Horizontal Case Packer Manufacturer in China

JOCHAMP is your one-stop horizontal case packer machine provider based in China. We manufacture advanced automated packing machines that can improve inventories and minimizes consumed time on item separation. You can tell us your desired specifications and trust our customization services and processes.

- Easy to operate

- Made with automatic checking functions

- Faster & Cheaper

- Accurately packed the items

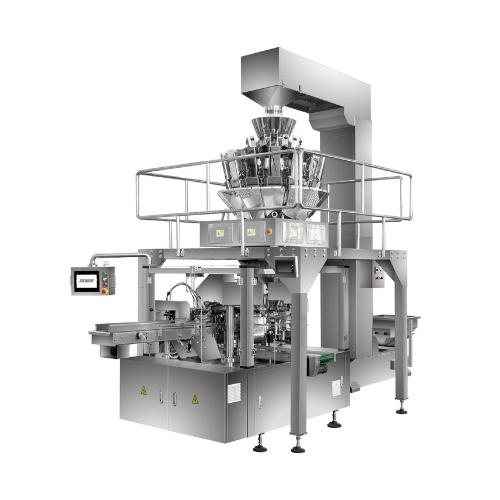

JOCHAMP Horizontal Case Packer

An efficient horizontal case packer that employs both mechanical and pneumatic motion control is available from JOCHAMP, cost-effective equipment. Different types of packing, such as standard slotted cases or half-slotted cases, trays, or wrap-around boxes, are all possible with this system. In addition, it has a wide range of options for future usage.

The machine can produce 10 to 15 boxes per minute, a good compromise between its power and size. The case packer formed a tube when the engine ran and forced the products within. The entire box then went towards the outlet, and the machine closed all the flaps and sealed them on both sides.

It is possible to put the automatic horizontal cartooning machine upstream or downstream of the packing line; either way, it functions well as a standalone unit. We can supply you with a one-stop solution for your packaging equipment needs. If you have any questions, please shoot us an email straight away!

Horizontal Case Packer Advantages

Using the advanced horizontal case packers indeed helps quicker and cost-effective production processes. They have designs that include the complete level of automatic production. JOCHAMP manufactures them with functional components that make the process faster.

The horizontal case packaging machines are designed with flexible packaging. They are formed with high standard capacity. These packaging machines can seal and fill the solids, dry, and liquid products. JOCHAMP assures packaging without problems or damages.

Utilizing the horizontal design case packer machines will secure them from damages, moisture, dust, and other external elements. These case packer machines are suitable for the foods and medicine industries as they get rid of hand contacts and maintain their hygiene.

JOCHAMP manufactures the specific case packaging machine with easy maintenance. They are also user-friendly packing machine types. You can check their functional components automatically and quickly. JOCHAMP provides them with maintenance directions.

Vertical & Horizontal Case Packer Differences

The horizontal and vertical case packer machines have multiple similarities than differences. But the following defines some of their feature differences.

- Design & Structure: Horizontal packing machines utilize film rolls and move them over a plow that forms gusset bottoms. The vertical ones require more force than horizontal machines.

- Film Folding: The folded flat film by horizontal machines is done in two dimensions. They run across the following seal stations. And the vertical case packers simultaneously seal the products and fill bags.

- Filling Processes: The horizontal ones supply the items to the film from the top with a pulled open bag. While the vertical case packer machines cannot give a 100% fill volume as the horizontal machine can. Unlike the horizontal ones, they have no fully open gusset.

- Limitations: As vertical machines utilize more force, they are unsuitable for rigid materials. Both packaging machines have the same production limitations and are used by operators.

JOCHAMP Horizontal Case Packer Industries Serve

Due to its competitive pricing, many businesses have embraced horizontal case packer solutions. This equipment is used in various sectors to pack items that come in both solid and liquid forms. Some of the applications are as follows:

- Food Manufacturing Industry: Products such as bread, cakes, pastries, liquid beverages, alcoholic drinks, and non-alcoholic drinks are some of the goods this business type packages.

- Business in the Pharmaceutical Sector: It includes gauze cloth, injections, blisters, and infusions for packing purposes.

- Agricultural Industry: The horizontal packaging machine is ideal for packaging fertilizers and seeds.

- Manufacturing of Cosmetics: This application includes wet wipes for cleaning dogs, refreshing newborns, cleaning cosmetics, and other relevant purposes.

