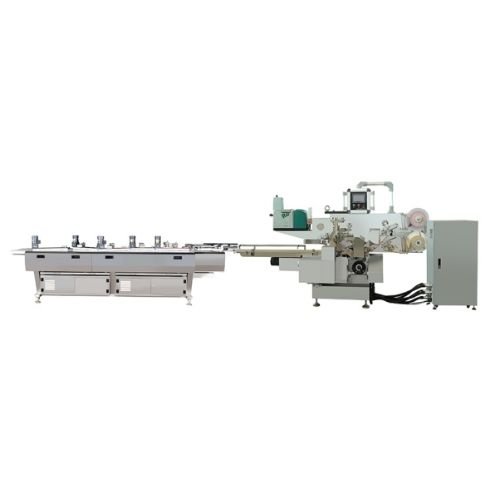

Chocolate Foil Wrapping Machine Manufacturer in China

Jochamp offers chocolate foil wrapping machines that feature compact structure, multifunctional wrapping ways, and low energy consumption. For more than 15 years, we have been producing a wide range of excellent quality chocolate foil wrapping machines at reasonable prices.

- Comply with the standards from ISO, CE, SGS, and cGMP

- Providing customization services

- One-stop wrapping machine solution

- Offers lifetime after-sales service

Jochamp | Chocolate Foil Wrapping Machine Supplier

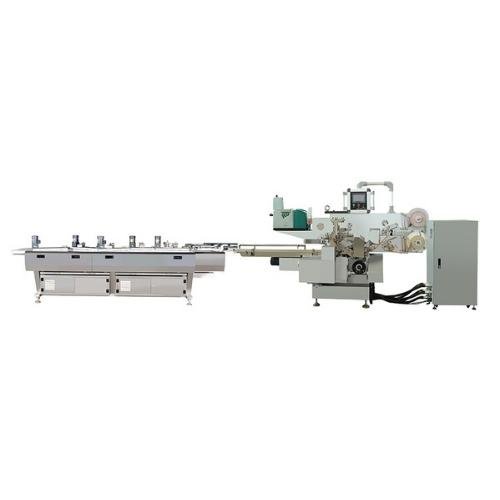

Jochamp supplies chocolate foil wrapping machines that can wrap many different types and shapes of chocolates. Our chocolate foil wrapping machines can perform single-stage or double-stage wrapping. They can wrap chocolate products into various sizes according to your needs. Also, they can wrap the chocolates at a high speed and in a beautiful packaging appearance. For the sealing mechanism after wrapping the chocolates, they usually use heat or glue sealing depending on what you require. Our chocolate foil wrapping machines are also equipped with an overload protection device, HMI control system, and PLC control system for more stable, accurate, and easier operation.

Furthermore, our chocolate foil wrapping machines can be customized as per customers’ request. Jochamp provides regular after-sales care and guidance on how to maintain them. Our wrapping machines come with 1-year quality assurance. We aim to provide high-quality wrapping machines with favorable price.

If you want to know more details about our chocolate foil wrapping machines, feel free to contact us!

Various Chocolate Foil Wrapping Machine for Your Choice

Different Chocolate Foil Packaging (3)

Jochamp Chocolate Foil Wrapping Machine Advantages

The chocolate foil wrapping machines are equipped with a PLC control system where all of its operations are here controlled and configured. The PLC control system makes the machine easy to operate & user-friendly.

The product contact surface of the chocolate foil wrapping machines is made from food-grade, hygienic, easy-to-clean, and highly corrosion-resistant 304 stainless steel. That is why they are safe for contact with chocolates.

Our chocolate foil wrapping machines are safe to operate due to their safety features such as an advanced overload protection system, emergency stop function, safety door system, safety covers, and many more.

Jochamp fabricated the chocolate foil wrapping machines from high-quality materials so they will have a service life. Also, the electrical appliances and accessories used for the machines are high-quality and durable.

