Food Cartoning Machine Manufacturer in China

Jochamp is a professional food cartoning machine manufacturer. We provide high-speed machines that seal and protect food products. It is available in a wide range of dimensions, designs, and specifications. Custom your food cartoning machine with us!

- Compact and innovative design

- Low noise operation

- Simple to use and maintenance

- Designed with a PLC control system

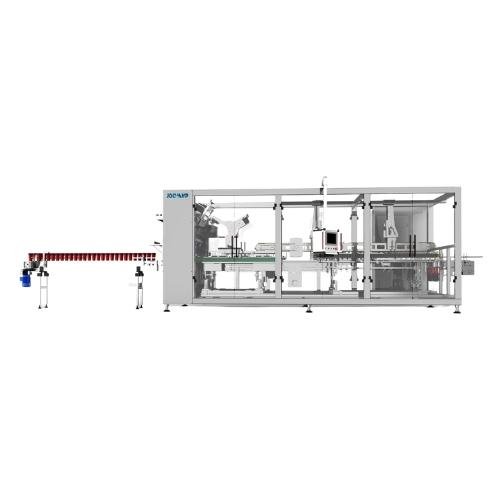

JOCHAMP Food Cartoning Machine

Food cartoning machine is a type of packaging equipment. This machine put food products such as bakery, snacks, ready meals, or frozen products into the carton automatically. The process is open, load, close, and seal cartons. The carton products are now ready for storage, distribution, handling, and marketing purposes.

Jochamp manufacture high-performance and more precise structure machine. It provides a lower defective rate and failure rate. These machines allow for better quality control and broader production flexibility. It also offers greater productivity, safer working conditions, and easier scalability.

For more details about our food cartoning machines, discuss your needs with one of our skilled sales assistants. We will help you check your operations and identify an appropriate solution for your business. Message us now!

Types of Food Cartoning Machines

Food Cartoning Machine Features

Food cartoning machines provide operations increase productivity, reduce operational costs, and improve product quality.

All our custom food cartoning machines are a cost-effective way of packaging and handling products. Direct prices for your specific machine order.

Our high-technology design machines are made from quality steel materials and branded parts. These are the best choice for your business.

Jochamp offers flexibility in the layout design for a custom-tailored food cartoning machine. You can send the specific details now!

Design and Types

Jochamp can manufacture different types of food cartoning machines suitable for your production line. This is available in standard and custom specifications. Some are the following:

- Food Carton Sealing Machines

- Semi-Automatic Food Cartoners

- Food Vertical Cartoner Machine

- Horizontal Food Cartoning Machine

- Automatic (Robotic) Food Case Packing Machines

- Automatic (Robotic) Food Cartoners & Vertical Cartoners

Features and Benefits of Food Cartoning Machines

- Strong steel machine body design

- Stronger rust resistance and longer life

- Automatic or manual feeding

- Equipped with an advanced PLC control system, Touch Screen display

- Stable and easy operation

- Open mechanical design

- Custom mechanical structure of different cartons

- Can be connected to the existing packing line

- Advanced overload protection system

- High speed with maximum output of 50-500 cartons/min.

- Wide range of applications

Strong Metal Construction

The food cartoning machine body is covered with high-grade 304 stainless steel. It is metal surface-treated for durability, corrosion resistance, and longer life features. Plus, our team use internationally renowned brands for electrical appliances and accessories such as Schneider, Siemens, Panasonic, Delta, SMC, Mitsubishi, etc.

The raw materials are thoroughly checked and inspected with meticulous quality control. Our specialists controlled the machine assembly and testing to guarantee functional and high-performance characteristics. All cartoning machines have passed ISO9001, cGMP, CE, and SGS, certifications.

Why Choose JOCHAMP Food Cartoning Machine

Jochamp specializes in manufacturing and selling advanced food cartoning machines. We provide 15+ years of product and machinery expertise. Our machines are made from strong stainless steel for corrosion-resistant properties. The parts are meticulously sourced from international branded brands worldwide.

The machine’s contact surface is drug and food-grade for safety. It is designed with a smaller footprint suitable for simple facility setup needs or space limitations. Jochamp food cartoning machines are user-friendly with a variety of automatic feeding mechanisms, powerful industrial control systems, and more extensive expansion options.

