Vertical Cartoning Machine Manufacturer

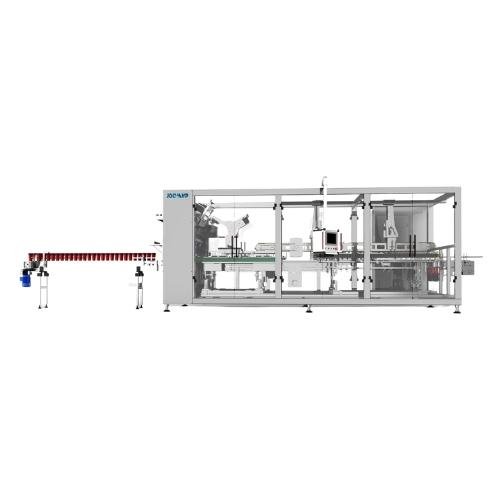

JOCHAMP is a leading manufacturer of vertical cartoning machine, built with a reasonable and compact structure. The adjustment and operation of the machine are convenient. It can guarantee user-friendly, higher automation, and simpler operation.

- High format flexibility

- Simple format changeover

- High-quality and high efficiency machine

- Faster delivery

JOCHAMP Vertical Cartoning Machine

JOCAHMP vertical cartoning machine is manufactured to load, close, and form chip board cartons. They are easy to use, compact, and created up to 60 cartons every minute. Being a leading vertical cartoning machine manufacturer in China, we develop two models, and these are:

Hand Load: The vertical cartoning machine will open automatically. Then, the carton presents to the fill zone and its content can be hand loaded by the person. The top lid can be automatically tucked or left open, or glued shut once loaded.

Automatic: The machine comes with feed conveyance system. It can ensure automatic product accumulation and fill directly into the carton. It could reduce the human interaction needs.

JOCHAMP offers extensive expansion options for vertical cartoning machines: glue spraying, conveying, manual folding, coding, and labeling. We aim to provide every client with high quality machines at a competitive price.

Contact us now!

JCZ-60 Vertical Cartoning Machine

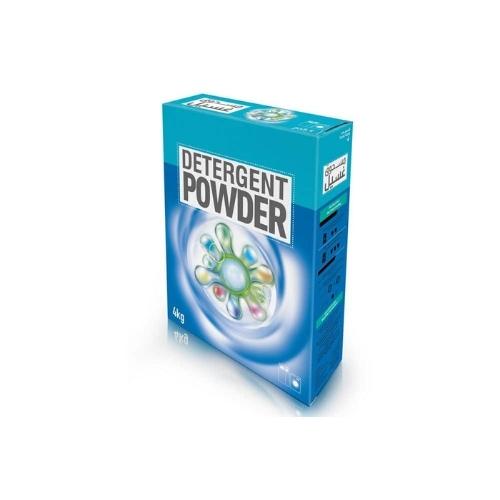

Automatic cartoner in top load form, friendly to granules, powders, bulks, especially laundry detergent, bulk candy/chocolate, milk powder, biscuits, pasta, pet Food,cereals, snacks, etc.

- Friendly to granules, powders, bulks

- The same applies to food, medicine, cosmetics, stationery, hardware and other industries.

- Large reserve space for manual loading or automatic loading position

- Open design, no hidden space, easy to clean and maintain

- PLC control system and HMI

- accept customization

- Quickly switch products without tools

- Full 304 stainless steel cover

- no carton, no filling

- CE, IOS9001, GMP certification

- Overload automatic shutdown function

JCZ-60

- Technical Parameter

- Features

- Optional

| Model | JCZ-60 |

| Power Type | 380V 50HZ |

| Total power | 3kw |

| Dimensions | 4200*1400*1650mm |

| Packaging form | carton packaging, special mode for bulk cartoning |

| Air source | 20m2/h |

| Max carton size | 250*250*110mm |

| Min carton size | 105*70*25mm |

| Weight | 1300kg |

- Friendly to granules, powders, bulks

- The same applies to food, medicine, cosmetics, stationery, hardware and other industries.

