Professional Vertical Case Packer Supplier

Rely on Jochamp for your next vertical case packer requirements. These case packers are designed to take up goods from an infeed insert and transporters, by a vertical motion.

- Ideal machine for unsteady goods; prone to slipping

- Efficiently packs loose tubes and uneven bottles items

- Boosting the production efficiency for any fabricator

- Serves many packaging industries

JOCHAMP Vertical Case Packer

The vertical case packer, a substitute to the “pick and place” system, gently controls goods and packs them in vertical movement. Its design allows machine operators to have better access to the inner workings of the machine. Therefore, identifying and analyzing mechanical issues is much faster and more effective.

Moreover, the custom vertical case packer is often used for the food industry that uses rectangular or lay-flat cartons, dairy applications that use gable-top boxes or gallon jugs, industrial cans, and other items. It comes in either painted or heavy load stainless steel construction. These machines are perfect if you’re looking for low-maintenance and built-to-last packaging machines.

Please send us your inquiries!

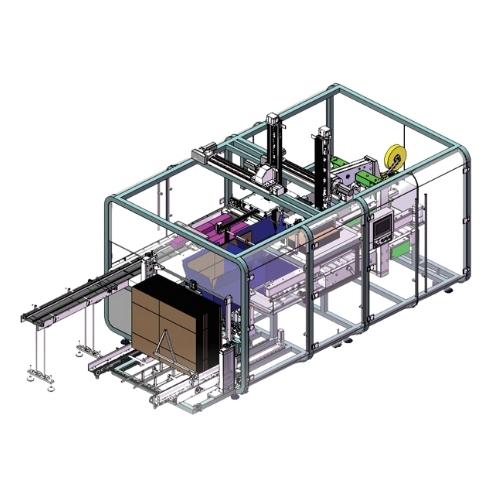

JC-600 Vertical Case Packer

JC-600 automatic packing and palletizing machine is a fully automatic packaging equipment that integrates unpacking, upstream product stacking, packing, sealing and other processes. It is the most ideal solution to solve the problem of small packaging space at the end. Thanks to the application of the full servo system and the lack of box detection, product incoming detection, stacking overload protection, carton position detection, etc. at each station, the entire production process is monitored and controlled.

- All aluminum alloy body, easy to clean and corrosion resistant

- Open design with no hidden corners

- Four-servo control system to ensure accurate action parts

- Integrated design fully automatic packing machine

- Modular design, tool-free operation, quick product changeover, easy maintenance

- PLC control system and HMI

- Safety door protection mechanism

JC-600

- Technical Parameter

- Features

- Optional

| Item/Model | JC-600 |

| production capacity | Less than 200 (boxes/hour) |

| Robotic grasping production capacity | 10 (times/min) |

| Sealing method | Tape or hot melt adhesive |

| carton size | Minimum 300x250x200mm

Maximum 550x500x400mm |

| power supply | 380V 50HZ 7.5KW |

| air pressure | 0.6mpa |

| Air consumption | Less than 1³m/h |

| Dimensions | 5000x2000x2900mm |

| weight | 2500kg |

| main material | Aluminum alloy, 304 stainless steel |

- All aluminum alloy body, easy to clean and corrosion resistant

- Open design with no hidden corners

- Four-servo control system to ensure accurate action parts

- Integrated design fully automatic packing machine

- Modular design, tool-free operation, quick product changeover, easy maintenance

- PLC control system and HMI

- Safety door protection mechanism

- Lack of case alarm, lack of tape alarm

- Stacking Palletizing System

- Modular gripping mechanism, no tool switching

- Comply with GMP standard, CE, IOS9001 certification

Secondary packaging line integration

Labeling Machine

printer

Glue sealing machine

Stainless steel

heavy duty casters

Leaflet Automatic Dispatcher

export conveyor line

Vertical Case Packer Benefits

We carefully select the best stainless steel grade for vertical case packer machines for a more compact construction; specifically from 316-grade.