Products Suitable For Horizontal Case Packer

The JOCHAMP horizontal case packer is available in several different configurations. It is suitable for side packaging products that load more successfully when placed horizontally. These products include cylindrical items, multi-packs, cartons, nested goods, and multi-packs. Horizontal case packer packages items such as:

- Cartons made of chipboard

- Multi-packs

- Spherical products

- Cups Within Cups

- Caulking Tubes Wallpaper Rolls and Tape Rolls

- Paper Plates

- Towels made of paper

- Toilet Tissue Rolls

- Rolls of Wrapping Paper for Gifts

Why Choose JOCHAMP Horizontal Case Packer

JOCHAMP is a provider of industrial packaging solutions worldwide, mainly horizontal case packers. Case erectors, robotic logistics operations, and ergonomic hand-packing machines are some of the packaging machinery we design and produce. Our staff is prepared to collaborate with you in formulating the appropriate system that meets your requirements.

Thanks to our horizontal case packer’s increased customization and flexibility, businesses can boost their production levels. The packaging solution comprises various parts, all of which work together to make the machine function properly. They include: Feed link or in-feed conveyor, pull film structure or film former, coding machine, intelligent touch screen, automatic sealing, etc.

The side-loading capabilities of our horizontal case packer may be beneficial to the consumables of various renowned industries. Do you wish to learn more about the benefits that JOCHAMP may provide for your company? Check out the extensive list of available customizations we serve in the business world.

JOCHAMP - Your Constant Manufacturer in China

Our team can personalize this model of the packaging solution by adding a module variety, including the following:

- Several different infeed systems, each tailored to the products’ characteristics, orientation, and speed.

- A second magazine works well in the outside container, doubling the device’s capability.

- User added protections

- Hot-melt sealing device

- Remote service components

Get in touch with us right away for more information on the customization of the horizontal case packer!

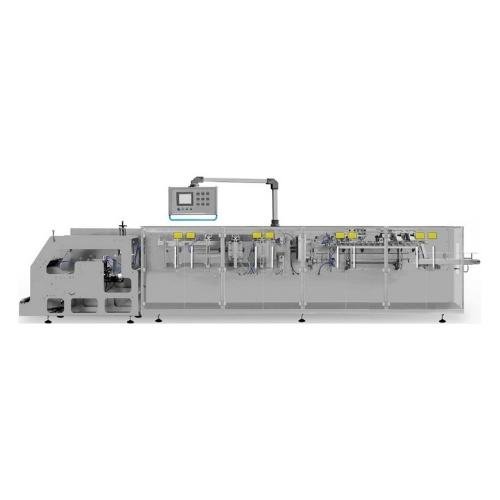

There are two primary varieties of horizontal packing machines we can offer. They are as follows:

Semi-automatic Horizontal Packaging Machine: This machine allows the packaging various items into different pack sizes in small quantities. Filling and sealing products such as chemicals, medicinal powders, meals, drinks, and beauty products offer several benefits.

Fully Automatic Horizontal Packaging Machine: Fills and closes a pre-made pouch with the product. It occurs in approximately 40–200 bags each minute. It features a circular layer positioned in the middle and transports the bags to different stations at sporadic intervals.

High Performance Horizontal Case Packers for Your Project

We manufacture horizontal case packers that are manufactured with different machine options such as:

- Conveyor to move pallets or products from one line to another

- Laner for collation of products to the next process

- Adjustable features for automatic adjustment of cases and products

Our horizontal case packers are suitable for integrating with other machines such as:

- Centralized palletizer

- Modular palletizer

- Integrated palletizer

We offer horizontal case packers that can perform a variety of functions including:

- Product inspection systems

- Barcode reading, check weighing, and case inspection

- Labeling, coding, and marking equipment

Related Products

Horizontal Case Packer: The Ultimate Guide

There are many horizontal case packer machine available in the market. A reason this guide will help you choose effective and reliable case packing machines. Keep reading to learn more.

A case packer machine operates through automation by setting up a tray and loading the products from the top, bottom or side.

Remember, the procedure gets complete by closing the wrap around case using glue or the tape.

The machine applies both the air cylinder and servo to control the loading and sealing of the product in compact system.

Horizontal case packer

Some of the most common uses include:

- Packaging of cakes, biscuits and breadsticks.

- Applicable in the packaging and sealing of wet and dry pet food.

- Chewing gum, candy and bubble gum apply the horizontal case packer for packaging and sealing.

- Companies producing beverages prefer this machine because of its safety benefits.

- Applicable in packaging water and both the alcoholic and non-alcoholic drinks.

- Horizontal case packer machine ensures proper packaging of both wet and dry pet foods. This machine ensures the bags are safe, standard and reliable by offering both end seals.

- Preferable for the packaging of chewing gum, toffee, candies and bubble gums.

- Horizontal case packer is applicable in the packaging and sealing of cosmetic wipes, baby wipes and those wipes for cleaning pets. The wipes can be wet or dry ones.

- Pharmaceutical industry applies the case packer machine for efficient packaging of the drips, gauze bandages and quality syringes.

- Ensures proper sealing on both ends of the horizontal bag by enabling packaging of seeds and chemicals.

