If you have a chocolate production line, you need a reliable and efficient chocolate packaging machine. This guide will answer all the questions you’ve been asking about chocolate wrapping machines. So, if you want to learn more about chocolate wrapping machines, read this guide.

1. Why buy a chocolate packaging machine?

There are several benefits to buying a chocolate wrapping machine. These advantages include:

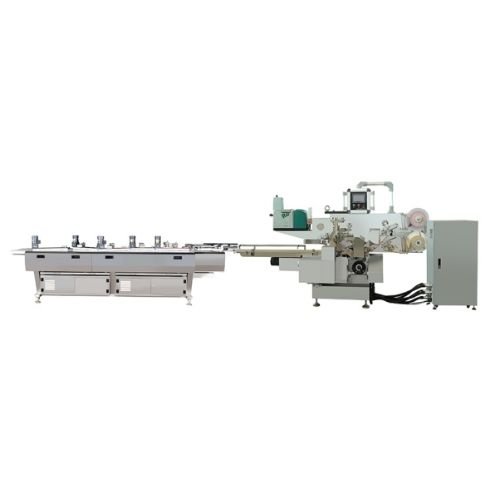

Chocolate Packaging Machines

1) Increase production

The machine will let you pack several chocolate products per unit time. The production capacity of a fully automatic chocolate packaging machine is higher than that of a semi-automatic or manual packaging machine. This allows you to meet customer needs in a short period of time.

2) Accurate packaging

Using a chocolate packaging machine will improve the accuracy and efficiency of the chocolate packaging process. This is especially true for the automatic version, since you will set the packaging parameters and run independently of the machine. In addition, the machine enables repeated packaging of chocolate products without compromising quality.

3) Improve hygiene

Chocolate packaging machines ensure no contamination of chocolate products. This machine is made of high-quality stainless steel material, easy to clean and corrosion-resistant. At the same time, it also ensures that the chocolate packaging process complies with the standards set by international bodies. This makes the final product suitable for human consumption.

4) Easy to maintain

This machine adopts high quality stainless steel material, which is easy to clean and maintain.

5) Improve the aesthetics of chocolate

Using a chocolate wrapping machine can improve the appearance of your chocolate products. This means it will attract customers who are likely to buy more products. For you, this means your sales and profits will increase.

6) Versatility

You can use the chocolate packaging machine to pack other products, This feature will increase your sales and profits as you can meet different packaging needs.

7) Safety

Automatic chocolate packaging machines have sensors that automatically shut down the machine when a malfunction is detected. This will save you a lot, which in turn will increase the production cost of repairs and damage.

8) It’s faster than manual packaging

In a situation where you need an operator to pack the chocolate by hand, this will take you a lot of time. On the contrary, this machine can guarantee you to pack a variety of chocolate products in a short time.

9) Ease of use

Since most tasks are done automatically, you can easily use and operate the chocolate wrapping machine. After setting the packaging requirements, all you need to do is monitor the packaging process from a central point. This is possible because the automatic version comes with a Programmable Logic Controller [PLC] and Human Machine Interface [HMI].

10) Reduce human labor

Using a chocolate wrapping machine will reduce the number of operators you need because they can perform tasks independently. This in turn will reduce your production costs.

2. What is the difference between a chocolate packaging machine and a chocolate packaging machine?

The purpose of these two chocolate machines is to preserve chocolate products, but they may have some differences. Chocolate packaging machines place chocolate in packaging that is in direct contact with the chocolate product. Chocolate packaging machines place the packaged chocolate product in a second package, box, or container. Furthermore, chocolate packaging is the second process for storing chocolate products.

3. What are the typical features of a chocolate packaging machine?

Features of Chocolate Packaging Machine

Since there are several types of chocolate packaging machines, they also have different characteristics. Here are some of the features you’ll find in these machines:

- The machine is equipped with PLC and HMI to simplify the operation and monitoring process.

- Can use CPP, PET, BOPP, NY, AL and other different packaging materials to package chocolate products.