- Large reserve space for manual loading or automatic loading position

- Open design, no hidden space, easy to clean and maintain

- PLC control system and HMI

- accept customization

- Quickly switch products without tools

- Full 304 stainless steel cover

- no carton, no filling

- CE, IOS9001, GMP certification

- Overload automatic shutdown function

- Whole food, pharmaceutical grade product contact surfaces

- Safety door structure

- Siemens, Schneider, Delta, Siemens, sick and other brand electrical appliances and accessories.

- Low noise operation (70 decibels within 1 meter)

- Free sample packing test

Multi-head weigher

Auger Filler

vibrating plate feed

Remote system inspection, maintenance and upgrades

Automatic feeding mechanism for different products

glue sprayer

coding machine(Embossing, inkjet, laser coding)

leaflet folder

Labeling Machine

Checkweigher

Why JOCHAMP Vertical Cartoning Machine

The vertical cartoning machines is manufactured with compact design. It can save floor space in the facility along with its little footprints.

The entire body of the machine is made from 304 stainless steel and can be applied different surface treatments for corrosion resistance.

The vertical cartoning machine comes with advanced overload protection system. This could improve safety and minimizes failure loss.

Provides different expansion options to meet your different needs: coding, labeling, conveying, manual folding, glue spraying, and more.

Vertical Cartoning Machine Application

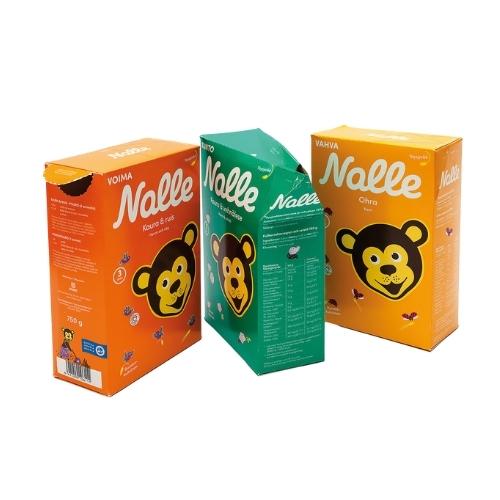

JOCHAMP vertical cartoning machines accurately and quickly fill cartons with flowable, loose products using gentle handling and excellent carton control. We provide numerous types of vertical cartoning machines to exceed specific applications for different markets. These machines are great packaging solution for small pastas, powders, small pet treats, and bite-sized candies.

The machines have index motion for quick integrate with numerous filling systems like augers and weighers. Once loaded, JOCHAMP vertical cartoning machine will secure a carton with electric glue guns and servo flap tuckers for end-flap, sift-proof gluing. It can also save floor space in facility thanks to its compact design.

Features

JOCHAMP supplies vertical cartoning machines with the following benefits:

- Fully welded, heavy-duty steel mainframe

- Protect guides and stainless-steel driveshafts

- Ethernet connectivity module

- Auto lug chain lube and central lubrication

- Easy-to-change carton lugs or pockets to accommodate numerous sizes

- Open flap rejection and detection

- Low-level indicator powered extended carton magazine

- Compliant with ANSI, OSHA, LOTO, UL, ISO, and NFPA

What Can Vertical Cartoning Machine Do?

Our fully automatic vertical cartoning machine features numerous industry-first advancements that gain superior reliability, speed, and repeatability. It can reduce equipment versatility.

