Vegetable Packing Line Supplier in China

For your packing needs, Jochamp provides a vegetable packing line composed of automated machines used in keeping goods fresh for a long period.

- Offers a full line of vegetable packing machines

- Asian price, European quality

- 15 Days delivery time

- 7/24 Hours immediate response service

JOCHAMP Vegetable Packing Line

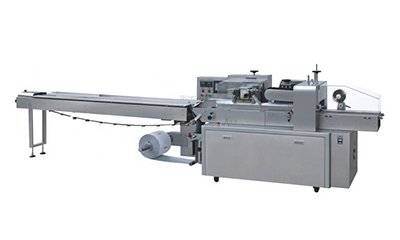

Vegetable packing line includes the following machines – sterilizing washing machine, cutting machine, packing machine, drying machine, de-water machine, labeling machine, and more.

You will need this reliable packing line especially if you’re a company that sells, produces, and distribute canned vegetables, frozen market, or fresh vegetables (e.g. carrots, cauliflower, leafy greens, potatoes, mushrooms, onions, and many others).

Allow Jochamp to serve you a full line of vegetable packing solutions. These packing lines are designed to maintain product quality and retain packaging integrity. We can help you get the right machines for your packaging needs. Rest assured we provide machines that can achieve a safe, money-saver, and profitable packaging line.

Be one of our business partners! For your specific needs, please notify us.

Vegetable Packing Line Benefits

All incorporated machines in the vegetable packing line are easy to operate. All of these machines can improve packaging work efficiency and productivity.

No worries when it comes to the durability level of every vegetable packing machine. At Jochamp, we guarantee you will get durable with premium quality machines.

Sterilizing washing machine, which is included machine in vegetable packing line provide efficient cleaning. It fully sterilized vegetable-packed items.

The vegetable packing line is food grade. It means that all the included machines can provide safety to the vegetable products against impurities or bacteria.

Vegetable Packing Line: How Your Business Benefit?

Vegetable Packing Line keeps products surviving for a longer time. You will need this if you’re company focuses on supplying vegetable products. Its further social advantages include:

- Eliminates or reduces product damage, food microbial load, and conserves energy.

- Needs less waste management and disposal because it motivates the ‘recycling’ of leftover foods (for use as pet food or green waste).

- Prevents adulteration possibility and tampering.

- Vegetables are presented in a proper sanitary and ideal manner.

- Displays food info and helps customers make informed purchases.

Custom Packing Process

The vegetable packing line includes custom processes like vegetable sorting, initial sanitizing, lifting, vegetable cutting, secondary cleaning, vacuum packaging, and vegetable centrifugal dehydration. This process can be customized based on your needs and plant.

Sorting process – This is the first step. It uses a selection table where vegetable passes through for easy selection. The unqualified vegetables will be discarded.

Washing process – A washing machine is used in washing vegetables/fruits. The machine is able to remove vegetable residues such as pesticides and mud.

Cutting process – According to your desires, the vegetables can be custom cut into further shapes, slices, strips, and shreds. We offer advanced cutter machines for this process.

MACHINE QUALITIES

- User-friendly and simple to operate controls in one mobile control panel.

- Empty bag containment; if there is no product, there is no bag.

- Memory performance, which allows 99 groups of package specifications to be saved (product viewpoint, packing motion, and bag size).

- Box-motion cutting machine for superior product packing and sleek packaging.

- Cutting preventative measures: after the cutter cuts the product, the machine will stop.

- Pure PE film is used on the machine

- Full controlled core sealing part and the end sealing part movement.

Why Choose JOCHAMP Vegetable Packing Line

Jochamp has the complete equipment needed and technical expertise in the vegetable packing lines. We also understand the newly developed packing methods to provide the expected standards.

Our vegetable packing lines are designed to provide a protective design for packed goods against damages. Whether your company is about selling, importing, or marketing vegetables or fruits, then you need our vegetable packing line. It consists of a complete line of vegetable packing machines including the washing machine, cutters, packing machine, drying, labeling machine, and so on.