We can customize food cartoning machines according to your specifications. You can provide your logo or design. Jochamp is dedicated to supplying superior quality machines with your budget. If you need a one-stop-solution manufacturer in China, you can rely on Jochamp. Contact us today!

To satisfy your specific requirements, Jochamp provides full customization for your machines. We can etch the logo of your brand on the equipment. These will help your business be more productive than others. Some are the following specifications you must provide:

- Machine size, color

- Production capacity

- Automation level

- Machine’s material and designs

- Maximum output and carton size

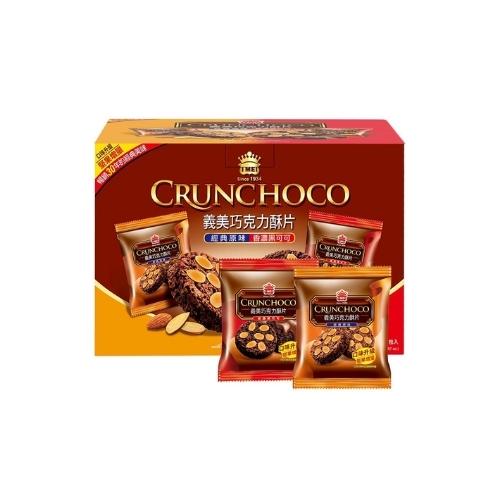

No matter what your food product applications are, our machines are ideal due to their efficient, fast, and affordable features. These are capable of packing goods of different sizes and packaging types such as bags, tins, trays, sachets, etc. The following are some of the products our machine can package:

- Snacks foods, ready meals

- Pet foods

- Milk powder products

- Ingredients and mixed goods

- Frozen products, Confectionery products

- Cereal boxes, bars, bakery products, etc.

Custom Food Cartoning Machine Based on Your Applications

Biscuit Carton Packaging can easily be integrated into other machines to be an automatic whole line. Features a touch screen HMI controls for easy operation. With 15+ years of production experience, Jochamp can design the right cartoning machine for your business.

For seafood products, avail super efficient seafood carton packaging machines at an affordable cost at Jochamp. Our packaging machines provide the perfect presentation for seafood that prolong it’s shelf life.

For fast and convenient frozen food carton packaging, we manufacture perfect package solutions suitable for medium or large-size factories. It has a food-safe and complete stainless steel structure for maximum durability.

For your steak carton packaging, the Jochamp packaging system can satisfy your production. It is made from sanitary packing material, that preserve their product quality and pack securely. All our machines are designed precise packing at a high speed.

We can design a bread carton packaging machine that adopts a uniaxial or biaxial servo control system for reliable and high-efficiency operation. It is compliant with GMP standards and has passed CE certification guaranteeing long-lasting and accurate construction.

For convenient and accurate packing operation, you can rely on Jochamp. Our packaging machines can pack plenty of food products such as various types of candies. It features a hygienic design, easy to clean and maintain.

Related Product

Food Cartoning Machine: The Ultimate Guide

The decision to switch to a food cartoning machine can be challenging.

Not only does it involve the machine specifications, but it also impacts many of your processes and staffing decisions, not to mention the potentially massive impact on your bottom line.

This article aims to help you with this process.

It covers the basics of food cartoning machinery, which is essential to choosing the right type of machine for your business.

After all, you don’t want to spend thousands of dollars on features you don’t need and won’t use.

food cartoning machine

Most food production companies use the food cartoning machine, also known as a “food cartoner,” to pack their products.

Using this machine, you can form, fold, and fill different types of cartons with food items.

While some cartoning machines require human labor, most operate automatically.

For this reason, a cartoning machine is an integral part of the production line in food manufacturing.

Food cartoners are optimized for use in food production plants.

Mainly, these machines are used to pack bulk or pre-packed food items such as cereals, seeds, dry pasta, biscuits, pastries, frozen food, flour, sugar, salt, tea, coffee, and pet food.

The machine is also used for packaging confectionaries, meal ingredients, and ready-to-eat foods.