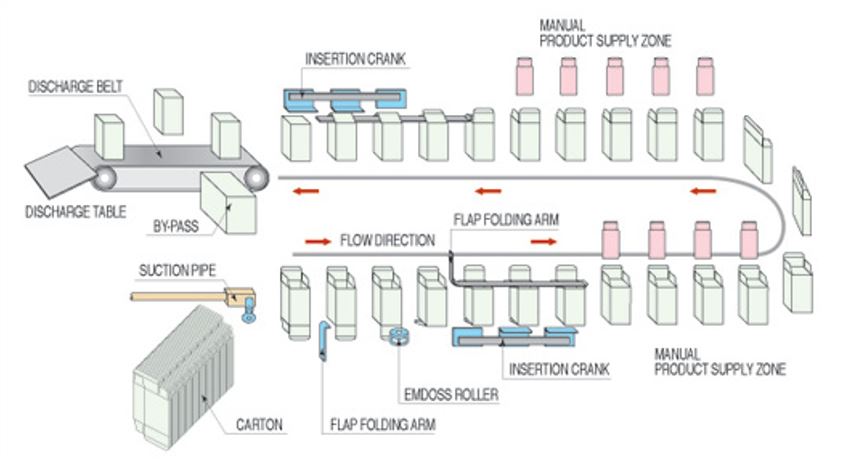

JOCHAMP vertical cartoning machine features special erect cartons and carton feeders in the specially-sized bucket. It can accommodate the cartons in an integrated suction cup placed throughout the whole machine’s arc path. This design minimizes friction between cartons and rails. Also, prevents the delicate carton surfaces from scratching and scuffing.

Choose JOCHAMP for Your Vertical Cartoning Machine Needs

Our vertical cartoning machine is distinguished by its excellent compactness and versatility. The main features of these machines are ease of use, fully automatic or manual product loading, and tool-less format changeover.

JOCHAMP vertical cartoning machines have the productivity of up to 80 cartons every minute. It has powerful and simple industrial control systems that are easier to operate. All of our machines are fabricated from durable raw materials like 304 stainless steel. The entire body is covered with surface treatments to achieve stronger corrosion resistance.

JOCHAMP Vertical Cartoning Machine

JOCHAMP vertical cartoning machines are great for automatic load or hand load applications for nutraceutical, pharmaceutical, personal care, and medical device industries. They are even capable of packaging goods with numerous inserts due to their hand load area of nine feet.

The vertical cartoner is versatile to run corrugated cases. It has a special prebreak orbital erector feature that allows the cases to be erected in addition to cartons. This feature makes the vertical cartoner a perfect choice for applications like top load case packing.

- Whole drug and food-grade product contact surface

- Open mechanical design

- Free sample packing test

- Customized support for carton’s mechanical structure

- Protective cover and movement mechanism protection open the emergency stop feature to ensure safe operation

- No product, no suction box function

Why Choose JOCHAMP Vertical Cartoning Machine

Flat carton blanks and other material transportation have a risk of danger to the operator when the material is added while the machine is running. Therefore, we manufacture vertical cartoning machines with safeguard detectors to prevent potential injuries.

We offer vertical cartoning machines that are integrated with photoelectric sensors to detect boxes on the conveyor belt and fill the cartons with the specific product quantity. This feature offers reliable counting, wear-free, and non-contact.

JOCHAMP designed a vertical cartoning machine with a signal lamp. It detects the machine’s operational status for monitoring. The operational status is visually displayed that can be viewed even from a considerable distance. Therefore, reducing downtime.

We offer a vertical cartoning machine that is manufactured with an open frame design. This design allows the operation debris to fall to the floor without obstruction. It has a guard door made from Lexan material that is easy to remove. Thus, providing easy access for cleaning and maintenance.

Related Product

Vertical Cartoning Machine: The Ultimate Guide

This guide will help you choose a perfect vertical cartoning machine for your packaging solutions. So, whether you want to learn about the design, features, working principle or compare it other machines – you will find all information right here.

Vertical Cartoning Machine refers to a mechanically driven packaging equipment suitable for packing items that needs to be vertically loaded in a carton.

The machine forms, fills and seals the carton boxes, and can package up to 40 boxes per minute.