If you need our vegetable packing line offers and services, please get in touch with us!

JOCHAMP Vegetable Packing Line

Jochamp vegetable packing line involves custom sorting services, sterilizing, drying out, vacuum package, cutting, slicing, and shredding vegetables. It ensures perfectly sterilized products, all machines included are easy to clean and very hygienic.

- carrot packaging

- leafy vegetables like lettuce

- potato

- red beet

- radish root

- tomato

- shallot

- cabbage

- onion

- okra

- eggplant

- and many others

Plastic Bags. Polyethylene film is the primary material for vegetable and fruit packing. Aside from the low material costs, they are also transparent, allowing for rapid contents inspection, and can accommodate high-quality graphic designs. Plastic films come in a variety of widths and grades, but they can be crafted to stabilize the environmental gases inside the bag.

Wire-Bound Crates. Made out of woods. This material is used widely for packing sweet corn, snap beans, and many other vegetables. Popular for their sturdiness, rigidness, and stacking strength features.

Wooden Lugs and Crates. This one is made for packing stone fruit, potatoes, and apples. There are different sizes which can lift vegetables with 15-, 20-, or 25-pounds weight.

Shrink Wrap. It is the latest packing method for individual products. Vegetables suitable for this packing type are onions, sweet potatoes, apples, cucumbers, sweet corn, etc.

Custom Packaging Lines for Any Industry

The automated packaging line is the packaging process that requires no manual human interference. It comes with numerous machines – bottling and filling machines, carbonators, cleaning machines, heat sealing machines, labeling machines, etc.

Blister packaging line uses PVC and PET materials for packing different commodities. In this type of packaging line, each product is positioned in deep-drawn pockets. It ensures accurate product info and a strong packaging solution.

High speed packaging line is a production line on which finished products are safely packaged. It guarantees product safety during the shipment and handling process. It includes a flow packing machine, folds packing machine, and more.

The food packaging line secures products by packing them in different patterns – boxes, cans, cartons, bags, trays, pallets, etc. All packaging methods can protect products during transportation.

If your company sells or produces pharmaceutical products (e.g. capsules and tablets), then choose Jochamp pharmaceutical packaging line. All machines included in this line limit the particle reproductions and provide precise product info printed outside the packaging material.

Related Product

Vegetable Packing Line: The Ultimate Guide

I know you are probably looking for high quality vegetable packing line.

A reason this guide explores all vital information about vegetable packing line such as features, designs, uses, and classification, among others.

Take a look:

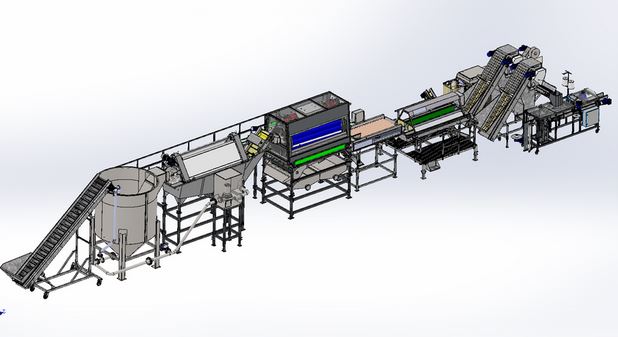

Vegetable packing line is a piece of multifunctional equipment designed to handle different aspects of the processing of vegetables before getting to the market.

This equipment washes, picks, cuts, rinses, de-waters and packs a wide range of vegetable products depending on set parameters.

It is largely used in different vegetable and fruit processing companies to provide the necessary efficiency.

vegetable packing line

Notably, vegetable packing machine is available in different varieties.

It implies that different types are designed for different vegetables.

The available varieties are specific for particular vegetables and fruits.

However, you can find integrated and tailor-made vegetable packing machines designed to package different vegetables.

Nonetheless, the notable types in the market include the following;

Cabbage Lines

As the name indicates, this vegetable packing line is designed specifically for cabbages.

It is available in different sizes and comes with different specifications depending on your packaging demands.

