Cup Filler Pouch Packing Machine Supplier in China

JOCHAMP provides a high-quality cup filler pouch packing machine that helps you reduce your packaging costs and improve your output. We specialized in the customized automatic packaging production lines for over ten years.

- SGS, CE, ISO9001, and cGMP certifications

- 15 days delivery time

- One-year quality assurance

- Lifetime after-sale service

JOCHAMP Cup Filler Pouch Packing Machine

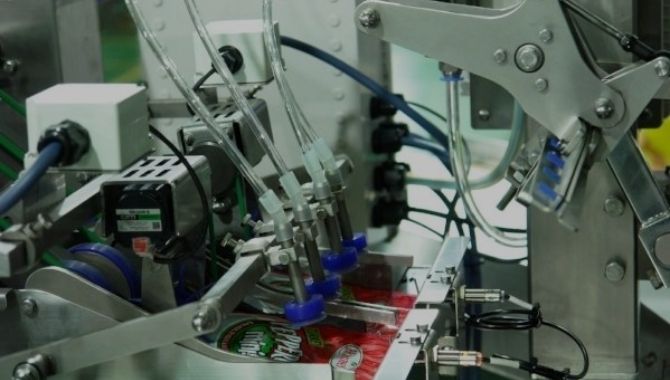

JOCHAMP cup filler pouch packing machine is widely used for granules and free-flowing powder packaging in the center seal pouch. A gusset pouch is possible with this machine and it looks like a collar. Sometimes, it is known as a collar-type machine. The volumetric cup assembly is being used as a filler.

At JOCHAMP, we only use high-grade raw materials to produce our cup filler pouch packing machine. We ensure the electronic and electrical components of the machine have performed numerous tests. Then, we fitted it in the packing machines. It can help you easily maintain and reduce the risk of machine breakdown.

For your cup filler pouch packing machine needs, you can rely upon us. Email us now!

Types of Cup Filler Pouch Packing Machine

Why JOCHAMP Cup Filler Pouch Packing Machine

All the contact parts of this machine are made from food-grade materials to use in the food, non-food, and pharmaceutical industries.

The machine is designed to assist the post-production stage. Thus, it increases efficiency levels in the work process.

Our machines featured atomizer operations to ensure reduction of operator intervention and lower maintenance.

Equipped with numerous features for easy setup, including dual motors, independent sensors, and drives for excellent control.

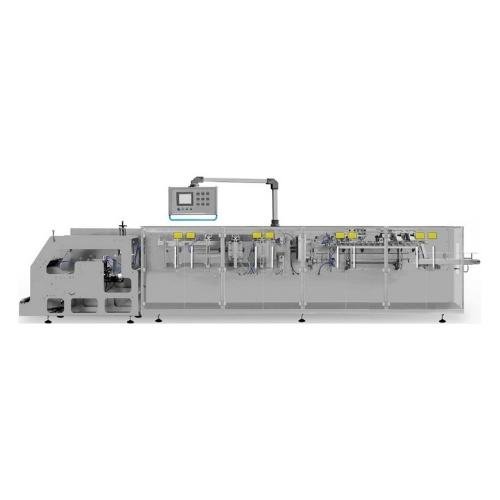

Fully Automated Cup Filler Pouch Packing Machine

If you’re going to enhance ROI in your packaging and production processes, JOCHAMP has a solution. We provide a fully automated cup filler pouch packing machine. These machines are widely used in most industries such as pharmaceutical, food and non-food industries, and more. It helps you extend efficiency while maximizing profits.

- Numerous filling devices

- Automatic material unloading, weighing, bag pulling, and bag sealing

- GMP standard compliant

- Quantitative sub packaging

- Intelligent detection

Unique Features of Cup Filler Pouch Packing Machine

JOCHAMP is a well-known supplier of cup filler pouch packing machines due to its unique features, such as:

- Fully-automatic collar-type form

- Easy to maintain and operate

- Suitable with any automatic cup filler system and weighing

- Suitable for any type of aluminum foil and heat-sealed laminated film

- Versatile and can change easily from one pouch to another

- Food-grade stainless steel parts (304/316)

Advantage of Cup Filler Pouch Packing Machine

JOCHAMP is a leading manufacturer of fully-automated cup filler pouch packing machines in China. these machines are widely utilized for packaging:

- Rice, Cereals, and Namkeen

- Kurkure and Tea

- Fryames and Rings

- Whole Spices and Grains

- Soya Chunks

However, JOCHAMP can custom-made your packing machine needs. Please send us your specifications.

