Liquid Packaging Line Supplier in China

Jochamp is a reliable liquid packaging line supplier in China. This line consists of reliable machines approved by cGMP, ISO, CE, and SGS. Complete types include washing/cleaning machines, cap sealing machines, and more.

- Easy to operate machines

- Good condition machines at competitive rates

- Custom-built to your packaging needs

- Compact structures

JOCHAMP Liquid Packaging Line

Liquid Packaging Line is a group of machines that work together under a line and package liquids into a vessel. These lines are essential for making the packaging process quick and easy. They are widely used for industries such as pharmaceuticals, dairy products, personal care, pesticides, and many more.

Jochamp provides a complete liquid packaging line for packaging liquid items into any bottle size and shape, containers, pouches, or plastic ampoules. All machines can pack explosive materials, acids, chemicals, and more.

Please send us your inquiries!

Liquid Packaging Line Benefits

Our liquid packaging line is composed of easy-to-clean machines. High-quality and corrosion-resistant.

All machines are very simple to operate. No need for special abilities or equipment.

The machines have strong versatility features. They are versatile when packaging liquid items.

We offer a liquid packaging line with anti-drip designs. It means they are not prone to rust.

Machines for Liquid Packaging Line

Jochamp offers a complete liquid packaging line to exceed various packaging requirements. Always rely on us, we can aid in finding the most excellent packaging system or machines for your business.

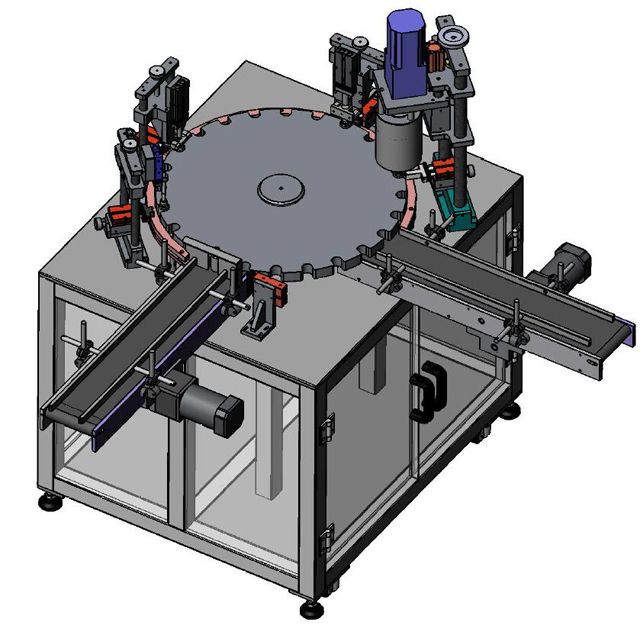

- Turn table

- Bottle cleaning/washing machine

- Liquid filling machine

- Bottle visual inspection machine

- Bottle inspection table

- Cap sealing machine

- Packing conveyor

- Labeling machine

ADVANTAGES

Precision – Packaging system from filling to labeling and sealing, all machines are precisely made and have each role in maintaining efficient packaging. It guarantees +/- 0.5% precision.

Simplify the cleaning process – Our liquid packaging lines are easy to clean. The simpler to clean, the lesser time required to spend cleaning machines and parts. They become faster or operate again.

Ease of flexibility – If the machines are flexible enough, it contributes a lot to an efficient packaging system. With this advantage, the machine can accommodate different types of liquids and containers. Also, they can be easily upgradable.

Liquid Packaging Line for Many Industries

Jochamp liquid packaging line makes the liquid packaging procedure easy and speedy with less labor force. This packaging line is suitable for any industry including:

- Food & beverages

- Pharmaceutical industry

- Dairy products packaging

- Cosmetics

- Paint

- Personal care

- Oil

- Cleaning material

- Pesticides

- Lubricants

Why Choose JOCHAMP Liquid Packaging Line

For the past 12 years, Jochamp has been building, designing, testing, and installing complete lines for packaging and bottling. We are one of the leading companies in China, and we supply almost all types of liquid packaging lines.