Typically, you can use this type of carton packaging machine to pack food, cosmetic, and pharmaceutical products.

Insertion of products is usually done by the operator however, automatic vertical cartoner inserts items using a pick-and-place system or robot.

Different from horizontal cartoning machine, vertical cartoners often function as stand-alone machine.

But you can as well integrate the machine with other equipment in the packaging line, like case packer, overwrappers, among others.

Vertical Cartoner Machine

There are various types of vertical cartoning machine, though the basic parts of cartoning machine include:

Feeder Unit:

Feeder system is the part of the cartoning machine that feeds the carton making materials. The feeder unit is made of a conveyor belt and a series of rollers that push the box into the succeeding component.

Folder:

The folder is the component that folds the top and bottom flaps of cardboard boxes to make them stronger.

The folder is adjustable in order to fit any size or shape of box to be manufactured.

Puncher:

Here, the vertical cartoinng machine punches holes into cardboard boxes so that they can be tied with string or wire ties after being filled with products.

Seamer:

The seamer seals two edges together using glue or staples in order to make them stronger.

Labeler

At this part is where the machine prints information on your cartons such as price or weight before final packaging.

You can use the labeler to print barcodes as well if needed.

Some of the most common vertical cartoner machines include:

Semi-Automatic Vertical Cartoning Machine

Semi-automatic vertical cartoners involve both manual and automatic operation.

For instance, the feeding of cardboard into the machine is done manually.

Similarly, you can configure the cartoning machine to perform subsequent processes automatically.

semi automatic vertical cartoning machine

The operation of this equipment is very simple, making it very easy to control.

For that matter, the cartoner type is a cost-effective solution for small to medium businesses that need to package their product in boxes.

You can use the carton packaging equipment to pack various products such as cosmetics, food, medicine and so on.

Automatic Vertical Cartoners

Automatic vertical cartoning machine is a high-speed carton packaging machine with a fully automatic cartoning system.

It is a unique packaging solution that offers high production speed and efficiency, with minimal to no manual operations.

Automatic vertical cartoning machine

The machine has been designed to pack multiple cartons simultaneously, which saves time and labor costs.

Some of the main advantages of automatic vertical cartoning machine include:

Flexibility

You can configure the machine to pack any size or shape of carton with a wide range of product types.

Some of the products you can pack with the cartoner include foodstuff, beverages, cosmetics, pharmaceuticals, among others.

High Level Of Automation:

The automatic vertical cartoning machine has been designed with an advanced control system that allows for consistent quality and high efficiency levels.

You can set the vertical carton packaging equipment to run for 24 hours without any human intervention.

Compact Design:

Because of the machines’s compact design, you can install it in space size without compromising on production capacity or performance capabilities.

High Speed Production Capability:

Automatic vertical cartoning machines allow for high speed carton packaging.

The machine has different speed configurations, which allows adjustment of cartoning speed as per your specifications.

Fully automatic vertical cartoners are more expensive than semi-automatic versions. Nevertheless, they offer great value for money because they can be used by large businesses with high volumes of products to package.

Rotary Vertical Cartoning Machine

A rotary vertical cartoning machine uses rotary movement to cut and seal the products in the carton.

You can use this type of vertical cartoning machine for packaging a variety of products.

The cartoner is a high-speed carton packaging equipment with a large production capacity.

A motor drives the transmission mechanism to rotate at high speed, which makes the worktable rotate.

rotary vertical cartoning machine

You can us the cartoner equipment for both small and large-scale carton packaging applications.

The versatility and efficiency of the rotary vertical cartoner allows for easy integration into existing packaging lines.

Continuous Vertical Cartoning Machine

As the name suggests, continuous vertical cartoning machine allows you to produce cartons consistently at high speed.

The continuous vertical cartoning machine is mainly composed of feeder, packaging chamber, sealing device and control system.

Besides, the machine features a vertical conveyor belt over which the carton blanks are fed to a series of stations.