Why Choose JOCHAMP Cup Filler Pouch Packing Machine

JOCHAMP is a leading automated packaging solution in China, delivering high-quality cup filler pouch packing machines. We have been focused on manufacturing and R&D of packaging machinery for over ten years. Being a popular name in the industry, we aim to provide you with robust build, low maintenance, and easy-to-operate packing machines.

JOCHAMP cup filler pouch packing machines are perfectly designed to accommodate the post-production stage. It also increases efficiency levels in the work process. Our machines are fabricated with excellent features like atomizer operations. This could ensure a reduction of operator intervention, lower maintenance, and low power consumption.

At JOCHAMP, all of our packaging solutions are in compliance with international certifications like cGMP, CE, RoHS, and SGS. We support one-year quality assurance and lifetime after-sale service. Contact us for more information!

Cup Filler Pouch Packing Machine

The cup filler pouch packing machine is used where the weight variation is not yet crucial, especially in relatively cheap products. It is also utilized where the products have better flow characteristics and required high production speeds with a minimum equipment cost.

JOCHAMP cup filler machine has reliable mechanical parts that are easy to maintain. Our machines are easy to set up and it has double motors – one for the pulling of the laminates and the other one for the disc rotation. This feature is needed for excellent control as the motors have independent sensors and drives for motion. Thus, the cup filler pouch packing machine is easy to set up.

The vertical and horizontal sealing can be done pneumatically. It can guarantee precise sealing and its temperature control is possible through PDI temperature controllers.

The quality of the seal is affected when there is a consistent temperature. It could affect a pouch’s life. However, JOCHAMP’s cup filler machines come with a camera. These cameras allow for sensing eye mark location. It also comes with a batch coder that prints lot code, date code, and MRP at the appropriate location on the pouch.

Custom Cup Filler Pouch Packing Machine Based on Your Applications

It is fabricated with a sturdy design and can guarantee 24/7 operation, easy to operate, and easy maintain.

The micro-adjustable cup filler packing machine is manufactured from food-grade materials, especially the contact parts.

Guarantee new high-tech design to ensure the best performance. These machines have to fill weight that delivers fine-tune to ensure adherence to specifications.

Related Product

Cup Filler Pouch Packing Machine: The Ultimate Guide

Before choosing your next cup filler pouch packing machine, read this guide. It covers all information on cup filler – from features, parts, working principle to classification criteria. So, if you want to learn more about cup filler for pouch packaging machine, read this guide.

A cup filler pouch packing machine is an automatic type of machine you use in packaging products like food and pharmaceuticals.

cup filler pouch packing machine

You can employ this machine in packaging products including jelly, pet food, coffee granules, biscuits, candy, and frozen food.

A cup fillers is an inexpensive alternative for volumetric filling of free flowing products.

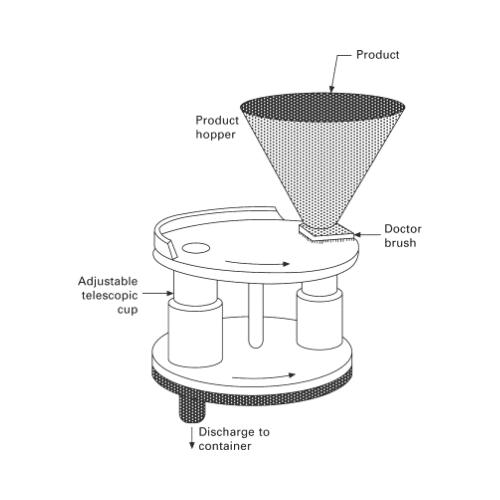

The concept is straightforward as you dip your cup into product before leveling with a straight edged blade.

This method differs from conventional approaches since the product flows from a hopper with a knife for an edge.

cup filler

Where application is low speed, you employ cup fillers as reciprocating devices.

However, applications with higher speeds utilize rotary systems you can scale up to match various speed requirements.

You find the use of the cup filler pouch packing machine in almost all sectors as follows:

- A cup filler pouch packing machine in the agricultural sector packages dairy products such as milk and seeds.

- A cup filler pouch packing machine is useful in the pharmaceutical businesses for syrup packaging and other medications.

- In the food industry, you employ the cup filler pouch packing machine in packaging beverages such as cocoa, coffee and tea.

