Semi-Automatic Cartoning Machine Manufacturer in China

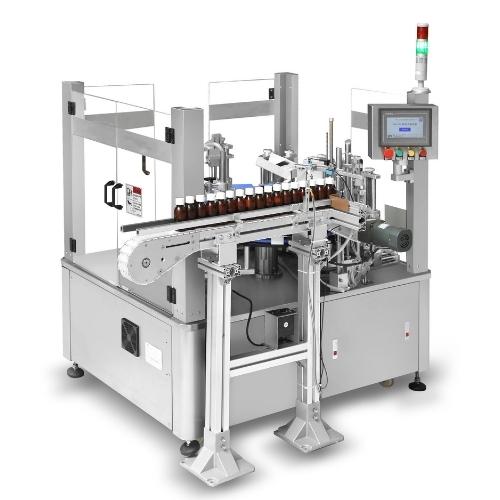

Jochamp is manufacturing many different models of high-speed and low-noise semi-automatic cartoning machines at low prices. Our semi-automatic cartoning machines are commonly used for laboratories, start-ups, individual users, etc.

- Approved by the ISO, SGS, CE, and cGMP

- Offers customization services

- Provides free sample packing test

- More than 15 years of manufacturing experience

Jochamp Semi-Automatic Cartoning Machine

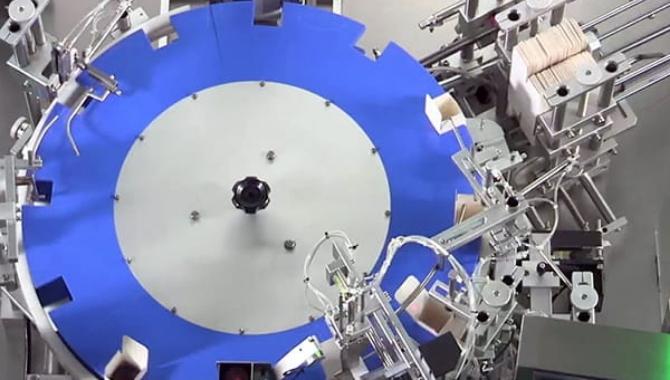

At Jochamp, we have a wide range of semi-automatic cartoning machines to offer. There are mainly 2 types of semi-automatic cartoning machines such as horizontal and vertical semi-automatic cartoning machines. They consist of a box conveyor, a device for closing and opening the flaps, a carton magazine, a folding system, etc.

The semi-automatic cartoning machines are excellent for packing and preparing items efficiently to increase work time and productivity. They can open the flaps for manual insertion of products. Then, they will fold and close the flaps automatically.

Our semi-automatic cartoning machines have easy operation, low noise operation, excellent energy efficiency, heavy stainless steel construction, and high-end PLC control system. They are the ideal choice for small businesses, start-ups, individual users, and laboratories. Also, they can be filled with a variety of containers, pouches, bottles, tubes, blister packs, sachets, and other bag of products.

If you want to know more about our semi-automatic cartoning machines, do not hesitate to leave us a message.

Various Semi-Automatic Cartoning Machine Models for Your Choice

This basic semi–automatic cartoning machine is manually loaded and suitable for tongue or automatic locking cartons.

Adding glue spraying function to basic function enables semi–automatic cartoning machine to use hot melt for carton closure.

Adding an automatic feeding system based on product customization to the basic equipment enables automated production.

Jochamp Semi-Automatic Cartoning Machine Features

The semi-automatic cartoning machines are super cost-efficient. You do not need to hire additional workers just to finish your packing and your production costs and labor costs will be reduced.

The semi-automatic cartoning machines are highly resistant to corrosion as they are made from naturally corrosion-resistant material, the stainless steel. As a result, they are very hygienic.

Jochamp semi-automatic cartoning machines are easy to operate. They have HMI and a high-end PLC control system which is also easy to operate. You don’t need to hire very skilled staff to operate them.

All of our semi-automatic cartoning machines have IOS9001, CE, and SGS certifications. We manufacture using raw materials that are certified by the cGMP. So, we ensure you that they have excellent quality and reliability.

Semi-Automatic Cartoning Machine Types

The semi-automatic cartoning machines have 2 main types such as:

Vertical Semi-Automatic Cartoning Machine – The vertical semi-automatic cartoning machines can send the carton boxes in a vertical position. The insertion of products in the vertical cartoning machines typically begins at the top. The vertical cartoning machines can be used for dried pasta, rice, and many more.

