Leading Top Load Case Packer Manufacturer in China

JOCHAMP is a leading manufacturer of top load case packers which is a highly intelligent machine for automatic cartooning, folding, product loading, and cartoon top-selling in one machine. Our top load case packers are widely used canton-boxed packed products for medicine, cosmetics, healthcare, and so on.

- High-efficiency side loading technology

- Can make 40 cases per minutes

- Automatic case management system

- Single pick-head load capacity from 30lbs

JOCHAMP Top Load Case Packer

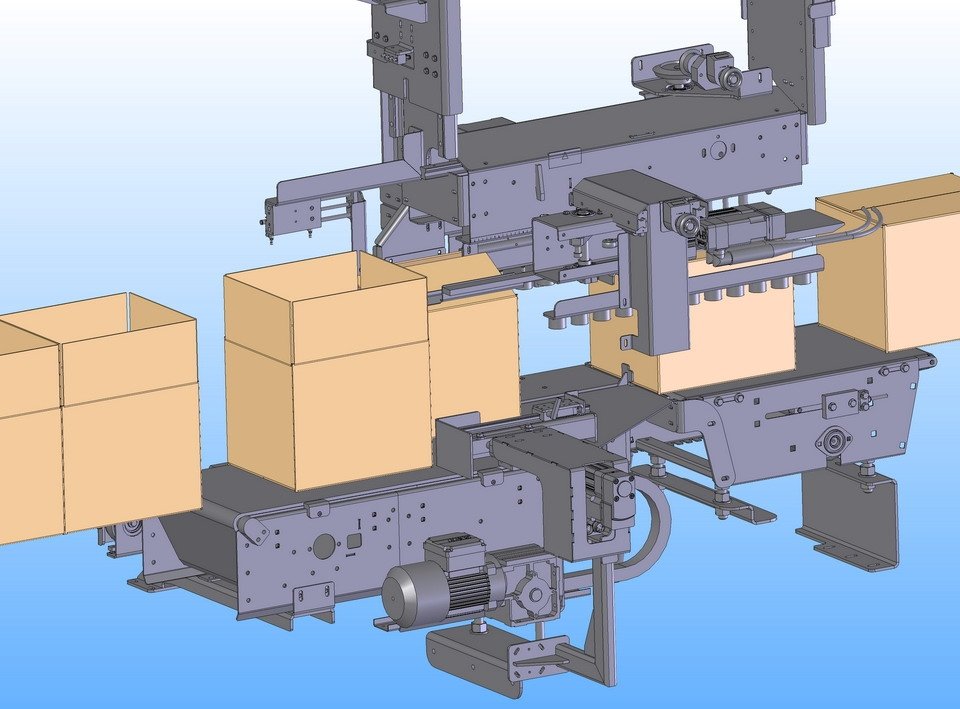

As a supplier of top load case packers, we designed for superior flexibility that can handle a wide cross-section of products, case types, and sizes, for different applications. Our top-load case packer is robotic machines that are often presented as the answer to the increasing economy. We manufactured a top load case packer that offers high performance to achieve higher throughputs while simultaneously multi-tasking.

Our top load case packer has a pick and place feature that can control and manages cases. It can achieve synchronously by securing the case flaps and placing and picking products. This machine can be engineered with a single and dual gantry with a 6 or 3 pick head system and also with dual or single infeed product equipped with automatic case management.

You can message for the inquiry!

JC-504 Top Load Case Packer

The machine integrates the functions of unpacking, packing and sealing into a body frame. Powerful functions, compact design, can make full and rational use of factory layout.

- The whole machine integrates automatic unpacking, automatic packing and sealing. The equipment is small in size and high in automation.

- The protective cover of the whole machine has an open design, and the station is open for easy maintenance and cleaning. It is beautiful and elegant, and fully meets the requirements of GMP.

- The French Schneider high-end PLC control system is equipped with 3 servo motors

- Double servo manipulators cooperate with imported slide rails.

- Germany Festo solenoid valve, AirTAC cylinder, pneumatic assembly design.

- Each station is precisely in place, with photoelectric detection, fault alarm, and material protection.

- Material warehouse inspection, delivery inspection, and tape inspection to ensure that the finished product is

JC-504

- Technical Parameter

- Features

- Optional

| Model | JC-504 | |

| Design maximum production capacity | 360 (box/hour) | |

| Actual production capacity (cases/minute) | Less than or equal to 4 depends on the number of boxing actions | |

| carton size | minimum | 300X200X180 |

| maximum value | 500X400X350 | |

| Packaged object size | minimum | |

| maximum value | 500X400X350 | |

| power supply | AC380/three-phase/50Hz power consumption: 7.5kw | |

| air pressure | Air pressure: 0.6MPa air consumption: less than 1 cubic meter/hour | |

| Dimensions (L×W×H) | 4000*2000*2500 | |

| Weight (kg) | 2500 | |

| main material | Aluminum alloy, 304 stainless steel, carbon steel | |

- The whole machine integrates automatic unpacking, automatic packing and sealing. The equipment is small in size and high in automation.

