Linear Weigher Packing Machine Manufacturer in China

Jochamp has a rich experience and reliable linear weigher packing machine manufacturer in the industry. From raw materials to machine assembly and testing, every step is meticulously monitored by experts. Jochamp is your one-stop linear weigher packing machine solution provider.

- Automatic adjustment

- High accuracy and stable ability

- High-precision controller easy operate

- Equipped with an easy-open system

JOCHAMP Linear Weigher Packing Machine

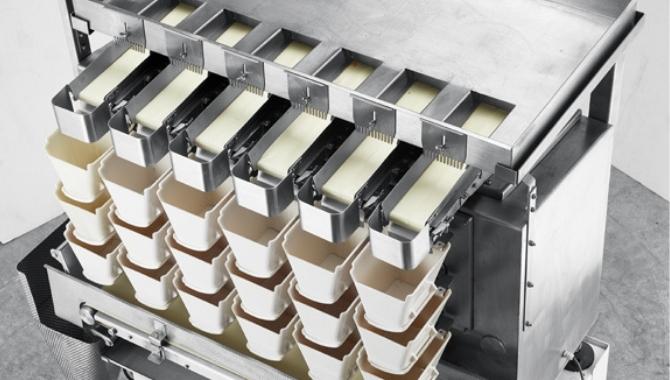

Jochamp linear weigher packing machine has fast, quick, and exact dosing. Makes it simple to integrate with packing equipment and get a consistent package weight. Linear weigher packing machine comes in a variety of versions depending on the product to be filled. It’s manufactured with high-quality sensors and has the newest modular design, auto-adjustment, providing monitoring, convenience, and stable performance. The structure is entirely composed of stainless steel.

You can find your desired linear weigher packing machine at the best rates and in excellent condition in Jochamp services. We welcome international queries. Contact us Now!

Types of Linear Weigher Packing Machines

Jochamp Linear Weigher Packing Machine Feature

Our linear weigher packing machine has an intelligent machine without making any adjustments to the parts, the packing speed and bag length can be adjusted via the screen.

Jochamp has been a professional provider for almost 15 years. Different packaging materials are enabled by a temperature controller with heat balance. Automatic stop function, safe operation, and film preservation.

Jochamp linear weigher packing machine offers high efficiency to make, fill, seal, cut, heat, and achieve the date/lot number all in one go. These packing machine is ideal for all linear weigher uses.

Jochamp offers low loss, labor-saving, and is simple to operate and maintain. For your customizing linear weigher packing machine, Jochamp is a good choice.

Main Performance And Structure Advantages

Jochamp linear weigher packing machine attribute with high accuracy and reliability, simple to operate high-precision controller, automatic error correction. Furthermore over and under tolerance auto alarms, as well as problem auto diagnosis.

Besides, the anti-vibration and anti-interference super filter function keep the linear weigher packing machine process stable and accurate. If you’re searching for a unique and good quality linear weigher packing machine, Jochamp has the best option to offer for you. Just send your application packing machine, and we will give you the best solution.

Wide Range of Application

Measurement, filling, and other duties can be completed using the linear weigher packing machine. It can be used to package a variety of powders and small particles with good or poor flow properties and consistent density.

It is widely used in quantitative packaging of granular and powdery materials such as salt, sugar, seeds, rice, detergent, coffee, desiccant, powder, and other non-sticky, bulk, or granular materials that can all be packed using a linear weigher packing machine. Bag making, filling, sealing, cutting, counting, and hot pressing codes are all automated procedures by using a linear weigher packing machine.

Linear Weigher Packing Machine Automatic Design

Automatic weighing: adopt advanced imported microcomputer control technology for accurate automatic weighing.

Automatic blanking: strong vibration design, small quick, efficient intelligence.

Automatic packaging: after blanking, a three-side sealing package design is adopted to seal firmly and aesthetically.

Automatic Cutting: automatic cutting is completed for sealing and packaging.

Why Choose JOCHAMP Linear Weigher Packing Machine

Jochamp is a leading linear weigher packing machine manufacturer and supplier in China. We have a professional design institute and a well-experienced staff to manufacture linear weigher packing machines and other equipment. All packing machines have been certified by CE, SGS, ISO9001, and cGMP. With numerous skilled engineers and a wealth of experience in the field.

Many types of packing machines have been built and developed by Jochamp, including linear weigher packing machines and many others. We have made remarkable progress in recent years as a result of our good credit and service. Standard packaging machinery inventory, with a 15-day delivery timeframe.