Horizontal Semi-Automatic Cartoning Machine – The horizontal semi-automatic cartoning machines can operate intermittently or continuously. You can insert the products from the side of the horizontal cartoning machines. These machines are widely used in the food industry. They are ideal for cakes, pizza, grains, and so on.

Various Types of Carton Closing Structures

The semi-automatic cartoning machines from Jochamp support a wide variety of carton closing. Below are some of the examples:

- Hot-melt adhesive sealing – This type of closing structure is intended for cartons that will carry heavier items. The hot-melt adhesive sealing is done by applying hot glue to the flaps of the cartons to make a permanent seal.

- Folding structure – This type of closing structure is the most common closure type for carton boxes.

- Self-locking structure – The cartons that have a self-locking structure have flaps that fold together without the use of tape or glue.s

- Tuck-in closure – This type of carton closure is also known as a tongue insert. The tuck-in closure makes use of the carton flaps to make a long-lasting closing method. The tucks or also known as tongues can be found on either the panel of the carton or on panel two.

Advantages of Semi-Automatic Cartoning Machine

Using semi-automatic cartoning machines have a lot of benefits such as:

-

- Low cost of maintenance.

- The semi-automatic cartoning machines can be configured with safety devices such as Human-Machine Interface (HMI) to protect the machine’s integrity.

- Since the semi-automatic cartoning machines do not need the require of skilled labor, you can employ a semiskilled labor.

- The semi-automatic cartoning machines are adjustable to have a wide range of sizes

- and shapes of cartons.

- Our semi-automatic cartoning machines have an overload protection system to lower the failure loss.

Why Choose Jochamp Semi-Automatic Cartoning Machine

Jochamp semi-automatic cartoning machines are widely used in many industries such as cosmetics, food & beverage, and pharmaceutical industry. We manufacture them from materials that meet the requirements from cGMP. They are made from 304 stainless that meets the food-grade standards.

The semi-automatic cartoning machines have high-end HMI control system and touch-screen PLC control system to have an easy operation. They can be also be integrated with various optional devices such as auto infeed conveyor, hot-melt glue applicator, leaflet placer, and hot-stamp imprinter for coding series numbers, expiration dates, and other labels.

All of our semi-automatic cartoning machines are manufactured in accordance with the standards from ISO, CE, SGS, cGMP, and other global quality standards. We offer them with a 1-year warranty.

Moreover, we are offering customized semi-automatic cartoning machines to suit your specific needs in the business. If you want our customized solutions, please feel free to contact us!

Jochamp Semi-Automatic Cartoning Machine

The semi-automatic cartoning machines have a lot of amazing features such as:

- Full 304-grade stainless steel cover

- Low noise operation

- Very easy operation

- Large reserved space for manual loading

- High packing speed

- Food-grade & drug-grade product contact surface

- High corrosion resistance

- Low energy consumption

- Easy to clean & hygienic

- Alarm for boxes not open

- Hot-melt glue closing

- Small footprint

- Safety door structure

- Overload protection system

The semi-automatic cartoning machines can be used for cartoning a wide variety of items such as:

- Bottles

- Blister packs

- Cosmetics

- Tubes

- Ampoules

- Bearings

- Containers

- Vials

- Droppers

- Food items

- Inhalers

- Other products

Why Choose JOCHAMP Semi-Automatic Cartoning Machine

Semi-automatic cartoning machines from JOCHAMP is guaranteed to provide consistency and seamless quality. With consistent output, you can surely have a competitive edge in your industry. Therefore, providing your customers with satisfaction while improving your brand. Our semi-automatic cartoning machine will allow you to all your production levels according to your requirements.

The semi-automatic cartoning machine has mechanical operation matching. It can be flexibly adjusted in speed. The rotating operation mode makes it have a small footprint that the horizontal cartoning machine does not have.

activated an instruction from an on-demand operator. These machines can also be operated by two persons to ensure quality control on delicate products. It can be tailored according to your unique business requirements.

With its semi-automated function and operation, rest assured that all our semi-automatic cartoning machines can provide your business with overall productivity while assuring increased output. Its seamless consistency in quality can provide greater efficiency and ease of your production. We produce semi-automatic cartoning machines to strengthen your packaging standards.

JOCHAMP engineers will work closely with you if you purchase our semi-automatic carton machine. We can tailor your designs and requirements to meet your expectations and provide the best solution for your application. Our team will make sure that your needs are exactly met.

Related Product

Semi-Automatic Cartoning Machine: The Ultimate Guide

I know you are looking for highly effective and reliable semi-automatic cartoning machine. Or, you want to learn more about semi-automatic cartoning machine. Whichever the case, this guide has all information you need.

