Horizontal Cartoning Machine Manufacturer in China

JOCHAMP expertly manufactures various structures of cartoning machines, including horizontal ones. We offer these horizontal cartoning machines that form the cartons by gluing blanks, introducing the goods automatically, and closing the cartons. Choose our offered machines now!

- Heavy-duty structure

- Without tools required for carton replacement

- Made from fully welded steel frames

- Connected with ethernet connections

JOCHAMP Horizontal Cartoning Machine

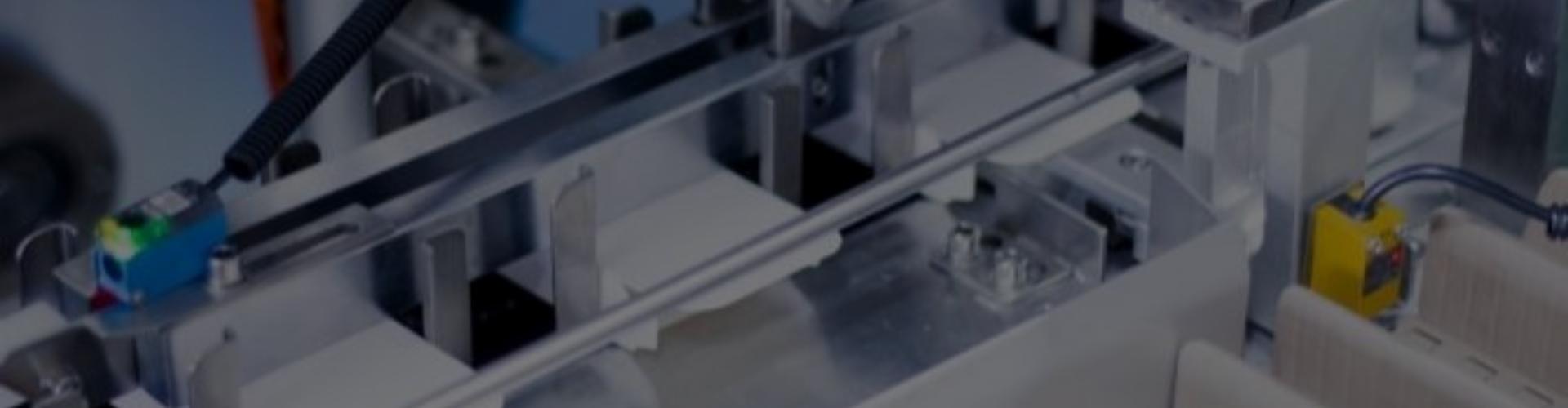

The horizontal cartoning machines feature accuracy and speed. These automatic machines use robotic technology to achieve proper packaging. They flawlessly and accurately load the products by intermittent or continuous motions. JOCHAMP provides washdown specifications for frozen products to minimize the rusting conditions and maintain the pristine looks of the machine.

JOCHAMP customizes your desired machine designs and sizes. We ensure that all the series of cartoning machines we supply have passed CE, SGS, ISO9001, and cGMP certification standards. Our incredible experience and advanced technology equipment guarantee high-quality and excellent machine performance.

Don’t hesitate to communicate with JOCHAMP now!

Multiple Models of Horizontal Cartoning Machine for Your Choice

Entry–level cartoning machine with speed of 30–70PPM, simple mechanical structure, suitable for small factories and start–ups.

Advanced intermittent cartoning machine suitable for wider size range, with speed up to 100PPM.Add more additional functions.

Flexible robot front-end feeding system realizes precise product positioning & removal of defective products.

The enlarged cartoning machine featuring a relay-type suction box device is particularly well-suited for packaging larger cartons.

The continuous-motion cartoning machine boasts a faster speed and more stable operation, making it a reliable choice for efficient packaging.

Why Choose JOCHAMP Horizontal Cartoning Machine

JOCHAMP manufactures horizontal cartoning machines, ideal for users and businesses. These machines are easy to use and applicable to various organizations. They can operate different product packaging with high efficiency and productivity.