Many of our customers have been with us for a long time. If you’re a new customer, please email us an inquiry right away.

JOCHAMP Linear Weigher Packing Machine

Jochamp offers advanced technology characteristic, below are some of the characteristics that linear weigher packing machine have:

- Weigh-form-fill-seal type, fully automatic, and efficient.

- A film that is simple to install and autocorrects the film’s excursion.

- Use a sophisticated operating system that is simple to operate and programmable.

- Electric and pneumatic components from well-known brands are used, giving in a stable and long-lasting circle.

- Grand new modular control system.

- Adopt a vibrating feeding system to make products flow more fluently.

- The parameter can be freely adjusted according to production.

Jochamp has professional and trusted services, they are some of the services that we list for all clients worldwide.

- Focus on packing machinery R&D and manufacture for over 15 years.

- All packing machines are certified by CE, SGS, ISO9001, and cGMP.

- One-year quality assurance, lifetime after-sales service.

- Regular after-sales care, giving guidance on maintenance.

- European quality, Asian price.

- Global localized installation, after-sales, and training support.

- One-stop linear weigher packing machine solution.

- Free sample test.

- All types of packing equipment are available to purchase.

Advantages Working with Jochamp

Intelligent linear weigher packing machine was manufactured 4 main weighing and packaging machine including weight checker, linear weigher, multihead weigher, and packing machine. These are provided with 12 months quality assurance and lifetime after-sales service.

Our design, technical and engineering teams create customized weighing and packing equipment solutions to match the needs of our customers. You can choose the design and specifications of the machine based on your applications.

Jochamp pays high attention to pre-sales service and after-sales services support. We ensure that we communicate well to know and troubleshoot the problem 24/7. We’re excited to collaborate with you on new solutions, designs, technologies, and services.

With skilled research and development team, Jochamp guarantees to satisfy your OEM and ODM request. We use our rich knowledge and expertise to create innovative automated systems for packing, labeling, weighing, and handling food and non-food goods.

Related Product

Linear Weigher Packing Machine: The Ultimate Guide

Let’s look at some of the fundamental aspects about linear Weigher packing machines.

Whether you want to learn about features, applications, benefits, classification criteria, and equipment integration, just to mention a few.

You will find all information right here.

A linear weigher packing machine is a self-operating machine you attach to packaging machines whose sole purpose is to weigh product.

The dosing device’s principal role is to separate the product into predetermined doses established by the operator before packaging.

linear weigher packing machine

Linear weigher packing machine possess high-speed, precision weighing and automation degree.

You therefore find their use in quantitative packaging of dry or wet granular food.

Some of these foods include: confectionery, nuts, potato chips, flakes, biscuits, pet food, puffed food, frozen vegetable food, and candy.

Linear weigher packing machine tackles the issue of huge measurement inaccuracies produced by manual weighing.

You find a linear weigher packing machine with the following parts:

- Drive: The drive includes AC electromagnets that control the movement of the belts carrying the product from the weigher.

- HDI Control: This includes a touch screen on which the operator can set desired parameters for the linear weigher packing machine.

- Vibrating Channels: This part feeds product into the weighing hoppers.

The vibrating channel stops when the hopper’s measured weight exceeds the predetermined value.

- Weighing Hoppers: You mount this on the weighing scale that determines the product’s weight. When the product wright in the hopper exceeds the predetermined value, the hopper unloads into the packing machine.

You find the linear weigher packing machine essential in the packaging of granular dry and wet foods in desired quantitates.

This machine consists of vibrating channels that feed product into the weighing hoppers.

You mount the hoppers on a weighing scale(s) that you use to determine the product’s weight.

The vibrating channel stops when the measured weight in the hopper exceeds the predetermined value.

Consequently, the hopper unloads the dose to the packing machine.

You find use of the linear weigher packing machine for dosing granular materials with a unit weight of around 2-3 grams.

You find the following benefits in using a linear weigher packing machine:

- The linear weigher packing machine cuts packaging costs by eliminating need for manual labour which is comparatively slow and expensive.

- This machine safeguards the body from the harmful effects of select raw products as in when weighing manually.

- Using a linear weigher packing machine ensures product quality by having consistent weight for each packaged product.

- When using a linear weigher packing machine instead of manual labour, you can guarantee product hygiene and safety.

- You improve productivity substantially by employing the linear weigher, which can pack up to 50-80 bags per minute.