At each station, the cartons are filled with product then sealed and sent on their way through the system.

Most adopt double-deck transport belt to transport the products from feeder to sealing chamber to packaging chamber.

This improves the speed of conveying products, saves energy consumption and increases production efficiency.

The continuous vertical cartoning machine has many advantages such as large production capacity, high automation level and stable performance etc.

For that matter, you can integrate the machine in high speed production lines.

Intermittent Vertical Cartoning Machine

The machine consists of an intermittent motion mechanism and a sealing device.

Intermittent vertical cartoning machine comes with an adjustable height system which allows it to accommodate different sized items.

Because of the adjustable height, you can pack different types of items without needing any additional tools or equipment.

With this type of vertical cartoner machine, you can make a variety of cartons, like paper cardboard, corrugated cardboard, and other carton types.

Some of the applications intermittent vertical cartoning machine include packaging of products like food, medicine, cosmetics and other products that need specific care.

Here are some of the main benefits of vertical cartoner machine to your business:

- High Speed: Vertical Cartoning Machine is capable of producing up to 2000 cartons per hour, depending on the size of the product being packaged.

This allows you to produce large quantities of product in very little time, which reduces production costs and increases profits.

- Efficient: You can use the equipment for both large- and small-scale packaging requirements.

Due to its high-speed capabilities, you are able to produce large amounts of products quickly and efficiently.

- Compact Design: The compact design of Vertical Cartoning Machine allows it to fit into smaller spaces and work more effectively.

With regards to this, you do need a large amount of space in order to operate this equipment effectively.

- Easy Programming: Comes with an easy programming system so you can set up each product with an individual programme according to its size and weight.

- Low Operation Cost: Compared to other types of packaging machines, the vertical cartoning machine has a low cost of operation.

It does not require much maintenance or repair and you can also operate it for many years without needing replacement parts.

This makes the cartoner an ideal choice if you do not have enough funds for heavy equipment investments or maintenance costs.

- Less Labor Required: You need low manpower since there is no need to move on both sides and all parts are fixed in a certain position.

Due to this fact, the vertical cartoning machine can be operated by one person only or two persons at most.

As a result, you will achieve higher efficiency with respect to cost of operation.

- Easy To Operate And Maintain: Operating the machine is very easy because it is controlled by a computer system.

You only need to set up the parameters through the programmable logic controller (PLC), then start working immediately without any additional intervention.

In addition, vertical cartoner has an automatic feeder that makes the product flow smoothly into the machine.

Vertical cartoning machine and the vertical flow wrapping machine are two types of packaging machines used for packing of products.

vertical cartoner machine

The main difference between the two machines is that while they both use similar principle, they do not use similar packaging materials.

As you already know, vertical cartoning machine uses mainly uses cardboard for packaging. Conversely, vertical flow wrapping machine is designed to wrap products in plastic wrap or other flexible materials such as foil or paper.

Another difference between these two machines is the way they seal their products. Vertical cartoner uses glue, tape or staple pins to seal the carton boxes.

On the other hand, working of vertical flow wrapper involves heat sealing techniques with a sealing bar or roller.

vertical flow wrap machine

During packaging, the sealing mechanism melts the edges of the film together around the product being packaged.

The Vertical Flow Wrapping Machine can be used for many different types of items such as food products, pharmaceuticals, and even electronics.

You can also use the equipment as a stand-alone machine or integrated into a packaging line.

The two key parts of vertical flow wrapping machine include the following:

- Feeding Section: Product tray moves along with conveyor belt while the film rolls feed into the wrapping section.

- Wrap Section: A knife cuts the film into required size depending on type of product to be wrapped.

A vacuum station sucks up the extra wrapper material so that it doesn’t interfere with further working of packaging machine.

Subsequently, the wrap material travels through an infeed roller.

The material gets attached to infeed ring at its outer edge with help of vacuum suction pad at its inner edge.

