Carton Former Machine Manufacturer in China

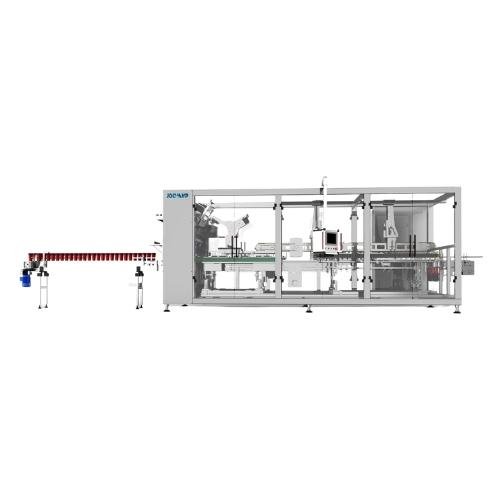

JOCHAMP has a wide selection of carton former machines that can handle a variety of cartons and trays at different speeds, sizes, materials, and styles. Our machines are adaptable and can be configured to fit customers’ individual requirements.

- Highly corrosion-resistant, easy to clean

- Flexibility in the production line

- Intelligent fault diagnosis system

- The machine passed CE, ISO9001, SGS certification

JOCHAMP Carton Former Machine

A carton former machine is a continuous motion machine that shapes, forms, and closes cartons used for manual or automatic top loading of different products. This machine has a highly programmed system control, which is easy to use and maneuver. Moreover, it is also a no-tool machine solution that displays high speed during operation.

JOCHAMP offers a carton former machine with the availability of various models — it can be single lane, dual lane, or custom. However, all machines are constructed to provide excellent and long-running performance. That can handle all-around carton forming and higher production quantities.

Furthermore, JOCHAMP is the leading manufacturer of carton former machines for end-line packaging machines. We continuously develop and innovates versatile configuration for all carton former machine that will suit your industrial applications. If you are interested in our product, kindly message us immediately for assistance.

Types of Carton Former Machine

JOCHAMP Carton Former Machine Advantages

JOCHAMP carton former machines are high-efficiency, easy-to-use automatic equipment that is appropriate for strong, ecologically friendly applications.

JOCHAMP may offer low prices while maintaining a high level of quality. And strong construction that can last for a long time. Choose JOCHAMP to get an affordable price.

Our company has excellent support created and manufacturing the carton forming machine. Compact design, appealing appearance, and efficient energy usage.

Customers can select their preferred carton former machine sizes, styles, and types. JOCHAMP is your one-stop carton former machine solution provider.

How Our Carton Former Machine Work

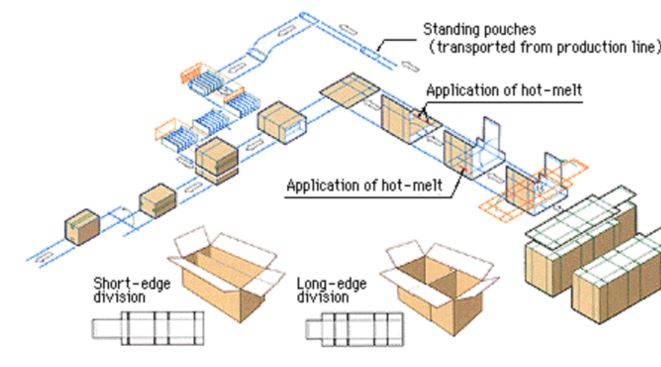

The machine pulls a single sheet of cardboard at a time. It pulls through the forming plows and then erects the cardboard’s side and end panels while folding small flaps. As it outreaches at the bottom, there is a pneumatic control that folds and locks the rollover flaps.

At some point, this carton former machine used flat punched cardboard sheets that pushed it down to form precise and robust cartons, which can be glued, lock-styled, or sealed. The carton is formed from singular to triple lane depending on the configuration.

Wide-Ranging Scale of Structures

The carton former machine is engineered for the most complex carton forming applications. Its outstanding concept offers a wide-ranging scale of applications and advantages in the packaging industry. This machine has a high-end format and program representing superb performance and flexibility.