Some common linear weigher packing machine specifications are as follows:

- Maximum current usage of 5 Amperes.

- Measurement accuracy within +/- 0.5 and 1 percent.

- Packing speed of up to fifty bags per minute depending on the machine configuration.

- Power supply need of 220 V, single phase and a frequency of 50 Hz.

- Wide working weight range between one gram and one kilogram.

- An HDI interface with alphanumeric display for touch controls.

- Capability for integration with other machines and equipment.

- Material discharge through pneumatic pan operation.

linear weigher packing machine

Some common linear weigher packing machine types include:

- Single Head Linear Weighers: These machines have only one feeding head and are suitable for small scale production plants.

- Two Head Linear Weighers: These have two heads which significantly increase the production capacity and thus suitable for medium sized operations.

- Multi-head Linear Weighers: These machines have in excess of two heads and you can find machines with even 32 heads.

You can achieve wide weighing requirement with these machine types and thus support large scale production.

You can complete measurement and filling with a linear multi-head weigher.

You can also package various products with varying degrees of flowability and homogeneous density.

Other notable features of a linear multi-head weigher packing machine include:

- Enhanced equipment speed and anti-interference capabilities by using a digital weighing sensor with high-precision.

- The machine is simple to use, maintain, and operate at a minimal cost.

- Use of modern digital signal processing and a weighing mechanism that is both fast and stable.

- You can vary product specifications to satisfy the needs of a wide range of clients when using his machine.

- You can weigh a variety of materials simultaneously, allowing for mixed-material packaging.

linear multihead weigher packing machine

When purchasing a linear weigher packing machine, consider the following:

- Material Properties: Includes the product’s size, shape, viscosity, and other attributes.

- Precision in Weighing: A good sensor will ensure you obtain a perfect balance of speed and precision.

- Special Requirements: There are different functionalities of linear weighers including: waterproof and rust-proof.

For instance, when you have a waterproof weigher, you can wash it regularly.

- Weighing Hopper Count: You determine a linear weigher’s weighing speed by the hopper count. The weighing speed increases with more weighing hoppers.

The linear weigher packing machine differs for the conventional weigher in the following ways:

Different Test Data Reliability

The sensor weighs employing dynamic situations because the conventional weigher weighs with material addition.

For a linear weigher, where you impact the weighing object, the sensor detects unstable weight resulting in inaccuracies.

Weighing Speed

In a conventional weigher, you undertake coarse measurement and fine measurement the latter taking the longest time and influencing speed.

The liner weigher machine contrarily achieves speeds up to 6 times faster employing rapid optimization and combination computation.

Drop Error

You find this error common in linear weighers causing substantial inaccuracy.

Occurs when the electromagnetic vibrating feeder stops and the weight value in the hopper reaches the predetermined value.

Weighing Range Difference

The weighing range of a linear weigher is greater than that of a conventional weigher with the same accuracy.

Under typical conditions, you can achieve up to four times the weighing range accuracy of a conventional weigher with a linear weigher.

conventinal weigher

Different Working Approach

While feeding, the quantitative automatic packaging scale weighs and continues feeding until you obtain desired weight data.

A small discrepancy between the target weight and obtained weight requires adjustment through fine measurement.

A linear weigher employs the permutation and combination principle in the automatic optimization and calculation of weighing unit’s load.

You find the following interventions handy in increasing the efficiency of a linear weigher packing machine:

- Automating the machine such that it automatically shuts down in case of inadequate material or absence.

This protects the weigher’s operation stability and prevents damage from operating when empty.

- Employ the gain function to modify the amplitude strength and make the material conveying seamless.

- Present the vibration machine’s setup function such that you can independently set up the amplitude instead of applying general setting.

- Set a weighing and counting function such that you can utilize numbers while weighing items during computation.

This provides customers with additional options and is superior to counting in grams.

- To control material addition, apply the primary vibration setting.

- Using a sequential discharge function helps you avoid blockage by discharging product into the weighing hopper in order.

The linear weigher packing machine combines modern technology to enhance performance and efficiency.

You ensure consistent output by ensuring proper use as well as daily maintenance.

Some of the precautions when using a linear weight packing machine includes:

- Before leaving their positions, shift workers must clean up the machine by removing dust, discharging water, and powering down.

- Make weekly inspections of the machine’s transmission and moving components, tightening loose parts and oiling movable parts.

- Personnel trained in debugging should master the machine’s performance, operating modes, working state, working methods, and common error diagnosis.

