Sachet Filling Machine Supplier in China

Jochamp supplies sachet filling machines which perfect for packaging powder products, granules, or liquid products. It got massive recognition in the market because they provide cost-effective and convenient packaging.

- CE, SGS, cGMP approved machines

- 7/24 Hours customer service

- 15 Days delivery period

- Free sample trial

JOCHAMP Sachet Filling Machine

Sachet filling machines are first-class sachet packaging equipment. These machines are better option for packaging shampoo, cereals, coffee, sauce, tomato ketchup, juice, liquid products, palm oil, jam, and more. Quick sealing and filling, Jochamp can customize sachet filling machine depending on your requirements.

For many sachets style, whether 4-side seals, 3-side, foreign sachet, or stick sachet, rest assured these machines can accommodate them for you. They are fully automated machines and multi-function. If you are manufacturer, seller, or distributor of any products that needs to be packaged using sachet, you can count on Jochamp sachet filling machines.

Please get in touch with us for your inquiries!

Types of Sachet Filling Machines

Sachet Filling Machine Benefits

Our custom sachet filling machines can accommodate various packaging and sealing styles. They are very convenient to use.

Finished products from these machines are effective branding tools. The machine can print your custom logo or image on each product.

Enjoy using these machines for your sachet filling/packaging projects. They are user-friendly; can be operated without using special skills.

Aside from their quality, sachet filling machines are offered at lower rates. They provide excellent packaging results, without affecting your budget.

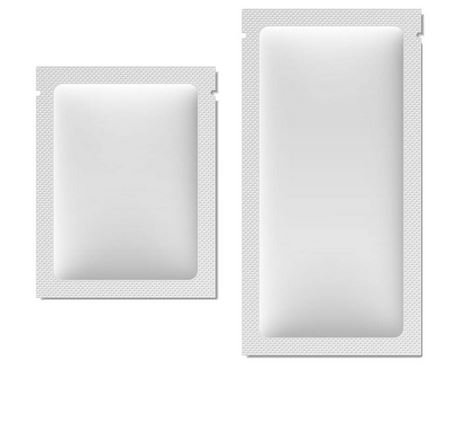

Sachet Pack Styles

3-Side Seals –It has basically 3 sides of seals. There is a specific filling/sealing machine used to create this style. The machine uses plastic or paper laminated film rolled in the process.

4-Side Seals – This style is forged using hand. Then, the machine used in achieving this style has 4 side seal sealers.

Stick Packs – It is mostly the preferred packaging style in the pharmaceutical and food industry. The machines used have high speed, heavy output, outstanding stick pack results, and more.

Center Seals – The machine for center seals are easy to operate. Unlike other styles, its machine has diverse sachet sealer and former.

Easy to Operate

Most Jochamp sachet filling machines are simple to use and operate. The machines don’t really require extensive engineering or technical knowledge to operate.

Our machines are also user-friendly, with straightforward color Touch Screen interacting components.

Besides that, our professional technical support services are available to train and assist your company.

Machine Types for Any Packaging Needs

For Ketchup – 3 sides or 4 sides seal styles are great machine options. They are high-speed machines that can fill 3ml ketchup, 5ml, 15ml, 20ml, and up to 200ml per sachet. Your custom logo can be printed on it for effective branding.

For Sugar – With flexibility and simple operation, Jochamp sugar sachet filling machines are great for your sugar packaging. They are made of food-grade, premium stainless steel.

For Shampoo – Its machine provides standard or customized sachet packaging sizes. They are fully sterile and can enhance packaging performance.

For Powder – Used to accommodate various types of powder products packaging (seasoning, chili powder, coffee, milk powder, etc). Filling capacity: 5g, 10g, 100g, 150g.

Why Choose JOCHAMP Sachet Filling Machine

In China, Jochamp occupies more than 3000 square meters of factory. We are your great source of different sachet filling machines, the perfect option for pharmacy products, food elements, granules, liquids, and more.