The safety and security of a business are important factors. JOCHAMP supplies them with safety manuals and instructions. We design them with better consistency that provides safety performance, and extends transportation security.

JOCHAMP horizontal type of cartoning machines has compact designs. This design achieves consistency and quality than other marketed machines. It helps level up the branding openings and permits noteworthy plans. However, they are customizable.

JOCHAMP ensures horizontal cartoning machine quality packaging. We always prioritize the requested specifications during production. It assures the customers’ satisfaction with cost rates that meet their expectations.

How Horizontal Cartoner Works

JOCHAMP designs horizontal cartoner with simple operations. The process of cartoning starts with taking flat and seaming the cartons individually. It begins from an inline horizontal carton magazine feeder. The cartons are erected apiece with square shapes into the carton carriers. Once positioned, folding close and sealing carton bottoms occur. After that, the cartons are transferred to the loading place to encounter the product trays.

The products are placed into the trays manually or automatically. The trayed products are moved into load stations and pushed into the cartons. After filling the cartons, the top flaps are closed and sealed. And finally, discharge the finished carton from the machine.

Horizontal Cartoning Machine Salient Features

JOCHAMP manufactures high-quality horizontal cartoning machines with high standard features. The following tells about machines’ characteristics.

- Automatically stops the products when the box is not in a position

- Adjustable specifications to suit different products

- Designed with PLC that automatically exposes the boxing speed and finished product quantities.

- Displays stop, and alarms automatically

- No product and carton controls

We also customize the machine features you desire and need.

Horizontal Cartoning Machine Product Markets

Multiple products are ideal for horizontal cartoning machines operations. They are the suitable machine for cartoning various goods, such as:

- Pouches

- Personal care

- Frozen foods like ice creams

- Snack bars

- Stick packs, like drink mixes

- Long goods such as pasta

- more

Choose Horizontal Cartoning Machine from JOCHAMP

JOCHAMP ensures high-quality equipment, as we have more than 15 years of manufacturing packaging machines experience. We provide multiple satisfying services to help boost business. JOCHAMP has professional engineers that solve your cartoning machine desires. Plus, we assure fast delivery without damaging your customized machines.

Our cost-effective horizontal cartoning machines are beneficial to your packaging facilities and business. With our expert designing team, we prioritize your sample drawing details during production. Expect quick response and satisfying answers to your questions from our friendly sales staff.

Contact us for further details and send us your required specifications now!

JOCHAMP Horizontal Cartoning Machine

To define what cartoning machine suits your business or factories, consider the following differences between horizontal and vertical cartoners:

- Horizontal Cartoner: The cartoning machine pushes the products from the side into the carton. This cartoner is end-loaded. It is applicable for cartoning products that require tight-fit packaging.

- Vertical Cartoner: This cartoning machine is top-loaded. It is where products are placed or assisted from above to the carton. This cartoning machine is suitable for all other products as it features flexibility.

JOCHAMP assists in choosing suitable cartoning machines. Drop a message now!

JOCHAMP professionally designs a series of horizontal cartoners with multiple benefits, which include:

- Made and structured using high-quality materials

- Enhanced safety with lockable guard doors

- Come with adjustable spindles for easy changeover

- Available with washdown construction made with stainless steel

- Come with a protection guide and driveshafts

- Enhanced carton magazine, Low-level power indicator

- Highly customizable components and specifications

Feel free to negotiate with JOCHAMP to elevate your business to the next level!

