I know you are looking for highly efficient and reliable box folding machine. A reason this guide explores all fundament aspects of box folding machine such as design, parts, working principle, to classification, just to mention a few.

1. What Is Box Folding Machine?

It is a machine which is mainly found in manufacturing and assembling industries that is comprised of different parts which work to press and fold cardboards to make boxes.

box folding machine

2. Uses Of Box Folding Machine

Pharmaceutical industries

It is used for packaging of drugs to be transported to different places.

Food industry

Food packaging requires boxes to aid in packing of the processed foods before taking them to the market places.

Cosmetics industry

Cosmetics are packed and transported to various places for marketing.

Electrical companies

The companies require a high quality box folding machine to aid in making boxes for the storage and transportation of the products.

3. Advantages Of Automatic Lid And Base Box Folding Machine

Some of the main advantages include:

Quality

The machine offers quality products which are durable and presentable due to its ability to handle the cartons with minimal human aid.

Efficiency

The machine is quicker and reliable. It works based on the commands issued b the operator.

Reduced Accidents At The Working Area

Use of machines lowers labor rate. A reduced labor reduces movements at the working area.

Durability And Reliability

The machine is able to work anytime and at any given condition in the long run.

4. Types Of Box Folding Machines

Some of the most common options include:

– Manual Box Folding Machine

A manual box folding machine comprises of a hinged base.

The base handle is screwed while in use and can be unscrewed as well after use.

Screwing helps the box remain compact during the folding process.

manual box folding machine

The cardboard to be folded is slides in between the hinge base and tightened using the adjacent screws.

– Semi-automatic Box Folding Machine

A Semi-Automatic box folding machine can either be vertical or horizontal.

The materials, through the operator, are put manually into the machine.

Its operation is simple due to lack of automatic in-feed, though it reduces the speed of results as well as production capacity.

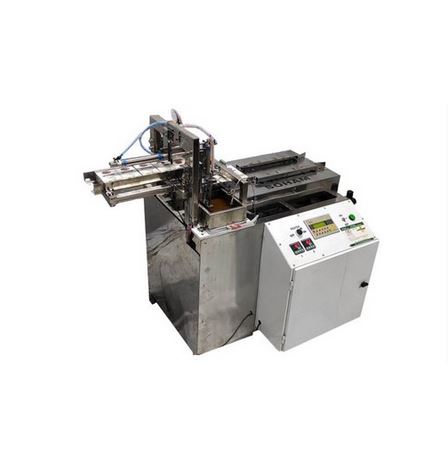

semi automatic box folding machine

A Semi-Automatic machine requires several operators.

– Fully Automatic Box Folding Machine

It requires less at the working environment.

It can confirm the integrity of the box to ensure proper quality is achieved.

The machine has a folding system, ink printers, brochure insertion system and a hot melt gluing system.

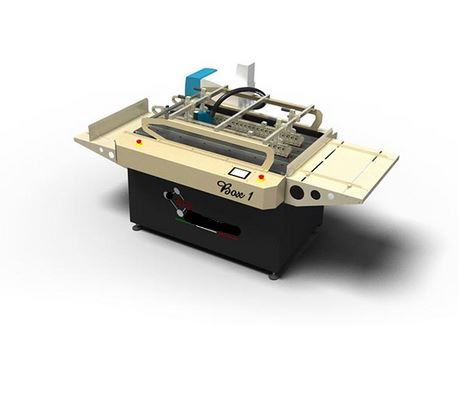

automatic box folding machine

All of the machine’s operations rely on a digital control unit to perform its duties.

A computerized system with less human aid, runs, controls and modulates all the operations of the machine.

– High Speed Box Folding And Gluing Machine

It is widely used on different products.

A high-speed folding machine works continuously and at a high speed.

It is efficient in packing and hi-tech equipment.

Can open and pack boxes, fold leaflet attach batch numbers and seal.

high speed box folding and gluing machine

Frequency invertor issued to change speed and a photoelectric to control each station.

Can be operated separately or integrated with other machines.

It can melt hot glue to seal on boxes.

– Robotic Box Folding System

With robotic box folding system, the machine opens up the cardboard and folds the flaps. After filling the cardboard boxes, it seals the bottom part of the box with a tape.