In our own facility in China, we own over 50 technical patents and selected 10+ expert technical sales with over 5 years of experience. All have a wide knowledge of providing your custom-built packaging lines.

Whether you necessitate a liquid packaging machine to finalize your packaging systems, you can count on Jochamp. We can provide cost-effective equipment that can deliver better results.

To gain more knowledge about our offers and services, please contact us directly.

JOCHAMP Liquid Packaging Line

Jochamp liquid packaging machines offer numerous features and major qualities to exceed your packaging demands.

- Come in various sizes option

- Constructed for item flexibility

- Durable construction – made to last

- Minimal break for cleaning & maintenance

- Simple setup with swift adaptation qualities

- Custom-made according to your budget and certain needs

- Systems range from physical tabletop to totally automated

- Choices for sanitary, corrosive, or unsafe environments

All custom-made liquid packaging machines are built exactly as per your specifications and certain applications. As result, it guarantees trouble-free operation. They are widely used to package products such as:

- Automotive and petroleum products

- Personal care and cosmetics

- Industrial and household cleaning products

- Bottled beverages and water

- Corrosive and acids products

- Sealants, paints, and stains

- Agricultural goods

- Food sauces and more

Custom Packaging Lines for Any Application

The blister packaging line is made intentionally for pharmaceutical business and packagers. To pocket prescription medicines, the process utilizes pre-formed plastic with a cavity.

Case packing line is a fully automatic machine used to wrap products from the side, bottom, or top. After that, this line uses tape or glue to seal and secure the case.

The food packaging line aid food products preserved for 3-5 times longer. It can package products such as grain, bread, cakes, crackers, cookies, meat products, and pastry. These are packaged by cartons, boxes, bags, cans, or custom material.

The ampoule packaging line is a group of automated machines such as ampoule sealing machines, sealing machines, washing machines, sterilizing machines, labeling machines, and more. It is effective in preserving a sample, usually a liquid or solid.

Related Product

Liquid Packaging Line: The Ultimate Guide

In this guide, you will find all information you need about liquid packaging line.

Whether you want to learn about filling technology, working principle, features or specifications – you will find all information right here

It refers to a batch of equipment synchronized together in a line for filling products with various viscosities into different container types.

This machine, in some applications, is also known as a flow filling machine and fills liquids into containers through volumetric or qualitative filling.

liquid packaging line

liquid bottle line

The entire liquid bottle line is efficient with a standard production productivity and precision filling line.

It is constructed in various designs, and in many instances, you can find it in different sizes and easily customizable based on your production demands.

Remarkably, liquid bottle line is a fundamental element in manufacturing industry since it enhances efficiency and product quality.

The latest liquid filling equipment in the market are somewhat sophisticated pieces of technology.

It comes with a wide range of mechanical and electronic parts integrated together to run filling lines seamlessly and speedily.

Ordinarily, this equipment is available in different designs, and each has various parts depending on the model and other design requirements.

Nevertheless, here are the main parts of this machine you are likely to find across different models;

In-Feed Pan

Commonly referred to as a hopper, it is designed for depositing the product in bulk in readiness for filling process.

The in-feed pan features a trough-shaped hopper that allows easy product loading manually or by integrated bulk feeders.

Filling Head

It is the part that interfaces with the packing, which, in this case, is the bottle to where the product is delivered into.

PLC Control Unit

This refers to mini-computers built into the equipment’s systems to control and automate production lines.

It allows you to regulate the process speed and volume of products to be filled among others.

This unit is programmed, observed and synchronized through Human-machine Interface (HMI).

Drive System

It refers to a professionally engineered mechanism operating the equipment in a carefully systemic, perpetual series of metered product quantities.

It is automated and timed to ensure product dispensing is synchronized with the bottle or container movement.

Tanks

Various liquid filling machines have different tanks and, in some instances, in various spots.

Moreover, tank size, location and product depend on various factors, including the material, fill principle and production demands among more.

Hence, a standard tank may exist for every liquid filler, but changes are likely to arise based on unique traits of each production need.

