Multi-Head Weigher Packing Machine Manufacturer in China

Jochamp is an experienced manufacturer of high-speed multi-head weigher packing machines that have high accuracy in quantitative weighing and packaging. We offer the multi-head weigher packing machines with a one-year warranty.

- Over 15 years of experience

- Complies with the standards of ISO, CE, SGS, & cGMP

- High-quality at very affordable prices

- Offers custom multi-head weigher packing machines

Jochamp Multi-Head Weigher Packing Machine

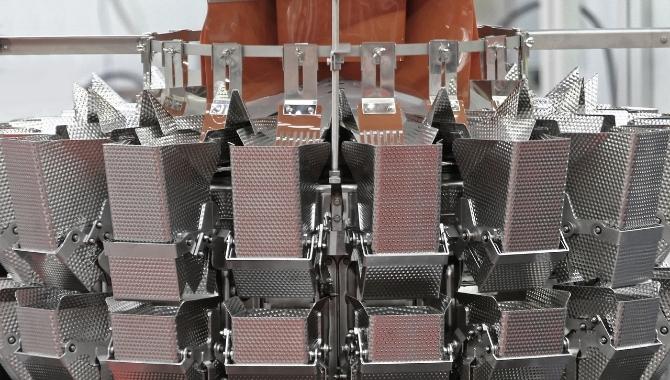

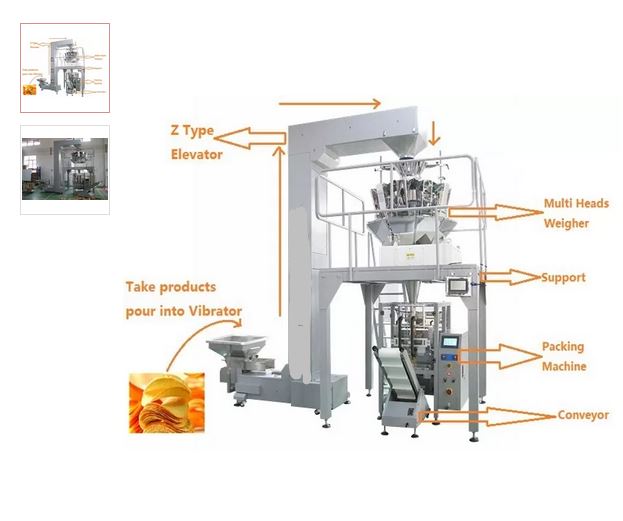

The multi-head weigher packing machines are mainly equipped with vertical form fill seal packing machine, multi-head scaling weigher, bucket elevator, Z Conveyer, working platform, and more. They are commonly used for weighing and packing bulks, solid, or pieces products.

Moreover, the multi-head weigher packing machines have high-speed packing, highly accurate weighing, and stable operation. They can form bags made from a variety of packing materials such as paper laminating film, laminating film, aluminum foil, and many more.

The multi-head weigher packing machines are also made from high-grade stainless steel to guarantee food safety and hygiene. They have high corrosion resistance, automatic shutdown function, low noise operation, and ease of operation.

At Jochamp, we offer many different types of multi-head weigher packing machines for you to choose from. If you have specific needs in mind, feel free to contact us! We are offering customization services.

Types of Multi-Head Weigher Packing Machines

Jochamp Multi-Head Weigher Packing Machine Advantages

The multi-head weigher packing machines are easy to operate. In fact, one person is enough for operating the machine. Due to that, you will require fewer workers and your labor costs will be lessened.

The surface, body, and other components of the multi-head weigher packing machines are made from high-grade stainless steel. And stainless steel is very easy to clean, hygienic, and safe for food.

The multi-head weigher packing machines have excellent resistance to corrosion and rust. That is because they are made from material that is highly corrosion-resistant such as stainless steel.

Jochamp has the expertise in manufacturing custom multi-head weigher packing machines. We can manufacture them based on your requirements and deliver them within 15 days.