- The protective cover of the whole machine has an open design, and the station is open for easy maintenance and cleaning. It is beautiful and elegant, and fully meets the requirements of GMP.

- The French Schneider high-end PLC control system is equipped with 3 servo motors.

- Double servo manipulators cooperate with imported slide rails.

- Germany Festo solenoid valve, AirTAC cylinder, pneumatic assembly design.

- Each station is precisely in place, with photoelectric detection, fault alarm, and material protection.

- Material warehouse inspection, delivery inspection, and tape inspection to ensure that the finished product is qualified.

- The adjustment of the replacement specification station adopts the self-locking wrench, rocker and handwheel to exchange quickly and have strong versatility.

case erector

carton sealer

Secondary packaging line integration

carton sleeve inner bag

Labeling Machine

printer

Glue sealing machine

Stainless steel

heavy duty casters

Leaflet Automatic Dispatcher

export conveyor line

JOCHAMP Top Load Case Packer Advantages

We provide top load packers that is reliable for product handling. This machine can able to pack various types of products such as wet wipes packed in flow packs, tubes, or zip packs into cases, cans, cartoons, and many more. It is also known as an integrated handling robot that gently allows to the handling of products that are difficult to pick and achieve the same flexibility.

Our top load case packer has proven performance features. It can erect cases and accurately picks at speed for up to 20 cases per minute. We manufacture a top load case packer that has a unique walking beam and dual-sided opposing vacuum to make and ensure cases all through the closing line station without the need for flight lugs. It is proven and tested that our top load case packer can do a task in a few minutes.

As a manufacturer, we make sure to give high quality including the top load case packer that has a rugged stainless steel frame. That frame was built for three shift per day operations. It has a servo belt that drives the top load case packer to ensure quit and for the high-speed operations. Our top-load packer has also a digital gauge and scale with a pointer that allows for a quick and no tool changeover.

JOCHAMP provides a top load case packer that has durable features due to its quick change-out heads. For being durable all parts of our top load case packer are made of metal, stainless steel, and more. It is also easy to use especially to pick or place assembly with the help of a vacuum or gripped pick that with quick-change tooling to provide precision on product handling.

What is Top Load Case Packer?

The top load’s case packer is a heavy-duty machine that are built to be dependable under multi-shift conditions. It offers fast effective means of case packing multiple layers or products and it is designed for your specifications. Our top load case packers are ideal for flexible packaging solutions. It is the top-loading and collations technologies to ensure optimum reactions between products, machinery, and packaging materials to create the most effective packer for your application.

Our top-load case packer is the number one solution for packaging and accommodates the unique demands associated with pouches, handling bags, trays, cartons, cups, tubs, bottles, cans, and overwrapped products.

At JOCHAMP we offer a unique ability to seamlessly erect, load, and sell top load cases with one compact machine. Our top-load case packer is innovative design features, simple menu-driven combined with advanced servo technology to accommodate a wide variety of product types with less product maintenance and handling.

Don’t hesitate to message us now!

Benefits of Top Load Case Packer

JOCHAMP provide a top load case packer that is suitable for different industry application including food and beverages, cans, and so on. Our top-load case packer is an ideal packaging solution for flexible packaging for different facilities or corporations. Below are the following benefits when using our top load case packer in your business.

- All servo driven

- Balcony design

- Offers compact footprints

- All belt drives give low noise and longer life service

- Has a unique positive dual vacuum case erector

- Provides accurate and fast changeover of less than 5 minutes

- 2-axis servo to place and pick up

- Has a gripper pic with quick-change tooling

- Low maintenance and easy access to all components

- User friendly

Why choose JOCHAMP Top Load Case Packer

As a provider of top load case packers, we ensure to give the high quality and flexible machines for packaging. It can use to pack bags, pouches, and other flexible products. Our top-load case packer is one of the fastest machines for a growing form of packaging in our industry. It is very useful for manufacturers of different types of products, retailers, and for consumers.

Our top load case packer can offer several quality advantages including lightweight materials, can provides customization in packaging size and shapes, ultimate protections, creative graphics, creative graphics, and more.