Custom Horizontal Cartoning Machine for Various Industry

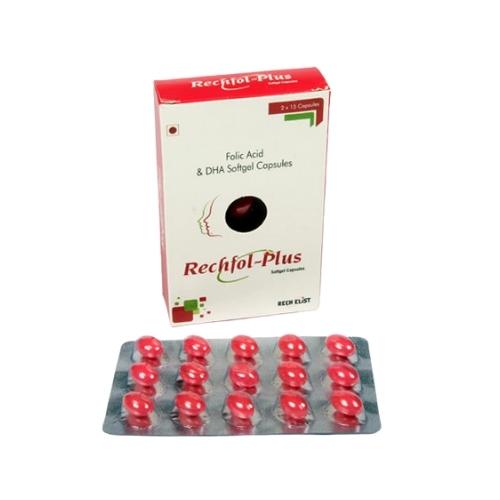

The horizontal cartooning machine is essential in the pharmaceutical business for boxing products such as ampoules, vials, blisters, strips, tablets, or oral solutions. It also aids in the prevention of medicine falsification. In a box, the machine can imprint the anti-counterfeiting function.

A horizontal cartoning machine aids in packaging goods such as dessert, powdered milk, sweets, cocoa, grains, and ready-to-eat meals in carton boxes. This packaging’s principal aim is to preserve the food’s freshness and prevent it from being contaminated by environmental forces.

Packaging chemicals in cartons protect the environment from dangerous exposure to toxic compounds. It is helpful for packaging containers and bundles of substances like plant nutrients, paints, adhesives, cleansers, oils, creams, household cleaners, etc. The mentioned machine is also helpful in ensuring safe arrival and shipping.

A horizontal cartoning machine plays a crucial part in packing personal hygiene items, such as soap bars, cosmetics, colors, sun protection, lotion, etc. The bright and appealing carton layouts prevalent in the personal care market safeguard the items. It also helps capture the attention of consumers.

Related Product

Horizontal Cartoning Machine: The Ultimate Guide

This guide will help you learn and choose perfect horizontal cartoning machine for all your applications. Whether you want to learn about the working principle, features, design or parts – you will find all information right here.

Take a look:

A horizontal Cartoning Machine is a type of carton forming equipment suitable for cartoning, collating and labeling of flat packages (boxes).

The equipment uses a packaging technology that seal and pack paper carton using high-speed linear actuator to control sealing, cutting and forming actions.

Horizontal cartoning machine has the characteristics of simple compact design, less space requirement and low noise.

Moreover, it adopts advanced technology, with high accuracy and stability.

It is widely used in food, chemical, medical and pharmaceutical industries for packing products like foodstuff, medical and pharmaceutical products in plastic/paper cartons.

horizontal cartoning machine

Let’s look at the 4 common types of horizontal cartoning machine you will find in the market during your search for the best option to buy:

Intermittent Horizontal Cartoning Machine

Intermittent horizontal Cartoning machine is a high speed, fully automatic cartoner which works in an intermittent mode.

It can run in both intermittent mode as well as a continuous mode.

The cartoner machine has an adjustable accelerator that allow you to adjust the speed of the machine according to the requirement.

It is the only system which brings together all of the productivity, efficiency and ergonomic advantages of continuous Cartoning in one machine.

intermittent horizontal cartoning machine

This cartoning machine type combines a high-speed horizontal carton-forming with an ultra-fast carton loading station equipped with an electronic label feeder.

The equipment produces a variety of cartons from simple to complex, from small to large size.

Continuous Horizontal Cartoning Machine

Continuous horizontal cartoning machines are designed for high speed and continuous operation.

It uses a horizontal transport system with a conveyor belt to transport the cartons at high speed through the various operations.

Continuous horizontal cartoner has been specially designed to ensure that different sized cartons can be filled and sealed at the same time.

continous horizontal cartoning machine

The machine can facilitate high production rates, ranging from 150 to 800 cartons per minute or more.

Moreover, this type of horizontal cartoning machine is capable of making single-sided or high double-faced cartons depending on your needs.

Automatic Horizontal Cartoning Machine

Automated horizontal cartoner machine is designed to pack and seal your products automatically in uniform cartons.

The equipment allows you to fill and seal cartons quickly and accurately, saving you time.

The closed-loop system is pre-programmed with your standard weights, eliminating the need for manual adjustments when switching between products.