Our custom case packers provide high-speed operations. These machines make sure to pack your items efficiently to accomplish on-time delivery.

Your private labels and custom ideas on every carton will be done with high accuracy using our vertical case packing machines. 100% Accurate

All of the packaging equipment we provide are user-friendly. Feature with touch-panel settings for more efficient and smooth packaging process.

Vertical vs Horizontal Case Packer: Choosing the Right Solution

Both vertical case packers and horizontal case packers provide excellent performance, simple maintenance, quick changeover, and a tiny footprint. But if you are doubtful about what is more appropriate for your packaging business, then this guide is for you.

- Horizontal Case Packers: As the name implies, these machines collect the item and then place it in the open case, which is geared on its edges. Ideal for firm products which easy to push (e.g. soaps, carton bundles, cartons).

- Vertical Case Packers: Vertical case packers lower items into the case’s open top. Ideal for products that easily slip if pushed (e.g. loose tubes, foil sachets, irregularly formed bottles.)

These case packers refer to how the goods are positioned in the case/carton/boxes. Both methods work equally well but are applied to different item packages.

Custom Vertical Case Packer Characteristics

Jochamp provides vertical case packers with numerous features and characteristics, such as:

- Pick and place system with one axis servo motor.

- Layout with a strong frame.

- Its frame is covered with perspex panels, and there are access guards on all edges.

- Case infeed conveyor powered by a low friction slat chain conveyor.

- All devices are adjustable for tool-free handover.

- Equipped with a digital HMI for configuring output parameters, factors, and an alarm display built into the machine.

- Electrical cabinet in accordance with IP 54 standards.

JOCHAMP Spares & Support Services

Machinery malfunctions: If you have any problems with your industrial equipment, from minor to major, we’ll get you back up and running as soon as possible.

First-rate components: For your sense of security, we only use authentic, supplier-manufactured, and accredited spare parts.

On-site storage: We have a large selection of stock on hand today, so you won’t have to wait for shipment.

Professional assistance & maintenance services: Our engineers are fully trained and capable of both common and unpredicted problems. We also ensure to repair and fix machines professionally.

Spares: We can provide any and all repair parts for your machine, from motors and sensors to belts and bearings. Everything runs smoothly and with great reliability. Spares and parts are available from our headquarters, with the normal next-day shipment.

JOCHAMP: Your One-Stop Vertical Case Packers Supplier

Jochamp manufactures vertical case packers with high-speed, quick changeover, and standard labeling features. It assures incredible output and significantly improved uptime, making the process easier for the production team and satisfying customers. These machines are perfect for many industries such as toiletries, cosmetics, pharmaceuticals, the food industry, and housewares.

As a reliable supplier in China for over 15 years, we offer the highest quality vertical case packers. Our company is composed of more than 15 mechanical engineers and over 20 after-sales service teams for smooth assistance. From vertical case packer to any kind of case packer machinery, we have wide knowledge you can count on.

Allow our professional team handles your custom vertical case packer requirements!

Loading your case from the vertical side ensures that your merchandise is never lost. The vertical case packer is a traditional machine alternative to a “pick-and-place” system that gently holds your goods.

Vertical loading of your products is required if they are:

- Food applications in rectangular shaped or lay flat boxes

- Food requirements involving delicate or sensitive ingredients

- Dairy applications with gable-top packages or gallon jugs

- Topped with plastic wrap or a translucent film

- Industrial bottles and cans

We offer customized vertical packaging solutions for products from numerous industries worldwide, including:

- Cosmetics field

- Daily chemical

- Food industry

- Pharmaceutical industry

- Confectionery

- Bottled beverages & drinks

- Noodles

- Fruit & vegetables

Custom Vertical Case Packer for Industries

The vertical case packer integrates loading, folding, unpacking, and vertical side sealing of cartons. Comes with a direct factory price, these vertical case packers are easy to maintain and simple to operate. It also guarantees smooth and efficient operations.

The specific case packer machine is automatic machinery that assembles trays and loads products from the vertical side. After the product is packed, the case is sealed and closed with tape or glue. We provide an extensive variety of automated vertical case packers with advanced technology and modern controls.