Moreover, in the packaging industry, the top load case packer is involved from the beginning of large packaging industry. It is commonly used for handling food, picking, placing, palletizing, and case packing. Top load case packer can solve the issues related to a hard to handle products, fluctuating throughput rates, tight plant layouts, and multiple access manipulations. We provide different types of top-hold case packers that are flexible for the packaging industry. Message us now!

JOCHAMP – Trusted Top Load Case Packer Provider in China

As your trusted supplier of top load case packers that can fit into any existing production lines and integrated as part of complete packaging solutions including case erecting, tray forming, robotic palletizing, and sealing.

Our top load case packers are widely used to pack bottles, containers, cartons, bags, widgets, and more. DUCHAMP manufactured a top load case packer to meet the market needs of the packaging industry. These top load case packers from JOCHAMP ensure to give flexible packing patterns including the packing of different products into the same cases.

Message us now!

JOCHAMP Top Load Case Packer

We provide a top load case packer that offers different integration options including the following below:

- Infeed Conveyors. To the manual process

- An inspection System. is the process to ensure that all packages are packed properly.

- Lane Diverters. A design to keep the line organized and efficient for product cumulation.

- Check Weighing. To keep all products packaged consistent with the help of a weight system

- Product Orientation System. To keep products properly oriented to keep safety and security.

- To complete the automated process

- Pallet conveying. The operator can be freed up to other areas or lines or the plant with the help of pallet conveying

- Stretch wrapping. It is used to ensure the packages are protected while shipping.

We manufactured a top load case packer that offers different features that are widely used for different industry and business packaging application. Consider the following below:

- Designed for different variety of flexible packages

- To accommodate any types of products

- A good solution for contact packers, specialty product makers, etc.

- Occupies similar floor space like a hand pack operations

- Offer fully automated performance

- 12 picks or more per minute with a wide case range

- Reduce labor needs

- Adapt to packaging line speed

- Optional integration of case erectors for a complete packing system and more.

Custom Top Load Case Packer to Skyrocket your Business

We provide a top load case packers that offers industrial construction features. It has a robust tube framing and automotive finishing.

As a manufacturer of top load case packer that offers ergonomic design to have many access points for cleaning and maintenance. It is operator friendly and has a touchscreen interface.

We have a professional engineers who plans and make our top load case packer. JOCHAMP provides a customized top-load system for a wide range of end effectors to eliminate change parts and can handle your specific application for packaging.

Related Product

Top Load Case Packer: The Ultimate Guide

Integrating top load caser packer can improve efficiency in your packaging process.

To make choosing top load case packer easier and simple, this guide explores everything you need about this machine.

So, keep reading to learn more.

Top load case packer

A top load case packer is machine that works automatically by loading items into a tray or wrap around case from the top.

You then close and seal the case with tape or glue after completion of the loading process.

Top loading a widely employed method of case packing which you can undertake manually or automatically.

You can employ a top case packer for cartons, flow-packs, flexible pouches, glass bottles, and sachets.

For automatic top-load case packers, you find use of X-Y gantry system, mechanical axial movements or industrial and delta robots.

The choice of movement is dependent on the application, speed, product, and packing type.

When using the top case packer, you identify the following benefits:

i. Branding Possibilities

You can print graphical designs on the wrap-around corrugated cases and shelf-ready trays of top load cases. You find this can serve as an excellent marketing tool for your product.

ii. Multiple Formats

You can form full-size corrugated and solid board blanks when employing the top load case packer. Furthermore, you can operate both the tray and wrap around in the same machine with minor modifications.

iii. Package Protection and Integrity

The top load case packer folds and seals the cardboard around the product providing greater protection and structural integrity. You note that this enables pallet optimization by enhancing case stacking strength.

iv. Sustainable Packaging

You can employ sustainable packaging with top load case packers. This entails the use of natural, ecologically friendly, and reusable packaging materials as well as waste minimization.

v. Saves Material for Packaging

The way you furnish the corrugated blank is such that it meets the product dimensions therefore avoiding waste. Working with cases with lower heights significantly saves on board costs.

Additionally, you glue the industrial flap and seal on the packer, eliminating need for a separate pre-gluing operation. Consequently, you eliminate an extra step between supply and end use. You note that this allows delivery of more cases on a single pallet, positive carbon footprint, and lower logistical costs.

vi. Saves Time

Compared to RSC case blanks, you can fit more corrugated blanks in the magazine of a top load case packer. You will only need to load the magazine fewer times, resulting in enhanced efficiency for other tasks.

vii. Saves Space

Usually you require three separate machines for case forming, loading, and sealing. However, with a top load case packer, you can perform all these operations on a single small machine. You therefore minimize the space requirements for machine installation.

viii.Suitable for Food and Pharmaceutical Industries

You can employ the top load case packer for a wide range of products in the food and pharmaceutical industry. The top load case packer can handle different products safely with large format capability.