We offer a wide variety of sachet filling machines, custom-built according to your specific product packaging. All types have the best price and first-class quality. In addition, we provide modern technology, user-friendly manuals, better technical assistance, and more add-on services.

If you have a packaging business and you need sachet filling machines, choose Jochamp to supply for you. They come in numerous selections to match your specific packaging demands.

To learn more about our machine offers and services, please contact us!

JOCHAMP Sachet Filling Machine

Sachet outputs using our machines offer several benefits to marketers, other brand manufacturers, consumers, and retailers. These machines also allow efficient production and precise packaging. Other benefits include:

- Compact saving on ground space

- Easy to operate with basic manuals

- Affordable than other brands

- Aids in preserving the quality

- Custom-built to meet your unique demands

- Eco-friendly, recyclable packages

- Great preservation to extreme temperatures, air, and moisture

- Effectively market and brand products

- Asian Price / EU Quality

- Approved by ISO9001, SGS, and CE certifications

Our sachet filling machines are mostly preferred today by many manufacturers and customers. It is applicable across several sectors and industries. Some products that require these machines include:

Liquid food commodities – The machine used is custom-made for packaging pastes, liquids, jams, and many others. It is perfect for industries dealing with milk, honey, edible oil, fruit juice, or shampoo.

Tea and coffee sachets – Our sachet filling machines are a great option if your business is about manufacturing, rebranding, or distributing coffee and tea products. All the machine types are fully automatic and user-friendly.

Food packing – These are intended for food packaging in liquids, powder, or different granules. All machine types are completely automated and fill 1-150gs food products.

Custom Filling Machines for Multiple Packaging Needs

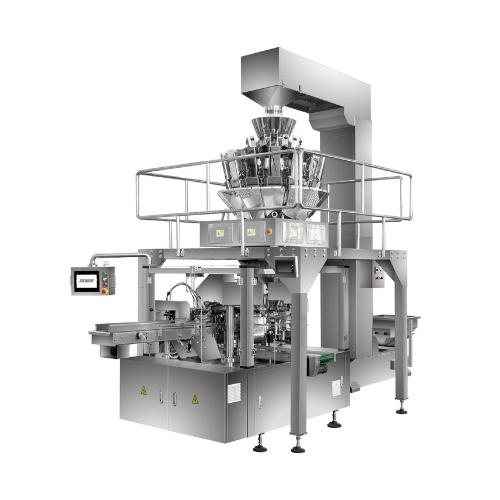

The Pre-made Pouch Packing Machine With Multi-Head Weigher is a sealing machine and self-sufficient packaging solution. They are easy to maintain and clean machines. You no need wasting several hours when setting them up. These machines also operate quickly.

The horizontal form film seal machine (HFFS) is a combination of sealing and filling machine. They offer maximum efficiency, availability, hermetic seals, and perfect system adjustability.

In short called as VFFS machine, they are machines implementable to packaged products into bags. Their benefits include low workable costs, capacity to use various materials, and have printing and labeling features.

Auger filler packing machines are machines that fill the exact amount into vessels. Commonly, they have simple construction, maintenance, and easy cleanup advantages. Delivering accurate packaging and viability is their main purpose.

Related Product

Sachet Filling Machine: The Ultimate Guide

Probably, you want to learn about the filling technology, design, features, working principle, dosing systems or benefits of sachet filling machines.

Well, this guide explores all information you need about sachet filling machines.

So, before investing in your next sachet packaging machine, read this guide.

Filling and sealing machines for sachets are primarily used for packaging and closing sachets containing granular liquids and powdered components in industries.

The packing material is usually Polyethylene single lay film.

This machine uses ultraviolet radiation to disinfect itself.

sachet filling machine

Some of the various use of filling machines are:

Liquid Food Products

The sachet filling machine is most commonly used in the food industry, mainly when working with milk, honey, fruit juice pastes, jams, edible oil, and water.

They are usually custom produced for such purposes, saving manufacturers a lot of energy and time.