Why Choose Jochamp Multi-Head Weigher Packing Machine

- Rich Experience – Jochamp has been manufacturing all types of multi-head weigher packing machines for more than 15 years. We also have an experienced engineer team and after-sales service team to serve every customer.

- On-Time Delivery – We ensure on-time delivery through our standard process management system.

- Quality Services – We are offering lifetime after-sales service, 7×24 hours quick response service, and regular after-sales care. We can give you guidance on the maintenance of the packing machines.

- Quality Guarantee – Jochamp fulfills a strict quality control at each stage of the multi-head weigher packing machines production process. From raw material to final products, from RFQ (Request for Quotation) to PO (Purchase Order), from delivery to documents, every process is reviewed by our well-trained and professional quality control specialists to ensure your satisfaction.

Variety of Bag Types

The multi-head weigher packing machines can form many different types of bags and pouches such as:

- Quad seal stand up pouch

- Spouted pouch

- Pillow bag

- Brick shape bag

- Flat bottom stand up bag

- Gusset bag

- Resealable zipper pouch

- Slider zipper pouch

- Other customized premade bags or pouch

Moreover, the bags can be added with easy tear notch and holes such as Euro slot and round holes. Various sealing patterns such as fin seal, lap seal, and other seals are also available.

Multi-Head Weigher Packing Machine Characteristics

- Automatic alarm protection function – to minimize the loss

- Automatic process of measuring, weighing, bag making, printing, feeding, filling, etc.

- Made from food-grade and corrosion-resistant stainless steel that complies with the GMP standards – to guarantee food safety

- Touch screen PLC intelligent control system – for easy operation

- Capable of making various types of bags

- Easy and quick to change bag size without a complicated process

- Uses electric and pneumatic components from famous brands – for stability and long service life

- Has optional devices such as an automatic film correction motor, heat transfer printer, anti-static device, and more.

- Auto-detection function – the bag can’t be fed or heat sealed if the machine detects that the bag is not open completely; therefore, the bag can be recycled

- With servo motors – to achieve accurate positioning and packaging and for stable, smooth, and high-speed operation

- Temperature controller – to have stability in various temperatures

Jochamp – Multi-Head Weigher Packing Machine Manufacturer in China

Jochamp is a global supplier of multi-head weigher packing machines for over 15 years. We are manufacturing them in accordance with the standards of ISO, cGMP, CE, SGS, and other international quality standards. Also, we manufacture them from high-grade raw materials to ensure their quality.

Our multi-head weigher packing machines have a low failure rate, precise structure, low defective rate, long operating life, and low power consumption. In only one operation, they can accurately weigh, fill, seal, form bags, and print labels, codes, batch numbers, dates, etc.

Moreover, Jochamp has expert engineers and more than 3000 square meters factory that enable us to produce a wide range of high-performance multi-head weigher packing machines. We also have the ability to customize them in accordance with your specifications. For your inquiries, feel free to leave us a message.

Jochamp Multi-Head Weigher Packing Machine

The multi-head weigher packing machines can be used for quantitative weighing and packing solid, bulk, and pieces materials. They are suitable for packing and weighing food and non-food products such as:

- pet food

- cheese

- candy

- coffee bean

- cereal

- nuts

- rice

The multi-head weigher packing machines have a lot of features such as:

- Energy-efficient

- High packing speed

- Easy to clean & hygienic

- High corrosion resistance

- Long service life

- Low loss

- Easy maintenance & installation

- Low defective & failure rate

Custom Multi-Head Weigher Packing Machine to Skyrocket Your Business

The sachet filling machines have low power consumption, strong corrosion resistance, and high packing speed. They are commonly used for packing liquid products such as shampoo and sauce, powder products, granular products, and many more. Also, they can be customized to form back-sealed stick packs, 3-side seal sachets, 4-side seal sachets, and many more.

The auger filler packing machines are ideal for filling and packing all-dry powdered products and granular products such as sugar, chemical powder, spices, baking soda, flour, and many more. They are widely used in the pharmaceutical, cosmetics, food, and chemical industry.