The design of this vegetable packaging line enables easy and comfortable cleaning of the cabbage.

cabbage lines

It cuts off the cabbage stump, and the blowers remove the outer leaves before packaging.

This equipment is fast, and a single user can clean an average of 1ton of cabbage per hour.

Carrot Lines

These are types of vegetable packing lines designed for cleaning and processing carrots.

Ordinarily, carrots are seemingly complicated vegetables to clean and package efficiently.

Since carrots are stored with lots of soil, washing can be challenging because the soil gets sticky, increasing a lot of washing time.

carrot line

However, a perfectly designed carrot packing line cleans and grades carrots into various categories in a product-friendly way.

Onion Lines

Majorly, onion processing line come in handy in removing the tail and separating the loose skin before packaging.

onion line

Upon removal and separation of leaves and loose skin, the equipment selects, grades and packs the product in readiness for market.

Potato Lines

Ideally, different companies handling potato processing have unique demands as far as washing and grading are concerned.

Potato packing lines are available in different designs depending on the type of potatoes you are processing.

potato packing line

Nonetheless, you must ensure you get the right settings based on the specific potato processing you are handling.

Integrated Vegetable Packing Lines

These are essentially types of vegetable packing lines with ability to process different vegetable products on a single unit.

It means you can use this type of packing line to process cabbages, carrots, onions, potatoes, parsnips etc., on one line.

This line supports combination of specific root and tuber vegetables you want to clean, grade and pack.

Integrated vegetable packing line is advantageous because it allows efficient processing without changing the units.

Thus, it is fast, effective, and guarantees desired results as far as vegetable packing is concerned.

Different vegetable packing lines have different features based on a wide range of parameters and type of vegetable it processes.

Hence, it is imperative to look into the specific details when buying this equipment to ensure you obtain one with right features for your application.

However, some primary features of most vegetable packing lines include the following;

Stainless Steel Construction

The framing and various moving parts of this equipment are made using sturdy stainless steel material.

Of course, this material is notable for its excellent tensile strength, making it hard-wearing and, in the long run, increasing its service lifespan.

Stainless steel is also hygienic, which is a fundamental aspect of any food handling equipment since it is easy to clean and maintain.

Furthermore, this material is visually appealing to the eye, increasing its overall value.

Highly Automated

Most parameters of a typical vegetable packing line are highly automated.

Automation, in this aspect, is imperative because it ensures high efficiency, performance, speed and throughput.

Besides, this feature guarantees accuracy, especially during packing based on the settings.

Low Energy Consumption

A typical vegetable packing line is energy efficient because of most of its automated parameters.

Low energy consumption thus means that you save a reasonable amount of money during production process.

Of course, this is fundamental because it increases profit margin, which is integral to business sustainability and growth.

Highly Reliable

The automation functions make vegetable packing line highly reliable.

It performs all operations according to the settings, increasing precision, performance and efficiency.

Easy To Operate

This equipment comes with well-labelled buttons for different functions.

In essence, operating this instrument does not necessarily require specialized skills.

You only need to press a particular button based on the specific function you want to attain.

Customizable

You can customize vegetable packing line to suit the various prevailing packaging demands.

Often, some enable you to scale it down or up depending on production needs.

It is also possible to customize it based on type of vegetable you are processing, workshop area and handling capacities.

Ideally, this is important because it enhances vegetable packaging processes efficiency and inhibits wastage.

This equipment is multipurpose, and thus you can use it to attain different functions in a typical vegetable processing setting.

Some notable uses of a typical vegetable packing line include the following

Grading

It merely refers to sorting and separating vegetables and fruits in different grades based on size, color, shape, and volume.

The essence of grading, in this case, is to arrange the products for marketing according to price value.

This equipment uses stainless-steel grading rollers, which increase gradually over various grading sizes

Cleaning

Vegetable packing line has a lavatory water tank designed for washing specific vegetable or fruit products.

It agitates produce inside the tank to deliver maximum cleaning results.

Cleaning removes wax, dirt and pesticides from the fruit and vegetables before undergoing other processes and ultimate packaging.