In this way it reduces labor costs, enables more accurate filling, and delivers a higher quality product to your customers.

automatic horizontal cartoning machine

Moreover, automatic horizontal Cartoning machine uses multiple cameras to detect objects at all angles and automatically adjusts position of its sensors accordingly.

This allows it to produce high quality, consistent packages every time.

Semi-automatic Horizontal Cartoning Machine

The semi-automatic horizontal cartoning machine is a high-speed machine that helps you to pack your products in carton boxes quickly and accurately.

Here the cartoner machine performs its main operations automatically, while some like loading of cardboard is done manually by operators.

The semi-automatic horizontal Cartoning machine is ideal for medium to high volume production.

It features a highly efficient hydraulic system that automatically adds labels to the product.

Its modular design allows it to be easily scaled up or down. The machine can be easily adjusted and customized to suit your unique requirements.

semi automatic horizontal cartoning machine

This machine is perfect for those businesses that need their cartons in bulk.

The equipment is ideal if you are looking for a bulk packaging solution to help you save money and improve quality control.

The main benefits of horizontal cartoning machine include the following:

- Easy Operation:

Horizontal cartoners are easy to operate, which means that even a novice can learn to use it in a short period of time.

You just need to follow the instructions given by the manufacturer and set up the machine correctly. After that, you can start using it without any problem.

- Low cost:

The price of horizontal cartoner machine is not very high as compared to other equipment like vertical cartoning machine.

Also, you don’t need any special training for its installation and maintenance because it doesn’t have complex mechanisms or parts like other machines.

- High-Speed Operation:

Horizontal carton packaging machine can process up to 500 cartons per minute. This greatly reduces the production time and increases efficiency.

- High-Precision Positioning:

The machine uses a positioning system with high precision.

Therefore, the feature ensures that your products are packaged accurately and neatly, and also improves product quality.

- Easy To Maintain:

Horizontal cartoning machine is easy to maintain because of its simple structure and all-in-one design. It does not have many parts for maintenance and replacement, hence even if there is an emergency, you can repair it quickly.

Moreover, you can also use it for long periods of time without any damage or malfunctioning.

- Low Noise:

The horizontal cartonermachine has low noise when operating. This is because it only uses one motor instead of two or three motors like vertical carton packing machines do.

Moreover, the machine’s speed is relatively slow compared with vertical carton packaging machines, which makes it produce less noise while working.

- High Capacity:

A high capacity horizontal cartoning machine machine can handle a larger volume of products each day.

This guarantees less downtime and more productivity for your business.

- Compatibility:

This type of cartoning machine is compatible with other equipment and systems in your production line, which can greatly increase efficiency.

It ensures this by making it easier for employees to perform multiple tasks at once.

The two machines are used for different purposes, but they are both used to package products.

Again, the main difference between the two is that horizontal flow wrapper uses a roll of material like paper or plastic for packaging.

To compare these two machines, let us first understand what a horizontal flow wrap machine does. In this type of packaging machine, the wrapping material is pulled horizontally across the product by two rollers.

horizontal cartoner machine

These rollers are called drive wheels, and they are powered by a motor that is located underneath the machine.

Also, the product you want to package sits in between two guide rails (also known as guiderails).

Again, the guide rails keep the product straight and centered so it can be properly wrapped in plastic film or paper.

Remember, the guides also allow for easy removal of finished products from underneath the machine.

The Horizontal Flow Wrapping Machine is a highly versatile packaging machine, which can be used for wrapping and palletising products of different shapes and sizes.

horizontal flow wrap machine

It is an ideal solution for small and medium-sized businesses as it has the ability to wrap products quickly and efficiently.

You can use this packaging machine type in different industries like food, pharma, cosmetics and others.

The following are some of the features of Horizontal Cartoning Machine:

- Adopts hydraulic lifting structure, which has high reliability, low noise, easy maintenance and flexible adjustment function.

- Adopts automatic feeding system, which is convenient for installation and operation.

- Can automatically adjust the height of the guide plate according to the size of the carton, which can pack cartons with different sizes and shapes.