The linear weighing packing machines can be used for weighing and packaging granulated products and powder products such as seasoning powder, sesame, rice, salt, milk powder, etc. They are eliminating the need for manual weighing, filling, and packing. As a result, you can have accurate and fast weighing.

The single-lane stick pack machine is suitable for packing powder, granular, cream, and liquid products such as coffee powder, ketchup, soy sauce, and so on. It can form narrow and long pouches. Typically, it has weighing and various dosing systems depending on the materials that will be packed.

The weighing and packing machines are used for precise weighing and quantitative packaging of a variety of materials. They are mainly composed of a feeding hopper, storage hopper, weighing hopper, weighing sensor, discharge hopper, discharge gate, and more. Also, they have high weighing accuracy and high packing speed.

Related Product

Multi Head Weigher Packing Machine: The Ultimate Guide

In this guide, you will find all information about Multi Head Weigher Packing Machine such as features, parts, working principle, types, applications, etc. So, if you want learn more about multi head Weigher machine, read this guide.

A multi-head packing machine is also known as a combination weigher packing machine.

It is comprised of two main parts; the multi-head weigher and the packing machine. You can use a multi-head weigher packing machine for rapidly weighing accurate incremental volumes of granular and other irregular-shaped products.

multi head packaging machine

The products are then packed into containers according to the specifications fed in through the programmable logic controller (PLC).

You can use a multi-head weigh packing machine for applications that are critically reliant on speed and accuracy.

It is ideal for weighing and packaging granular products, most irregular food materials.

You can also use this machine for other manufactured hardware materials such as plastics and resins.

Specifically, you should consider a multi-head weigher packing machine for:

Packaging Of Sticky Products

You can use your multi-head weigher packing machines to weigh and package sticky food products such as whole and pastes of fish, cheese, poultry, meat, etc.

You can consider screw feeders or belts for conveying these sticky products since vibration alone will not be effective on them.

Granulated Products

A multi-head weigher packing machine is the most ideal equipment for fast and accurate packaging of powdered and granulated products.

You can use it for products such as loose tea and granulated coffee.

The machine will move these products along the processing and packaging line chain through vibration.

Fragile Products

You can use a specially customized multi-head weigher packing machine to package delicate confectionaries such as biscuits and chocolates.

These customized machines possess cautionary inserts and less inclined descent angles that enable them to handle brittle products.

Complex Products

You can also use a multi-head weigher packing machine to package a mixture of assorted food products. You can optimize the distribution system of your multi-head weigher packing machine.

Hence facilitate an easy and efficient mixture or compartmentalization of different food products in a single package.

You can also package other types of food and feed products using this type of packaging machine. These products include nuts, fruits, pet food, edible seeds, frozen food and feed, puffed food, etc.

A multi-head weigher packing machine is a complex, multi-component machine that has its parts assembled for the sole purpose of precise and fast packaging.

A basic multi-head weigher packing machine constitutes the following components:

Feeding system: The feeding machine is responsible for supplying your products to the multi-head weigher machine.

This machine is connected to the multi-head weigher through a conveyor and pushes the products through constant vibration or other suitable mechanisms.

Conveyor: Most multi-head weigher packaging machines use Z-Type conveyors for their convenience.

It is responsible for delivering the products into the multi-head weigher.

Multi-head weigher machine: This component precisely weighs the bulk product fed in through the conveyor. It is made up of the following components:

Main vibrator: This is located in the top cone of the weigher and is responsible for distributing the product to the linear vibrator.

Linear vibrator: This component causes the linear vibrating pan to channel the product to the feed hopper.

Feed hopper/Intermediate hopper: It is responsible for redistribution of the product to the underlying weigh hopper once the contents of the latter are redistributed.

Weigh hooper: This component is responsible for detecting the actual weight of the product and conveying the information to the controller for decisions on which of the allotments to be combined.

Packing machine: This component is responsible for filling the products into packages and sealing the packages accordingly.

