ampoules and neck centering for appropriate filling process.

Moreover, the machine also applies the principle of no ampoule-no filling.

When it comes to sealing, it starts with preheating using adjustable flames and an oxygen flow meter.

Sealing station also contains oxygen and other combustible gases.

When choosing an ideal ampoule packaging line, it is advisable to look into its numerous features to ensure you get the right one.

Some of the notable features of this equipment include the following;

- High production rate with ability to produce between 120-250 ampoules per minute

- Intended ampoule diameter like 8-head ampoule filling and sealing is ideal for ampoules with a diameter of 9-17mm.

- Aluminum/stainless steel profile frame

- Power consumption of around 380V 50Hz

- Additional accessories like PLC system for monitoring production process.

- 5 kg/Cm2 liquid petroleum gas pressure

- 1kg/Cm2 oxygen and Nitrogen pressure

- 1ml to 10ml filling range for 8-head ampoule filling and sealing variant

- 50mm to 95mm height for 8-head ampoule filling and sealing variant

Of course, this equipment comes in handy in filling and sealing different products into ampoule bottles.

Some notable advantages of using this packaging line include the following;

a. Enhances easy and convenient handling and storage of the drugs at the exact content and amount required for hospital usage.

b. Guarantees higher output since it is quite fast, reliable and efficient. Essentially, this increases sales turnover and business profitability.

c. Improves employee safety within the workplace since the machine is automated and performs all the fundamental operations in production process.

d. Increases efficiency since it rarely breaks down, and accuracy is guaranteed. This ensures orders are supplied within the timelines without any product recalls.

e. The sealing effect of this machine ensures the products are adequately protected from dust and impurities likely to cause contamination.

f. It enhances uniformity in filling and sealing the ampoules, which is imperative, especially in adhering to the required quality standards.

g. The machine features flow meters ideal for ensuring the flames are easy to regulate.

h) Troubleshooting Ampoule Packaging Line

Occasionally, you may encounter a few anomalies when using this equipment.

Such instances, however, are quite rare, but some of the ways of troubleshooting such errors include the following;

- Unleveled fills – Solving this requires the machine to be placed on a flat floor designed for production.

- Head dive failure – Often arise due to mechanical issues. To solve it, ensure you check all the airlines and air compressors to ensure all connections are tight.

- Sealing failure – Solving this issue requires adjusting the sealing unit at a proper angle to guarantee sealing system efficiency.

- Delayed changeover – Make sure the production line has the right spacers.

- Conveyor belt delaying delivery – It is solved by system adjustment accordingly.

Ampoule Filling And Sealing Machine Maintenance

The efficiency of this machine is largely dependent on the routine maintenance undertaken from time to time.

Ideally, you can maintain this machine using different methods, but the notable practices include the following;

- Lubricate all the moving parts of the machine using recommended lubricants. It is essential because it reduces friction in such parts hence extending their durability.

- Use the right diagnostic tools to diagnose the possible errors and issues surrounding the machine. It helps to detect the actual problem and solving it accordingly.

- Always change worn-out or damaged parts using recommended OEM parts. It enhances efficiency and prevents short-term failures of such parts and components.

- Ensure the machine is always clean each time you complete the production process.

This is necessary since it enhances the durability and reliability of the equipment.

Cleaning prevents the machine parts from rusting and corroding, which easily wear out parts.

You can find ampoule packaging equipment in a wide range of sectors across different manufacturing firms.

Ordinarily, this machine is flexible hence used for various applications such as the following;

Pharmaceutical Sector

It is the main area where the use of this machine is quite common since it plays a vital role.

Of course, this is reliably because most drugs and doses are stored in ampoule bottles.

The high demand for these products necessitates need to adopt a fast, effective and dependable ampoule packaging line.

Hence, this industry is among the leading beneficiaries of the ampoule packaging line and its related innovations.

Chemical Sector

Various chemical substances used in different laboratories are often filled in respective bottles using ampoule filling and sealing machine.

There is a need to ensure such chemicals are accurately filled with no impurities.

Food Processing And Packaging

A wide range of food industries processing drinks and beverages use this packaging line for their various products.

It increases production throughput in this sector, enhances efficiency and saves labor and other overhead costs significantly.

Cosmetic Industry

Several cosmetic products are usually packed and sealed using this particular line.

For instance, lotions and natural oils are easily filled and sealed with assistance of ampoule packaging line.

This equipment is usually subjected to different quality standard certifications.

However, these certifications usually vary depending on the specific target market or country of origin.

The notable quality standards, nonetheless, include the following;

cGMP

It refers to Good Manufacturing Practices as enforced specifically by FDA.

Ordinarily, this machine is designed to facilitate processing of pharmaceutical and chemical substances, which require high standard levels.

Thus, cGMP offers systems which guarantee appropriate design, monitoring and control of such machines and their processes.

Besides, it means the machine conforms to up to date systems, which is imperative in enhancing performance and efficiency.

USFDA

This essentially refers to the specific guidance documents published by the FDA regarding the ampoule packaging machine.

Usually, the USFDA standards may reference standards such as guides, practices, test methods, and material specifications developed through voluntary consensus.

CE Standard

It is a quality standard certification ratifying that the equipment conforms to the stipulated health, safety and environmental protection requirements.

This standard is predominantly required in the EU region, especially for equipment manufactured outside the region.

Of course, it is a fundamental standard since it guarantees safety of the machine to the user and the environment in general.

Related Resources:

For all your ampoule packaging needs contact us now.