Chocolate Foil Wrapping Machine Materials

To fabricate the chocolate foil wrapping machines, we use various high-quality, food-grade, and wear-resistant materials such as aluminum and 304 stainless steel. The surface of the machine that will have contact with the chocolates is specifically made from 304 stainless steel due to its strong corrosion resistance. Also, stainless steel is easy to clean and does not affect the products since it is hygienic.

The other parts of the chocolate foil wrapping machines are also made from surface-treated metal to enhance their service life and resistance to corrosion, blackening, and oxidation. All of the materials we use are in line with the GMP standards. They comply with the food & drug hygiene conditions.

Options for The Chocolate Foil Wrapping Machine

The chocolate foil wrapping machines from Jochamp can be added with a variety of optional machines, accessories, or systems depending on what you need. Some of the options include:

- Vibrating Chocolate Compensation Machine

- Duplex Stations (made-to-size)

- Labeling Machine

- Export Sorting System

- Docking Weighing Packaging Machine

- Rotary Feeder

Why Choose Jochamp

- Rich Experience – Jochamp has been producing and exporting all kinds of chocolate foil wrapping machines for more than 15 years.

- Reliable Quality – All of the chocolate foil wrapping machines we are supplying have certifications from CE, ISO, SGS, and cGMP. Therefore, you can rest assured of the quality of our wrapping machines.

- Efficient Service – At Jochamp, we provide lifetime after-sales services, customization services, technical services, and other services. We have a professional team that can assist you from design to installation of the machines.

Your Reliable Chocolate Foil Wrapping Machine Supplier | Jochamp

Jochamp has been specializing in producing different models of high-performance chocolate foil wrapping machines for more than 15 years. Our goal is to provide quality products and services. For that reason, our expert QA team control quality in the whole production process of chocolate foil wrapping machines. Every process is controlled from raw materials to the assembly of wrapping machines. We also perform various inspections and testing on the wrapping machines before their shipment.

All of our chocolate foil wrapping machines comply with ISO 9001, SGS, CE, and cGMP standards. The raw materials we use are thoroughly inspected and comply with the GMP standards. We use the highest quality and corrosion-resistant stainless steel to guarantee food hygiene and durability.

Moreover, to complete your specific requirements, we can customize the chocolate foil wrapping machines based on your requirements. We can also provide a free sample packaging test.

For your inquiries, do not hesitate to send us a message!

Jochamp | Chocolate Foil Wrapping Machine Supplier in China

- No chocolate, no foil function

- Advanced overload protection system

- PLC control system & man-machine interface

- The whole product contact surface is food-grade

- Intelligent compensation system & color mark tracking to ensure product consistency

- Exquisite packaging appearance

- Strong corrosion resistance & longer life

- High energy efficiency

- Low noise & easy operation

- Multifunctional wrapping ways such as single-layer or double-layer foil wrapped

- Adopt servo motor controls

- High packing speed

The chocolate foil wrapping machines are used for wrapping various types and shapes of chocolates using aluminum foil. Some of the products that are suitable for the machine include:

-

- Chocolates with a flat bottom

- Flat-shaped chocolates such as coin shapes, flat heart shapes, flat fish shapes, & flat rectangle chocolates

- Spherical chocolates

- Oval chocolates

- Ellipse chocolates

- Ball shape chocolates

- Hemispherical chocolates

- Rectangular chocolates

- Cube chocolates

- Other shaped chocolates

Our Services

Our professional team can give you regular after-sales care and guidance on how to install and maintain the chocolate foil wrapping machines. Depending on the situation, we can provide our installation training or guidance through online media or even onsite.

Jochamp has an expert R&D team that is capable of supporting your ODM & OEM orders. We can customize the chocolate foil wrapping machines in accordance with your exact specifications.

We have a team that can quickly respond to your inquiries about our services or chocolate foil wrapping machines. Our friendly team is willing to assist you and answer questions at any time of the day.

Our chocolate foil wrapping machines are offered with 1-year warranty and life-time aftersales care. We guarantee to provide assistance if there are any mechanical problem. Also, we will provide guidance on the maintenance of the wrapping machines.