You also find this machine useful in packaging peanuts, pet food, tomato paste, meat, and other frozen feeds.

- The beauty industry employs cup filler pouch packing machine in packaging gels, creams, lotions, shampoo and jellies.

Utilizing a cup filler pouch packing machine has a variety of benefits as follows:

- They operate faster and effectively due to automation allowing you to wrap many goods in a minute.

For instance, you can find cup filler pouch packing machines that can achieve speeds of up to 120 bpm.

- When using cup filler pouch packing machine to package products, it is such that it preserves the product consistency.

During packaging, it adds nitrogen in to the pack extending the item’s shelf life.

- It employs roll-stock film in producing its pouches, which is typically less costly as opposed to buying ready-made.

Consequently, you can make many packs thus positively affecting output.

- The cup filler pouch packing machine’s heating jaws aid in increasing the rate of packaging per minute.

As a result, bagging takes less time allowing increased production.

- The cup filler pouch packing machine features a data monitoring system that can identify sealing points’ obstruction.

This is important to know to identify faulty seals during packaging.

- Compared to alternative packaging options, the cup filler pouch packing machine is inexpensive to buy while still durable and effective.

- Cleaning and maintaining a cup filler pouch packing machine is simple with an unbroken change-over speed.

As a result, you can derive positive results from it quickly.

Some of the outstanding features of a cup filler pouch packing machine include:

- A touch screen and a modular design for simple and effective operation.

- Capability to propel the pouch film forward from central position.

- Fast operation speed should be standard for the cup filler pouch packing machine.

- It ought to have a negligibly minimal energy and carbon footprint.

- Should have a film sensor and tracking system alongside an automatic edge guidance.

- Stainless steel construction with ability to withstand corrosion.

- The cup filler pouch packing machine’s HMI needs to be at least bilingual to be useful to the majority of users worldwide.

- The machine should be package larger bag sizes if it is huge.

- This machine should work with a variety of small and medium-sized bag packaging equipment.

- You find this machine with an internal temperature control system.

The main parts of a cup filler pouch packing machine are as follows:

- Cross Sealing Jaws: These jaws help to seal the product pouches’ top and bottom ends.

- Film Transfer Belt: Allows easy movement of the film through the forming area.

- Finished Product Conveyor: Collects the items from the machine and transports them elsewhere for additional packaging.

- Low Friction Roller: Sends the film into the shaping portion.

- The Forming Collar: This device aids in forming flat film into a cylindrical tube for packaging.

- Throat Metal Detector: Identifies metals that enter the goods while mixing.

- Vertical Sealing Bars: In the forming area, these bars seal the film tube’s edges.

- Vibrator Feeder and Shaping Tube: This part charges the products into the machine.

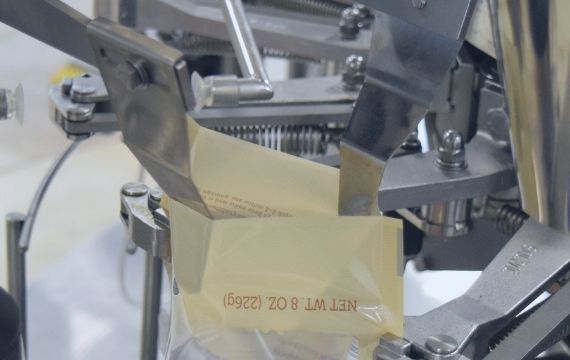

You first feed a plastic film roll into the machine’s long, empty conical tube during start up.

A film transport belt situated on the side of the forming tube pulls the film web located at the machine’s front.

The film unwinds from the roll and fed through the machine’s rear-mounted weighted pivot arm.

As it passes through the back, the arm maintains strain on the film.

You can also pass the film through the printing apparatus, to print information such as logo and product details.

After that, an optical device registers the film identifying registration markings. The device moves the film, correctly positioning it in preparation for cutting.

Then, as the film passes through a film tracking sensor, the system can determine its position.

The film sends a signal for an automatic correction whenever it deviates from its regular position.

Through the bottom-mounted horizontal sealing bar clamps, the outer edge seals to create a bag. A complete bag drops into the weighing table for product filling.

When the bag reaches the recommended weight, the machine stops before another bag enters the weighing section for filling.

A horizontal sealing bar seals the top of the filled bags then a conveyer transfers them to a bagging/cartonizing station.