It can also carton sauces and beverages already packed in pouches or bottles.

Food cartoning machines are either semi-automatic or fully automatic. There are also manual models.

Here are the three main categories of food cartoners used in assembly lines:

Vertical Food Cartoner

A vertical food cartoner is excellent for handling bottles, vials, and jars.

Damaging the product during processing is minimal, as this cartoner eliminates long in-feed systems.

As a result, the operator gets the chance to lower processes and footprints.

vertical food cartoner

Vertical food cartoners can be divided into four subcategories:

- Integrated Delta 3 Systems (for high and accurate PPM)

- Continuous Motion Turret Loaders (for speeds greater than 200-PPM)

- Intermittent Motion Top Load (for high precision and flexibility)

- Manual Load (for cost efficiency)

Horizontal Food Cartoner

The horizontal food cartoner is famous for handling bulk food products and achieving high speeds for high-demand applications.

For this reason, it is most commonly used in the end-of-line packaging plants. It is an ideal choice for products with a stable base, with one or two items inside them.

horizontal food cartoner

A horizontal food cartoning machine can be divided into three subcategories:

- Fully automatic (for best efficiency and finishing)

- Semi-automatic (for higher efficiency and better control)

- Manual loading (for flexibility and cost efficiency)

Wrap-around Food Cartoner

The wrap-around cartoner or sleever forms the carton around the product.

It is super-efficient when handling wrap-around sleeves and for products like single pouches and blister packs.

This food cartoning machine uses little carton material and requires minimal handling.

However, the gluing system of this cartoning machine isn’t very trustworthy. Besides, it has a low production speed.

wrap around food cartoner

Nevertheless, they’re still the preferred choice for food cartoning because they offer several customization options.

Like the other two cartoners, sleever can be divided into three subcategories:

- Fully automatic (for best efficiency and finishing)

- Semi-automatic (for better efficiency and more control)

- Manual loading (for flexibility and cost efficiency)

Indeed, most businesses that carton food by hand to prepare it for sale don’t look forward to this process.

It is tedious and time-consuming if the quantity is large enough, but it can also pose a danger to those doing the packing.

In addition, some products don’t lend themselves to manual cartoning.

At a certain point, cartoning machines can become a necessity for food packers, and the benefits of such equipment remain essentially the same whether semi-automatic or fully automatic cartoners are used.

The use of cartoning machines offers other advantages, such as

Consistency and Reliabilty

Cartoning machines form, fill, and seal cartons consistently every cycle.

Aside from the fact that human hands cannot seal cartons in the same way, the long time spent cartoning products can lead to fatigue.

If we’re honest, boredom, which leads to inconsistent and unreliable packaging.

Speed in Cartoning

Manual cartoning can be a fairly consistent and reliable way to prepare products for the shelf when given enough time or divided into enough shifts.

However, as the number of workers increases, the time taken to avoid fatigue, boredom, and injury would ultimately lead to inefficient product cartoning.

Food cartoning machines are typically faster than manual cartoning, with automatic machines reaching speeds of up to 200PPM or more.

Ease Of Operation

Although it doesn’t get much easier than putting products in the box and sealing it, good cartoning machines are built to make things easy for the operator.

Semi-automatic machines usually require the operator to place the products in the carton and slide the combination into position to fold and seal the carton.

This saves time and improves the accuracy and precision of the packaging.

With automatic machines, the process is fully automated

Versatility

Food cartoning machines are versatile enough to handle a range of carton shapes and sizes.

This advantage provides both a cost-effective and efficient solution to the food cartoning process.

Integration

Some manufacturers specialize in a particular type of machine in the food packaging industry, whether liquid filler, a sealer, a labeler, or other equipment.

Cartoning machines can be integrated into existing packaging lines, provided the space for the equipment is available.

Some packaging companies also automate processes incrementally.

This means that processes like filling or labeling are already automated when a packer searches for a cartoning machine.

The advantage of integrating cartoning machines into an existing system is that you have the opportunity to grow and automate at your own pace.

Quality Control

Using cartoning machines for food can increase the food packaging process’s efficiency, speed, and reliability.