- The operators of a linear weigher packing machine need adequate training allowing them to master the setup and packing methods.

Additionally, they should be capable of debugging and adjusting the machine parameters easily.

- You should not allow untrained persons to operate the linear weigher packing machine. Furthermore, clean both the internal and external features of the computer box daily ensuring no loose wiring.

The following maintenance interventions are necessary for a linear weigher packing machine:

- Clean the weighing platform after disconnecting power to prevent electric shock.

You can employ a soaked gauze to wipe the weighing pan and other sections using a neutral cleaning agent like alcohol.

- Use warm water to clean the conveyor allowing simple loading and unloading on a weekly basis. Use warm water and soak the machine’s belt drive for five minutes in boiling water.

- Use a damp cloth and neutral detergent avoiding use of organic solvents like benzene. Such solvents can initiate corrosion to the machine parts.

- Additionally, use damp clothes instead of brushes with metallic bristles to avoid scratches on the machine body.

- Where you use the machine for packaging food products, use neutral detergents, soap or organic solvents for disinfection.

- As a result of the cleaning agents’ adherence causing difficult to eliminate rust, apply cleaning solution.

A neutral detergent or soap can remove rust initiated by salt or iron powder when operating the linear weigher packing machine.

Sometimes the linear weigher packing machine may exhibit undesired responses during operation.

You can employ the following stratagems to troubleshoot your machine:

- First, see if the troubleshooting tips in the product documentation can help you find a quick solution.

You find the simplest explanation is frequently the correct one.

- Check whether power transmission is okay by inspecting the power chords and sockets. It could be the machine was disconnected without your awareness.

- Carry out a cable inspection ensuring the connection is secure without visible damage.

Having a wire exposed, a chord broken or an undesired knot can all contribute to breakage and stalling.

- Carefully identify codes appearing on your machine’s display.

Such codes could be illustrative of issues to do with machine calibration issues and even excess weight on the scale.

- You can troubleshoot an error code by retrying the action resulting in the error code itself. Usually, manufacturers provide documents containing error codes and their indication which can be helpful in the troubleshooting exercise.

- The linear weigher packing machine can also indicate fluctuating readings on the display.

For instance, you can place material on the weighing scale and the reading fails to settles on a constant value.

In this case, it could be your machine needs recalibration due to potential interference from debris which needs removal.

Also, it could indicate old age and time for replacement or an overhaul.

- Furthermore, vibrations close to the scale, as well as air currents from an HVAC system or window can cause drift.

You find many weighing scales in linear weigher packing machines sensitive to even the tiniest gusts or vibrations.

- You can also need to update your machine drivers as a troubleshooting maneuver just like you do your PC.

Engage a manufacturer who offers software support allowing you to carry out updates via USB.

You can integrate the following equipment with your linear weigher packing machine:

Belt Feeders And Screw Feeders

Belt feeders constitute short conveyors designed to regulate material flow.

This is by withdrawing material from one location and certifying equipment downstream receives the correct volume.

Screw feeders measure bulk items at a precise rate with a standard conveyer fed by another.

The material amount discharged is usually directly proportionate to that amount introduced at the entrance of a screw conveyor.

Discharge Chutes

A discharge chute receives material from a belt drive and directs them to the desired location.

Dust Collection System

A dust collector’s setup consists several pieces working together to provide a safe permissible exposure limit for dust particles.

Such a system will include a catch hood, ductwork, an air mover, and intake and exhaust ducting.

Outfeed Conveyor

The outfeed conveyor transfers filled and weighed packs from the weighing platform to a defined height or the delivery container.

Surge Bins

You find these at the inlet as bulk storage containers which you can utilize for extra product storage. You can also employ them as part of a material moving system.

Supply Hoppers

You typically connect these to weighing and filling systems, thus allowing consistent flow of material to the weigher.

Single Head Linear Weigher

You find the single head linear weigher packing machine ideal for free-flowing products at low speed.

These products include spices, coffee beans, granulated items, ground coffee, confectionery, grated cheese, dried fruit, and powders.

single head linear packing weigher

You can achieve good accuracy and speeds reaching 10 fills per minute, depending on the product quantity and product type.

Two-Head Linear Weigher

Two-head linear weighers are ideal for both mid-scale and large production operations given their excellent speed and weight accuracy.

two head linear weigher

You can implement this machine both automatically and semi-automatically while using vibration and belt drive weighers.

More Resources:

For all your linear Weigher packaging machine, contact us now.