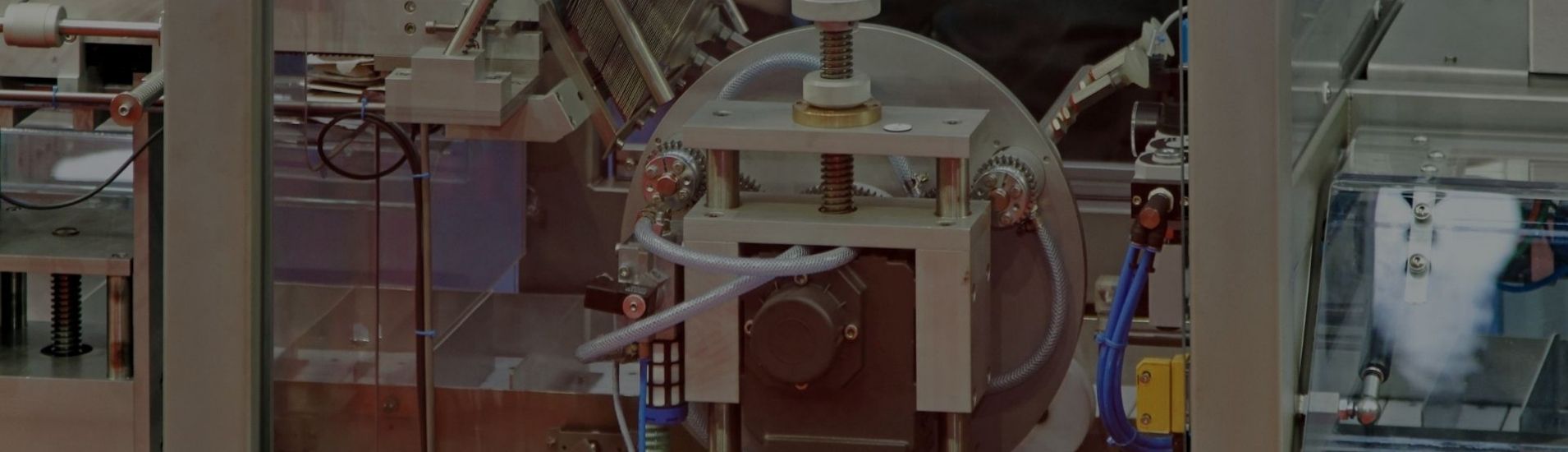

Automatic Cup Filler Pouch Packing Machine

This is the most economical machine you can use for filling and packing products.

It contains fully automatic components including filling heads and conveyor systems on solid, robust frames.

automatic cup filler pouch packing machine

Except for directing and supervising the filling process, the machine needs relatively little human input. It has an integrated, personalized, PLC that enables precise container positioning and reliable rotations.

Semi-Automatic Cup Filler Pouch Packing Machine

A semi-automatic cup filler pouch packing machine requires human intervention for certain aspects of the operations.

It consists of many components including a PLC servo driven motor that rotates a screw inside the filling tube.

The screw’s movement allows products transfer from the hopper to the bottom of the container.

You achieve precision by correctly adjusting the screw spins.

semi-automatic cup filling pouch packing machine

A semi-automatic cup filler pouch packing machine can fill various items, including spices, dry milk, detergents, and powders.

You can improve the accuracy of a cup filler pouch packing machine by undertaking the following:

Achieve the Auger’s Maximum Speed

You achieve precise weight management by ensuring the auger’s rotation rate is between three and four times.

The correct speed lessens the number of accumulated product pouches at the hopper.

Cleaning the Machine

By regularly taking the pieces apart and cleaning them, you prevent buildup of dirt which can significantly impair functionality.

Enhancing Hopper Fill Level

To ensure that you get the desired results, you can alter the tooling system to guarantee consistent weighing of products.

Utilizing the Horizontal Infeed Screw

This can help you increase the accuracy of the machine by guaranteeing the machine continuously maintains an accurate fill level.

This requires you to make use of level sensors in the auger hopper.

There are a few things you need to make sure are accurate before you can debug a cup filler pouch packing machine.

Make sure the equipment configuration is proper and that the temperature and humidity levels are appropriate.

If you change the product or film web, also adjust the machine settings. You must troubleshoot if all of these are true but the issue persists.

Some troubleshooting incidents include:

- If the device won’t power, you can have a problem with incoming electricity.

- Low air pressure or failing to reset safety circuit can make the machine unresponsive.