HMI Control System

This part features a touch-screen or button-operated system that allows the operator to control different machines’ functions and parameters.

It is easy to use and understand, making it effective in enhancing the efficiency of the liquid filling and packaging process.

Sensors

These are devices, modules or subsystems designed to detect changes and events in the equipment and transmit the information to computer processor.

In this equipment, sensors synchronize products and containers by monitoring different elements.

For instance, sensors determine whether there are any bottles to fill and whether there is an adequate product in the chute to fill in the container.

Discharge Hopper

It is a funnel-shaped component where product is fed into in readiness for sizing quantity or volume.

Conveyor System

This unit features conveyor belts or chains that facilitate movement of containers from one location to another.

Other equally important parts of liquid packaging line include the following;

- Bottle support trays

- Pneumatic cylinder for tray lifting

- Electric unit

- Inlet solenoid valve

- Corking unit

- Cork collection tray

Ideally, efficiency is a core element in determining a successful liquid packaging line.

You have to consider a wide range of factors to optimize efficiency of this particular system.

The main aspects you must have in mind to build a super-efficient packaging line for liquids include the following;

Product Viscosity

Different liquids used in packaging lines have varied viscosity, which is merely the thickness of the product.

It is a significant determinant element when choosing right machine to buy and use in production process.

Notably, using the equipment for wrong viscosity level could considerably hinder productivity and are likely to cause breakdowns.

Thus, you need to establish the product’s viscosity using a viscosity chart when choosing a suitable machine.

Precision

The equipment should guarantee accuracy in all its different parameters, including filling, sealing and labeling.

Equipment’s accuracy ratio should never be all over the place since it could lead to inconsistent results and product waste.

Hence, ensure you purchase the machine from a company guaranteeing accuracy of +/- 0.5%.

High Flexibility And Easy Changeover

Flexibility and ease of changeover of this equipment are also fundamental to designing an efficient packaging line system.

In essence, it implies that the machine should have the ability to accommodate multiple types of bottles or containers and products without need for changing parts.

Some equipment can also handle multiple bottle sizes as long as there is consistency in liquid’s viscosity.

Product Specifications

Other than viscosity, it is also important to establish other aspects of the product, whether automotive, corrosive, molten or food-grade etc.

If you are handling corrosive products, ensure the equipment is corrosion-resistant and constructed using suitable materials.

It is vital because it ensures the machine is protected from possible damage that would lead to unnecessary breakdowns.

Ease Of Cleaning

This element also plays a fundamental role in building the efficiency of the liquid packaging line.

A machine that is easy to clean saves ample time and allows you to resume the operations within shortest time possible.

Besides, an easy-to-disassemble equipment also allows you to clean it faster.

However, where possible, always choose a machine with the CIP feature allowing it to clean itself automatically.

This feature enhances efficiency since it inhibits the need to disassemble the equipment to clean the hard-to-access parts and components.

Particular Product Challenges

Some liquid products come with various challenges as far as filling and packaging functions are concerned.

Thus, it is advisable to include particulates in such liquid products to dictate the type of pumps and seals ideal for the equipment.

Furthermore, the bottles or different containers used for liquids can also be a determinant factor in determining the type of filler to use.

In modern manufacturing processes, liquid packaging machines come in handy in facilitating efficiency.

It is beneficial in different ways but majorly as follows;

Guaranteeing Reliability And Consistency

This equipment eliminates a wide range of uncertainties likely to be experienced during the filling process.

If you desire highly volumetric fill, level fill or any other, you can easily attain it with this equipment.

In essence, using this machine guarantees you utmost uniformity and reliability, which are essential in production process.

Easy Usability

Modern liquid packaging equipment have a pretty straightforward operator interface.

Besides, such interfaces use touch screens with easy-to-understand commands making the entire usability quite simple.

As such, the operator gets enough room to choose various times and volumes to complete each cycle.

In essence, it makes it easy to operate and monitor the various functional aspects of the equipment during the filling process.

Saves Time

This equipment is as fast and can fill and pack several containers within a shorter time frame depending on different factors.