Related Product

Chocolate Foil Wrapping Machine: The Ultimate Guide

In this guide, you will find all information you are looking for about chocolate foil wrapping machine. Whether you want to learn about design, features, specification, parts or working principle – all information you need is right here.

A chocolate foil wrapping machine is a piece of equipment you can use to wrap chocolates.

You can wrap chocolates manually but there are some reasons why wrapping them using a machine is better.

chocolate foil wrapping machine

These are the reasons you should invest in a chocolate foil wrapping machine include;

- Using a chocolate foil wrapping machine increases production and this leads to high returns.

With the high returns, you can get larger profits.

- When you use a machine to wrap chocolate, it has features that you can use to decorate the chocolate in many ways.

This improves the look of the chocolate making them attractive. a

- With a machine, you are assured the whole process is efficient and accurate.

It is highly unlikely to get products that are not of the required quality.

- A chocolate foil wrapping machine saves time. You can get high output within a short time because the machine is fast.

- It is cost-effective. Buying the machine initially might seem expensive but you will be able to get value for your money within a short time.

- With a chocolate foil wrapping machine, you do not need many employees since the machine does most of the work.

- Using a machine to wrap the chocolate ensures there is no contamination to the chocolate through human handling.

The machine improves hygiene.

- A chocolate foil wrapping machine has an easy layout which is quite easy to operate and clean.

- There are no fumes or smoke with a chocolate foil wrapping machine.

This means the working environment will be clean and there will be no health hazards.

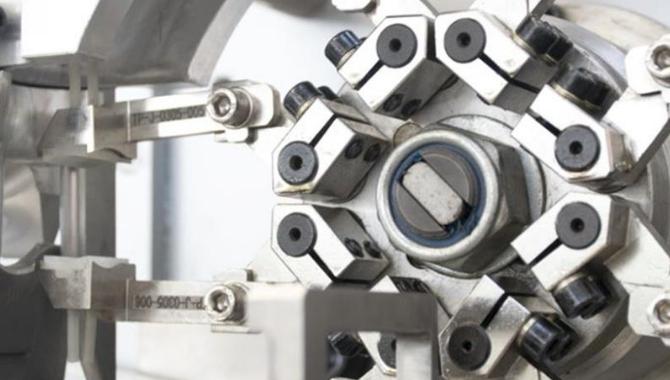

The parts of a chocolate foil wrapping machine;

- Automatic PLC control system with a touch screen. This is where you can see the control parameters.

- The feeder system is responsible for feeding the machine with the wrapping and the chocolate.

- An automatic printing system prints the needed information on the wrapper.

- A distribution system that has motors, conveyor belts, and gears to control speed, and drive machine operations.

- Shower lubricant distribution system.

- The wrapping system wraps the chocolate.

- Automatic sensors and alarming systems.

- Oil pallets which you can remove.