It is also cost-effective, which makes the quality control process very simple and leads to maintaining a high standard of product.

Note that the benefits of automating the cartoning process vary from project to project, as does the level of automation.

However, the above benefits are often the motivating factors for making the switch.

When looking for the best cartoning solution that can make the entire food packaging process more efficient, faster, and more reliable.

An analysis of the packaging material, product needs, space, and budget for a project should always be conducted.

For any food production company, it is essential to understand the functions, operating systems, structure, and parts of the food cartoning machine to take full advantage of its benefits.

A simple food cartoner generally consists of four different parts and components. These are the mechanical, electrical, pneumatic, and light components.

Specifically, there is the control panel, often a PLC system in automated systems.

The programmable logic controller (PLC) is the heart of automatic food cartoners.

It allows the operator to set almost all controls for the system’s filling, folding, sealing, and other functions through a simple interface.

Modern PLC systems are equipped with human interface (HMI) systems.

This helps the operator issue instructions, revoke them, and even intuitively stop all operations when necessary.

It also allows the operator to change the parameters and requirements of the production process to achieve the desired set point within a specific time.

There is also an electrical panel that houses the primary wiring/connections of the machine.

Likewise, the electric motor is an integral part of the food cartoner. Its principal function is to convert electrical energy into mechanical energy.

Other parts and components include:

- Lubrication system

- Carton packing tools and pneumatic system

- Inkjet printer

- Safety system

- Conveyor belts

- Guard rails

- Rollers

- Box chute

Again, the primary function of a food cartoning machine is to transform a carton blank into a box filled with a product.

The process is as follows:

First, an operator loads carton material into the machine. The cartoner then picks up the material and cuts it into sheets of the desired dimensions.

Once the sheets are in place, the machine begins folding them into different types of boxes.

The next step is to fill the finished boxes with the desired products.

This is done either with the help of a mechanical sleeve or with the help of compressed air. After that, the machine folds the cartons’ sides and seals them.

Some food cartoning machines even include glue or adhesive that secures the cartons for more effective sealing.

In addition, some of these machines have a palletizing system for the larger cartons or wrap the cartons with plastic, which is essential for shipping/distribution.

Depending on the type of carton, the product it contains, and the transportation requirements, there are many sealing options to choose from.

Some of the most common sealing techniques are:

Water-Activated Paper Tape

Also known as gummed tape, this is a starch-based adhesive on a paper backing that becomes tacky when moistened.

It can be made using animal glue too.

The tape is commonly used to seal heavy food items’ cartons and protect the contents from tampering during shipping.

Reinforced tape (RGT) is sometimes used as well. In this type of tape, two layers of paper are laminated with fiberglass.

Asphalt was used for laminating adhesives in the past, but now it is usually made of atactic hot melt polypropylene.

This sealing technique offers several advantages, including the fact that it can be torn off by hand, has excellent adhesion, and requires minimal pressure.

It’s also an ideal choice for environmentally conscious customers because it’s biodegradable and recyclable.

Water-activated paper tape can also be overprinted, which is a plus.

Pressure-Sensitive Tape

This type of tape consists of a pressure-sensitive adhesive applied to a durable plastic backing (usually polypropylene or polyester).

Unlike the water-based alternatives, it’s not biodegradable.

It’s a cost-effective solution for general applications, especially at high speeds, making it the preferred solution for most food packaging.

The tape requires high pressure to achieve a good result. The adhesive can also withstand extreme temperatures, such as cold storage.

It can also be overprinted cost-effectively.

Although strong and relatively durable, the pressure-sensitive plastic tape is susceptible to cracking and can break on impact.

Adhesive

An adhesive or glue is a mixture in a liquid or semi-liquid state that glues or bonds objects together. Adhesives can come from either natural or synthetic sources.

The types of cardboard materials that can be glued are varied, but they’re handy for gluing thinner materials.

Staples

The staples used in closing cardboard boxes are similar to those used in the office. However, they tend to be larger and sturdier.

One advantage of stapling food cartons is that this technique provides a sturdy closure that can withstand the rigors of shipping and multiple handling.

Stapled cartons are also tamper-resistant, but they’re tough to open.