Top case load packer machine

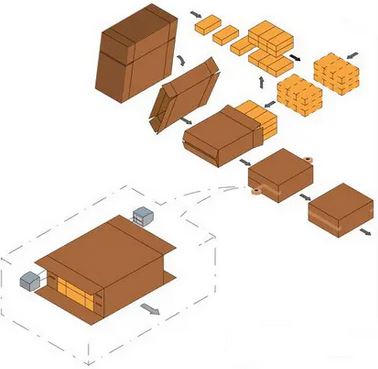

You can classify the parts of a top load case packer into three as follows:

Forming Systems

The forming system is necessary for the formation of the case in which you load the product. The forming system automatically folds cartons and assembles boxes either with covers or without.

You find the following parts in a forming system:

- Carton magazine unit: Usually has a robotic arm that uses suction cups to capture cartons from the magazine.

- Hot glue spraying mechanism: This mechanism adds glue to the flaps holding them together.

- Conveyer: Carries the carton after creation in the mould.

- Hand wheels: Allow you to make changes to the format through adjustments.

Loading systems

The loading system of a top load case loader is necessary for putting product in the formed case. You find the most common options for loading systems to be two axis or multi-axis robotic system.

A multi-axis robotic system typically has a flexible design that fits well in a production line with compact spacing thus conserving space. You find the following parts:

- An electric actuator: Typically consists a pair of orthogonal slide axes and sometimes even six.

- Robotic arms: The arms are necessary for product transfer from a conveyer or platform into the case. You can have different arms depending on your product weight.

Closing Systems

The closing system is necessary to seal the case and its contents thus securing them for transport. You can have a tri-seal, compact right angle, or inline top seal depending on your case design.

An inline top seal for instance can handle different shapes and sizes of carton. Such a closing system can have a performance rate of up to 200 cartons per minute.

Some of the parts of a closing system are:

- Variable Speed Drive System: This determines the performance of the closing system of the top load case packer.

- Turning Chains: These are usually servo-controlled capable of handling bulging and enormous cartons.

Top case load packaging

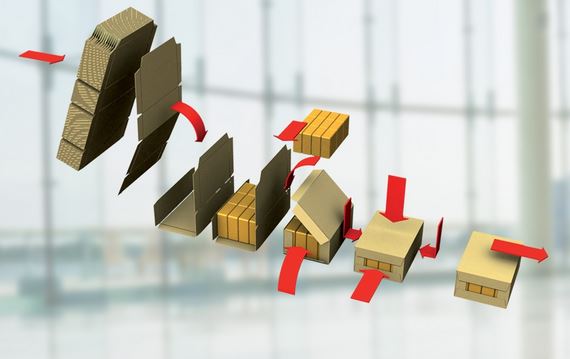

A typical top load case packer features a modular mechanical and control system design. You find this design capable of a variety of product handling systems using continuous or sequential technology.

The working of a top load case packer entails three main processes as follows: case forming, case loading and case sealing. Servo motors drive the case forming process in a compact and positive vertical manner.

A mould intakes carton from a magazine unit and shapes them in the desired form of packaging. A conveyer then transfers the empty case to a loading table. From here, a multi axis robotic system picks and places the product in the box from above in the desired quantity.

The case with contents travels further by conveyer to a sealing section where you seal the top to enclose the products. There are several sealing methods depending on the case design, and you can automatically or manually carry out the process.

You can seal the top flaps with glue or adhesive tape and ensure you square the case. The formation, loading, and sealing stations have a compact and ergonomic design accessible for human intervention.

You can achieve speeds of up to 30 cases per minute depending on the payload, types of products and collations. An automatic visual inspection and sensor system employing x-rays helps you monitor the process to catch errors.

You find the following features of a top load case packer:

- Capability to form and seal the bottom of the case.

- A pick and place system for top loading of the product.

- Stainless steel build ideal for food processing.

- Use of adhesive tape and/or hot melt glue for case sealing.

- Product placement within the box based on form and rigidity.

- A modular structure that is customizable and incorporating numerous components.

- A dispenser for empty boxes employing automation or gravity.

- An erector for forming the box and a roller conveyor for loading.

- Suction cups on a motorized arm for picking and opening the closed carton ensuring maximum precision.

- Manual or automatically insertion of products into the case.

- Automatic or semi-automatic flap opening systems ensuring squaring of the case.