Hence, speed, in this case, is an absolute advantage since it guarantees higher throughput, which translates to higher sales.

Furthermore, some modifications integrated into the machine, such as capping, multiple heads, and labeling features, enhance the speed.

Offers Excellent Versatility

Most companies producing liquid products usually specialize in different types of such products.

Therefore, this equipment comes in handy in such instances since it allows for filling different products.

Often, a few adjustments are usually conducted on the equipment to enable seamless shifting from one product to another.

In essence, this reduces running costs and improves general efficiency in the production process.

Eliminates Unnecessary Bottlenecks

Manual filling and packaging of liquid products in bottles and containers is susceptible to several human errors leading to bottlenecks during production.

Therefore, a systematic packaging line prevents such occurrences, given the equipment is integrated with components to maintain production flow.

Of course, this is fundamental because errors during packaging are reduced immensely.

Saves Cost

Using this machine reduces operational costs considerably.

It is energy-efficient and hardly requires intense labor since most parameters are automated.

Besides, it hardly experiences unnecessary downtime making it a cost-effective system in the production process.

A standard liquid packaging line consists of several machines designed to perform a designated function in the overall production process.

The notable individual units in this line include the following;

Rotary/Linear Bottle Washing Machine

It is used mainly for cleaning functionalities in the line.

Some uses of this machine include washing bottles, air-jet, waterjet, and internal and external washing.

linear bottle washing machine

Rotary/Linear Filling Machine

The role of this piece of equipment in liquid packaging line is to fill the container or bottle with respective product.

It is available in different designs, and some feature multiple heads for increased production capacity.

linear filling machine

Common rotary filling machines are digital, viscous, electronic, volume, ampoule, injectable, semi-automatic etc.

Ropp/Screw Cap Sealing Machine

This is the component for sealing the bottle or container to prevent the content from spilling out.

The common capping machines used in this packaging line include chuck cappers, spindle cappers, snap cappers and vertical wheel pluggers etc.

screw cap sealing machine

Measuring Cup Placement Machine

It is designed to determine the quantity or volume of liquid material filled in the bottles or containers.

measuring cap placement machine

Inspection System

This unit inspects filled bottles by manually examining each bottle for quality assurance.

However, its speed is dependent on number of booths it contains.

inspection system

Labelling Machine

It is dispenses and applies labels to bottles and containers or packages.

labelling machine

Cartoning Machine

This unit collates, wraps and seals the bottles or containers into respective cartons or packages.

Ordinarily, it group bundles counted bottles for easy conveying and transportation.

cartoning machine

Packing Conveyor

It is a piece of mechanical handling equipment leading to a labeling machine for subsequent packing, printing, and blistering or striping.

packing conveyor

Each type of this packaging line has its operating mechanism depending on its features, design construction, components and type of liquid.

However, most of these lines incorporate same basic stations or components, each responsible for one or more phases within the bottling process.

Moreover, the layout of these machines may vary since different manufacturers arrange bottling line equipment based on production objectives.

Essentially, the process starts with loading empty bottles into the machine or conveyor belt.

The bottles then go through a cleaning process subject to vacuuming to eliminate all air to allow filling of the bottles.

The bottles pass through a filling station, which in many instances includes an in-line or rotary filling device.

Immediately the bottles are filled with specific liquid material; some are vacuumed to remove excess air.

It is a significant phase depending on the type of liquid product you are filling in the bottle.

Bottles then pass through the cap sealing machine to seal the container and move to the labeling applicator for branding.

The last step entails the bottles moving to the cartoning machine for bundling and later to the packing conveyor to await shipping.

In a liquid packaging line, it is imperative to determine the balance between efficiency and flexibility for your application.

In-line liquid filling equipment fills bottles in single-file formation, approximately 4-20 bottles at a time.

rotary filling machine

Hence, it is an ideal choice to consider for small and medium scale production entities.

They exhibit excellent flexibility in accommodating different bottle shapes, lower cost and are easy to change product over without using change parts.

On the other hand, a rotary liquid packaging line is costly and usually complex to operate.