Finished product discharge section: This component is the depository for the completed products.

multi head weigher parts

As the name suggests, a multi-head weigher packaging machine has multiple components.

The first component is the multi-head weigher which is attached to the product in-line packaging system to achieve desired packaged end product.

Multi-head weigher has a pool hopper that receives the products to be packaged.

Additionally, fed-in products then move to the weigh-hopper as more space is created when products exit terminally.

The movement of your products through the packaging system will be facilitated either through vibration, centrifugal force, or gravity.

Also, weigh hoppers measure the weight of products they hold incrementally and add them to achieve the target weight previously set in the PLC.

Once the computerized weigher determines the ideal combination of product weights that sums up the target weight, it is transferred to the bagmaker or the packaging machine underneath it.

The product undergoes the processes of the packaging machine and the finished packages/sachet/cartons are dislodged in the output section.

A multi-head weigher packaging machine should possess the following key features:

- Highly reliable

- High packaging efficiency

- Precise and fast packaging

- Easy to use, clean, and maintain

- Support a broad range of application

- Possess multi-stage weight calibration

- Automatic product feeding mechanism

- Smart fault/failure alarms

There are different types of multi-head weigher packaging machines classified according to the level of automation.

These include:

multi head weighing machine

Semi-Automatic Multi Head Weigher Machine

These multi-head packaging machines require the full-time intervention of an operator. They have at least one of their functionalities automated.

Most semi-automated multi-head case packers have automated case management functionality by default.

These packers are a great selection if you have to package a wide range of assorted products using a single machine.

semi-automatic multi packing machine

You can easily customize these machines to the requirements of your line production needs.

Fully Automatic Multi Head Weighing Machine

A fully automatic multi-head weigher packing machine offers superior performance than all other types of packaging machines described above.

The operator is only involved in setting packaging parameters in the control panel.

Also, the machine performs all the packaging processes after the packaging parameters have been set.

automatic multi head weigher packing machine

This machine is critical in high volume production and has a higher packaging throughput compared to other levels of automation.

A multi-head weigher packaging machine possesses the following key advantages:

Precise And Fast Packaging

Precision packaging is potentially the single most important advantage of a multi-head weigher packing machine.

Precision packing is vital in eliminating giveaways and enhancing customer trust in product consistency and integrity in your products.

It increases the yield per product unit and is critical for the large-scale packaging of valuable products like coffee and loose tea.

Ideal For Food Packaging

The design and fabrication of a multi-head weigher packing machine are ideal for filling and packaging food products.

They offer the utmost food safety standards and can be used to package sticky food products that would otherwise not be possible while using generic types of product packaging machines.

Versatile Degree Of Automation

This type of packaging machinery is available in assorted levels of automation. Fully automated multi-head weigher packing machines are available and can be suitably integrated into production lines that produce voluminous quantities of a specific product.

On the other hand, you can select manual machines if your production line is not as demanding and semi-automatic machines if you are packaging diverse products.

Selecting a multi-head weigher packing machine is contingent on many factors that affect your operations, either directly or indirectly.

These factors include:

Type Of Product Being Packaged

The machine you select will depend on the nature and types of products you intend to package.

Different products require different machine specifications.

For instance, you will be better off selecting a vertical multi-head weigher packaging machine if you are packaging granulated or powdered products.

Choose a horizontal one if you are packaging solid or block products.

Packaging Efficiency and speed

A multi-head weigher packaging machine is renowned for fast packaging of precisely weighed products. Consequently, it is only reasonable that you select a machine that is highly efficient and fast.

The selected multi-head weigher packing machine should manage to package the product at an optimal speed that will meet the supply requirements of your operations.

You should select a machine that is attached to a multi-head weigher with many heads if your operations demand fast packaging.

Changeover

The type of machine you select will also depend on the variety of products you will be packaging.

You should choose a multi-head weigher packaging machine that offers optimal flexibility for automation and changeover options.

This will enable you to package multi-dimensional products using the same machine.