- Packing speed ranges from 0 – 1500 pieces/min.

- Stainless steel body structure to keep the product hygienic.

- Chocolate packaging machine is easy to use and has a long service life.

- Photoelectric sensors improve the accuracy of the chocolate packaging process.

- User friendly design.

- The packaging process is automated.

- It comes with a variable wrap speed that you can control via an electronic controller.

- After the machine is filled, there are scissors or a serrated knife to cut the package.

- It also has sensors that detect the end of the packaging process.

4. What types of chocolate packaging machines are there?

The different machines you can find include:

1) Manual Chocolate Packaging Machine

This is a machine that you will mainly use for the small scale chocolate packaging process. The machine requires an operator and takes longer than a fully automatic chocolate packaging machine. Also, it is less expensive than the automatic version and not as accurate and efficient.

2) Automatic Chocolate Packaging Machine

The system has features suitable for large-scale chocolate packaging. This machine is expensive, but will save you a lot of money in the long run. It is more accurate, reliable and efficient than manual counterparts.

Automatic Chocolate Packaging Machine

5. What are the main components of the chocolate packaging machine?

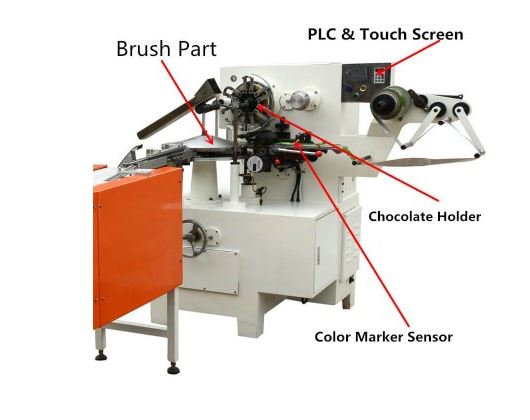

It may come with different parts depending on the type of machine. Also, you will find some main components in the chocolate packaging machine: Chocolate Packaging Machine Parts

1) Control panel

This section allows you to monitor and control the chocolate packaging process. In addition, you can enter packaging parameters such as speed through the system.

2) Dancer’s arms

This part is a freely moving roller that positions itself according to the packaging material.

When the wrapping material has the correct tension, it will maintain a neutral position.

When the tension of the wrapping material is high or low, the dancer’s arms automatically adjust.

3) Conveyor system

This part will help move chocolate products from one part of the machine to another.

4) Seal

These systems will help seal and cut packaging materials. They can have heating elements or a sawtooth pattern. The heating system will seal the packaging as the sawtooth pattern will cut the packaging material from the main film.

5) Discharge area

After the chocolate packaging process, the product exits the machine through the unloading area and enters the next production stage.

6) Movie system

This is a component with many links that will assist in pulling the wrapping material in a smooth rolling fashion.

7) Feeding tube

This part will align the product packaging with the film to ensure an adequate seal.

8) Sensor

These parts keep you and the machine safe. Anomalies will be detected and you will be notified via the control panel. In extreme cases, it will shut down the machine to remove further damage. Additionally, it helps eliminate chocolate products that do not meet minimum packaging parameters. This will ensure that defective products do not go to the next stage.

9) Vibration system

This part will assist in conveying the chocolate product through the feeding tube to the feeding system.

10) Car

This part converts electrical energy into mechanical energy to drive the various parts of the machine.

11) Hopper

It stores all the chocolate products before moving on to the next production stage.

12) Electrical System

This part contains all the electronic components that drive the chocolate packaging machine.

It contains fuses, wires and safety switches.

6. How does a chocolate packaging machine work?

Here’s how the machine operates:

Stage 1: Preparation

Here you make sure that all the chocolate products and packaging materials are in place. Furthermore, a complete production line has different machines to assist this operation. Make sure to pack the chocolate wrapper into the film system. Also, make sure the machine is fully operational before you start packing.

Stage 2: Packaging and Forming

The conveyor system transports the chocolate products to the packaging area. At the same time, the wrapping material will be formed with the aid of the dancer’s arms and formed collars. As the chocolate passes here, a wrapper forms around the chocolate, encasing it.