Besides, during production, you can hardly stop the process in rotary machine if a problem arises.

Additionally, it takes a lot of time to change over, and each changeover is quite costly.

However, rotary filing lines produce high speed and ability to fill numerous bottles in each cycle hence ideal in large scale production.

in line liquid packaging line

Ideally, this liquid filling unit provides a precise volume of specific liquid into every container, irrespective of shape or volume variations.

It is expensive to operate given the special instruments it requires for calibration, timing and balance.

You can use it with low viscosity or thick products, depending on specific variant you select.

Gravity Filler

It is arguably the simplest filling method that liquid machines use.

Product, in this case, supplied in bulk is pumped in a holding tank above several pneumatically operated valves.

Each valve is timed independently by filler’s master computer to allow an accurate volume of liquid to flow to the container via gravity.

Pump Filler

It features a pump that helps move the product through its pathway and to a waiting container.

However, the choice of pump depends on product you are running, fill sizes and whether there is particulates.

Net Weight Fillers

This technique utilizes a weight value to shut off when filling different products in bottles.

In essence, the filler typically tares the container value and fills it to specific weight values.

Overflow Filler

It uses a nozzle set such that immediately the liquid gets to a particular level in the bottle or container and overflows back to a holding tank.

Overflow filler creates unique fill into the system by forming a seal over the bottle allowing liquid to recirculate.

Pressure Fillers

This technique involves pressurizing the container with inert gas to equal the pressure of an inflowing liquid.

It then relieves pressure from the container, which allows the liquid to displace gas.

This packaging line is available in different designs hence has varied features.

However, the basic features you are likely to find in most of the machines used in liquid packaging lines include the following;

- Conveyor systems with different speeds for more flexibility

- Ability to package liquids with varying viscosity levels

- Integrated PLC control systems for easy machine configuration

- Ability to add extra filling heads to increase production throughput

- Easy to customize based on handling capacity and workspace available

- Variable production speed based on machine settings

It offers a wide range of advantages in a typical production process making it a worthwhile investment.

Some of these benefits include the following;

- It conforms to cGMP standards, which means it is safe, giving you immense peace of mind.

- This variant features an advanced “No-bottle, No-filling” technology arrangement. Ordinarily, this feature enhances efficiency and prevents wastage.

- Higher production speed is guaranteed since it features a double head that makes it easy to fill several bottles within shortest time possible.

- It comes with a wide range of salient add-on features, such as an expanded buffer tank. This increases the efficiency of the machine and guarantees desired results.

- The material used for constructing this equipment are strong hence guaranteeing unmatched durability. It can withstand different harsh mechanical and environmental conditions.

Investing in high-speed liquid packaging machinery produces a number of benefits for any packaging business.

Here are the main advantages why you need to buy this machinery;

Increased Production Throughput

It allows you to package liquids with different viscosity levels within a shorter time in multiple containers within each cycle.

Ordinarily, it has several fill heads and inline systems that can attain up to 120 bottles per minute, allowing filling of several bottles in a day.

Versatility

The design construction of a high-speed liquid packaging machine is built for multiple containers and different products.

Hence, it gives the business the necessary versatility, which is vital in enhancing efficiency in production process.

Versatility also helps in reducing operating costs since it eliminates the need to use different machines for different products.

Easily Upgradable

Ordinarily, this equipment allows you to upgrade the speed based on desired handling capacity.

Therefore, if you encounter increased production demands, you can easily add more fill heads to match your requirements and vice versa.

Lower Operator Interaction

This machinery has simple hand adjustment to shift from one bottle to another.

Besides, crucial settings are set on a centralized location accessible from a touchscreen interface.

Ultimately, it makes it possible for you to improve the overall efficiency and attain the desired results.

Excellent Precision

In addition to high-speed filling, this equipment also guarantees high accuracy and eliminates inconsistencies.

It allows repeatable, reliable and uniform fill with each cycle, whether the filling is based on weight, volume, level or other measurements.

Of course, this is beneficial since it enhances high sales and increases profitability, which is fundamental to business sustainability.

For all your liquid packaging machines, contact us now.