Let’s dive right in.

A semi-automatic cartoning machine is an equipment that assembles, folds, shuts, and seals the carton. The device is loaded with blank carton magazines.

It then creates carton boxes that are used to store products.

Once the products have been packed manually (or automatically) into the folded cartons, the machine seals the carton.

semi-automatic cartoning machine

The machine can be used to package a wide variety of products. It can also accommodate cartons of various designs made with different raw materials.

The semi-automatic cartoning machine has a simple, user-friendly design. It utilizes manual labor as its feeding system is not automated.

Additionally, the machine’s simple design is easy to operate and requires semi-skilled labor.

Semi-cartoning machines’ features may vary from one manufacturer to the next.

The components may also vary depending on the type and size of the semi-automatic machine.

Some of the features of the semi-automatic cartoner machine include;

- It features a reduced carbon footprint.

- Most semi-automatic cartoning machine is user-friendly, implying they are simple to use.

- The machine can be used to package various types of products.

- Semi-automatic cartoners require minimal set-up time.

Its simple design also shortens the time needed to change tools during adjustments in cartooning requirements.

- The basic design of the machine makes maintaining the semi-automatic cartoner easy.

- Commonly, the semi-automatic cartoner is built with stainless steel that has passed the GMP standards.

- Semi-automatic cartooning machines have inverters used in regulating the machine.

- Finally, the semi-automatic cartoner has safety guarding.

There are different types of raw materials for cartons that are used in the semi-automatic cartoning machine.

The material used varies according to the products being packaged. The different types of cartons that can be used in the semi-automatic cartoners include;

Rigid cartons; the Rigid cartons are more substantial and therefore offer more protection to the packaged products.

They are mainly used for high-value products.

Foldable cartons; these cartons help minimize both storage space as well as transportation costs.

They come in various shapes and sizes; as such, you can choose and/or customize one to suit your needs.

Corrugated cartons; these types of cartons are assembled by sticking together two arched flute pads. They come in varying shapes and sizes. They are also cost-effective.

Shoulder carton; This type of carton utilizes two different raw materials. The top and bottom are Rigid cartons, while the middle uses the shoulder carton.

Customized cartons; these types of the carton are entirely dependent on the consumers’ needs. They can be created in any shape, size, and color according to the customers’ preferences.

Mailer’s carton. This type of carton is suitable for packaging products that are small in size.

Sliding carton; The sliding carton is made up of separate pieces. It has the inner box and the exterior sleeve.

Telescope carton; This types of carton consist of two parts. It has a cover and a base.

Conventional slotted carton; This is the standard type of carton used in packaging. The standard slotted carton comes in a range of sizes but is otherwise uniform in its basic design.

Complete overlap: These cartons have flaps covering the entire top of the carton. This enhances the strength of the carton.

Semi-conventional carton. This carton has an opening on the sides for placing the products.

The semi-automatic cartoner machine has primarily four parts. These parts are;

Carton magazine; the magazine contains blank cartons that are to be folded into boxes.

Conveyor belt; the conveyor is essential as it transports the carton through the various packaging stages.

Folding system; the folding design is responsible for bending and forming carton boxes depending on the parameters set.

A starwheel; is essentially a part that is responsible for the opening and closing of the flaps.

There are other additional parts whose presence may vary from manufacturer to the next.

It may also vary depending on the type of semi-automatic cartooning machine you select.

These different structural features include;

An alarm system; most semi-automatic cartooning machines have an alarm system to alert on different needs.

An alarm for assembled boxes that remain closed. There can also be an alarm system for when carton levels are low in the magazine

A pickup arm, some semi-automatic, has components that use suction force to pick up and transfer boxes from one station to another.

A handwheel; the handwheel together with a reference ruler are used when changing the format of the semi-automatic cartooning machine

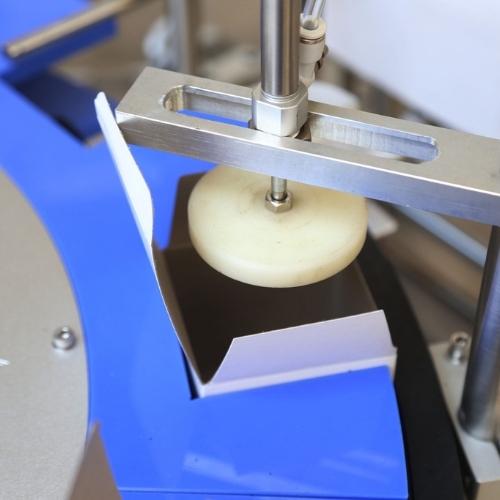

A sealing device; such devices use varying methods to seal the boxes, such as hot melted glue.