chocolate foil wrapping machine

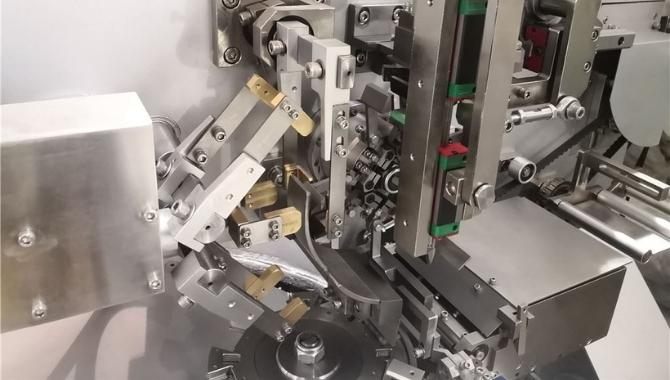

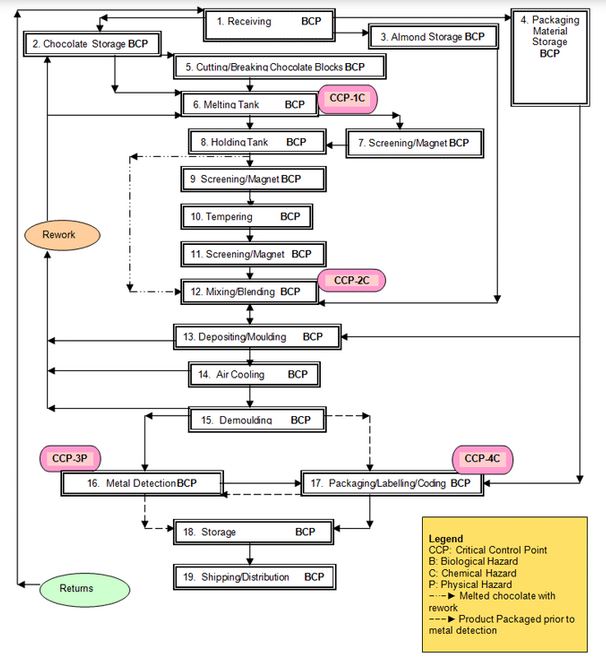

Chocolate foil wrapping is not a very complicated process. Here is a step-to-step application of how the machine works;

- First step involves the preparation of the chocolate and the wrappers which are the main ingredients.

At this step, the machine gets the chocolate from the production line. Then you feed the wrappers on the wrappers hopper.

You should also check to confirm if the machine can function well before powering it.

- Second step involves chocolate wrapping. There are several wrappers such as foil, pieces of paper, or even polythene.

The machine automatically wraps the chocolate depending on the wrapping stage.

- Third step is where the machine trims the chocolate wrappers into the desired sizes.

It then automatically moves the wrapped chocolate to the sealing stage.

- Fourth step is where the machine uses glue or laser heating to automatically seal the loose ends of the wrapped chocolate.

- Fifth step involves printing labels and logos on the wrappers.

Their main aim is for identification and also for aesthetics.

The machine prints important information such as the manufacturing dates and expiry dates on the chocolate wrappers.

- The last step is where the product goes through inspection.

This is to ensure it meets the required standards and the wrappers and seals are of the best quality.

When everything meets the requirements the machine automatically packs them in cartons.

chocolate making and wrapping

The two are machines you can use to wrap your chocolate but they wrap different types of chocolates.

A chocolate foil wrapping machine is a machine that wraps either ball chocolate or ellipse chocolate using several kinds of foil.

A chocolate coin wrapping machine on the other hand is a piece of equipment that wraps chocolate that has the shape of a coin.

chocolate foil wrapping machine

A chocolate foil wrapping machine uses foil to wrap the chocolate but for the coin wrapping machine, you can use several materials.

These two machines are all automatic and they do not need a lot of human intervention for them to run.

Although the initial cost of the machines is high, production is also high resulting in high returns.

Both the chocolate foil wrapping machine and the chocolate coin wrapping machine warp different sizes and shapes of chocolates.

chocolate coin wrapping machine

These are two different machines with different functions.

A chocolate foil wrapping machine is a machine that wraps either ball chocolate or ellipse chocolate using several kinds of foil.

On the other hand, a chocolate fold wrapping machine is a piece of equipment you can use to fold the wrapper of the chocolate as a sealing technique.

The chocolate fold wrapping machine can wrap chocolate in two films at the same time.

Both the wrapping machines have high production output and high returns but have a very high initial cost.

Both the machines are great especially if you have a big demand and they save on time.

chocolate fold wrapping machine

Any machine can experience malfunctions and it is up to the manufacturer to understand the machine and how they can solve some of the problems.

Below are some of the malfunctions and their solutions;

- Wrapping film feed belt does not move – this happens when the belt is tight against the tube.

You solve it by ensuring the belts are loose and adjusting the gearbox of the film feed motor.

- Wrapping film running off the machining center – this occurs when the wrapping film is not in the film spindle or the film is loose.

To solve this you should ensure you align the machine belt properly and replace the wrapping films.

- Inconsistent bag lengths – this may be due to a feed belt that is not clean, or bad film threading.