More over, it comprises of a modular structure and an adjustable system that makes it flexible in automatic box folding system.

robotic box folding system

It is fast and can handle different activities at the same time.

The system requires less human aid, hence reliable in various areas.

5. Box Folding Machine Vs Box Sealing Machine

A box sealer folds the flaps and seals the top and bottom of the box as a box folding machine only folds the cardboard without sealing.

A box sealing machine can seal one side or both sides based on the demand, a factor that the box folding machine does not take part.

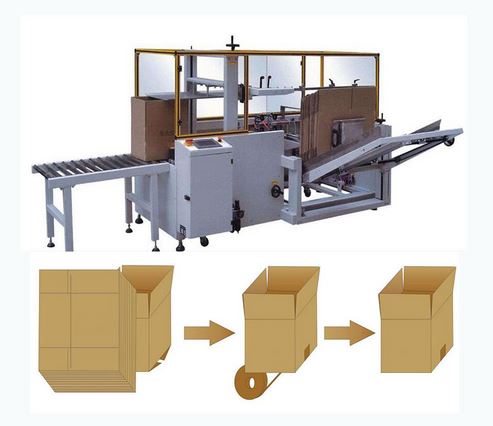

box sealing machine

You can also learn more about carton sealing machine.

6. Carton Erecting Machine Vs Box Folding Machine

A carton erector sharpens up the box, folds the bottom flaps and seals them while a box folding machine does not take part in sealing the product.

carton erecting machine

A carton erector keeps one side open and seals only the bottom part as the box folding machine does not do the initial sealing process but only folding.

You can also learn more on case erector.

7. Parts Of Box Folding Machine

Feeding Point

A box to be folded is introduced at this point into the folding machine.

This part depends majorly on the machine in use and the features of the box to be folded.

Based on the machine, feeding points vary due to the ability to fold different box sizes.

Pre-breakers

Pre-breakers turn the carton material straight hence making it smooth to enhance easy folding process.

It depends on a specified degree of heat for it to be efficient and reliable. The heat is controlled by the control panel.

Folding Unit

It is the main point in the folding process where the actual folding is done.

It comprises of different features that aid in the folding process.

Folding of the box’s base flaps is majorly facilitated with the crash-lock module, which works through the use of a hook or non-hook-based system.

Separating Compartment

Boxes with poor folding technique from the good ones are separated at this point. The activity is done b use of sensors which are used for the separation process.

Binding Section

As the name suggests, this is a binding point. Adhesive application on various box parts is done.

Binders are used too.

This part strengthens the box making it stronger in order to lift heavy loads.

Control Panel

Speed and temperature are set at this point. These are the two main parameters that help in the folding process.

A control panel can have a Liquid Crystal Display that offers easier viewing during the folding process.

8. How Box Folding Machine Works

Box folding process begins by having all the right parameters set up correctly for effective operations.

Through the feeding point, a cardboard is introduced into the machine.

The rate at which the cardboard is introduced depends on the speed level of the operation procedure and also the type of the machine being used.

Cardboard size introduced into the machine will determine the size of the box to be folded as the final product.

Introducing the cardboard into the machine facilitates the movement of rollers in different positions, as the cardboard moves from the feeder to the pre-breakers.

At this point, the cardboard is ironed to smoothen it.

A control panel is set to manage the heat in the pre-breakers since a lot of heat might burn the cardboard as low heat might cause wrinkling.

The box, while at the cutting section from the pre-breakers, it is cut into the preferred dimensions by use of cutters.

After acquiring specified dimensions, the cardboard moves to the folding section which varies based on the type of box to fabricate.

The folding part works on different parts of the folds to make boxes based on speed set by the machine.

While folding, some boxes do not gain the required quality. Through a separation chamber, the quality boxes are separated from those of poor quality.

Separation chamber ensures quality standards are achieved.

From the separation chamber, the box proceeds to the adhesion sage where the bottom part of the box is applied with adhesion. This process increases durability and strength of the box.

Adhesion can be done by application of glue or cello tape, based on the machine type in us or the box specifications.

Final stage in box making process is by testing the box based on its durability and strength before use.

9. Limitations Of Automatic Box Folding Machine

Some of the limitations include:

High Cost Of Purchase

The cost of acquiring the machine is very high, hence it requires adequate budgeting.