Pharmaceuticals, Chemicals, and Household Hygiene

Pharmaceutical powder manufacturers, spice powder, and chemical powder manufacturers employ these devices.

They are also crucial since they aid in packaging cleaning products used in houses.

Tea And Coffee Sachet Packing

Manufacturers typically have a wide choice of product packaging options from which to choose.

For high-volume production manufacturers and small volume production manufacturers, a sachet filling machine is the most acceptable alternative for easy packing of coffee and tea.

Food Items

Typical sachet filling machines are designed to package food in liquid, powder, or granular form.

Usually, an automated liquid sachet packaging machine is suitable for foods in juice or paste form, such as tomato paste, mayonnaise, and ketchup.

The sachet filling machine can also automatically package food additives and powders.

Sachet packaging machines do have various benefits, which are:

- Packing machines for sachets are small and conserve floor space, which every manufacturer wants.

They all require a machine that takes up little room and allows other equipment to enter, and is cost-effective in the long term.

- Another advantage is that the sachet filling machine has user-friendly instructions that make it simple to operate.

Most of this equipment is automated, allowing producers to create reliable, uniform sachets with few defects.

- Typically, the sachet packing machine is configured, with the operator entering required specifications into the machine’s interface.

The cost of an automated workforce will reduce, and customer satisfaction will be improved.

- Because they require less material than other packing processes, sachet packing machines are cost-effective.

At the same time, the packing materials require less room. Shipping, containerization, and storage costs will reduce.

- The sachet packaging also has the advantage of preserving quality.

Besides the packaging contains typically modest quantities of products; thus, opening the sachet usually exposes a small amount of the contents, safely protecting the rest.

- It also allows manufacturers to create and personalize sachet designs to make their products stand out.

Packaging sachet machines may also make cachets meet market demand in various sizes and forms.

Typically, if you want to get a competitive advantage in the market, you must choose from multiple designs and packaging options.

- Generally, sachet machine packaging makes it simple to brand and advertise sachet products.

- It is also feasible to sell in compact packs. Smaller packaging is more convenient for customers.

Some of the most common options include:

Liquid Sachet Filling Machine

The liquid filling sachet machine handles the packing of liquid sachets.

Normally operates with high pressure, also known as liquid filling pressure.

When the reservoir liquid’s pressure equals the amount of air in the sachet, liquid flows into the sachet depending on its weight.

liquid sachet filling machine

Because a feature enables the liquid sachet filling machine to respond to varied sizes

Liquid fillers are usually straightforward—sizes without replacing parts. It will automatically stop when the machine belt has no more sachets to fill.

Powder Sachet Filling Machine

Powder sachet machine fillings use mostly to load powder sachets.

Typically used in the pharmaceutical industry to maintain excellent efficiency and productivity during the manufacturing process.

In the market, this machine is always in high demand.

These machines generally operate at a pace of 108 strokes per minute, are fully automated or semi-automatic, and function effectively to provide the most outstanding results.

powder sachet filling machine

It is a dependable machine for work productivity.

The fillers’ packaging powder sachet machine’s driving mechanism is user-friendly and compatible since the motor provides the necessary push to the spinning elements.

Granules Sachet Filling Machine

Filling granule sachet machines pack granular materials such as nuts, coffee and beans.

This machine is ideal for the food industry because it allows granular to be packed tightly in sachets, extending their shelf life and making transportation more accessible.

granule sachet filling machine

It is simple to operate, with excellent packing speed, consistency, and uniformity on granular sachets.

The parts of the sachet filling machine are;

Dosing System

It is a crucial component of the sachet machine, as it is in charge of filling and dispensing the product into various packaging.

The auger filler, and screw elevator are the three major components of a dosing system.

Typically, the augur and filler distribute the product into packs or sachets.

The elevator screw will offer a mechanical movement that will assist the filling in performing its function.

Control System

PLC system control is commonly used in semi-automated and fully automatic sachet filling machines to aid in the total synchronization of the mechanical parts.