Furthermore, water used to clean the product is recirculated in the water tank and reused for cleaning more vegetables.

Cutting

This is a fundamental function of this machine, especially when you are processing root vegetables.

It basically chops off the unwanted parts and separates them from the vegetable before moving to the next phase.

Polishing

It is the act of applying a wide range of organic compounds on surface of vegetables and fruits during processing.

The essence of polishing or waxing is mainly to improve the appearance of such products.

Polishing gives vegetables a premium look since it eliminates irregularities in the product and enhances their shelf-life.

Inspection

This refers to sorting any waste between products like rotten or damaged pieces and deposited on a waste belt.

Vegetable packing line features conveyor belts that can dispose of the wastes directly into a box or another waste belt.

Packaging

This equipment has box fillers designed to fill out boxes of different sizes efficiently and in a product-friendly method.

The design of vegetable packing line features a reduced fall height that enables it to fill out continuously when boxes are replaced.

An advantage of using this machine is that you can always assemble or disassemble specific components depending on your processing and handling capacities.

Packaging fresh vegetables is an integral step in the journey from grower to consumer.

You must use convenient containers to handle, transport, and market the fresh produce.

The market currently has over 1,500 types of packages used for new materials and concepts.

Ordinarily, container standardization for packing vegetable is one way of reducing cost.

But the several options available in the market due to market demands make it difficult to stick to container standardization in this industry.

Nevertheless, you need to know some fundamental packaging tips for a fresh vegetable to enhance product quality and shelf-life.

Some essential vegetable packaging ideas are as follows;

Use Biodegradable Materials

Consider packing vegetables in biodegradable or recyclable packaging materials.

Many consumers buying fresh produce in different markets worldwide tend to be the most concerned regarding environmental issues.

Include Graphics On Packaging Material

Your vegetable packaging material should incorporate a few graphics for sales appeal.

Ordinarily, you need to be creative in your packaging elements to boost your sales demands easily.

Distinctive lettering, multi-color printing and logos are the common graphics you can incorporate.

Aim For Longer Product Shelf-Life

The specific material you use for vegetable packaging should guarantee a longer product shelf-life.

Usually, vegetables are highly perishable products and packaging style, and material determines their shelf-life.

Several factors affect market forces; thus, a specific timeline for selling the goods is never guaranteed.

Hence, to reduce wastage and save on cost going for an ideal material that offers a longer shelf-life is advisable.

Pack According To Temperature

Temperature changes are common in different surroundings.

Ensure you use the right materials and strategies to prevent vegetables from damaging due to temperature changes, whether in transit or at marketplace.

Flexible Packaging Is Essential

Fresh produce are sensitive thus requires proper consuming handling after purchasing.

Therefore, it is recommended to use a flexible pack that makes it easy for the consumer to carry the product without necessarily touching it.

Minimizing consumer handling of fresh vegetables prevents them from spoiling.

Moreover, flexible packaging offers convenience since they are easy to handle.

Convey Brand Message

Packaging vegetable is an ideal way to market your brand message and convey relevant product information to the consumers.

A well-packaged product and brand information on vegetable packs keeps the consumer interested in more details.

It is important because it increases brand visibility, which, in the long run, increases sales and profitability.

Vegetable packing line offers numerous benefits, which has enhanced the growth of this industry significantly.

The main advantages of this system include the following;

Improves Throughput

Increasing productivity and reducing labor demands are among the core drivers for this particular equipment.

It comes with several automated features; hence the line can run continuously with minimal downtime for maximum throughput.

Essentially, this reduces labor requirements and, in the long run, cuts operational costs considerably.

Increases Accuracy

Accuracy and consistency are among the top elements for consumers in the current market value.

Vegetable packing line has advanced capabilities that guarantee accurate and consistent results from the automated handling process.

It sorts and grades different products into various categories with high precision and uniformity.

Ordinarily, this is beneficial because it enables you to establish specific products for particular markets.

Moreover, it makes it possible for you to determine and project the price value based on the particular product grading.