Another disadvantage is that packaging cartons must be additionally lined or have overlapping flaps to protect the goods inside from damage when the staples are driven through the carton.

In addition, staples can be a potential hazard (for injury) to workers.

As a food packaging professional, you must consider several points when choosing a machine that offers the best food cartoning solutions. These include:

- High operating speed

- Good performance

- Easy to operate and use

- Easy to maintain

- Budget-friendly

- Size should be variable depending on space

- Easy to repair

- Availability of space.

You need to do thorough research to find the best and most efficient food cartoning machine.

With the help of the internet, it’s much easier to do a lot of research these days.

Read the reviews and feedback and learn more about the features and functions of the machine.

Also, make sure that you choose based on the features.

The features are one of the most exciting parts of a machine, and they can also make it more beneficial.

Some of the features you should look for in a food cartoner are:

- Manual/Semi-automatic/Fully automatic: As you know, there are three types of operating systems for the food cartoning machine.

These are manual, semi-automatic, and fully automatic.

According to your requirements for commercial use and your budget, you can choose the most suitable system.

Note that there’s a significant price difference between these three systems.

Therefore, you should plan your budget well and store accordingly when looking for security packaging and sealing machines for your commercial purpose.

- Productivity: The production capacity of a food cartoner plays a significant role.

Accordingly, you need to choose between the market’s capacity options based on the size and volume of your product.

- Power consumption: when you’re choosing a packaging machine, you must undoubtedly pay attention to the power consumption of the machine.

Some machines consume less power and offer competitive productivity. You can choose according to your requirements.

Don’t forget to look at the safety features too.

Admittedly, using food cartoning machines generally speeds up the packaging process.

It also makes it possible to meet greater production demands while increasing consistency and reliability.

However, these machines always require an operator or technician to ensure the machine’s proper functioning.

Most importantly, you should try to clean the machine after each day of production.

This helps avoid the accumulation of dirt, dust, product, or debris that could affect the machine’s performance.

How much cleaning is necessary and how much time you need to do it’ll depend largely on the equipment and products used, as well as the environment in which the cartoning takes place.

Some food cartoners are wash-down capable, so most of the line can be hosed down to wash away contaminants.

Other machines only need a quick wipe down with a clean cloth to prevent dirt and dust build-up.

In addition to cleaning the machine, you should inspect the cartoner to ensure all components, especially wear parts, are in good working order.

Have the operator check the conveyor belts, electric motor, bearings, rollers, etc., to ensure that these wear and contact parts haven’t exceeded their useful life.

If wear parts need to be replaced, the operator is also usually responsible for that.

Remember that while automatic cartoning machines can run continuously without human intervention; the equipment operator is still essential to ensure the equipment’s efficiency, consistency and reliability.

Without quick intervention, expert setup and changeover, and proper maintenance, the equipment cannot perform to its full potential, and it’s still up to the human to provide these skills.

Unlike the cartoning machine, which packs products into cartons, the case packer uses trays or wrap-around cartons.

A case packer for the food industry sets up a tray/wrap-around carton and loads it with products from the side, top, or bottom.

It all depends on the type of case packer.

food cartoner machine

After the product is loaded into the tray/case, the machine closes the cardboard and seals it with adhesive or tape.

Both machines use biodegradable cardboard materials to pack food items.

The only difference is that cardboard trays are usually less strong and durable than cardboard boxes. Therefore, they’re more commonly used for packaging self-supporting or semi-self-supporting products such as milk and juice bricks.

case packer

Otherwise, cartoning and case packing machines can meet all product packaging requirements, from slow to medium-speed to high-speed solutions.

In addition, they can be used for various types of products and materials in the food industry.

The benefits of using robotic technology in food cartoning go far beyond what you might think.

Some of these benefits include:

- Cost-effective quality control

- Improved packaging efficiency

- Reduced costs (low recurring cost + high production speeds)

- Increased worker safety and food safety

- Improved brand image due to consistent quality products

In conclusion, food cartoning machines or cartoners help businesses meet production goals, as they are fast and efficient when packing on large projects.

They are also highly versatile and keep costs low over time.

For all your food cartoning needs, contact us now.