JOCHAMP carton former machine is produced in high-speed set-up, which runs and withstand even in continuous heavy-duty operation. Our carton former machine is competent in accomplishing thousands of cartons in diverse measurements, depths, designs, and structures.

Carton Former Machine Function Characteristics

Our carton former machine is built within a perfect conditioned electrical energy and mechanical structure that gives smooth operation, low noise, high intensity, and superior abrasion protection, ensuring precise machine transmission. It also has an enclosed lubricating system type that secures transmission accuracy.

In addition, the entire carton former machine is compact and has a strong connection within system units and components that offers high precision of performance, reliability, convenience, accelerated production, and extended service life.

Why Choose JOCHAMP for Carton Former Machine

JOCHAMP has over 15 years of being the worldwide best manufacturer and supplier of high-end carton former machines and packaging systems. Through our exceeding experience, skills and knowledge in this field, we can fulfill our core mission to propose and develop high innovation carton former machines solutions.

Our carton former machine is helpful in many industries and applications, as it ables in keeping up the high rising levels of protection for all finished products. All components’ movements are specifically designed to produce a certain desired function in achieving the fastest and easiest work.

JOCHAMP consists of professional engineers who designed and perfected different models of carton former machines with respective working principles, capacity, and qualities. As your trusted manufacturer, we assure to give you the best machine solution for you. Contact us or visit our webpage to discover some of our versatile carton former machines and the advantage of each.

We manufacture carton former machine based on a customer’s interest and requirements. All of our machines are made with outstanding durability and exceptional features, such as:

- High control and supply voltage

- An adjustable dual two-foot powered magazine for a single sheet of flat blank cartons

- High speed and reliable carton staging

- Ease of adjustment

- Tool-less changeover

- Energy consuming

- Accurate and convenient operation

- Accessible in three forming controller

- Fast format alternation for various packages

There are innumerable benefits to using carton former machines in any industrial business. Below are the most common benefits observed by business successors and enthusiasts while using carton former machines:

- Carefully formed an extensive range of cartons in different measurements and styles without having any damages

- Consistent optimal carton display

- High accessibility

- Low labor-services cost and maintenance fee

- Only required minimal area

- Sturdy machine equipment that is approved with standard components.

JOCHAMP Carton Former Machine Advanced Services

JOCHAMP is capable of completing carton forming machine projects to a very high standard. Given a diverse crew and a positive approach, on time and on budget. A comprehensive construction and design package is available. We provide customized solutions to all of our clients in order to exceed their expectations.

JOCHAMP assures that carton former machines are guaranteed high quality. JOCHAMP adheres to all industrial machine standards and certifications. Our top priority has always been quality. The best reward at JOCHAMP is the trust of our many delighted clients, who value our machines’ outstanding design and reliable technology, as well as our quick and always-available support and service.

JOCHAMP carton forming machine may provide a one-of-a-kind solution by creating retail-ready packages, stackable trays, and standard shipping containers in a variety of sizes and materials. Choose us to provide equipment and systems that are continually updated for the newest technology, safety and ergonomics requirements, and maintenance savings.

Related Product

Carton Former Machine: The Ultimate Guide

Carton forming is an important process during packaging. This guide will help you choose an effective and reliable carton former machine that meet your unique specifications. Whether you want to learn about features, advantages, specifications or design – you will find all information right here.

Carton former machine is a versatile, high-speed, continual motion equipment designed to create cartons for automatic or manual top loading of items.

The machine uses flat carton blanks to form different carton designs and structures, with or without cover.

You can customize the carton forming machine to your specifications, configurations and performance, guaranteeing a high degree of versatility.

There are various applications of carton former machine, and you can use it either as stand-alone equipment, or integrate within a packaging line.

carton forming machine

The following are the main parts of carton former machine:

Control Panel

Using programmable logic controller system, the control system helps in automatic control of all the carton forming process.

This is among the most vital carton forming machine parts that assists you to manage the:

- Number of cartons in each cycle

- Number of items per pack

- Print application

- Fluid and electrical indicators

- Product placement

The Human-Machine Interface of the PLC enables you to modify the production parameters to attain the required results.