An infeed ring on infeed roller keeps tension on wrapper material during travel through wrap section.

This results in perfectly straight seam line during wrapping.

Automatic: Most advanced vertical cartoner machines incorporate an infeed conveyor system that automatically collects items and fill into box carton directly.

This eliminates the necessity for human interaction.

- Heavy-duty, fully-welded concrete steel main frame

- Stainless steel drive shafts and protect guides

- Automatic lug chain lube and central lubrication

- Full-height guard doors having interlocked stainless steel frame

- Lockable guard doors

- Servo motor-driven rotary carton feeder having pre-break

- Extended carton magazine

- Easy-to-change lugs or carton pockets to allow for multiple sizes

- No carton control

- Spindle adjustments having center-lining to ensure fast and easy changeover

- Open flap sensing and rejection

- Cycle stop mode

- Hot melt glue mechanism

- Ethernet Connectivity module

- Compliant with ISO, OSHA, LOTO, ANSI, UL, and NFPA

Operation of vertical cartoner machine is quite simple.

The cartoning process starts with drawing flat, side seamed boxes one after the other from vertical carton box magazine feeder.

A vacuum-powered rotary carton feeder places each carton in a carton pocket set on a carousal conveyor.

Subsequently, the machine folds, closes and seals the bottom flaps of the carton box, using a number of closure styles.

The machine applies hot-melt or tuck-in closure techniques to close the bottom flap of the carton.

After that, the carton is then transferred vertically to the loading section.

At the product loading section, you can manually or automatically load your items into the cartons.

The loading is done from both edges of the vertical cartoning machine.

When loading is complete, the vertical cartoner plows, closes and seals the top flaps. Consequently, the system discharges the finished carton box from the packaging equipment to a conveyor.

working process for vertical cartoner machine

Cartoning machines are categorized as either vertical or horizontal, based on how you load the cartons into the machine. Both types of cartoners can be manual or automatic.

Horizontal Cartoners

Also referred to as end-load cartoner, horizontal cartoning machine collects blank cartons, opens them horizontally into carton box flights.

The machine then fills the boxes manually or automatically.

horizontal cartoner

You can pack a single product (bag or tray) or several products into the cartons using the machine.

Automatic horizontal cartoners use a barrel cam loader to place your products into the boxes.

Horizontal cartoners are ideal for packaging bulk goods and achieving high packaging speeds during increased demands cases.

For that matter, this type of cartoning machine is the commonly employed in end-of-line packing sector.

Vertical Cartoners

With vertical cartoning machine, the equipment collects carton materials from a carton magazine feeder and folds them vertically to carton flights.

You can package one or more items either manually or using automatic vertical cartoner machine.

Based on the use, the machine can fold the end flaps together and then close them.

When dealing with bottles, jars and vials, this cartoning machine type is the best choice.

You should choose this cartoner version if handling these products since it avoids prolonged in-feed systems, which reduces chances of product damage.

For that matter, the machine allows you to reduce operations and minimize the machine footprint.

In a nutshell, vertical cartoning machine is perfect for products that are easy to toss over, like unevenly shaped containers.

Furthermore, this cartoner type is an ideal choice for hard to press goods like plastic or foil pouches.

On the other hand, horizontal cartoner machines are appropriate for complex items having a wide base stack and move fast like cereal boxes.

Vertical cartoning machine are used for both retail and commercial packaging.

The machine is widely used to pack different kinds of goods including food and beverage, chemicals, pharmaceutical products, stationary items among others.

Vertical cartoner finds use in the following industries:

- Food industry

- Clothing and textile sector

- Cosmetic and pharmaceutical industry

- Electronics industry

- Chemical Industry

- Grain/Spice Industry

- Tobacco industry

- Toy industry

- Vegetable and fruit industry

- Sports industry

For any questions or inquiry on vertical cartoning machines, contact us now.