Supplier

Your packaging machine supplier is one of the most important considerations you have to factor in when selecting a multi-head weigher packaging machine for your production line.

You should select brands from suppliers who have a reputation for producing high-quality and reliable products.

Experienced suppliers manufacture more reliable and efficient packaging machines that produce less waste, package highly stable products, and consume very low energy among other attributes.

Your supplier should also offer exceptional after-sale services. They should have high technical staff that can respond to distress calls very fast in case of emergencies and machine breakdown.

This is a rotary packaging machine that is attached to a multi-head weigher packer.

You can use this machine to package granulated food products and other irregular or bar lump materials such as melon seeds, puffed or frozen food, and snacks.

You can also use them for packaging liquid products into pouches and bottles.

Multi-head weigher rotary packaging machine fills and seals products in a container following a circular motion. The rotary filling process takes place in the filling zone.

The machines have the whole filling process, from start to finish, near the rotating platform. This shortens the time required to fill containers, giving it unmatched packaging speed.

multi head weigher rotary packing machine

It comes with a multi-head weigher with between 25 and 100 filling heads.

A multi-head rotary packaging machine has a compact design with a smaller footprint that is ideal for space-limited operations.

You can easily customize it to your specifications. It is also easy to operate, maintain, and implement a changeover.

Vertical Multi-head Weigher Packaging Machine

This machine comprises a multi-head weigher attached to vertical packaging machinery.

A vertical multi-head weigher packing machine is highly suitable for packaging granulated and powdered products.

It is ideal for packing products like powdered spices, milk powder, coffee granules, cocoa powder, and loose tea granules.

vertical multi head Weigher machine

The weighing and filling tasks will occur in the multi-head Weigher.

Also, the other procedure including product sealing, quality control, and end-of-line tasks will take place in the packaging machine.

A multi-head weigher vertical packaging machine is easier to operate compared to its horizontal counterpart.

This machine is also more suitable for packaging sticky food products. Its orientation favors optimal process flow for sticky products, unlike its horizontal counterparts.

Horizontal Multi-head Weigher Packing Machine

A multi-head weigher packaging machine offers superior packaging of solid food products that require precise measurements.

You can use this type of multi-head weigher packaging machine for packaging your confectionaries, fresh produce, and other solid products that require precise measurements.

The horizontal package machine is ideal for high throughput applications and packages a higher volume of goods compared to its vertical counterpart.

You should also consider a multi-head weigher packing machine if your production line deals with highly diverse product lines.

horizontal multi head weigher machine

It offers superior versatility and you can easily tweak its operation to accommodate a wide range of assorted products.

It also has a faster product packaging speed compared to a vertically oriented multi-head weigher packing machine.

This machine enables you to package very high volumes of solid products within a short time compared to its vertically oriented counterpart.

Products packed with a horizontal machine also possess superior and precise packaging qualities which accord them a top-notch professional appearance.

You can integrate a multi-head weigher packing machine with assorted equipment and machinery to meet the specific requirements of your production line.

The conveyor system and the automatic product feeding machine are the most common equipment used alongside the multi-head weigher packing machine.

You can also configure the machine’s operating system by enhancing its user interface and intelligence for optimal process interaction and performance.

You should consider the following precautions when handling a multi-head weigher packing machine:

- Ensure that the machine is operated by highly trained personnel only.

The personnel should be trained by the manufacturer/suppliers of the machine in diverse aspects such as working procedures, modes of operation, and troubleshooting.

- Clean and fix any loose wiring terminals in the computer box on daily basis.

- For newly installed machines, inspect the mechanical parts and rectify appropriately after a week and thereafter schedule a monthly inspection.

- Ensure that you replenish the oil in the lubrication system appropriately. You have to inspect for leakages and confirm oil levels every shift.

- Ensure that the working area is tidy at the end of every shift.

Also, remember to disconnect gas and electricity after the shift or when then the machine is not in operation.

Other Related Resources:

Linear Weigher Packing Machine

For all your multi-head weighing machine, contact us now.