Electrical System

This is the part that powers the carton former, which it does from the electrical panel.

All electrical connections, both electrical circuitries and mechanical system, of the machine originate from the electrical panel.

Electric Motors

All movements during operation of carton forming machine come from the electrical motor.

The motor helps in the conversion of electric energy to mechanical energy needed to run the moving components of the cartoner.

Automatic Lubrication System

As the name suggests, this part of carton former machine lubricates the moving parts automatically to guarantee longer service life.

The automatic lubrication system also prolongs repair and maintenance interval, decreases labor costs and increase productivity.

Pneumatic System And Cartoning Pack Tooling

Here is where the actual carton forming operation takes place.

Employing vacuum suction, the pneumatic system draws in flat carton blanks to commence the carton forming process.

The carton blanks are put into the equipment via the carton storeroom, having front and rear parts mounted with mid and front plates.

Being mobile, the mid plate is adjustable to the length of the carton box.

Safety System

Most carton forming machines feature safety systems that help to prevent incidents and accidents in case of breakdown.

Such safety features include emergency buttons at the control panel, and guide rail at the conveyor system.

Conveyors, Rollers And Guide Rail

Linked to rollers, the conveyors helps in cartons movement from one section to another.

Their motion is due to the motors that are linked to gear box, which determines the motor speed.

Moreover, the guide rail direct the conveyor belts, thereby essential in preventing it from going off course, which can cause accidents.

Carton Chute

Dependent on the manufacturer, some carton former machines feature a chute mechanism.

The carton chute is helpful in ejecting the cartons formed from the machine for subsequent packaging.

Printing System

Modern carton former machines feature a printing system that helps in labeling of the cartons with information like date of manufacture and expiry.

The function of carton former machine is to transform a carton blank to a carton box filled with products.

Similarly, the machine allows you to fill several different items in one carton.

Cartoners feature a carton magazine compartment that has an automatic arm. The role of this arm is to pick up carton blanks from the magazine using suckers.

Operation of the carton former machine involves picking one carton from a bunched cartons stack and erecting it.

The equipment then fills the erected with items or bag of items (or several items).

After filling the items through an open end, the cartooning machine then seals by tucking the carton’s end flaps.

On the other hand, some types of carton former machines use some type of adhesive.

Subsequently, a conveyor transports the carton formed from the machine to the next stage of packaging.

You can easily change the format by simply changing the configuration from the PLC.

carton forming process

There are many benefits that come with inclusion of carton former in your manufacturing business. Some of the reasons why you need carton former machine include:

Improved Efficiency

Buying a cartoning machine may help enhance your packaging process efficiency.

This equipment finishes packaging procedures at a quicker rate and with greater precision compared to human personnel.

Your workers can attend to other crucial operations in the manufacturing process since carton former machine need minimal human intervention.

Cost Saving

Carton forming machine can help you save money.

You will require very few operators when you purchase automatic carton former machine. As a result, you will cut cost of production and save greatly on wages every year.

Minimizes Packaging Errors

There are high chances of mistakes your workers are put on longer shifts.

Investing in cartoner machine can help you avoid these uncalled for errors that can be costly.

Though the equipment is not 100 percent error-free, it considerably minimizes the frequency of error.

Increase Custom Satisfaction

Investing in carton former machine can boost customer satisfaction in your products. This is because the equipment can assist you attain high quality packaging standards consistently.

Specifically, an automatic cartoning machine inspects the cartons integrity, which makes sure that any defective packaging is removed.

Enhanced Safety

Fully automatic carton former machines ensure high degree of safety.

As a result, the operators are not susceptible to health hazards and injuries since they do not take part in the packing operation.

This can be particularly crucial when handling radioactive, irritating, corrosive, or toxic products.

Here, the cartoner will not only ensure safety of your workers but also help you avoid probable lawsuits.

High Productivity

Buying a carton former machine is a perfect investment guaranteeing high rate of production. You can double or even triple your present out with this equipment.

During selection of carton forming machine, you should opt for an equipment that will be in line with your manufacturing goals.