A higher purchasing cost might as well discourage suitable buyers.

Requires Skilled Personnel To Operate The Machine

Employing skilled personnel will increase another expenditure costs. This will increase the budgeting level since most skilled personnel demand high pay in order to operate the machine.

Requires Electricity In Order To Function

There is no possibility to install the machine in areas where there is no electricity. This is a key factor in its productivity.

10. Increasing Efficiency Of Box Folding Machine

There are different factors affecting the efficiency of a box packing machine, for instance;

Box Folding Machine Operator

Any machine operator dictates the machine efficiency as an expertise will always reduce the machine downtime. This enhances performance of the machine.

An operator can easily detect any issue and rectify.

Proper Box Folding Machine Maintenance

It is done by ensuring all the operation systems of the machine are well aligned.

Broken parts are replaced.

Loose parts are tightened.

Suitable Materials In A Box Folding Machine

Cardboards are the materials used in he folding process.

Use of other materials can result into other machine complications for instance breakages.

11. Integrating Box Folding Machine With Box Sealing Machine

Box folding machine and box sealing machine can be integrated to form a consistent system. Whereby the two machines work in a very closely related manner by providing quality results based on the operation demand.

A cardboard placed at the feeding point will directly be led to the folding machine before being conveyed to the sealing point at the same point without any human intervention.

Well, you can integrate box folding machine with box sealing machines and box erecting machines. In most cases, these machines may come as a single unit.

12. Troubleshooting Box Folding Machine

Before trouble shooting is done, one must have identified the problem facing the machine. Some of the common issues comprise of;

Incorrect Folding And Box Wrinkling

It occurs in different ways like using of a poor structural surface cardboard. This can be rectified by replacing the cardboard.

If the feeder does not accept the cardboard size, then there is need of adjusting the size of the feeder.

You can as well avoid overloading or under loading the feeder with cardboards.

The best way to maintain the machine is by having a feeding rate corresponding with the uptake of the cardboard by other parts of the machine.

Recommended alignment and lubrication of the cardboard to avoid or simply reduce wastes is key.

Slower Folding Pace

This can, in most cases be affected due to power issues to the machine.

Also, it can be due to incorrect lubrications on the conveyor belt.

Hence, sufficient power voltage is required to be supplied to the machine and proper lubrication of the conveyor is required.

Poor Quality Of Adhesion

Poor adhesion quality causes weak box properties hence low efficiency.

It occurs in situations with finished adhesion.

This is solved by changing the adhesive or repeating the process.

Cardboard Jamming

It is when the folding is affected.

This can be caused by the misalignment of the conveyor belt hence some cardboard parts stick to the conveyor.

Regular repairs and maintenance is key in solving the above issue.

Curling Edges

It occurs due to rapid processing of thin cardboards.

The problem can be solved by use of thick materials or slowing down the speed of the rollers when the thin material is applied.

13. Maintaining Box Folding Machine

Cleaning Of The Machine

Any machine will require cleaning to reduce dust getting into the engine or other sensitive parts.

Repairing Broken Or Loose Parts

Broken parts leads to poor work rate, hence need for replacing them in order to achieve a desired efficiency.

Loose parts might cause injuries hence need to tighten them or remove them in cases where they are less needed.

Regular Maintenance

Continued maintenance reduces the chances of machines to stop or break down during operations.

14. Types Of Cartons A Box Folding Machine Can Form

– Single Piece Tuck Top Box

A single piece tuck box is a strong and durable box.

It comprises of a double sided walls with a top opening having a closing tuck flat which goes into the bottom tray.

They require no gluing and are very easy to assemble.

– Straight Tuck Box

A straight tuck box folds cardboards from the front to the back in a similar direction.

Its slits lock from each closing flap. This keeps the top and bottom of the box in place in order to maintain the contents inside the box.

Since this activity is practical, it offers plenty of space for information and branding.

Such types of boxes are important in makeups, perfumes and cosmetics.

– Lock Bottom Box

Due to the bottom flaps that push into each other, the boxes are meant for heavy goods.

The base is very strong that it cannot open even when there is heavy load.

– Half Box

It is a rectangular section of a periodical or newspaper.

The box is marked at the top or bottom.

For all your box folding machines, contact us now.