Safety guards. The standard guards are made of electro-welded wire mesh.

They prevent the carton from falling over, ensuring the integrity of the machine’s operation and the operating personnel’s safety.

The first step involves the position of the carton by the safety guard rails.

After that, the mechanism responsible for pushing, which is generated by the push plate, opens the carton.

Besides, the bottom of the carton is then joined to a vacuum suction cup that is propelled by its pneumatic system.

This procedure is carried out beginning with the back to the front to ensure that the carton is upright when it gets to the feeding bay.

With the semi-automatic cartooning machine, feeding the products into the carton is done mechanically.

The personnel ensures that the products are placed accordingly in the carton.

After the product has been placed into the carton, the conveyor belt transports the loaded carton into the folding area.

This is carried out by the steel railings. The railings fold both the right and left flaps at the same time using a rotating motion.

Remember, the aim of the folding is to close the box.

Again, the semi-automatic cartooning machine has a cam which that is fixed to a motor that propels the plate to carry out the folding process on both sides.

Also, the box is then moved to the next stage. The next stage involves sealing the box.

This is a very critical stage as it ensures the safety of the products stored inside the carton boxes. The carton flaps are sealed at the front.

Additionally, the push plate then initializes the push, which causes the lid to bend, thereby securing the lock.

After the box has been sealed, the semi-automatic cartooning machine then uses its label to control the adhesive.

It is also responsible for closing all ends completely and sealing the box.

Finally, the machine then inspects the sealed carton to ensure that all the requirements have been met. The machine will be able to detect boxes that have not been properly sealed or boxes that have not been loaded with the products.

The semi-automatic cartoning machine mainly helps in automating the packaging process.

This helps quicken the packaging time, thereby saving on operations costs and time. Other benefits include;

- Semi-automatic cartoning machine is capable of handling a variety of operations.

The semi-automatic machine can produce various types of cartons such as ampoules, pouches, vials, blister packs, and different types of bottles, among other types.

- Semi-automatic cartoning machine allows you to package multiple products of different varieties at the same time.

Therefore, you can pack complementary goods such as toothpaste and toothbrush using the same machine.

- Semi-automatic cartoning machine uses limited in comparison to fully automated heavy-duty industrial packing machines.

They include, the low power consumption helps reduce the overall production cost.

- Semi-automatic cartoning machine can be configured with additional safety devices to protect the basic structure of the machine.

- Semi-automatic cartoning machine has changeable parts and can therefore be adjusted to meet various cartooning requirements.

There is a wide range of applications for the semi-automatic cartooning machine.

The type of semi-automatic carton used depends on the type of product to be packaged.

Semi- automatic cartooning can be used in packaging;

- Grain and Spice.

- Fruits and vegetables.

- Chemical.

- Tobacco.

- Sports equipment.

- Toys.

- Clothing and textiles.

- Electronics.

- Food and beverages.

- Pharmaceuticals and cosmetics.

Vertical, Semi-Automatic Cartoning Machine

The vertical cartoning machine has a vertical (from the top) feeding system for both the products and the cartons.

Its production process involves inputting the cartons into the machine. The machine then overlays the folds of the carton.

Next, the products are inserted from above.

vertical semi-automatic machine

The machine then closes the carton and finishes by printing and stamping the selected dates on the sealed carton.

The vertical, semi-automatic machine utilizes a vertical operation layout to prevent product damage.

It has change-over parts that can be easily adjusted to accommodate its vertical carton input.

Horizontal Semi-Automatic Cartoning Machine

The horizontal cartoning machine is a type of semi-automatic machine whose feeding system for both the products and the cartons is horizontal (from the side).

Its production process involves inputting the cartons into the machine. The machine then overlays the folds of the carton.

The next step is to insert the product from above.

Also, the cartoner then concludes the process by closing the carton, printing and stamping the selected dates on the sealed carton.

horizontal automatic machine

Its horizontal cartoning format helps increase the stability of the carton as well as the product placement.

This reduces the risk of the cartons falling off during product placement as well as during the sealing process.

The production capacity of a semi-automatic cartoner varies according to the type and size of the semi-automatic cartoner.

Larger semi-automatic cartooning machines are used for large-scale productions and, as such, have a higher production capacity.

Likewise, semi-automatic cartoning machines that are smaller in size are generally used for small-scale production and, as such, have a lower capacity.