You can also experience low air pressure if you don’t reset the device or safety circuit.

- The temperature of the jaw becomes abnormally high or low.

You can attribute this to a malfunction of the temperature sensors or failure to warm up sealing jaws.

- The jaws can occasionally stop working because the assembly is non-functional.

- The printer can stop working if it receives no power or has a damaged cable. You can power it up or replace the cable.

- You can also have a situation where the film doesn’t track properly. This occurs when the film deviates from the center.

- Both vertical and horizontal sealing could be problematic. It could be that the seals are insufficient what with them containing products.

Use the specified temperature, pressure, and time to create ideal seals to solve this issue.

Whatever machine you own, you must take proper care of it.

You increase the machine’s lifespan and avoid functional issues in addition to saving money when you undertake routine maintenance.

A cup filler pouch packing machine malfunction can stop an entire production line in its tracks.

By creating a sound routine, you may avoid the logistical hassles and delays related to repairs and part replacement.

Some strategies for maintaining a cup filler pouch packaging machine are:

Regular Lubrication

Lubrication is necessary to prevent wear and tear of moving parts in your cup filler pouch packing machine.

As the parts move you have friction which generates heat and wear that can lead to part breakdown over time if unlubricated.

Consistent Cleaning

Regular cleaning can reduce the length of downtime that comes with more intensive and infrequent maintenance.

Working on and using dirty machines is unpleasant. The presence of dust, grime, and debris on the equipment can conceal potential functional issues.

Routine Inspection

You can ensure that your machine has a long lifespan by subjecting it to regular examination.

Early detection of the issue may result in a fast and affordable solution. However, the longer the issue persists, the more likely the solution gets expensive.

Frequently Replacing Parts

The repeated use of packaging machine parts can cause wear and tear.

You should be well aware that the parts need changing frequently to prevent any slowing down and operation at best capacity.

Employ only highly skilled/trained employees or a licensed service technician to replace the parts.

You find parts in a cup filler pouch packaging machine divided into three: high-wear, medium-wear and low-wear.

You find the following safety features on a cup filler pouch packaging machine:

- Adding crucial components such as camshafts allows for numerous additional tasks.

Also, robotics ensure full automation of the cup filler pouch packaging machine.

- A programmable logic controller adds motion to the cup filler pouch packaging machine while directing automation.

- Having optoelectronic sensors around hazardous packaging machines is vital to stop them right away if a worker unintentionally comes in contact.

- Guard rails are effective in preventing interaction of personnel with dangerous machine parts thus preventing injury.

The kind of cup filler pouch packaging machine you require to complete a job effectively depends on the packaging application.

Many people favor the auger filler over the cup filler with the latter reserved for product that is free flowing and granular.

You employ the cup filler pouch packaging machine for items such as rice, coffee beans and other cereals.

While you can employ an auger filler for these items, a cup filler works more quickly and with greater accuracy.

Auger filler

When considering the filling rate, you find the cup filler better suited.

Compared to an auger filler, the cup filler cycle is faster, and the product enters the container more quickly.

While you can employ the auger fillers and cup fillers for similar items, the former has a larger product range.

Additionally, it functions more effectively than the cup filler.

Especially where the product lacks free-flowing qualities or is dusty, you find the auger filler unquestionably the best option.

You can have the cup filler as an independent semi-automatic device.

This can be at the top of a bagger or pouch machine vertically or horizontally oriented.

cup filler pouch packing machine

You can also find it as a component of an automatic or inline rotating system.

The benefits of a volumetric cup filler machine include:

- Filling grains such as rice into pouches using a volumetric cup filler eliminates the inconsistencies resulting from manual filling.

- Over time, products flavor and quality diminish when exposed to air. However, pouch packaging using a volumetric cup filler keeps freshness longer without the use of preservatives.

- Using a volumetric cup filler machine enhances production and packaging processes because there is less manual work.

- Using a volumetric cup filler prevents contamination from outside sources as it seals the pouch upon completion of the filling process.

- Volumetric cup filler pouch packaging is airtight preventing growth of microbes and thus extending the packaged product’s shelf life.

- When packaging products, there are regulatory and standard laws with regard to accuracy and safety. By ensuring similar weight of packages, a volumetric cup filler helps lower the likelihood of mistakes or inconsistencies.

- Your streamline your packaging operations by employing an automated volumetric cup filler for granular materials.

Related Resource:

For all your cup filler pouch packing machine, contact us now.