Another option for sachet filling machines is a bright touch screen display distinct from the devices.

Drive Mechanism

The sachet filling machine is generally driven by various mechanisms, the most common of which are a motor system and a power system combination.

Generally, the power system is present in the cabinet machine.

System/Product Conveyor Belt

The sachet filling machines use an occasionally moving conveyor belt to help transfer empty sachet bags from one location to another.

Loading System

This section is an exalt area where the sachets are loaded into the infeed channel so that they can pass through various stages.

The loading system always includes a set of pouch feeding rollers and gripping bag arms.

The Bag Opening System

These are commonly suction set pads that operate as zipper reclosures on sachet filling machines. Furthermore, the bag sensor will detect them once sachet packs reach this point.

Sachet filling machines will package liquids including fruit juice, milk, soy sauce, vinegar wine, beverage, frozen drinks, and soybeans.

Dusting System

There are dust management options accessible at this location. Modification is made to the dust collector basin, dust hood, and nozzles.

Discharge System

At this stage of the sachet filling process, the machine deals with entire sachet packages, which then fall into a container for further processing if necessary.

Generally, sachet machines are appropriate for working with powdered, granulated, and liquid goods.

They always work in categories such as:

- A multilane sachet packaging machine produces many sachet lanes simultaneously and cuts them into individual sachets.

When you need a lot of packaging, this is the most acceptable option.

- Single-lane sachet packing machines that only produce a single lane, providing a single extended pack cut into individual sachets.

Below is some guidance on how the sachet machine works.

Packing Roll Film Is Unwinding and Transport.

Winding down a large roll of pre-printing film material from the rolling stock is usually the first step.

After that, the material will wound up in a surrounding reel core at the packaging sachet machine’s back end.

The most common film materials include laminates, cellophane, a foil laminate, and polythene, depending on the industry preference.

Besides, the film will take from a reel by transport film belts located on the tube’s side, making the bags from the film material.

The jaws catch the film and move it downhill from the reel to the forming bag zone in machines without transport belts.

Maintaining Film Tension

When carelessly holding the film, unwinding off the reel, it tends to sag, causing it to wander while traveling through the packaging sachet machine.

A series of roller brakes apply pressure regularly to keep the filming material under consistent pressure.

Film Centering

The transport belt’s film location will detect an optical sensor installed in the packing sachet machines.

It ensures that the film is perfectly centered and autocorrects any wandering by recentering it.

Optional Printing or Embossing

When a printing unit is attached to the packing sachet machine, the film usually passes through this part.

At this point, inkjet printers or thermal ink can be used.

This part is crucial, especially when printing dates, brands, or a registration mark on the sachet packaging.

Sachet Information

The film will transfer to the sachet forming tube, which wraps around it until the opposite ends meet.

Here, the cylindrical tube is used to make the correct size sachet, sealed at the base, and terminates with a vertical seal.

Determining the width is through the forming tube, and the length will be determined by altering the sachet dimension of the parking sachet machine operational interface.

Material Filling Into The Sachet

After the sachets have been vertically and bottom-sealed, the contents can be filled.

The flat nozzle, round tube, or auger fillers that release liquid, powder, and granular components into the sachets.

They will link closely to the sachet packaging machine’s filling mechanism.

Besides, the filling system is primarily responsible for the precise weighing of contents.

The packing sachet machine will automatically coordinate its operations to realize the product when the sachet is open.

Sachet Sealing

The sachet has already been sealed at the bottom and vertically.

Also, the top piece, closed after receiving the content, is the only remaining portion to be completed.

Sachet Discharge

Sachet that has already been filled and sealed will discharge from the packing sachet machine at this level.

Besides, the product is now ready to be sold. A sharp knife positioned inside the sealing jaws cuts the sachet as the sachet is sealed.

It will then be released for further transmission. Depending on the type of sachet utilized and the equipment, this machine can manufacture 30-60 sachets every minute.