Jochamp offers vertical case packers made from stainless steel construction. It comes with GMP features, with custom models ranging from 500mm to 1500mm. These custom machines are suitable for different variety of semi-rigid and fully-rigid products.

Our custom vertical case packers are made of stainless steel frames – which are hygienic and hard-wearing. This machine features user-friendly touch panel adjustments. These machines are also secured by rotation overall switches.

Related Product

Vertical Case Packer: The Ultimate Guide

With the information in this guide, you can choose an effective and reliable vertical case packer machine. Whether you want to learn about features, design, working principle, or classifications criteria – read this guide.

This is a machine that lowers products into an open case from the top during packing.

It is the best method you can use for packing products that can easily slip, such as irregular bottles and loose tubes.

vertical case packer

Forming Systems -This is a process where flat carton blanks are converted into fully built cartons or cases for product loading.

The cartons are erected into various shapes; rectangular, triangular, double wall, frame wall and wave shaped cartons.

A stack of box blanks are put into a hopper.

Each blank is guided through a hot melt glue station into a forming assembly.

In the assembly the flaps are held under compression until the hot melt is cured forming a carton.

The material used to form the cartons are paper materials made from layers of wood based fibre and carton board.

The cartons are made by a high speed continuous motion machine.

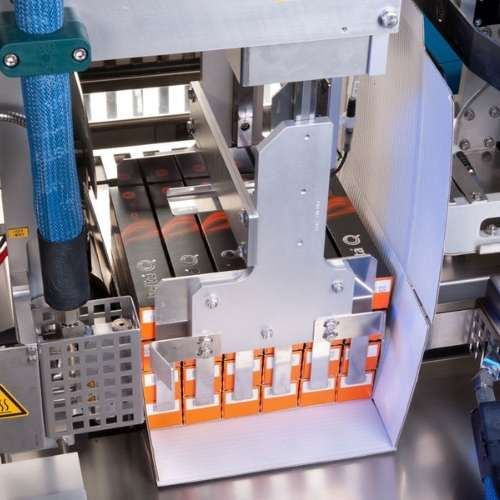

Loading systems –Most common options for loading include single axis robotic system, multi-axis robotic system, and two axis robotic system.

Robotic loaders are perfect for the most demanding production environments.

This is because Robotic loaders have the ability to load up to 700 products per minute.

Additionally, the vacuum cups on the robot picks a vertical case blank from the magazine.

The case is erected and the bottom closed by tape and the case is positioned for loading.

Bottles are fed on the robotic cell through a conveyor and collated in a pack pattern.

The robot picks the whole pack pattern and loads it in a case.

The case is then sealed.

Closing systems –Vertical case packers have closing systems which ensure that the cases are sealed in the correct manner.

The main types of case sealers include adhesive, carton tapes and automatic case taping machines.

Also, the way you seal the cases is important because this protects your product from spillage and damages such as breakages.

Case sealing when done well also improves the products appearance.

Some of the methods of closing cases include;

i). Tri-seal – seals a variety of carton sizes and shapes.

The machine can seal 80 cartons per minute.

Closes all traditional 3-flap style carton either glue formed or glue

Accepts cartons randomly without any special timing mechanism.

ii). Compact right angle case closer

The machine is very fast and seals a variety of sizes and shapes.

It can seal hinge cover tri seal carton with hot-melt adhesive at a speed of 120 cycles per minute.

iii). Inline top seal– It’s perfect for sealing of single flap vertical cases.

Has the ability to close cartons at a speed of 60 cartons per minutes

Most industries today have embraced the use case packers.

Such industries include food processing, manufacturing and pharmaceutical industries.

For you to improve your product packaging go for automatic packing machines.

Below are various type of case packers which will suit you depending on your product type.

Vertical Case Packer Top Loader

Suitable for making cases and trays.

It has top loading handling and pick and place systems.

vertical case packer top loader

The picking head is operated using vacuum or mechanical grippers designed according to the specific application.