You can solve this by cleaning the feed belt and adjusting the tension between the film feed belts.

- Wrapping films with creases – this may be because of a contaminated film path roller, a worn-out collar, or incorrect adjustment of the forming collar and set-up roller.

- Jams of film at the forming tube – this is when the seals are hot then they stick to the film.

Using good parameters to reduce too much heat.

- Unwinding of the film difficulties – this occurs when the zipper is caught on the collar or a belt with high contact pressure.

It may also be due to the high coefficient friction of the film. Cleaning and adjusting the forming belt will solve these problems.

- Bag is too long – this occurs when the bag length and the registration photo-eye are set incorrectly.

Ensure the bag length and photo eye registration are set correctly.

- Failure of the wrapping film to properly track – this may be due to the spindle being too loose or the film roll not being at the spindle center.

Ensure the film roll is well aligned to solve this issue.

- Difficulty in pulling down the film through the forming tube – this may be due to incorrect alignment on the setup and forming collar, dirty form set, and high friction on the film coefficient.

You can solve this by cleaning and adjusting the setting to reduce friction,

A chocolate foil wrapping machine is a piece of equipment that wraps several kinds of chocolate.

The machine has many uses and they include;

- It wraps different kinds of chocolate such as wafers, cookies, solids, pure chocolates, and inclusions.

- Machine offers several wrapping options such as fold and foil. You choose one that fits your needs.

- The machine has a printing option that you can use to print information such as expiry and manufacturing date on the chocolate wrappers.

It can also print decorations and logos.

- It can also pack the wrapped chocolates into a cartoon after the wrapping process is done.

- The chocolate foil wrapping machine is responsible for feeding ingredients into the cylinder, and also fills the chocolate into the machine.

- The machine is flexible enough to wrap different sizes and dimensions of chocolates.

- It is an automatic machine that wraps chocolates within a short time increasing the production rate.

Black foil wrappers and gold foil wrappers are both FDA-approved wrappers that are safe for food contact.

black foil wrappers

The black foil wrappers are great for preventing light from affecting the chocolate.

Additionally, gold wrappers on the other hand are perfect for improving the appearance of the chocolate.

Both the wrappers offer maximum protection to the chocolates by preventing environmental factors such as moisture.

gold foil wrappers

Wrapping chocolates in foil has so many advantages and the main advantage is the foil wrappers preserve the quality of the chocolate.

The wrappers have other advantages such as;

- Foil wrappers are the best to preserve the chocolate. They ensure the chocolates last for long life.

- The foil wrappers ensure that the chocolate is not contaminated since they are tight and no bacteria can pass through them.

- Wapping the chocolates in foil make them more appealing to the customer’s eyes.

The foil wrappers can be decorated to improve the aesthetics of the chocolate.

- With a chocolate foil wrapper, you can maintain the original flavors of the chocolates.

- Foil wrappers are lightweight and hence will not affect the weight of the chocolate. Its original weight will remain the same.

- The foil wrappers are easy to fold, making it easy to preserve the chocolate if it remains.

- Foil wrapping chocolate makes work easier for the consumer since it is easy to open.

Wrapping chocolate with a thin foil is beneficial because a thin foil will not add weight to the chocolate since it is lightweight.

Another advantage of wrapping chocolate using a thin foil is it makes opening the chocolate an easy task.

A thin wrapping foil protects the chocolate from contamination which may affect the product’s quality.

Thin foils cannot alter the original shape of the chocolate because it is lightweight.

Normally, the thin foils are non-sticky and smooth so the chocolate cannot stick to them.

Besides, the foils maintain the aesthetic value of the chocolate.

Thin foils ensure there is a maximum barrier between the chocolate and the surrounding.

A chocolate wrapping material should be able to protect the chocolate from environmental factors such as oxygen, and moisture.

It should also provide good air tightness to protect the chocolate from contamination.

To choose the best chocolate wrapping you should consider the following factors;

- Heat-resisting qualities of the chocolate – your wrapper should be able to meet the heat-resisting qualities of the chocolate.