Stage 3: Cutting and sealing area

After the chocolate packaging machine has packaged the chocolate, the packaging film is cut into chocolate size. At the same time, a sealing mechanism is provided to ensure the sealing of the packaging material. This may be through the use of a heating mechanism or a glue system. The chocolate in the package now leaves the area as a separate package.

Stage 4: Discharge Zone

Once the machine packs chocolate products, they now leave the unloading area to the next stage of production.

7. What are the advantages of a chocolate vertical packaging machine?

Chocolate VFFS plays a vital role in chocolate packaging. The following are the benefits of using this chocolate wrapping machine:

1) Versatility

You can use a single chocolate VFFS to produce many kinds of bag shapes. This is because it has several easily interchangeable components such as formed tubes and shoulders. Plus, you can make a wide variety of bags and even handle fragile chocolate products.

2) Wide range of packaging materials

Chocolate VFFS can use different types of packaging materials during the packaging process. Furthermore, various chocolate products require a unique packaging parameter. Additionally, you can use laminates during the packaging process to maintain the aroma and character of the chocolate product.

3) low operating cost

Another benefit of using a chocolate VFFS machine is its improved operation. This is accomplished by lowering the chocolate packaging process. Also, it is cheaper to operate this machine because they can be equipped with a tool-less conversion system. They also last a long time if you take good care of them and clean them well.

4) Speed of production

Its high production capacity ensures that you will meet all your production needs in a timely manner. The machine can pack several chocolate products per hour of operation.

5) Sealed package

An important factor in packaging chocolate products is airtightness. This ensures that no elements can enter and contaminate the chocolate product. There are additional protection functions that take place in the MAP [modified atmosphere pack]. Here, you will exchange the air inside the packaging material with an inert gas. This will help with antioxidants, thereby extending the shelf life of chocolate products.

6) Labeling and Printing

You can add extra features like labels and/or printers to the Chocolate VFFS. The printer will include information such as production and expiration dates, as well as other important information about the product. The pre-printing process is carried out using a labeling machine, which is an automatic process.

7) Product consistency

These systems will fill the packaging material with the exact quantity of chocolate products. This feature ensures that your product is in the correct quantity and weight.

8) Efficiency and reliability

Throughout the chocolate packaging process, VFFS ensures the accuracy and consistency of the chocolate. This allows you to pack several chocolate products without losing quality.

9) Easy to operate

The system integrates a touch screen for easy operation and monitoring.

10) Film tracking system

This allows for accuracy in the packaging process, allowing no waste.

11) Energy efficiency

The system has a low carbon and energy footprint and is therefore environmentally friendly.

7. What other products can be packed with the chocolate flow packer?

This machine is versatile when it comes to packaging products.

Here are some of the products you can pack with a chocolate flow packer:

- Toffee

- Cake

- Bread

- Candy

- Dairy

- Frozen food

- Chemical Products

- Pet food

- Poultry products

- Snack

8. What is the difference between the single-stage primary packaging and the two-stage primary packaging of the chocolate packaging machine?

Two-stage primary packaging is the packaging of chocolate in two consecutive steps using two packaging materials. Packaging of chocolate products using only one or two materials in one operation is called single-stage primary packaging.

9. What are the secondary packaging materials used in the chocolate packaging machine?

Secondary chocolate packaging is the material you will use outside of the primary packaging. It groups chocolate products to help create a stock keeping unit, often referred to as a SKU. Also, it is convenient to handle smaller chocolate products, putting them in one package.

Secondary packaging will provide supplemental protection that will maintain and maintain the integrity of the primary chocolate packaging. Also, you can use it as a container for transporting small cargo, so it is useful in e-commerce.