- Suitable for use with various types of cartons and boxes, including corrugated board, cardboard boxes, paperboard cartons, and plastic containers.

- Horizontal cartoning machines have safety features built into them to protect both the operator and the product being packaged.

This makes sure that nothing goes wrong during operation.

- Has a large number of options for customizing the product like color coding, labeling, branding etc.

Operation of horizontal cartoning machine entails inserting the products you are packaging from the side.

The first step involves placing the carton in the right position by the guide rail. The push plate then activates the push mechanism, which opens the carton.

Subsequently, the machine attaches the carton bottom to a vacuum suction cup that is driven by a pneumatic system.

This happens from the front and back of the carton to make sure it gets to the loading section at 90 degrees.

At the loading section, you pack the products manually, though gently and precisely. The chain conveyor of the horizontal cartoner will direct the carton boxes to folding section after loading.

Again, the primary aim in folding stage is to fold the boxes.

This operation is completed concurrently on the right and left ends of the steel guide rail through rotating motion.

Thereafter, the machine connects the cam to the motor in order to carry out the actual carton folding operation.

The folding is done on both ends of the track.

Remember, the next procedure is the most crucial in the operation of horizontal cartoning machine. Also, the system then seals the tongue in the front of the carton.

Subsequently, the push plate bends the lids and lead to a secure lock.

Consequently, the labeling system of the horizontal cartoning machine applies labels and eventually seal the box completely.

To summarize the working process of horizontal cartoning machine, the equipment checks the boxes accuracy.

It establishes the bad and good packaging by keenly assessing the carton structure.

Through the quality inspection, the machine separates those boxes that go straight to carton chute and bad packages that it ejects.

Based on the location where you introduce the carton into the equipment, there are two main types of cartoning machine.

For that matter, let’s look at the comparison between vertical cartoner vs horizontal cartoner:

Vertical Cartoning Machine

With vertical cartoner machine, you introduce the carton vertically into the equipment, mostly beginning the top.

The packaging machine can package the products automatically or manually.

Moreover, the vertical cartoner is appropriate for packing “naked” items that should or can be conveyed via gravity and sold by weight/volume.

vertical cartoning machine

Some of the products comprise of rice, dried pasta, among others.

Horizontal Cartoning Machine

Here, the cartoning machine packs your items from the side of the box. Vertical cartoning machine can operate in both continuous and intermittent mode.

The packaging equipment can as well fill the items automatically to the carton end and seal via hot melt application or flap insertion.

horizontal cartoning machine

The primary application of horizontal cartoning machine is for packing foods like vacuum-packed rice or coffee, grains, pizzas, cakes, among others.

Horizontal cartoning machine uses is increasing day by day. It is useful in various industries like food, electronics, glass, textiles etc.

The main application of horizontal cartoning machine include the following:

Packaging Of Food Items:

Horizontal cartoners are used by the food processing industries to pack products like cereals, cookies, chocolates, biscuits etc.

These machines help in creating customized boxes for packing products which are not possible with manual methods or other machines available in the market.

The products are packed into the carton boxes and then sealed with plastic tapes or labels. This helps to keep the food items fresh for a longer time period.

Also, these boxes are also used to transport the food items from one place to another easily.

Packaging Of Cosmetics:

Cosmetics companies use horizontal cartoners to create custom-made boxes for packing their products like lipsticks, creams, perfumes etc.

Packaging Of Electrical Items:

Electrical items like mobile phones, laptops and other gadgets are also packed using these horizontal cartoning machines.

They are used to pack them properly so that they remain safe from any kind of damage during transportation from one place to another.

This helps in reducing the risk of any kind due to mishandling during shipping. Also it helps in increasing the life span of these goods which increase their longevity.

Packaging Of Pharmaceuticals And Medical Supplies:

Horizontal Cartoning Machine is used in pharmaceutical industry for packaging of pharmaceutical products.

This machine is used to package the drugs in the form of tablets, capsules, liquids and other injectable medicines.

Other Related Machines:

For all your cartoning machine needs, contact us now.