· Efficient And Works At High Speed

The machine works at a very high speed packing high volume items.

- Machine Offers Precise Product Presentation

The machine packages the items and offers a presentable polished look.

· Wide Product Range Accommodation.

The machine is efficient in the packing of different product range. Bulky items and both the large and small items are accommodative within the machine.

· Cost-effectiveness

The machine applies the combination of both the servo and air cylinder motion, enabling it to erect, load and seal the product.

Thus choosing the machine for your work is much economic.

· Hygienic

Ensures safety of the goods by protecting them from damage, dust, and moisture. It reliably ensures product hygiene by making sure the food and medicines do not get into contact with the hands.

· Flexibility

The machine offers various options for usability. One has the option of using half slotted cases, trays, regular slotted cases or wraparound cases.

· User-friendly.

This is achievable by the nature of the machine features, such as having an open design. The open design enables ease of access for maintenance and for the users.

· Wastage Reduction

The horizontal case packer has an automatic checking function. This enables the machine to keep track and detect whether the bag is in its open or closed form. Thus preventing the products from spilling out of the bags and reducing wastage.

Some of the most common options available include:

Side Load Horizontal Case Packer

The machines mainly deal with bag in and box type of packages. Operation of the machine starts by erecting the packs to reach the stacking unit. Rows of the machine are at a stack point on the holding plate assembly. The collation is then pushed into the open case.

Lastly the case flaps then fold and close prior to the case discharge.

side load horizontal case packer

Features Of Side Load Horizontal Case Packer

Enables easy changeover

Has an intelligent layout that permits only one side operation during packaging.

The design is only fit for low wear and tear operations in line with low spare usage.

The cases on the machine are positioned in a square manner during the sealing process by bottom/top belts.

The final packing matrix in use determines the in-feed product on the machine.

Bottom Load Horizontal Case Packer

The machine maintains a vertical orientation of the case, it loads the products from the bottom part of the machine.

bottom load horizontal case packer

Top Load Horizontal Case Packer

The machine provides both the vertical packaging and flat packaging for the pouch items/products.

Offers better packing and sealing for the pouch and bottled products.

top load horizontal case packer

Features.

Has modular systems which enables the combination of multiple cells.

The machine contains both the case erector and lid applicator.

| HORIZONTAL CASE PACKER | VERTICAL CASE PACKER |

| Automated feeding systems such as the robotic version | Has various feeding systems |

| High speed operation | High speed operation |

| Technical to operate | Easy to operate |

| Packaging of single solid items | Packaging of powdery,granular and liquid products. |

| The items are put into the film through the top part of the machine. | Products are filled in the machine through the sides of the bag. |

| The films are folded flat, with two dimensions after it’s moved over the plow of the machine. | Both the bag filling and seals production happen at the same time. |

You should consider any of the following options:

- The machine has an open design so as to enable easy access for efficient maintenance and operation.

- The collation methods are multiple.

- It is operator friendly interface.

- Horizontal case packer has an automatic checking function that detects the closure and the openness of the bag.

- Poaches within the machine enables the packaging both the wet and dry products.

- Nature of filling the film is through the top part of the machine.

- The horizontal bags in the machine are always 2/3 to ¾ full.

- Contains all-servo design to suit customers’ requirements.

- Enables accommodation of all the cases;-half, regular, slotted, wraparound cases and trays.

- It is Pro-Adjust in functionality.

Some of the main parts include:

Coding Machine

Applicable in the printing of logos, dates and other texts on the pack using the printer.

In-feed Conveyor/Feed Link

The machine part applies the injection code made from 304 stainless steel powder, which enables safe and hygienic packaging.

Smart Touch Screen

The touch screen helps to set the parameters in the machine just before packaging.

Automatic Sealing

The part ensures proper sealing of the horizontal case packer by rotating hot air incision before and after packaging.

Film Former

A multi-linked film coordinates the pulling process of the film.

Allows easy rolling of the film as the packaging process is in progress.

Items Discharge Area

An area in which the packaged items discharge from as they await packing into carton boxes for storage.

First, Place the items which are either food or non food products on the in-feed conveyor of the flow wrapper.

Placement of the items at hand can be by automating a feeding solution machine or manually.

The in-feed conveyor then directs the product to the machine’s forming section.

After delivery of the products, the film gets drawn from the film feed assembly onto the forming area.

The section therefore develops into a film tube which generates encircling the product forming a fin-seal. Hence delivering it to the cutting head.

An end seal generates from the cutting head hence resulting into the cutting and sealing of individual packages.

Lastly the packages proper seals move directly to the discharge zone where they are put in cartons.

You may be interested in:

Packaging And Labelling Machine

For all your horizontal case packer machines, contact us now.