Features;

- Has both product collector and loader.

- Capable to pack 25 -30 cases in a minute.

- Easy setup and changeover time.

- Unique designs of bottom loading.

- Pick- tooling not required.

Intermittent Speed Case Packer.

Case erecting filling and closing is done at two points.

During the process of packaging the case blanks are held safely and placed well in all the stations

The whole process of packaging goes on well as products are treated carefully

Ability to produce 30 cases per minute.

intermittent speed case packer

Features

Has rapid change over time.

It is easy to clean the machine because of its excellent accessibility.

Handles the product gently by direct and smooth operation.

Axes are Servo driven.

Applications

Canned and jarred products

Plastic bottles applications

Continuous Motion Case Packaging Machine

The machine packs plastic or glasses applications of various sizes and shapes into cases.

This machine guides the products into cases continuously.

Products are handled gently as they are lowered into the cases.

It is the best for products that require high speed continuous motion

continuous case packaging machine

The feed conveyor of the cases can be adjusted to accommodate various sizes and heights of the cases.

The case die magazine are places vertically to allow the operator to to load them without stopping the packer.

Products such as bottles are packaged in cases that are partitioned

Applications

Bottles, metal and paper cans

Glasses carbonated and non-carbonated cans

Pet containers

Features

Product handling is done using servo motors

Speed of 45 cases per minute

Provides easy changeovers,

Has partition inserters

No tooling is required for changeover

Vertical Side Load Case Packer,

· Vertical side load packers can pack up to 100 products per minute,

- Using a conveyor the machine will load your product and wrap it with a protective film.

- The packer then drops the products inside the case

vertical side load case packer

Applications

The packer can be used to pack chemical products or liquid pouches,

You can use this packer for different types of products,

You food products such as meat and cheese can be packed using these case packers.

Features

Has the ability of keeping your product safe thus preventing damage and wastage.

To prevent the product from falling the packer is designed plates.

The machine gives you direct access to the ground because of its compact design.

Vertical Bottom Load Case Package

The packer loads your product from the bottom.

It handles products gently and does not need pick tooling,

The top of the product is not touched.

vertical bottom load case packer

Features

Can perform case forming, loading and sealing on one machine.

Has quick and easy changeovers

The operators’ zone s are visible and offer easy access

The packer has smooth and accurate transfer of cases from one station to another by driven trolleys.

You are sure of your cases being squared

Applications

Food applications with quadrangular or lay flat cartons,

Dairy applications with gallon jugs or gable tops,

Food containers with delicate and sensitive products

Industrial cans and bottles.

Products which have shrink wraps and transparent films on top

Wrap Around Vertical Case Packer

The machine wraps products as they move along the conveyor belts.

This machine is ideal for packaging heavy bundles.

Products are much safer and easy to handle because of the security and stability offered by the packer.

wrap around vertical case packer

The collation of the packs relies on the shape and dimension of the container

Used for packaging product with round oval and square shapes.

The operating mode is automatic

Applications

Bottles and boxes

Plastics, metals and cardboards

Features

Speed is 36 cases per minute dos product data recording

The machine communicate throughout the process.

This makes it easy for the operator to identify a fault.

Has a short changeover time (15- 20 minutes)

Packs products gently

The machine is fast and dependable

Partitions which protect your product

It is servo driven

Has low maintenance

Fully Automatic Vertical Case Packer

This packer is the best when you want to maximize your efficiency.

Additionally, the operation mode is automatic; does not require operator.

The packer forms, loads, and closes case on its own. This optimizes production.

automatic vertical case packer

Applications

All kinds of puffed foods

Washing, Milk and starch powders

Melon seeds, popcorn and peanuts

Glass and plastic bottles

Features

PLC computer control system

Quick and easy to operate

Easy to use touch screen can conveniently set parameters.

Has high speed picking and packing of cases

Can identify and display fault.

The sealing position is more accurate because of its high sensitivity fibre colour tracking.