At the same time, the cartoner should ensure efficient performance, while cutting cost in every aspect.

For that matter, let’s explore the key characteristics of carton former machine that you should look for:

- Production capacity of as much as 60 cycles per minute (each head)

- Able to create a wide variety of carton styles and sizes

- Lock or glue forming

- Has up to 3 forming heads

- Quick format change for different packages

- Automatic format change

There are three main types of carton former machine which we are going to discuss in details as follows:

Fully Automatic Carton Former Machine

Cartoner equipment of this kind are sophisticated and facilitate for feeding of carton blanks automatically.

This machine can check the quality of the carton packaging process, which is essential in ensuring high product standards.

automatic carton forming machine

Investing in this cartoning equipment can offer your business a competitive advantage or help you be ahead of your competitors.

Some of the unique features of fully automatic carton former machines include:

- Folding systems

- Inkjet printers

- Hot melt adhesive system

- Brochure insertion system

High Speed Carton Former

For maximal throughput, choose high-speed, fully automatic cartoner machine.

The equipment automates the whole box forming operation, including flaps folding, and can package a number of carton types.

high speed carton former

Moreover, fully automatic, high-speed cartoning machine offer quality, speed, and versatility, with a variety of upgrade and integrations alternatives.

Semi-automatic Carton Former Machine

With this type of carton former machine, you have to load the carton blanks into the equipment manually.

Though this makes it easy to run the equipment, it negatively influences the speed and production output.

semi-automatic carton forming machine

These types of cartoning machines are labor intensive in comparison to automatic carton forming equipment, thus you will need many operators.

Maintenance of cartoning machine serves an important purpose in safeguarding optimal productivity. To ensure efficient maintenance operation, first create a maintenance schedule and implement it regularly.

Checking for system failures is essential, as this might indicate necessity for repair or replacement. Regular maintenance prevents issues, saves money and prolongs the lifespan.

Carton former machine breakdown can lead to total production line failure.

For that matter, you should observe these maintenance routine to avoid downtime due to replacement and repair of parts.

Preventive Lubrication

You must keep the moving parts lubricated routinely as outlined in the cartoner machine manual.

If you neglect this preventive lubrication, breakdowns due to friction are normally not taken care of by the warranty.

Keep The Machine Clean

Periodic cleaning, if conducted regularly, can hinder long downtime periods due to more thorough, less often maintenance.

Furthermore, dirty equipment are uncomfortable to work on and operate.

Debris, dirt, and dust on the machine may as well harbor some potential issues with its performance. A simple wiping at the close of day can bring a lasting effect on avoiding greater problems in future.

Machine Inspection

Frequent inspection of the carton former machine is vital in guaranteeing an extended lifespan.

Timely detection of an issue may result in inexpensive fix, but you may incur more if you take time to spot the problem.

Inspecting the machine routinely ensures that it keeps producing to the same efficiency and precision as on the first day.

Routine inspection of all carton forming machine parts minimizes repair downtime and boost your general cost saving.

Changing Parts Regularly

Cartoner machine may wear down from continuous use.

Due to this, you will need to replace its parts regularly to ensure the machine keeps operating to its full potential.

Failure to replace worn out parts would impede the packaging line and interrupt your workflow. Therefore, to minimize downtime, you need to know the type of carton former machine parts used and the procedure of replacing them.

However, only a certified technician or a highly skilled and trained personnel should change the parts. Also, you should always consult your carton forming machine supplier to advice you on the right spare parts to use.

Using the appropriate replacement parts will lead to a better performing carton former machine.

To truly enjoy the benefits of fully automated packaging line, you need to integrate your carton former machine with other equipment.

Integrating machines will help improve the efficiency of the line since they are configured to form a totally automated process.

Carton sealing machine ensures secure loads by firmly sealing the carton boxes.

They come in fully or semi-automatic versions, and can incorporate some aspect of automation.

Incorporating a carton sealer equipment ensures uniformity and enhances speed, saving both the costs of operation and labor.

Moreover, the machine similar amount of adhesive with each batch, reducing wastage.

Related Information:

For all your carton former machines, contact us now.