Here are some of the ingredients you can use in secondary chocolate wraps:

- Box

- Filling

- Delimiter

- Reinforcements

- Bag

- Paper

- Corrugated cardboard

- Plastic box

- Tray

- Shrink wrap

10. Why is the third wrapping necessary in the chocolate packaging line?

This packaging is also known as shipping packaging or bulk packaging. Tertiary chocolate packaging is important for grouping large quantities of chocolate products to create a stock keeping unit [SKU]. It facilitates the transportation of chocolate products from one place to another.

Chocolate Folding Packaging Machine

For example, this might be from a chocolate production plant to a point of sale. During this packaging phase, you will be handling chocolate products as a distribution unit. The third packaging facilitates the safe transportation of large and or heavy chocolate products.

In addition, it will prevent damage to the product for easy handling, shipping and storage. An example of a tertiary package is a pallet with several secondary packages, stretch-wrapped for easy shipping.

11. Can you pack all chocolate products in a chocolate packaging machine?

Different packaging machines can perform different packaging processes. Also, you need a complete packaging line to package all chocolate products, from primary, secondary, and finally tertiary packaging.

12. What types of chocolate packaging machines are there?

Some of the most common machines on the market include:

1) Chocolate Foil Packaging Machine

Chocolate Foil Packaging Machine

The device uses a variety of foils to wrap the chocolate into ovals or balls.

Some of the advantages of this machine are:

- A frequency converter mechanism frequently switches package sizes.

- PLC is easy to operate.

- Has high production capacity.

- Also, it makes the product look more attractive.

- It saves costs because it has low operational requirements.

Some disadvantages are:

- This is expensive to buy and install.

- Any failure can shut down the machine for a long time.

Some of its main features are:

- Automatic lubrication system.

- Fast switching of foil and wrapping supply rolls.

- The packing tray contains several pistons that may move intermittently.

- It features a cam mechanism that relies on a three-phase synchronous motor to drive the process.

Additionally, you can optimize the machine by:

- Lubricate and clean the machine frequently.

- Replace the oil pan and fill it with fresh oil.

- Availability of production data for easy reference.

- Make sure that the raw materials are sufficient and the machine will not be idle.

2) Chocolate Folding Packaging Machine

This is a device that packs chocolates of different sizes into pills, or in envelopes. Alternatively, you can wrap the chocolate with multiple sheets of chocolate film at the same time.

Chocolate Folding Packaging Machine

Some of the advantages of this machine are:

- It allows you to set random exits horizontally to achieve multiple exits per unit time.

- Also, it can pack chocolates of different sizes because it is flexible.

- Color-coded tracking units enhance the packaging process.

- Fully automated, time saving and reliable.

Some disadvantages are:

- It is expensive to buy and install.

- Also, it requires a lot of work area installation.

Some of its main features are:

- Different gears control the speed of the process.

- The adhesive group strengthens the scale, mainly in the horizontal export.

- Full automation increases production capacity.

Additionally, you can optimize this machine by:

- Make sure there is enough raw material for the machine to run continuously.

- Enter the correct packaging conditions on the control panel.

- Clean and maintain the machine frequently.

- Installed on the production line, saving shipping time.

3) Chocolate Coin Packaging Machine

This is a device that wraps chocolate in the shape of a coin.

Chocolate Coin Packaging Machine

Some of the advantages of this machine are:

- Servo intelligent system, easy to operate.

- It produces low noise, thus minimising noise pollution.

- Fully automatic and can be directly connected to the entire chocolate coin production line.

- It comes with a touch screen for easy monitoring and control.

- Safety sensors enhance safety for all.

Some disadvantages are:

- High initial cost.

- It takes up a lot of building space.

Additionally, you can optimize this machine by:

- Make sure it is always in the correct operating state.

- Lubricate all moving parts to reduce wear and tear.

- Clean the machine frequently and thoroughly.

4) Chocolate Bar Packaging Machine

This is a device that wraps chocolate bars in cardboard or aluminum paper.

It is also hermetically packaged sealed.

Chocolate Bar Packaging Machine

Examples of chocolate bar packaging machines are as follows:

- Chocolate Bar Cartoning Machine

- Chocolate Bar Folding Machine

- Chocolate bar cross flow machine

Some of the advantages of this machine are:

- The best design ensures you achieve high quality packaging.