You should avoid a wrapper that may need to be heat sealed if the chocolate is heat sensitive.

- Aesthetics requirements – your wrapper should have a unique and eye-catching design, with beautiful color.

The prints should be unique to catch the attention of the buyer.

- Chemical composition of the chocolate – the wrapper should ensure it protects the chocolate and will not affect the chemical composition of the chocolate.

- Size and dimensions of the chocolate – choose a wrapper that will fit the size and dimensions of the chocolate fully.

- Wrapping material – the wrapping material should complement the chocolate well.

The material should protect the integrity of the chocolate.

The chocolate wrapping materials you use will affect the quality of the chocolate. You should choose the material that will best suit you.

Below is a list of wrappers that you can use to wrap chocolates;

- PVC film for blister packing – the wrapping consists of a PVC film and an aluminum blister foil.

The wrapping offers good barrier properties, especially from moisture.

- Rigid PVC film – this film seals together and leaves a hole in the middle for the chocolate.

This wrapping is very eco-friendly and recyclable.

- Metalized paper – this wrapping is eye-catching, eco-friendly, recyclable, and safe for direct food contact.

- PVC twist wrap – they are mostly used to wrap small chocolates. They retain the twist and are non-toxic.

- Waxed chocolate wrapping – this wrapping is oil-resistant so sticky chocolate will not stick to them.

It is also translucent and non-toxic.

- Aluminum foil – this has a shiny golden look. It is recyclable and eco-friendly.

Do a Regular Maintenance Check On The Machine

A maintenance check means looking at the machine parts and ensuring everything is in order.

Check on the feeder system, the sensors, and the sealing jaws to ensure everything is in order.

You may expose some parts of the machine to water resulting in rusting, and you can notice this during the maintenance check.

Also, check the oil levels in the machine and add more if needed. This will prevent damage to the machine.

Regular Lubrication

Machine lubrication is one of the critical steps in maintaining a chocolate foil wrapper.

Without proper oil lubrication, a machine cannot work well.

Lubricate the machine on the moving parts because of friction.

When you do not lubricate the machine, the parts may end up breaking or they will not move.

Therefore, it is important to clean the parts well and then lubricate them.

Clean The Machine Often

When using any machine, it is expected to get dirty or accumulate dust.

Parts such as the seals require daily clean-up.

You should dust and clean the machine regularly to ensure it remains clean.

If you use the chocolate foil wrapper for a long time without regular clean-up, it might cause issues to the machine and affect its working.

Also, you should ensure the machine is off when cleaning and use machine-friendly cleaners to avoid damaging the machine further.

Change Machine Parts Regularly

Anybody working with a machine knows that spare parts are essential.

When a machine has been used continuously for a long time, some parts tend to wear off quickly.

Some features are pretty long-lasting and do not need to be changed frequently.

For a machine to work effectively and for one to avoid excessive damage to the machine, the parts need to be changed.

These two machines are both chocolate wrapping machines. The difference is the type of chocolates they wrap.

A chocolate foil wrapper is a machine that wraps the chocolates using foil in ellipse or ball shapes.

A chocolate bar wrapping machine is equipment that packages chocolates in aluminum paper or cardboard wrappers.

A chocolate foil wrapper is quite an easy machine to use but with a bar wrapping machine, you have to train to use it.

chocolate bar wrapping machine

Both these machines are high production machines that save on time and have high returns.

The main disadvantage of these machines is the cost of purchasing and installing is very high.

Just like any other machine out there, the chocolate foil wrapping machine has its disadvantages.

They include;

- The initial cost of buying the machine is very high, and its installation is also very high.

It may be a problem for some people especially those with upcoming businesses or who are starting.

- The machine is large and hence will occupy a very large space. If you have a small working space it may be a challenge.

- You should ensure the machine runs frequently since it may malfunction if you don’t use it for long.

- The machine requires regular maintenance to avoid malfunctions since repairing it is very cumbersome.

For all your chocolate foil wrapping machines, contact us now.