The production capacity of a semi-automatic cartoner is measured in terms of how many cartons can be erected per minute.

Remember, the production capacity can range from as low as 40 cartons per minute to as high as 500 cartons per minute.

It is, therefore, best to select a semi-automated machine that is best suited to your scale of production with room for growth in the future.

Fully Automatic Cartoner

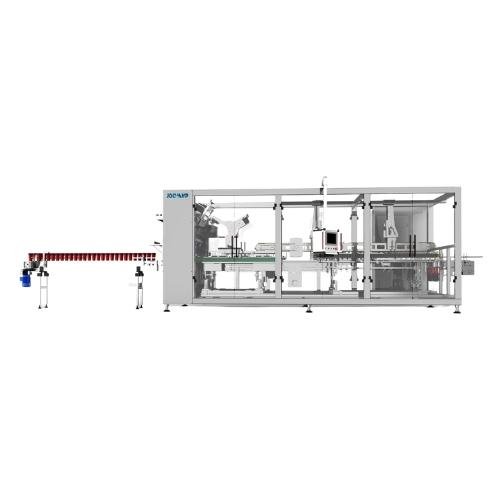

The fully Automatic Cartoner is a high technology machine that does not require any manual input during the cartooning process.

The Fully Automatic Cartoner includes an automated feeding system that helps in lightening the production load.

It requires a few skilled personnel to oversee the cartooning process. In the Fully Automatic Cartoner, the machine relies on a digital control unit.

fully automatic cartoner

The unit runs the machine by regulating, managing, and controlling the operations of the machine.

The Fully Automatic Cartoner caters to a multitude of needs. The available processes carried out by the machine include;

- Stocking of packaging materials.

- Overlaying the folds of the carton.

- Setting up the carton upright.

- Printing on the cartons.

- Heated spraying

- Insertion of the Product

- Closing the carton and,

- Dates Stamping.

Semi-automatic cartoning Machine

The semi-automatic Cartoning Machine requires manual input for some of its processes. It utilizes a manual feeding system.

This process slows down the production process in comparison to the Fully Automated Cartoner.

It requires more operators, but it can be operated by semi-skilled labor.

It has unique design features that enable it to handle a variety of cartooning requirements. It can be carton bottles, tubes, sachets, blister packs, and pouches.

semi automatic cartoning machine

There are more elaborate designs that include accessories such as Automated Folding Machines, Conveyor belts, and carton magazines.

It is essential to properly maintain your Semi-Automatic Processing machine.

It lengthens the lifespan of your cartooning device as well as ensures that all the operations run smoothly without interference from constant breakdowns.

The most important step is to set a routine maintenance schedule.

The frequency of the maintenance routine depends on the scale and frequency of use of the machine. Machines that are constantly being utilized should be checked on more regularly than machines that are used once in a while.

During the routine maintenance schedule, you should conduct the following activities;

- Conducting visual inspection to affirm that the machine is visibly in good physical condition

- You should do basic cleaning of the machine to prevent the build-up of dust and other dirt particles, which may slow down the productivity of the machine.

- You should check on the parts that are most likely to wear and the level of the lubricant.

- Deep cleaning to ensure that every part of the machine has no waste or debris that might lead to the malfunction of your semi-automatic cartoning machine.

- Maintenance of the cartoning involves installing software updates.

The machine is partially automated and, as such, requires regular updates to ensure operations run smoothly.

- You should change the highly wearable parts before they get too damaged.

- It is essential to keep track of the machine’s energy consumption levels.

A spike or a drop in the semi-automatic could signal a potential problem.

Several factors should be taken when choosing a semi-automatic cartoner.

Safety of the semi-automatic machine; it is essential to consider the safety needs of the machine. The safety of the operators should also be taken into consideration.

User-friendly surfaces are preferable as they boost the safety of the machine.

The size of the items that are to be cartoned; The size of the items should be taken into consideration as they determine the size of the carton.

The production capacity of the Semi-automatic machine; The Semi-automatic machine should be able to keep up with your scale of production.

Larger scales of production require cartooning machines with faster speeds.

Types of products being packaged; Different products have different needs and, as such, may require additional equipment in order to properly preserve the products.

Machine spare parts; you should take into consideration the machine’s change parts.

You should pick a semi-automatic machine that requires changing a few parts in order to adjust carton sizes.

Setting up area; it is important to consider the space you have available for installing your machine.

Selecting Mechanism; the equipment used to pick up the product should be compatible with that type of product.

For all your semi-automatic cartoning machines, contact us now.