Post-Discharge Operations

The sachets may need to undergo a quality control test to meet the packaging’s goal.

X-ray equipment, check weighers, and metal detectors may be used depending on the industry.

Some of the most common options include:

3 Side Seal Sachets

It’s a sachet packing and sealing machine that typically produces three-sided seal sachets.

The three-sided sachet seal usually uses packet sachets such as plastic and laminated paper rolls of film.

Creating the sachet packets requires a sachet former, also known as forming cubes, forged by hand.

The former must be smooth for the film to move smoothly when the packaging sachet machine drives the film roll.

3 side seal sachet

However, we recommended that one packing sachet machine only use 3-4 formers for convenience.

4 Side Seal Sachets

The four-side seal packing machine usually has the same function as the three-side seal packing machine.

Again, the only difference is the former, it comes with unique designs compared to the three side seal sachet.

4 side seal sachet

Another difference is the sealer that seals the sachets. But with multiple sachets like 3g,5g,10g,50g, and 100g with also different formers.

Stick Sachet

This design has a wide range of applications and is particularly popular in the pharmacy and food industries.

High speed with heavy output, attractive stick packs, and a wide range of industrial applications are just a few highlights.

stick sachet

Center Seal Sachet.

It is the most straightforward sachet packing machine to grasp for this type of design, as it has an entirely different sealer and former than the three above.

The film will be folded from the center seal packing machine and sealed from the bottom and top for the center seal packing machine.

center seal sachet

Automatic Sachet Making

It is a part of a multipurpose sachet packaging machine that produces sachet bags. Usually, it’s the first stage.

The sachets are cut into various sizes and sealed on one side, leaving the top open for content filling.

Measuring/Determining Quantity

The content filling will be done in each sachet, and then the sachets weighing will establish the exact quantity before being sealed.

Filling And Sealing Sachets

The multifunctional sachet packing machine fills each sachet with the contents before closing them and distributing them in the market.

Printing Sachets

Also, the expiration date, manufacturing dates, user precautions, and other essential information are all printed on the sachets at this level.

Cutting Sachets

It is the process after the sealing of sachet bags process completed.

The machine will push them to a spot that will be cut according to the machine setup and counted.

Counting Sachet fs

After the sachets cutting, the machine counts them as packing them into the appropriate boxes or containers for storage.

Control system

It is one of the most important aspects of a multilane sachet filling machine.

The optimal control for any machine should be tailored to the machine – a combination of human interface and digital PLC.

Again, the control system must also be user-friendly and ensure that operations run smoothly.

Drive Mechanism of Machine Parts

Servo motors, VFDs, vacuum suction, and electric motors are several driving solutions available for the moving parts of a multilane filling sachet machine.

For example, a servo motor is the most suggested option for a multilane sachet filling machine.

Mode of Operation

It is critical to select a multilane sachet filling machine with the appropriate mode of operation.

You can choose between semi-automated and fully-automated processes.

In this instance, your needs and applications will determine your chosen machine.

The Machine Design

This aspect is vital to remember depending on your applications; there are multiple designs to pick from for various fit uses.

Choose the most cost-effective, accurate, and high-speed multilane sachet filling machine.

Pollution And Dust Management System

When working with a multilane filling machine, dust is a common issue.

Another vital aspect to consider is the scoop feeder, dust hood, and dust vacuum unit, which will help to reduce dust emissions.

Quality Standards

Quality is the essential element for any sachet filling machine.

Check if the multilane sachet filling machine meets all the required standards and has the necessary certification like CCC and CE.

Speed of Packing

Another characteristic of the multilane filling sachet machine is that any manufacturer wishes to complete manufacturing more quickly and at a cheaper cost.

Each multilane sachet filling machine has a varied speed; you must choose the one with the fastest pace to manufacture a large number of sachets, such as 25-60 sachet bags per minute.

Related Resource:

Automatic Shrink Wrapping Machine

For all your sachet filling machines, contact us now.