Cuts cost because, the maintenance is simple and saves time and manpower.

The opening and closing speed of the hopper can be adjusted; this prevents breakages and wastage.

Semi-automatic Vertical Case Packer.

This packer combines hand packing with other mechanical processes done automatically.

Different product weights, shapes and sizes and materials can easily be packed in various sizes of cases.

After forming the case the operator transfers the product from the conveyor and loads it into the case.

semi automatic vertical case packer

Your case is then taken to the sealing station

Applications

Snack bags

Tubs for pets’ food

Bottles or liquids

Flow wrapped confectionery

Features

Has the ability to handle 30 cases per minute

Easy to adjust for various sizes of cases.

Servo motor controls the push mechanisms.

The monitoring area decodes multiple data matrices continuously.

Has user friendly interface and adjustable touch screen.

Industrial standards are read and decoded.

Horizontal case Packer combines product and then push the product into an open case which is oriented on its side.

Vertical case packer on the other hand, lowers the product into the open top of the case.

The two machines also differ in the primary products they package.

vertical case packer

Vertical case packers are appropriate for products that can tip over easily.

Such include irregular bottles and loose tubes

While horizontal case packer are ideal for products that are rigid and can be stacked and pushed.

The cost of vertical case packers is lower than horizontal ones.

Vertical case packers speed goes up to 400 bpm for pillow bags this is not possible with horizontal case packers

Horizontal case packer

There is a variety of applications that are packed using vertical case packaging machines.

They include

i). Food applications which have rectangular cartons

ii). Dairy applications with gallon jugs and gable tops

iii). Industrial cans and bottles

iv). Difficult to handle products,

v). Pillow bags

vi.) Pharmaceuticals

i). The case packer is alternative of the pick and place system.

ii). Handles your products gently.

iii). Machine operators can manage to access the internal activities thus detecting maintenance needs.

iv). Products are packed faster then what human labour would do.

v).The machine is most appropriate for food and dairy applications

vi). Has a LED lighting system which enables operators to observe the internal working of the machine.

By so doing the operators can identify a problem early enough and deal with it

vii), Some machines have the ability to form, load and seal. This increases your ROI (Return on investment)

vii). Vertical case packer will pack you product accurately according to the size, shape and other dimensions.

This improves the products appearance, protects it and will save you losses caused by breakages and refunds.

Getting an appropriate case packer will help to strengthen your production line.

The following are important features when choosing the best vertical case packers.

Machine Type

You need to choose a proper case packer for your production line.

A wraparound case packer is best for sturdy bottles

On the other hands vertical top case packer is appropriate for packaged liquids for maximum protection.

Your Production Need

Your production requirements will also dictate the kind of case packer the kind of case packer to choose.

For example if you intend to pack products that do not need to stand straight a side loader would do.

But if your products need to be upright to avoid spillages then a top loader is the best for you.

Changeover Needs:

This refers to the changing of settings on the case packing machine to package a different product.

Saving time during changeover speeds up your production line.

Choose a machine that has quick changeover.

Wraparound case packers are not flexible in terms of changeover.

Line Tracking Features

These features will save on time and cost because

- They select items from the in feed and place on the moving tray in the out feed.

- The features decrease you need for manpower.

- Have ability to detect defect products thus saving you the trouble of returns and refunds.

Floor Space

Your case packer should be compatible with the amount of space allocated to it.

Intermittent motion wraparound use small space .

On the other hand continuous motion wraparound are wide and long

Multi-functional case packers allows you to use less space.

Machine Restrictions

Think about the restrictions within which your machine can operate.

These include the hours of usage, weight limits and the cost of production cycle.

This helps to improve the lifespan of your case packing machine.

Production Speed

The machines speed should match the volume of production you want.

This is measured by the number of cases produced per minute.

Speed below 20 cases per minute can be done well using side load packers or intermittent motion case packers,

Continuous motion case packer and wraparound case packers are the best for high production volumes.

You may also like cartoning machine or case packer.

For all your vertical case packer machines, contact us now.