Minimizes Wastage

The operation process of vegetable packing line allows the user to set determined parameters for different functions.

Hence, this machine easily removes subjective elements from the product and increases efficiency.

Besides, it is designed to handle the product gently, which ensures reduced bruising on the vegetable.

In essence, this equipment reduces wastage immensely, which is integral in cutting operational costs and increasing profitability.

Saves Time

Packing vegetables can be time-consuming, especially if the operations are conducted manually.

It involves numerous aspects that makes the entire process time-consuming and laborious.

However, using vegetable packing line allows you to sort, grade, wash, wax and pack the products within shortest time possible.

Of course, the actual speed is dependent on the features and other capabilities of the equipment.

But an ordinary vegetable packing line packs up to one ton of vegetables per hour.

The importance here is that it allows the products to get to the market faster.

Moreover, it also ensures there is no stock shortage on the outlet shelves.

Boots Shelf Life

Most materials used in packing vegetable products are designed to allow the vegetables to last longer on the shelves.

Ordinarily, this machine takes the products through several stages, including sanitizing where applicable.

Hence, the products will have a longer shelf life, which is integral in preventing losses.

Reduces Potential Bottlenecks And Downtime

Manual vegetable packing is prone to many errors that lead to bottlenecks during production.

Hence, an automated vegetable packing line alleviates such bottlenecks since the machine has integrated components to keep up with production flow.

As such, chances of packaging errors using this equipment are close to nil.

Currently, there are over 1,500 materials used in packing vegetables.

Of course, this makes it a challenge to determine the most suitable one for your needs.

It means you have to be specific and know what’s best for you and the products when looking for the ideal packaging material.

Some elements to have in mind include the following;

Durable Quality

The vegetable packaging material you choose is only effective if it protects the product, irrespective of its uniqueness or innovation.

Ensure the material you choose will keep the products secure as they go through supply chain.

Invest in strong, tamper-proof packaging to avoid damaging the products, which in the long run is usually costly.

Size

The dimension of packaging material for vegetables is an important element to consider when selecting one.

Of course, these materials are available in different sizes, but it is important to determine the best one for your product.

While at it, ensure you maintain consistency in sizing for uniformity and aesthetics.

Eco-Friendliness

Currently, a large percentage of vegetable consumers tend to be conscious of the environment.

Besides, many authorities nowadays enforce the use of recyclable or biodegradable packaging materials.

Therefore, it would be ideal to ensure the specific packaging material you are using can decompose, or it is recyclable.

This is integral, especially in environmental conservation efforts.

Availability

It is imperative to go for a packaging material that is readily available.

The importance of this is it guarantees adequate supply throughout; hence you will never run out of it.

Cost

Always consider the price of vegetable packing material and ensure it fits within your budget.

The truth is you can find extremely expensive materials and also find affordable options in the market.

Hence, it depends on the specific vegetable product and whether the material guarantees a return on investment.

Target Market

Ordinarily, the specific consumer opening the package influences your packaging material decision.

Proper understanding of your market makes it possible to determine the ideal packaging material for your vegetable products.

The working principle of this equipment is straightforward.

Even so, it is important to note that the actual working principle may vary from one unit to another depending on the specific product.

Also, the specific auxiliary equipment integrated into the machine may influence how it works.

Technically, vegetable is fed into the equipment at the infeed end and enters brusher bed.

The force in brusher bed advances the vegetables, which tumble and expose surfaces to brushing.

Brushing removes dirt and sticky compounds from the surface material using forced air from the nozzles.

Vegetable then moves to lavatory water tank for further washing to remove the stubborn debris and prepare the vegetable for waxing.

Wax applicator applies the relevant waxing compound on the surface of vegetables to enhance their appearance and shelf-life.

After waxing, the product moves to the drying bed, where heat blower eliminates moisture to the recommended level.

It then moves to the inspection unit to determine defects and separate them from the god product. The defects move to trash lane along the belt edge through a trash chute.

Vegetable then moves to industrial packing unit for appropriate packaging depending on the grading system.

For any inquiries or questions on vegetable packing line, contact us now.