You find the top load case packer ideal for commercial and consumer packaged food, chemicals, and personal care applications.

Most of the products requiring top load case packers must remain upright during loading and shipping. Some of these products include foods such as pies, jars and bottles.

You find use of top case load packers in instances where you need to tightly secure the products in a case.

You can employ a centering frame with fingers for folding outwards the top flaps to facilitate seamless and unencumbered loading.

The centering fingers keep the flaps in the middle in the case of cylindrical items. Alternately, the fingers rest at the case corners when loading rectangular items. It is preferable to employ the adjustable centering frame for a wide range of case sizes.

Top Load Case Packer

You determine that the most prevalent method of case packing is top loading. When carrying out manually, the process is straightforward, and even much simpler when automated.

You can employ top loading for glass bottles, flexible pouches, flow-packs, and sachets. Nonetheless, when it comes to flexible products, you require elaborate evaluation, especially when employing automation, due to reduced flexibility.

For manual stuffing of flexible products, you can easily place partitions where needed, thus maximizing every unit space.

Bottom Load Case Packer

Bottom load case packaging

A bottom-load case packer erects and forms a case that you load from below before sealing. You apply the bottom load case packer to products where lifting using robotic arms for top loading is impractical. Such products can be bulky and fragile such as cakes and other baked products or container with liquids.

A bottom load case packer’s working typically commences with the automatic construction of the carton into a case. You then deliver the product for packaging to the loading station before stacking them in the desired pattern or quantity.

The loading process follows, undertaken from the bottom ensuring the process is smooth as possible. Sealing of the flaps at both ends follows the loading process by employing either glue or tape to adhere the covers.

Wrap around case packaging

When using the top load case packing machine, you load your case from the top either manually or automatically. When loading automatically, pick and place machines are effective and even efficient.

When using a wrap-around case packer, you employ flat sheets of corrugated blanks that are pre-cut rather than the standard box. In comparison to the box, the primary advantage of a wrap-around case is the case-saving ability. You find this is because you seal the minor and major flaps at the sides rather than on top.

You commonly employ the wrap-around case packer for canned foods or beverages. In this case, using corrugated material lowers carbon emissions and results in quicker ROI. You fashion the blanks around the pre-collated product before employing hot-melt adhesives for the sealing process.

Side load case packaging

A side load case packer differs from the top load case packer by virtue of the point of product loading. A side load packing machine loads product from the case’s side, in a top loader, you load product from the top.

Handling structural products or cartons is more common in side load case packing machines. Side load case packing has the advantage of being a mono-block method. Here, the machine constructs, loads, and closes the case while maintaining a small footprint.

You use side load case packing machines to pre-form the collation on low to high speed lines before case formation. When using a side load case packer, the product gets to the loading station before feeding into the case.

The case then continues down the line for flap closing and sealing, possible via use of adhesive tape or hot glue. Side load case packers are essential when working with compact spaces. However, they can only handle a limited number of products.

You can employ the top load case packer for pouches, cartons, flow-wraps, bottles and trays. Here, an X/Y system navigates the products by picking, lifting, moving and dropping them into a case over the top.

You can also employ a multi-axis robot to pick, move, and deposit products into the packaging. Using a robot is more efficient than gantries given their smoother arc movement resulting from their flexibility.

Both sets of motion systems employ vacuum suction to hold items. However, you can employ other gripping tools of a mechanical or pneumatic orientation based on the product.

Vacuum cups work well with items in pouches, trays, pillow bags, and flow wraps since they are light and fragile. Advanced pick-and-place machines can handle heavier items such as bottles in top load case packers.

HSC, trays and RSC are a common feature in top load case packing. You can also employ wraparound enclosures in some specialized applications, albeit to a small scale.

Adding more gantries or robots can positively impact your average top load rate. Case erectors and sealers in top load case packing machines are freestanding making their imprint larger than side load case packers’.

Nonetheless, X/Y gantry cost much less compared to robotic systems. Nevertheless, robotic systems require little maintenance and are capable of repurposing to other functionalities.

The innovative solution of top load case packers targets manufacturers employing automatic or semi-automatic packaging of bags, flow-wrapped items and pouches. A decent top load case packing machine can undertake about ten complete packaging processes per minute.

Where you have completely automated operations, you find use of an integrated case erector and sealer.

Using steel frames for these machines serves to extend their useful service life with their reduced imprint saving on floor space.

When working with different packaging requirements, you can streamline changeover to boost productivity and reduce downtime.

Furthermore, top load case packers employ a HMI which make operation and troubleshooting easier and quicker.

More Resources;

For all your top load case packer machines, contact us now.