- Full automation increases production speed.

- It offers various packages such as envelopes, cubes, tapes and more.

- The control panel can be operated and monitored conveniently.

- Also, it is gentle so there is no breakage during packaging.

Some disadvantages are:

- The initial cost of repairing it and maintenance is high.

- Also, you will need to be trained to understand the packaging parameters, which will add to the cost.

Some of its features are:

- DC motor with inverter.

- Easy to customize wrapper length and wrapping speed.

- Stainless steel material ensures high hygiene standards.

- Sensitive photo marking system ensures proper tracking and cutting.

Additionally, you can optimize the machine by:

- Comply with the packaging parameters of the machine.

- Regularly clean and maintain the machine to maximize its operation.

13. What is the speed of the chocolate packaging machine?

The speed of the machine varies from 0 to 300 bags per minute.

14. What are the chocolate packaging processes used by the chocolate packaging machine?

These include:

- Pleated packaging

Here, you’ll have a label to seal the wrinkled chocolate that forms after wrapping.

- belt

It requires wrapping the chocolate in wrapping material and sealing it with glue or heat.

- Foil packaging

The machine does not wrap chocolate with heat-sealing paper or aluminum.

- Twist packaging

By twisting the ends of the chocolate wrapper, you can seal the chocolate.

- Foil packaging

After it needs to heat the sealed ends, wrap the cylindrical chocolate.

- Set packaging

Here, you’ll wrap a net around the chocolate with one or two rolls of film, then heat to seal.

- Foil and tape packaging

It requires wrapping the chocolate in aluminum foil and then wrapping the aluminum in paper.

15. What material is used for the frame structure of the chocolate packaging machine?

The frame is made of stainless steel as it is durable and provides more strength.

16. Comparison of manual chocolate packaging machine and automatic chocolate packaging machine?

Manual machines are suitable for small-scale production, while fully automatic machines are suitable for large-scale production. Buying a fully automatic machine is more expensive than buying a manual machine. Manual machines require more manpower than fully automatic machines.

Fully automatic machines are more accurate and reliable than manual ones. The production capacity of fully automatic machines is higher than that of manual machines. Fully automatic systems can handle chocolates of different sizes because they are more flexible than manual machines.

Manual machines have fewer parts than fully automatic machines and therefore require more human support. It is possible to integrate a fully automatic machine instead of a manual machine in the production line.

17. Cold sealing film and heat sealing film for chocolate packaging machine, which is the best?

Since chocolate is a heat-sensitive product, cold sealing film is used.

18. Can you integrate an automatic chocolate feeding system into a semi-automatic chocolate packaging machine?

Yes, it is possible because they all have automated systems and feeding systems that will supply the chocolate to the packaging machines.

19. How to solve the fault of the chocolate packaging machine?

Align the belt correctly when the film is not in the center. Use a film with proper threading and center the film on the spindle if the wrap does not track properly. If you find that the bag length is inconsistent, please clean or replace the film feed belt while adjusting the tension.

Correct bag length setting, if you notice bag length getting longer, make sure the camera eye is registered in place. Replace or adjust the forming ring when the wrapping film is creased. If filming is difficult, clean and adjust the forming belt. If the film gets stuck in the forming tube, adjust the heat build-up of the moving parts to reduce friction.

20. What are the optional equipment for chocolate packaging production line?

All these are:

- Thermostat

- Chocolate automatic storage box

- Chocolate icing machine

- Automatic molding machine

- Automatic demolding

- Chocolate Granule Blender

- Biscuit Feeder

- Feeder mixer

- Particle metering machine

- Chocolate Pump

- Nut feeder

- Chocolate analyzer

- Filling and weighing equipment

21. What is the price of your chocolate packaging machine?

Prices range from $2,000 to $30,000. At Jochamp, we offer a range of chocolate packaging machines according to your specific needs and requirements. Contact us today for all your chocolate packaging machine needs.

Other Related Information:

For all your carton folding machine needs, contact us now.